Abstract

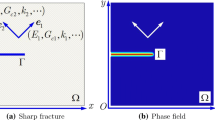

The materials with anisotropic fracture toughness are familiar in nature, e.g., anisotropic rocks, woods, and crystals. The deflecting crack propagation behaviors are often observed in these materials due to the anisotropic fracture toughness property. In this paper, the extended finite element method (XFEM) is developed for modeling the crack extending behavior in anisotropic fracture toughness medium. First, anisotropic fracture toughness profiles are introduced and embedded into XFEM, and the crack deflecting direction is predicted based on maximum energy release rate criterion. To capture the details of the twisting crack path as accurate as possible in XFEM, a mesh independent piecewise linear crack model is developed numerically. Then several numerical examples in studying the curved crack path in a material with the anisotropic fracture toughness property are given. With the techniques of XFEM embedded with anisotropic fracture toughness, the crack path in such anisotropic materials could be predicted and designed.

Similar content being viewed by others

Notes

There are 88 CPE3 elements (three-node plain strain element) and 2854 CPE4R elements (four-node plain strain elements with reduced integration) used in the Abaqus seam model.

References

Griffith AA (1921) The phenomena of rupture and flow in solids. Philos Trans R Soc A Math Phys Eng Sci 221(582–593):163–198. https://doi.org/10.1098/rsta.1921.0006

Gao H, Chiu CH (1992) Slightly curved or kinked cracks in anisotropic elastic solids. Int J Solids Struct 29(8):947–972. https://doi.org/10.1016/0020-7683(92)90068-5

Hakim V, Karma A (2005) Crack path prediction in anisotropic brittle materials. Phys Rev Lett 95(23):235–501. https://doi.org/10.1103/PhysRevLett.95.235501

Hakim V, Karma A (2009) Laws of crack motion and phase-field models of fracture. J Mech Phys Solids 57(2):342–368. https://doi.org/10.1016/j.jmps.2008.10.012

Chambolle A, Francfort G, Marigo JJ (2009) When and how do cracks propagate? J Mech Phys Solids Sep 57(9):1614–1622. https://doi.org/10.1016/j.jmps.2009.05.009

Takei A, Roman B, Bico J, Hamm E, Melo F (2013) Forbidden directions for the fracture of thin anisotropic sheets: an analogy with the wulff plot. Phys Rev Lett 110(14):144–301. https://doi.org/10.1103/PhysRevLett.110.144301

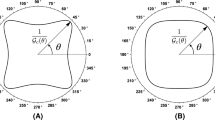

Gao Y, Liu Z, Zeng Q, Wang T, Zhuang Z, Hwang KC (2017) Theoretical and numerical prediction of crack path in the material with anisotropic fracture toughness. Eng Fract Mech 180:330–347. https://doi.org/10.1016/j.engfracmech.2017.06.013

Gao Y, Liu Z, Wang T, Zeng Q, Li X, Zhuang Z (2018) Crack forbidden area in the anisotropic fracture toughness medium. Extreme Mech Lett 22:172–175. https://doi.org/10.1016/j.eml.2018.06.006

Nasseri M, Mohanty B (2008) Fracture toughness anisotropy in granitic rocks. Int J Rock Mech Min Sci 45(2):167–193. https://doi.org/10.1016/j.ijrmms.2007.04.005

Kataoka M, Obara Y, Kuruppu M (2015) Estimation of fracture toughness of anisotropic rocks by semi-circular bend (SCB) tests under water vapor pressure. Rock Mech Rock Eng 48(4):1353–1367. https://doi.org/10.1007/s00603-014-0665-y

Chandler MR, Meredith PG, Brantut N, Crawford BR (2016) Fracture toughness anisotropy in shale. J Geophys Res Solid Earth 121(3):1706–1729. https://doi.org/10.1002/2015JB012756

Li W, Jin Z, Cusatis G (2018) Size effect analysis for the characterization of marcellus shale quasi-brittle fracture properties. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-018-1570-6

Ast J, Przybilla T, Maier V, Durst K, Göken M (2014) Microcantilever bending experiments in NiAl Evaluation, size effects, and crack tip plasticity. J Mater Res Sep 29(18):2129–2140. https://doi.org/10.1557/jmr.2014.240

