Abstract

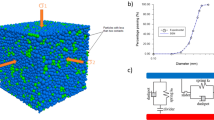

In the field of granular materials, a link between the microscopic variables (contact force and displacement) and macroscopic variables (stress and strain) requires an intermediate scale called the mesoscopic scale. An important class of mesostructure is the so-called loops, which are closed chains of grains in contact. In two dimensions (2D), these structures tessellate a material domain into elementary partitions that account for the physics of granular materials. However, this property no longer applies in three dimensions (3D). In this paper, we propose to identify 3D mesostructures that generalize the 2D properties of loops and their ability to account for the deformability of granular materials. To do so, a weighted Delaunay tessellation is used to partition a 3D specimen into tetrahedra. These tetrahedra are then merged through a criterion defined consistently with the one used to identify loops in 2D. As the 3D structures do not match the mathematical definition of loops, they are named clusters. A series of 3D DEM triaxial tests were performed to analyze the statistics of clusters during the loading path. It is shown that clusters behave analogously to loops, promoting an increase in the number of denser mesostructures during the strain contraction phase and looser ones during dilation. Furthermore, increasing amounts of looser clusters appear around force chains, promoting a decrease in the stability of the chained structures. Clusters are more diverse in shape and topology compared with loops. Thus, additional metrics besides the number of grains forming them are needed to characterize these structures. In this respect, we propose the concepts of order (number of external frontiers) and deformability.

Similar content being viewed by others

Notes

The limit between medium and large categories is defined by the largest cluster existing from the beginning of the test in significant amounts. Other initial conditions (like a looser soil) might be useful to precise which order is the most relevant to distinguish medium and large cluster groups.

References

Satake, M.: A discrete-mechanical approach to granular materials. Int. J. Eng. Sci. 30(10), 1525–1533 (1992). https://doi.org/10.1016/0020-7225(92)90162-A

Tordesillas, A., Walker, D.M., Lin, Q.: Force cycles and force chains. Phys. Rev. E 81(1), 011302 (2010). https://doi.org/10.1103/PhysRevE.81.011302

Tordesillas, A., Steer, C.A.H., Walker, D.M.: Force chain and contact cycle evolution in a dense granular material under shallow penetration. Nonlinear Process. Geophys. 21(2), 505–519 (2014). https://doi.org/10.5194/npg-21-505-2014

Kruyt, N.P., Rothenburg, L.: On micromechanical characteristics of the critical state of two-dimensional granular materials. Acta Mech. 225(8), 2301–2318 (2014). https://doi.org/10.1007/s00707-014-1128-y

Zhu, H., Nicot, F., Darve, F.: Meso-structure evolution in a 2D granular material during biaxial loading. Granular Matter 18(1), 3 (2016). https://doi.org/10.1007/s10035-016-0608-2

Liu, J., Wautier, A., Bonelli, S., Nicot, F., Darve, F.: Macroscopic softening in granular materials from a mesoscale perspective. Int. J. Solids Struct. 193–194, 222–238 (2020). https://doi.org/10.1016/j.ijsolstr.2020.02.022

Sun, X., Kob, W., Blumenfeld, R., Tong, H., Wang, Y., Zhang, J.: Friction-controlled entropy-stability competition in granular systems. Phys. Rev. Lett. 125(26), 268005 (2020). https://doi.org/10.1103/PhysRevLett.125.268005

Wanjura, C.C., Gago, P., Matsushima, T., Blumenfeld, R.: Structural evolution of granular systems: theory. Granular Matter (2020). https://doi.org/10.1007/s10035-020-01056-4

Blumenfeld, R.: Stress in planar cellular solids and isostatic granular assemblies: coarse-graining the constitutive equation. Physica A 336(3), 361–368 (2004). https://doi.org/10.1016/j.physa.2003.12.043

Peters, J.F., Muthuswamy, M., Wibowo, J., Tordesillas, A.: Characterization of force chains in granular material. Phys. Rev. E 72(4), 041307 (2005). https://doi.org/10.1103/PhysRevE.72.041307

Sun, Q., Jin, F., Liu, J., Zhang, G.: Understanding force chain in dense granular materials. Int. J. Mod. Phys. B 24(29), 5743–5759 (2010). https://doi.org/10.1142/S0217979210055780

Zhu, H., Nicot, F., Darve, F.: Meso-structure organization in two-dimensional granular materials along biaxial loading path. Int. J. Solids Struct. 96, 25–37 (2016). https://doi.org/10.1016/j.ijsolstr.2016.06.025

