Abstract

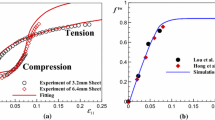

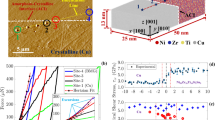

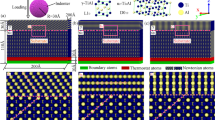

Molecular dynamics simulations have been performed to study the dynamic behaviors of single crystal aragonite under indentation, tension, and compression. The elastic modulus and hardness of single crystalline aragonite measured in our simulations are found in good agreement with experimentally measured values. Our simulation results show that the mechanical properties of aragonite crystal, including the elastic modulus, hardness, strength, and toughness, strongly depend on the crystallographic orientations and loading conditions. We have identified that this dependence is resulted from different deformation mechanisms, i.e., phase transformation, amorphous phase formation, dislocation, and twining. This work is an attempt to identify the deformation mechanisms in aragonite and to establish the relationship between the dominant deformation mechanisms and its crystallographic orientations and loading conditions.

Similar content being viewed by others

References

Menig R, Meyers MH, Meyers MA, Vecchio KS (2000) Acta Mater 48:2383

Berg GW (1986) Nature 324:50

Bridgman PW (1938) Am J Sci 239:7

Tyburczy JA, Ahrens TJ (1986) Geophys J Res 91:4730

Biellmann C, Guyot F, Gillet P, Reynard B (1993) Eur J Mineral 5:503

Fiquet G, Guyot F, Itie LP (1994) Am Mineral 79:15

Martinez I, Zhang J, Reeder RJ (1996) Am Mineral 81:611

Lin C-C, Liu L-G (1997) Phys Chem Miner 24:149

Luth RW (2001) Contrib Mineral Petrol 141:222

Suito K, Namba J, Horikawa T, Taniguchi Y, Sakurai N, Kobayashi M, Onodera A, Shimomura O, Kikegawa T (2001) Am Mineral 86:997

Ivanov BA, Deutsch A (2002) Phys Earth Planet Inter 129:131

Santillán J, Williams Q (2004) Am Mineral 89:1348

Ono S, Kikegawa T, Ohishi Y, Tsuchiya J (2005) Am Mineral 90:667

Ono S, Kikegawa T, Ohishi Y (2007) Am Mineral 92:1246

Oganov AR, Glass CW, Ono S (2006) Earth Planet Sci Lett 241:95

Liu J, Duan JJ, Ossowski MM, Mei WN, Smith RH, Hardy JR (2001) Chem Mineral 28:586

Bearchell CA, Heyes DM (2002) Mol Simul 28:517

Sekkal W, Taleb N, Zaoui A, Shahrour I (2008) Am Mineral 93:1608

Miyake A, Kawano J (2010) J Phys: Condens Matter 22:225402

Ruiz-Hernandez SE, Grau-Crespo R, Ruiz-Salvador AR, de Leeuw NH (2010) Geochim Cosmochim Acta 74:1320

Han YH, Li H, Wong TY, Bradt RC (1991) J Am Ceram Soc 74:3129

Liu LG, Chen CC, Lin CC, Yang YJ (2005) Phys Chem Miner 32:97

Kearney C, Zhao Z, Bruet BJF, Radovitzky R, Boyce MC, Ortiz C (2006) Phys Rev Lett 96:2555051

Hitoshi S, Musun K (2005) Phys Chem Chem Phys 7:691

Huggins ML (1922) Phys Rev 19:354

Huang Z, Li H, Pan Z, Wei Q, Chao YJ, Li XD (2011) Sci Rep 1:1

Villiers De (1971) Am Mineral 56:758

Smith W, Forester TR, Todorov IT (2007) STFC Daresbury Laboratory Daresbury. Warrington WA44AD, Cheshire, UK

Dick BG, Overhauser AW (1958) Phys Rev 112:90

Gale J (2005) Handbook of materials modeling. Springer, Printed in the Netherlands, pp 1523–1558

Pavese A, Catti M, Price GD, Jackson RA (1992) Phys Chem Miner 19:80

Dove MT, Winkler B, Leslie M, Harris MJ, Salje EKH (1992) Am Mineral 77:244

Jackson RA, Price GD (1992) Mol Simul 9:175

Catti M, Pavese A, Gale GD (1993) Phys Chem Miner 19:472

Jackson RA, Meenan PA, Price GD, Roberts KJ, Telfer GB, Wilde PJ (1995) Mineral Mag 59:617

Jackson RA (2001) Curr Opin Solid State Mater Sci 5:463

Braybrook AL, Heywood BR, Jackson RA, Pitt K (2002) J Cryst Growth 243:336

Pavese A, Catti M, Parker SC, Wall A (1996) Phys Chem Miner 23:89

Fisler DK, Gale JD, Cygan RT (2000) Am Mineral 85:217

Archer TD, Birse SEA, Dove MT, Redfern SAT, Gale JD, Cygan RT (2003) Phys Chem Miner 30:416

Barthelat F, Espinosa HD (2007) Exp Mech 47:311

Barthelat F, Espinosa HD (2003) SEM Annual conference and exposition on experimental and applied mechanics, p 187

Lu L, Chen X, Huang X, Lu K (2009) Science 323:607

Zhang Y, Huang H (2008) Nanoscale Res Lett 4:34

Li XY, Wei YJ, Lu L, Lu K, Gao HJ (2010) Nature 464:877

Acknowledgements

This work was supported by National Science Foundation under Award CMMI-0855795 and DARPA under Award Number N66001-10-1-4018. Simulations were performed at the High Performance Computing Center at the University of Florida.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, N., Chen, Y. Nanoscale plastic deformation mechanism in single crystal aragonite. J Mater Sci 48, 785–796 (2013). https://doi.org/10.1007/s10853-012-6796-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6796-1