Wang Z, Shen X, Akbari GM, Lin X, Wu Y, Liu X, Sun X, Kim JK (2015) Graphene aerogel/epoxy composites with exceptional anisotropic structure and properties. ACS Appl Mater Interf 7(9):5538–5549. https://doi.org/10.1021/acsami.5b00146

Pisarenko GG, Chushko VM, Kovalev SP (1985) Anisotropy of fracture toughness of piezoelectric ceramics. J Am Ceram Soc 68(5):259–265. https://doi.org/10.1111/j.1151-2916.1985.tb15319.x

Gómez-Monterde J, Schulte M, Ilijevic S, Hain J, Sánchez-Soto M, Santana OO, Maspoch ML (2016) Effect of microcellular foaming on the fracture behavior of ABS polymer. J Appl Polym Sci 133(7):43010. https://doi.org/10.1002/app.43010

Ando T, Li X, Nakao S, Kasai T, Shikidd M, Sato K (2004) Effect of crystal orientation on fracture strength and fracture toughness of single crystal silicon. In: 17th International conference on micro electro mechanical systems, pp 177–180. https://doi.org/10.1109/MEMSYS.2003.1189715

Li X, Kasai T, Nakao S, Tanaka H, Ando T, Shikida M, Sato K (2005) Measurement for fracture toughness of single crystal silicon film with tensile test. Sens Actuators A Phys 119(1):229–235. https://doi.org/10.1016/j.sna.2003.10.063

Uesugi A, Hirai Y, Sugano K, Tsuchiya T, Tabata O (2013) Effect of surface morphology and crystal orientations on fracture strength of thin film (110) single crystal silicon. In: 2013 Transducers & Eurosensors XXVII: the 17th international conference on solid-state sensors, actuators and microsystems (TRANSDUCERS & EUROSENSORS XXVII), June, IEEE 2013, pp 1946–1949. https://doi.org/10.1109/Transducers.2013.6627175

Li B, Peco C, Millán D, Arias I, Arroyo M (2015) Phase-field modeling and simulation of fracture in brittle materials with strongly anisotropic surface energy. Int J Numer Methods Eng 102(3–4):711–727. https://doi.org/10.1002/nme.4726

Li W, Rezakhani R, Jin C, Zhou X, Cusatis G (2017) A multiscale framework for the simulation of the anisotropic mechanical behavior of shale. Int J Numer Anal Methods Geomech 41(14):1494–1522. https://doi.org/10.1002/nag.2684

Shanthraj P, Svendsen B, Sharma L, Roters F, Raabe D (2017) Elasto-viscoplastic phase field modelling of anisotropic cleavage fracture. J Mech Phys Solids 99:19–34. https://doi.org/10.1016/j.jmps.2016.10.012

Moës N, Dolbow J, Belytschko T (1999) A finite element method for crack growth without remeshing. Int J Numer Methods Eng 46(1):131–150. https://doi.org/10.1002/(SICI)1097-0207(19990910)46:1%3c131::AID-NME726%3e3.0.CO;2-J

Liu ZL, Menouillard T, Belytschko T (2011) An XFEM/spectral element method for dynamic crack propagation. Int J Fract 169(2):183–198. https://doi.org/10.1007/s10704-011-9593-y

Zhao J, Bessa MA, Oswald J, Liu Z, Belytschko T (2016) A method for modeling the transition of weak discontinuities to strong discontinuities: from interfaces to cracks. Int J Numer Methods Eng 105(11):834–854. https://doi.org/10.1002/nme.4995

Zeng Q, Liu Z, Wang T, Gao Y, Zhuang Z (2018) Fully coupled simulation of multiple hydraulic fractures to propagate simultaneously from a perforated horizontal wellbore. Comput Mech 61(1–2):137–155. https://doi.org/10.1007/s00466-017-1412-5

Zeng Q, Wang T, Liu Z, Zhuang Z (2017) Simulation-based unitary fracking condition and multiscale self-consistent fracture network formation in shale. J Appl Mech 84(5):051004. https://doi.org/10.1115/1.4036192

Zeng Q, Liu Z, Wang T, Gao Y, Zhuang Z (2017) Stability analysis of the propagation of periodic parallel hydraulic fractures. Int J Fract 208(1–2):191–201. https://doi.org/10.1007/s10704-017-0233-z