Alshibli, K.A., El-Saidany, H.A.: Quantifying void ratio in granular materials using Voronoi tessellation. J. Comput. Civ. Eng. 15(3), 232–238 (2001). https://doi.org/10.1061/(ASCE)0887-3801(2001)15:3(232)

Al-Raoush, R., Thompson, K., Willson, C.S.: Comparison of network generation techniques for unconsolidated porous media. Soil Sci. Soc. Am. J. 67(6), 1687–1700 (2003). https://doi.org/10.2136/sssaj2003.1687

Reboul, N., Vincens, E., Cambou, B.: A statistical analysis of void size distribution in a simulated narrowly graded packing of spheres. Granular Matter 10(6), 457–468 (2008). https://doi.org/10.1007/s10035-008-0111-5

O’Sullivan, C., Bluthé, J., Sejpar, K., Shire, T., Cheung, L.Y.G.: Contact based void partitioning to assess filtration properties in DEM simulations. Comput. Geotech. 64, 120–131 (2015). https://doi.org/10.1016/j.compgeo.2014.11.003

Nguyen, N.-S., Taha, H., Marot, D.: A new Delaunay triangulation-based approach to characterize the pore network in granular materials. Acta Geotech. (2021). https://doi.org/10.1007/s11440-021-01157-1

Nicot, F., Darve, F.: The H-microdirectional model: accounting for a mesoscopic scale. Mech. Mater. 43(12), 918–929 (2011). https://doi.org/10.1016/j.mechmat.2011.07.006

Love, A.E.H.: A Treatise on the Mathematical Theory of Elasticity. Cambridge University Press, Cambridge (1927)

Weber, J.: Recherches concernant les contraintes intergranulaires dans lesmilieux pulvérulents. Bulletin de Liaison des Ponts-et-Chaussées 20, 1–20 (1966)

Bathurst, R.J., Rothenburg, L.: Observations on stress-force-favbric relationship in idealized granular materials. Mech. Mater. 9(1), 65–80 (1989). https://doi.org/10.1016/0167-6636(90)90030-J

Bagi, K.: On the definition of stress and strain in granular assemblies through the relation between micro-and macro-level characteristics. Powders Grains 93, 117–121 (1993)

Radjai, F., Wolf, D.E., Jean, M., Moreau, J.-J.: Bimodal character of stress transmission in granular packings. Phys. Rev. Lett. 80(1), 61–64 (1998). https://doi.org/10.1103/PhysRevLett.80.61

Satake, M.: Tensorial form definitions of discrete-mechanical quantities for granular assemblies. Int. J. Solids Struct. 41(21), 5775–5791 (2004). https://doi.org/10.1016/j.ijsolstr.2004.05.046

Nguyen, N.-S., Magoariec, H., Cambou, B.: Local stress analysis in granular materials at a mesoscale. Int. J. Numer. Anal. Meth. Geomech. 36(14), 1609–1635 (2012). https://doi.org/10.1002/nag.1063

Bagi, K.: Stress and strain in granular assemblies. Mech. Mater. 22(3), 165–177 (1996). https://doi.org/10.1016/0167-6636(95)00044-5

Kruyt, N., Rothenburg, L.: Micromechanical definition of the strain tensor for granular materials. J. Appl. Mech. (1996). https://doi.org/10.1115/1.2823353

Cambou, B., Chaze, M., Dedecker, F.: Change of scale in granular materials. Eur. J. Mech. A. Solids 19(6), 999–1014 (2000). https://doi.org/10.1016/S0997-7538(00)01114-1

Ball, R.C., Blumenfeld, R.: Stress field in granular systems: loop forces and potential formulation. Phys. Rev. Lett. 88(11), 115505 (2002). https://doi.org/10.1103/PhysRevLett.88.115505

Kruyt, N.P.: Statics and kinematics of discrete Cosserat-type granular materials. Int. J. Solids Struct. 40(3), 511–534 (2003). https://doi.org/10.1016/S0020-7683(02)00624-8

Nicot, F., Hadda, N., Guessasma, M., Fortin, J., Millet, O.: On the definition of the stress tensor in granular media. Int. J. Solids Struct. 50(14–15), 2508–2517 (2013). https://doi.org/10.1016/j.ijsolstr.2013.04.001

Oda, M., Kazama, H., Konishi, J.: Effects of induced anisotropy on the development of shear bands in granular materials. Mech. Mater. 28(1–4), 103–111 (1998). https://doi.org/10.1016/S0167-6636(97)00018-5

