Abstract

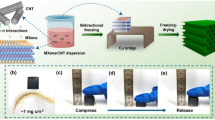

Enhancing anode performance is a critical step to improving the power output and energy storage of microbial fuel cells (MFCs). In this study, MFCs containing pseudocapacitive anode materials, such as polypyrrole-carboxymethyl cellulose (PPy-CMC) composite films, were used to coat the nitrogen-doped carbon nanotube (N-CNT)/sponge (S) for use in MFCs. The capacitive anode could function as a bioanode, store electrons generated from the microbial oxidation of a substrate, and release the accumulated charge as needed. Scanning electron microscopy results indicated that the composite anode had a three-dimensional macroporous structure with a large specific surface area, providing more sites for microbial attachment and growth. Experimental results showed that MFCs equipped with PPy-CMC/N-CNT/S capacitive bioanodes had a maximum power density of 4.88 W m−3, which was 1.34 and 1.71 times as much as those of PPy/N-CNT/S and N-CNT/S bioanodes (3.65 and 2.85 W m−3), respectively. Moreover, the charge–discharge time of 60–90 min, the total charge Qm of the MFC equipped with the PPy-CMC/N-CNT/S anode was the largest (5154.08 mC cm−2)—5.7 times higher than that of the N-CNT/S anode. The excellent performance of the MFC equipped with the PPy-CMC/N-CNT/S anode was attributable to the composite materials, which exhibited a large-pore structure, good biocompatibility, large capacitance, and high specific surface area. Therefore, this synthesized composite exhibited potential as a capacitive and biocompatible anode material in MFCs.

Graphic abstract

Similar content being viewed by others

References

Zhang D, Liao X, Liu Y, Zhong N, Xu Y (2018) Enhanced electricity generation performance and dye wastewater degradation of microbial fuel cell by using a petaline NiO@ polyaniline-carbon felt anode. Bioresour Technol 258:125–134

Zinadini S, Zinatizadeh A, Rahimi M, Vatanpour V, Rahimi Z (2017) High power generation and COD removal in a microbial fuel cell operated by a novel sulfonated PES/PES blend proton exchange membrane. Energy 125:427–438

Yang W, Wang X, Rossi R, Logan BE (2020) Low-cost Fe–N–C catalyst derived from Fe(III)-chitosan hydrogel to enhance power production in microbial fuel cells. Chem Eng J 380:122522

Hemalatha M, Sravan JS, Mohan SV (2020) Self-induced bioelectro-potential influence on sulfate removal and desalination in microbial fuel cell. Bioresour Technol 309:123326

Modestra JA, Reddy CN, Krishna KV, Min B, Mohan SV (2020) Regulated surface potential impacts bioelectrogenic activity, interfacial electron transfer and microbial dynamics in microbial fuel cell. Renew Energy 149:424–434

Mohamed SN, Hiraman PA, Muthukumar K, Jayabalan T (2020) Bioelectricity production from kitchen wastewater using microbial fuel cell with photosynthetic algal cathode. Bioresour Technol 295:122226

Yang Y, Zhao Y, Tang C, Xu L, Morgan D, Liu R (2020) Role of macrophyte species in constructed wetland-microbial fuel cell for simultaneous wastewater treatment and bioenergy generation. Chem Eng J 392:123708

Liang P, Wu W, Wei J, Yuan L, Xia X, Huang X (2011) Alternate charging and discharging of capacitor to enhance the electron production of bioelectrochemical systems. Environ Sci Technol 45:6647–6653

Guan YF, Zhang F, Huang BC, Yu HQ (2019) Enhancing electricity generation of microbial fuel cell for wastewater treatment using nitrogen-doped carbon dots-supported carbon paper anode. J Clean Prod 229:412–419

Mashkour M, Rahimnejad M, Mashkour M, Bakeri G, Luque R, Oh SE (2017) Application of wet nanostructured bacterial cellulose as a novel hydrogel bioanode for microbial fuel cells. Chemelectrochem 4:648–654

Liu XW, Huang YX, Sun XF, Sheng GP, Zhao F, Wang SG, Yu HQ (2014) Conductive carbon nanotube hydrogel as a bioanode for enhanced microbial electrocatalysis. ACS Appl Mater Interfaces 6:8158–8164