Wang T, Liu Z, Zeng Q, Gao Y, Zhuang Z (2017) XFEM modeling of hydraulic fracture in porous rocks with natural fractures. Sci China Phys Mech Astron 60(8):084612. https://doi.org/10.1007/s11433-017-9037-3

Yau JF, Wang SS, Corten HT (1980) A mixed-mode crack analysis of isotropic solids using conservation laws of elasticity. J Appl Mech 47(2):335–341. https://doi.org/10.1115/1.3153665

Amestoy M, Leblond J (1992) Crack paths in plane situationsII. Detailed form of the expansion of the stress intensity factors. Int J Solids Struct 29(4):465–501. https://doi.org/10.1016/0020-7683(92)90210-K

Kim JH, Paulino GH (2003) The interaction integral for fracture of orthotropic functionally graded materials: evaluation of stress intensity factors. Int J Solids Struct 40(15):3967–4001. https://doi.org/10.1016/S0020-7683(03)00176-8

Asadpoure A, Mohammadi S (2007) Developing new enrichment functions for crack simulation in orthotropic media by the extended finite element method. Int J Numer Methods Eng 69(10):2150–2172. https://doi.org/10.1002/nme.1839

He MY, Hutchinson JW (1989) Crack deflection at an interface between dissimilar elastic materials. Int J Solids Struct 25(9):1053–1067. https://doi.org/10.1016/0020-7683(89)90021-8

Bresenham JE (1965) Algorithm for computer control of a digital plotter. IBM Syst J 4(1):25–30. https://doi.org/10.1147/sj.41.0025

Shimrat M (1962) Algorithm 112: position of point relative to polygon. Commun ACM 5(8):434. https://doi.org/10.1145/368637.368653

He MY, Hutchinson JW (1989) Kinking of a crack out of an interface. J Appl Mech 56(2):270–278. https://doi.org/10.1115/1.3176078

He MY, Hutchinson JW (1989) Kinking of a crack out of an interface: tabulated solution coefficients. Technical report. http://www.seas.harvard.edu/hutchinson/papers/NewMECH113.pdf

Nuismer RJ (1975) An energy release rate criterion for mixed mode fracture. Int J Fract 11(2):245–250. https://doi.org/10.1007/BF00038891

Acknowledgements

This work is supported by the National Key Research and Development Program of China (No. 2017YFB0702003), the National Natural Science Foundation of China under Grant Nos. 11532008 and 11722218, Science Challenge Program No. JCKY2016212A502, and Tsinghua University Initiative Scientific Research Program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: The SIFs after crack deflection

Appendix A: The SIFs after crack deflection

Amestoy and Leblond [31] demonstrated that, the SIFs of fracture deflecting in direction \(\theta \) with a small enough length, \(\{\tilde{K}_I(\theta ), ~\tilde{K}_{II}(\theta )\}\), would linearly depend on the SIFs before deflecting, \(\{K_I,K_{II}\}\). Their results could be shown, with \(\theta =m\pi \), as:

and the coefficients in Eq. (A.1) expanded up to 20th order series are obtained as:

It is noted that \(F_{11}(m)\) and \(F_{22}(m)\) are even functions; \(F_{12}(m)\) and \(F_{21}(m)\) are odd functions.

Besides Amestoy and Leblond, He and Hutchinson [37, 38] showed a table for how the coefficients \(\{F_{11}, F_{12}, F_{21},\)\(F_{22}\}\) depend on m, which could be used with Eq. (A.1). Nuismer [39] also gave simple relations on \(\tilde{K}_I(\theta ;K_I,K_{II})\) and \(\tilde{K}_{II}(\theta ;K_I,K_{II})\), which are similar to Eq. (A.1):

A comparison among the results of Amestoy and Leblond [31], He and Hutchinson [37, 38], and Nuismer [39] is also given in the appendix of Gao et al. [7]. It is noted that the result of Amestoy and Leblond is both accurate enough and easy to use, therefore is also adopted in this paper.

Rights and permissions

About this article

Cite this article

Gao, Y., Liu, Z., Wang, T. et al. XFEM modeling for curved fracture in the anisotropic fracture toughness medium. Comput Mech 63, 869–883 (2019). https://doi.org/10.1007/s00466-018-1627-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-018-1627-0