Liu, J., Nicot, F., Zhou, W.: Sustainability of internal structures during shear band forming in 2D granular materials. Powder Technol. 338, 458–470 (2018). https://doi.org/10.1016/j.powtec.2018.07.001

Nguyen, N., Magoariec, H., Vincens, E., Cambou, B.: On the definition of a relevant meso-scale for upscaling the mechanical behavior of 3D granular materials. Granular Matter (2020). https://doi.org/10.1007/s10035-019-0972-9

Reboul, N., Vincens, E., Cambou, B.: A computational procedure to assess the distribution of constriction sizes for an assembly of spheres. Comput. Geotech. 37(1–2), 195–206 (2010). https://doi.org/10.1016/j.compgeo.2009.09.002

Gao, S., Meegoda, J.N., Hu, L.: Two methods for pore network of porous media. Int. J. Numer. Anal. Meth. Geomech. 36(18), 1954–1970 (2012). https://doi.org/10.1002/nag.1134

Kang, D.H., Choo, J., Yun, T.S.: Evolution of pore characteristics in the 3D numerical direct shear test. Comput. Geotech. 49, 53–61 (2013). https://doi.org/10.1016/j.compgeo.2012.10.009

Sufian, A., Russell, A.R., Whittle, A.J., Saadatfar, M.: Pore shapes, volume distribution and orientations in monodisperse granular assemblies. Granular Matter 17(6), 727–742 (2015). https://doi.org/10.1007/s10035-015-0590-0

Kuhn, M.R., Daouadji, A.: Multi-directional behavior of granular materials and its relation to incremental elasto-plasticity. Int. J. Solids Struct. 152–153, 305–323 (2018). https://doi.org/10.1016/j.ijsolstr.2018.07.005

Sufian, A., Russell, A.R., Whittle, A.J.: Evolving pore orientation, shape and size in sheared granular assemblies. Granular Matter 21(1), 4 (2019). https://doi.org/10.1007/s10035-018-0856-4

Mellor, D.W.: Random Close Packing (RCP) of Equal Spheres: Structure and Implications for Use as a Model Porous Medium (1989). https://doi.org/10.21954/OU.RO.0000DFC0. The Open University

Blumenfeld, R., Edwards, S.F.: Granular entropy: explicit calculations for planar assemblies. Phys. Rev. Lett. 90(11), 114303 (2003). https://doi.org/10.1103/PhysRevLett.90.114303

Kloss, C., Goniva, C., Hager, A., Amberger, S., Pirker, S.: Models, algorithms and validation for opensource DEM and CFD-DEM. Prog. Comput. Fluid Dyn. Int. J. 12(2/3), 140 (2012). https://doi.org/10.1504/PCFD.2012.047457

Christoffersen, J., Mehrabadi, M.M., Nemat-Nasser, S.: A micromechanical description of granular material behavior. J. Appl. Mech. 48(2), 339–344 (1981). https://doi.org/10.1115/1.3157619

Mehrabadi, M.M., Nemat-Nasser, S., Oda, M.: On statistical description of stress and fabric in granular materials. Int. J. Numer. Anal. Meth. Geomech. 6(1), 95–108 (1982). https://doi.org/10.1002/nag.1610060107

de Saxcé, G., Fortin, J., Millet, O.: About the numerical simulation of the dynamics of granular media and the definition of the mean stress tensor. Mech. Mater. 36(12), 1175–1184 (2004). https://doi.org/10.1016/j.mechmat.2003.01.002

Sufian, A., Russell, A.R., Whittle, A.J.: Anisotropy of contact networks in granular media and its influence on mobilised internal friction. Géotechnique (2017). https://doi.org/10.1680/jgeot.16.P.170

Deng, N., Wautier, A., Tordesillas, A., Thiery, Y., Yin, Z.-Y., Hicher, P.-Y., Nicot, F.: Lifespan dynamics of cluster conformations in stationary regimes in granular materials. Phys. Rev E 105(1), 014902 (2022). https://doi.org/10.1103/PhysRevE.105.014902

Xiong, H., Nicot, F., Yin, Z.Y.: A three-dimensional micromechanically based model. Int. J. Numer. Anal. Meth. Geomech. 41(17), 1669–1686 (2017). https://doi.org/10.1002/nag.2692

Acknowledgements

This work is supported by public funding through a Ph.D. scholarship with the university INSA de Lyon.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chueire, J., Daouadji, A., Nicot, F. et al. On the extension of the grain loop concept from 2D to 3D granular assemblies. Granular Matter 25, 57 (2023). https://doi.org/10.1007/s10035-023-01353-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-023-01353-8