Deeke A, Sleutels THJA, Hamelers HVM, Buisman CJN (2012) Capacitive bioanodes enable renewable energy storage in microbial fuel cells. Environ Sci Technol 46:3554–3560

Lv Z, Xie D, Li F, Hu Y, Wei C, Feng C (2014) Microbial fuel cell as a biocapacitor by using pseudo-capacitive anode materials. J Power Sources 246:642–649

Xiao Q, Zhou X (2003) The study of multiwalled carbon nanotube deposited with conducting polymer for supercapacitor. Electrochim Acta 48:575–580

Peng C, Zhang S, Jewell D, Chen GZ (2008) Carbon nanotube and conducting polymer composites for supercapacitors. Prog Polym Sci 18:777–788

Qiao Y, Li CM, Bao S, Bao Q (2007) Carbon nanotube/polyaniline composite as anode material for microbial fuel cells. J Power Sources 170:79–84

Cui HF, Lin D, Guo P, Zhu B, Luong JHT (2015) Controlled modification of carbon nanotubes and polyaniline on macroporous graphite felt for high performance microbial fuel cell anode. J Power Sources 283(1):46–53

Li P, Yang Y, Shi E, Shen Q, Shang Y, Wu S, Wei J, Wang K, Zhu H, Yuan Q, Cao A, Wu D (2014) Core-double-shell, carbon nanotube@polypyrrole@MnO2 sponge as freestanding, compressible supercapacitor electrode. ACS Appl Mater Interfaces 6:5228–5234

Chi M, He H, Wang H, Zhou M, Gu T (2013) Graphite felt anode modified by electropolymerization of nano-polypyrrole to improve microbial fuel cell (MFC) production of bioelectricity. J Microb Biochem Technol S 12:004

Yuan H, Deng L, Chen Y, Yuan Y (2016) MnO2/polypyrrole/MnO2 multi-walled-nanotube-modified anode for high-performance microbial fuel cells. Electrochim Acta 196:280–285

Zou Y, Xiang C, Yang L, Sun L, Xu F, Cao Z (2008) A mediatorless microbial fuel cell using polypyrrole coated carbon nanotubes composite as anode material. Int J Hydrog Energy 33:4856–4862

Lv Z, Chen Y, Wei H, Li F, Hu Y, Wei C, Feng C (2013) One-step electrosynthesis of polypyrrole/graphene oxide composites for microbial fuel cell application. Electrochim Acta 111:366–373

Yong Y, Sung-Hyun K (2008) Improved performance of a microbial fuel cell with polypyrrole/carbon black composite coated carbon paper anodes. Bull Korean Chem Soc 29:1344–1348

Yu F, Wang C, Ma J (2018) Capacitance-enhanced 3D graphene anode for microbial fuel cell with long-time electricity generation stability. Electrochim Acta 259:1059–1067

Xie X, Hu L, Pasta M, Wells GF, Kong D, Criddle CS, Cui Y (2011) Three-dimensional carbon nanotube-textile anode for high-performance microbial fuel cells. Nano Lett 11:291–296

Xu H, Wang L, Wen Q, Chen Y, Qi L, Huang J, Tang Z (2019) A 3D porous NCNT sponge anode modified with chitosan and polyaniline for high-performance microbial fuel cell. Bioelectrochemistry 129:144–153

Xie X, Ye M, Hu L, Liu N, McDonough JR, Chen W, Alshareef HN, Criddle CS, Cui Y (2012) Carbon nanotube-coated macroporous sponge for microbial fuel cell electrodes. Energy Environ Sci 5:5265–5270

Erbay C, Yang G, Figueiredo P, Sadr R, Yu C, Ham A (2015) Three-dimensional porous carbon nanotube sponges for high-performance anodes of microbial fuel cells. J Power Sources 298:177–183

Dahbi M, Nakano T, Yabuuchi N, Ishikawa T, Kubota K, Fukunishi M, Shibahara S, Son J, Cui Y, Oji H, Komaba S (2014) Sodium carboxymethyl cellulose as a potential binder for hard-carbon negative electrodes in sodium-ion batteries. Electrochem Commun 4:66–69

Gomez-Diaz D, Navaza JM (2003) Rheology of aqueous solutions of food additives—effect of concentration, temperature and blending. J Food Eng 56:387–392

