Abstract

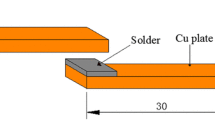

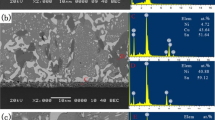

Sn–9Zn solder alloyed with cobalt (0, 0.5, 3 wt%) was bonded to Ni pad at 250 °C for various durations, and the effects of Co on the microstructure evolution and the shear behavior of the Sn–Zn/Ni joints were investigated by microstructural observations and shear tests. The results reveal that Co improves the shear strength and the interfacial microstructure of the Sn–9Zn/Ni joints significantly. Co is not only a diffusion barrier that impedes Zn from gathering at the interfaces to form Ni5Zn21, but it reacts with Zn in the composite solders with 3 wt% Co adding to the Sn–9Zn solder. When preferential Ni5Zn21 is transformed into Ni2Sn2Zn at the Sn–Zn–Co/Ni interfaces, ductile ruptures occur as Ni2Sn2Zn has similar elastic modulus and connects firmly with the solder. Accordingly, the strength of the Sn–Zn–Co/Ni joints reaches the highest. Moreover, the shear strength of the Sn–Zn–3Co/Ni joints maintains above 35 MPa after 90 min soldering, on account of the Ni2Sn2Zn remaining uniform ripples and fracture surfaces appearing with homogeneous Ni2Sn2Zn dimples. Whereas, at the Sn–Zn/Ni joints, the thick Ni5Zn21 layer and pores intensify the stress concentration and lead to a lower strength. In general, the addition of Co refines the interfacial microstructure that the Sn–Zn–Co/Ni joints are uniformly stressed and achieve desirable strength.

Similar content being viewed by others

References

S. Liu, S.B. Xue, P. Xue, J. Mater. Sci. Mater. Electron. 26, 4389–4411 (2015)

K. Suganuma, K.S. Kim, J. Mater. Sci. Mater. Electron. 18, 121–127 (2007)

J.C. Liu, Z.H. Wang, J.Y. Xie et al., Corr. Sci. 112, 150–159 (2016)

T. Gancarz, P. Bobrowski, S. Pawlak et al., J. Electron. Mater. 47, 50–60 (2018)

T. Gancarz, P. Bobrowski, J. Pstrus et al., J. Alloys Compd. 679, 442–453 (2016)

W.Q. Xing, X.Y. Yua, H. Lia et al., Mater. Sci. Eng. A 678, 252–259 (2016)

G. Ren, I.J. Wilding, M.N. Collins, J. Alloys Compd. 665, 251–260 (2016)

G. Liu, S. Ji, Mater. Charact. 137, 39–49 (2018)

M.M. Billah, K.M. Shorowordi, A. Sharif, J. Alloys Compd. 58, 32–39 (2014)

C.H. Wang, H.H. Chen, J. Electron. Mater. 39, 2375 (2010)

L. Zhang, J.G. Han, C.W. He et al., IEEE Trans. Electron Devices 59(12), 3269–3272 (2012)

L. Zhang, J.G. Han, C.W. He et al., Sci. Technol. Weld. Join 17(5), 424–428 (2012)

L. Zhang, J. Cui, J. Han et al., J. Rare Earths 30(8), 790–793 (2012)

Y. Hu, S. Xue, H. Wang et al., J. Mater. Sci. Mater. Electron. 22(5), 481–487 (2011)

M.L. Huang, X.L. Hou, N. Kang et al., J. Mater. Sci. Mater. Electron. 25(5), 2311–2319 (2014)

J.C. Liu, G. Zhang, J.S. Ma, J. Alloy. Compd. 644, 113–118 (2015)

K.S. Lin, H.Y. Huang, C.P. Chou, J. Alloy. Compd. 471, 291–295 (2009)

C.H. Wang, C.C. Wen, C.Y. Lin, J. Alloy. Compd. 662(25), 475–483 (2016)

Y.T. Chen, Y.T. Chan, C.C. Chen, J. Alloy. Compd. 507, 419–424 (2010)

J.X. Hu, F.C. Yin, M.X. Zhao et al., J. Alloy. Compd. 747, 815–825 (2018)

P.C. Reynolds, M. Stojanovic, S.E. Latturner, J. Solid State Chem. 184, 1875–1881 (2011)

C. Schmetterer, D. Rajamohan, H.S. Effenberger, H. Flandorfer, Acta Cryst. C 68(10), 65–67 (2012)

J. Chang, S.K. Seo, H.M. Lee, J. Electron. Mater. 39, 2643–2652 (2010)

C.H. Wang, H.H. Chen, W.H. Lai, J. Electron. Mater. 40, 2436 (2011)

J.L. Liang, Y. Du, Y.Y. Tang et al., J. Electron. Mater. 40, 2290 (2011)

C. Schmetterer, D. Rajamohan, H. Ipser et al., Intermatalics. 19, 1489–1501 (2011)

V. Gandova, G.P. Vassilev, J. Alloy. Compd. 609, 1–6 (2014)

N. Zhao, J.F. Deng, Y. Zhong et al., J. Electron. Mater. 46, 1931 (2017)

K.S. Lin, H.Y. Huang, C.P. Chou, J. Alloy. Compd. 471(1–2), 291–295 (2009)

A.S.M.A. Haseeb, T.S. Leng, Intermetallics. 19, 707–712 (2011)

Y.C. Huang, S.W. Chen, J. Mater. Res. 25(12), 2430–2438 (2010)

C.H. Wang, S.E. Huang, P.Y. Huang, J. Electron. Mater. 44(12), 4907–4919 (2015)

H.F. Lin, Y.C. Chang, C.C. Chen, J. Electron. Mater. 43(9), 3333–3340 (2014)

Acknowledgements

This work was financially supported by Ministry of Science and Technology of China (2017YFB0305700).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J.Y., Peng, J., Wang, R.C. et al. Effects of Co addition on shear strength and interfacial microstructure of Sn–Zn–(Co)/Ni joints. J Mater Sci: Mater Electron 29, 19901–19908 (2018). https://doi.org/10.1007/s10854-018-0120-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-0120-z