Abstract

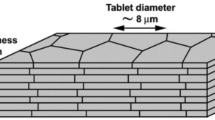

Nacre, also known as mother-of-pearl, is a hard biological composite found in the inside layer of many shells such as oyster or abalone. It is composed of microscopic ceramic tablets arranged in layers and tightly stacked to form a three-dimensional brick wall structure, where the mortar is a thin layer of biopolymers (20–30 nm). Although mostly made of a brittle ceramic, the structure of nacre is so well designed that its toughness is several order of magnitudes larger that the ceramic it is made of. How the microstructure of nacre controls its mechanical performance has been the focus of numerous studies over the past two decades, because such understanding may inspire novel composite designs though biomimetics. This paper presents in detail uniaxial tension experiment performed on miniature nacre specimens. Large inelastic deformations were observed in hydrated condition, which were explained by sliding of the tablets on one another and progressive locking generated by their microscopic waviness. Fracture experiments were also performed, and for the first time the full crack resistance curve was established for nacre. A rising resistance curve is an indication of the robustness and damage tolerance of that material. These measurements are then discussed and correlated with toughening extrinsic mechanisms operating at the microscale. Moreover, specific features of the microstructure and their relevance to associated toughening mechanisms were identified. These features and mechanisms, critical to the robustness of the shell, were finely tuned over millions of years of evolution. Hence, they are expected to serve as a basis to establish guidelines for the design of novel man-made composites.

Similar content being viewed by others

References

Currey, JD (1999) The design of mineralised hard tissues for their mechanical functions. J Exp Biol 202:3285–3294.

Lawn BR (1993) Fracture of brittle solids. Cambridge University Press, New York.

Wang RZ, Suo Z, Evans AG, Yao N, Aksay IA (2001) Deformation mechanisms in nacre. J Mater Res 16:2485–2493.

Currey JD, Taylor JD (1974) The mechanical behavior of some molluscan hard tissues. J Zool (London) 173:395–406.

Sarikaya M, Aksay IA (eds) (1995) Biomimetics, design and processing of materials. Woodbury, NY.

Currey JD (1977) Mechanical properties of mother of pearl in tension. Proc R Soc Lond 196:443–463.

Jackson AP, Vincent JFV, Turner RM (1988) The mechanical design of nacre. Proc R Soc Lond 234:415–440.

Menig R, Meyers MH, Meyers MA, Vecchio KS (2000) Quasi-static and dynamic mechanical response of haliotis rufescens (abalone) shells. Acta Mater 48: 2383–2398.

Barthelat F, Tang H, Zavattieri PD, Li CM, Espinosa HD (2007) On the mechanics of mother-of-pearl: a key feature in the material hierarchical structure. J Mech Phys Solids 55:225–444.

Barthelat F, Li CM, Comi C, Espinosa HD (2006) Mechanical properties of nacre constituents and their impact on mechanical performance. J Mater Res 21:1977–1986.

Wang RZ, Wen HB, Cui FZ, Zhang HB, Li HD (1995) Observations of damage morphologies in nacre during deformation and fracture. J Mater Sci 30:2299–2304.

Barthelat F, Espinosa HD (2005). In: MRS 2004 fall meeting. Boston.

Li XD, Chang WC, Chao YJ, Wang RZ, Chang M (2004) Nanoscale structural and mechanical characterization of a natural nanocomposite material: the shell of red abalone. Nano Lett 4:613–617.

Bruet BJF, et al. (2005) Nanoscale morphology and indentation of individual nacre tablets from the gastropod mollusc Trochus niloticus. J Mater Res 20:2400–2419.

Schaeffer TE, et al. (1997) Does abalone nacre form by heteroepitaxial nucleation or by growth through mineral bridges? Chem Mater 9:1731–1740.

Smith BL, et al. (1999) Molecular mechanistic origin of the toughness of natural adhesives, fibres and composites. Nature (London) 399:761–763.

Evans AG, et al. (2001) Model for the robust mechanical behavior of nacre. J Mater Res 16:2475–2484.

Song F, Bai YL (2003) Effects of nanostructures on the fracture strength of the interfaces in nacre. J Mater Res 18:1741–1744.

Li XD, Xu ZH, Wang RZ (2006) In situ observation of nanograin rotation and deformation in nacre. Nano Lett 6:2301–2304.