Yang C, Chen C, Pan Y, Li S, Wang F, Li J, Li N, Li X, Zhang Y, Li D (2015) Flexible highly specific capacitance aerogel electrodes based on cellulose nanofibers, carbon nanotubes and polyaniline. Electrochim Acta 182:264–271

Ma L, Liu R, Niu H, Xing L, Liu L, Huang Y (2016) Flexible and freestanding supercapacitor electrodes based on nitrogen-doped carbon networks/graphene/bacterial cellulose with ultrahigh areal capacitance. ACS Appl Mater Interfaces 8:33608–33618

Xu S, Yu W, Yao X, Zhang Q, Fu Q (2016) Nanocellulose-assisted dispersion of graphene to fabricate poly(vinylalcohol)/graphene nanocomposite for humidity sensing. Compos Sci Technol 131:67–76

Wang Y, Zheng H, Lin C, Zheng J, Chen Y, Wen Q, Wang S, Xu H, Qi L (2020) Development of a 3D porous sponge as a bioanode coated with polyaniline/sodium alginate/nitrogen-doped carbon nanotube composites for high-performance microbial fuel cells. J Appl Electrochem 50:621–630

Kumar GG, Kirubaharan CJ, Udhayakumar S, Ramachandran K, Karthikeyan C, Renganathan R, Nahm KS (2014) Synthesis, structural, and morphological characterizations of reduced graphene oxide-supported polypyrrole anode catalysts for improved microbial fuel cell performances. ACS Sustain Chem Eng 2:2283–2290

Walter X, Greenman J, Leropoulos I (2014) Intermittent load implementation in microbial fuel cells improves power performance. Bioresour Technol 172:365–372

Tang J, Yuan Y, Liu T, Zhou S (2015) High-capacity carbon-coated titanium dioxide core–shell nanoparticles modified three dimensional anodes for improved energy output in microbial fuel cells. J Power Sources 274:170–176

Zhang C, Liang P, Jiang Y, Huang X (2015) Enhanced power generation of microbial fuel cell using manganese dioxide-coated anode in flow-through mode. J Power Sources 273:580–583

Zheng J, Cheng C, Zhang J, Wu X (2016) Appropriate mechanical strength of carbon black-decorated loofah sponge as anode material in microbial fuel cells. Int J Hydrog Energy 41:23156–23163

Pant D, Bogaert GV, Diels L, Vanbroekhoven K (2010) A review of the substrates used in microbial fuel cells (MFCs) for sustainable energy production. Bioresour Technol 101:1533–1543

Papaharalabos G, Greenman J, Stinchcombe A, Horsfield I, Melhuwash C, Ieropoulos I (2014) Dynamic electrical reconfiguration for improved capacitor charging in microbial fuel cell stacks. J Power Sources 272:34–38

Li Y, Zhao X, Xu Q, Zhang Q, Chen D (2011) Facile preparation and enhanced capacitance of the polyaniline/sodium alginate nanofiber network for supercapacitors. Langmuir 27:6458–6463

Zhao Y, Liu B, Pan L, Yu G (2013) 3D nanostructured conductive polymer hydrogels for high-performance electrochemical devices. Energy Environ Sci 6:2856–2870

Peng X, Yu H, Yu H, Wang X (2013) Lack of anodic capacitance causes power overshoot in microbial fuel cells. Bioresour Technol 138:353–358

Grondin F, Perrier M, Tartakovsky B (2012) Microbial fuel cell operation with intermittent connection of the electrical load. J Power Sources 208:18–23

Acknowledgements

The project was supported by National Natural Science Foundation of China (21878060 and 21476053), Research Fund of State Key Laboratory for Marine Corrosion and Protection of Luoyang Ship Material Research Institute under the contract No. 6142901180401, Special plan for young Reserve Talents of Harbin University of Commerce (2019CX30), Research Project Fund of Harbin University of Commerce (2019DS082).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethics approval

This article does not contain any studies with human participants performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Pan, X., Chen, Y. et al. A 3D porous nitrogen-doped carbon nanotube sponge anode modified with polypyrrole and carboxymethyl cellulose for high-performance microbial fuel cells. J Appl Electrochem 50, 1281–1290 (2020). https://doi.org/10.1007/s10800-020-01488-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-020-01488-z