Kotha SP, Li Y, Guzelsu N (2001) Micromechanical model of nacre tested in tension. J Mater Sci 36:2001–2007.

Katti K, Katti DR, Tang J, Pradhan S, Sarikaya M (2005) Modeling mechanical responses in a laminated biocomposite. Part II. Nonlinear responses and nuances of nanostructure. J Mater Sci 40:1749–1755.

Okumura K, de Gennes PG (2001) Why is nacre strong? Elastic theory and fracture mechanics for biocomposites with stratified structures. Eur Phys J, E Soft Matter 4:121–127.

Gao HJ (2006) Application of fracture mechanics concepts to hierarchical biomechanics of bone and bone-like materials. Int J Fract 138:101–137.

Katti DR, Katti KS (2001) Modeling microarchitecture and mechanical behavior of nacre using 3D finite element techniques. Part 1. Elastic properties. J Mater Sci 36:1411–1417.

Peters WH, Ranson WF (1982) Digital imaging techniques in experimental stress-analysis. Opt Eng 21:427–431.

Chu TC, Ranson WF, Sutton MA, Peters WH (1985) Applications of digital-image-correlation techniques to experimental mechanics. Exp Mech 25:232–244.

Evans AG, et al. (2001) A model for the robust mechanical behavior of nacre. J Mater Res 16:2475–2484.

Manne S, et al. (1994) Atomic-force microscopy of the nacreous layer in mollusk shells. Proc R Soc Lond, B Biol Sci 256:17–23.

Feng QL, Cui FZ, Pu G, Wang RZ, Li HD (2000) Crystal orientation, toughening mechanisms and a mimic of nacre. Mater Sci Eng, C Biomim Mater, Sens Syst 11:19–25.

Song F, Bai Y (2002) Nanostructure of nacre and its mechanical effects. Int J of Nonlinear Sci & Numer Simul 3(3):257–260.

Blank S, et al. (2003) The nacre protein perlucin nucleates growth of calcium carbonate crystals. J Microsc-Oxford 212:280–291.

McNulty JC, Zok FW, Genin GM, Evans AG (1999) Notch-sensitivity of fiber-reinforced ceramic-matrix composites: effects of inelastic straining and volume-dependent strength. J Am Ceram Soc 82:1217–1228.

McMeeking RM, Evans AG (1982) Mechanics of transformation-toughening in brittle materials. J Am Ceram Soc 65:242–246.

Evans AG (1990) Perspective on the development of high-toughness ceramics. J Am Ceram Soc 73:187–206.

Saxena A (1998) Nonlinear fracture mechanics. CRC Press, Boca Raton, FL.

ASTM (2005) Standard E399-05: standard test method for linear-elastic plane-strain fracture toughness KIc of metallic materials.

McMeeking RM, Parks DM (1979) In: Elastic-plastic fracture, vol 668, pp 175–194. American Society for Testing and Materials (ASTM-STP), Philadelphia.

ASTM (2004) ASTM standard E 1820-01: Standard test method for measurement of fracture toughness.

Barker DB, Sanford RJ, Chona R (1985) Determining K and related stress-field parameters from displacement-fields. Exp Mech 25:399–407.

McNeill SR, Peters WH, Sutton MA (1987) Estimation of stress intensity factor by digital image correlation. Eng Fract Mech 28:101–112.

Sih GC, Paris PC, Irwin GR (1965) On cracks in rectilinearly anisotropic bodies. Int J Fract Mech 1:189–203.

Kamat S, Su X, Ballarini R, Heuer A (2000) H. Structural basis for the fracture toughness of the shell of the conch Strombus gigas. Nature 405:1036–1040.

Barthelat F, Tang H, Li C, Espinosa H (2007) On the microscopic origins of the toughness of nacre (submitted).

Acknowledgements

This work was supported by the National Science Foundation through award No. CMS-0301416. We would like to thank Dr. Ken Chong for his encouragement and support during this investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Barthelat, F., Espinosa, H.D. An Experimental Investigation of Deformation and Fracture of Nacre–Mother of Pearl. Exp Mech 47, 311–324 (2007). https://doi.org/10.1007/s11340-007-9040-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-007-9040-1