Abstract

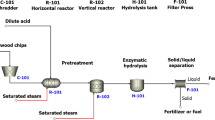

Cost-effective conversion of lignocellulose hydrolysate to optically pure lactic acid is commercially attractive but very challenging. Bacillus coagulans JI12 was isolated from natural environment and used to produce L-lactic acid (optical purity > 99.5 %) from lignocellulose sugars and acid hydrolysate of oil palm empty fruit bunch (EFB) at 50 °C and pH 6.0 without sterilization of the medium. In fed-batch fermentation with 85 g/L initial xylose and 55 g/L xylose added after 7.5 h, 137.5 g/L lactic acid was produced with a yield of 98 % and a productivity of 4.4 g/L h. In batch fermentation of a sugar mixture containing 8.5 % xylose, 1 % glucose, and 1 % L-arabinose, the lactic acid yield and productivity reached 98 % and 4.8 g/L h, respectively. When EFB hydrolysate was used, 59.2 g/L of lactic acid was produced within 9.5 h at a yield of 97 % and a productivity of 6.2 g/L h, which are the highest among those ever reported from lignocellulose hydrolysates. These results indicate that B. coagulans JI12 is a promising strain for industrial production of L-lactic acid from lignocellulose hydrolysate.

Similar content being viewed by others

References

Abdel-Banat BMA, Hoshida H, Ano A, Nonklang S, Akada R (2010) High-temperature fermentation: how can processes for ethanol production at high temperatures become superior to the traditional process using mesophilic yeast? Appl Microbiol Biotechnol 85:861–867

Abdel-Rahman M, Tashiro Y, Zendo T, Hanada K, Shibata K, Sonomoto K (2011) Efficient homofermentative L-(+)-lactic acid production from xylose by a novel lactic acid bacterium, Enterococcus mundtii QU 25. Appl Environ Microbiol 77:1892–1895

Bennett E (1958) Carbohydrate analysis, direct estimation of xylose in hemicelluloses. J Agric Food Chem 6:618–619

Bischoff K, Liu S, Hughes S, Rich J (2010) Fermentation of corn fiber hydrolysate to lactic acid by the moderate thermophile Bacillus coagulans. Biotechnol Lett 32:823–828

Bustos G, De la Torre N, Moldes A, Cruz J, DomÃnguez J (2007) Revalorization of hemicellulosic trimming vine shoots hydrolyzates trough continuous production of lactic acid and biosurfactants by L. pentosus. J Food Eng 78:405–412

Garde A, Jonsson G, Schmidt A, Ahring B (2002) Lactic acid production from wheat straw hemicellulose hydrolysate by Lactobacillus pentosus and Lactobacillus brevis. Bioresour Technol 81:217–223

Givry S, Prevot V, Duchiron F (2008) Lactic acid production from hemicellulosic hydrolyzate by cells of Lactobacillus bifermentans immobilized in Ca-alginate using response surface methodology. World J Microbiol Biotechnol 24:745–752

Guo W, Jia W, Li Y, Chen S (2010) Performances of Lactobacillus brevis for producing lactic acid from hydrolysate of lignocellulosics. Appl Biochem Biotechnol 161:124–136

Gutiérrez T, Ingram L, Preston J (2006) Purification and characterization of a furfural reductase (FFR) from Escherichia coli strain LYO1—an enzyme important in the detoxification of furfural during ethanol production. J Biotechnol 121:154–164

Hamzah F, Idris A, Rashid R, Ming S (2009) Lactic acid production from microwave-alkali pre-treated empty fruit bunches fibre using Rhizopus oryzae pellet. J Appl Sci 9:3086–3091

Hofvendahl K, Hahn-Hägerdal B (2000) Factors affecting the fermentative lactic acid production from renewable resources. Enzyme Microb Technol 26:87–107

John RP, Nampoothiri KM, Pandey A (2007) Fermentative production of lactic acid from biomass: an overview on process developments and future perspectives. Appl Microbiol Biotechnol 74:524–534

Kastner JR, Eiteman MA, Lee SA (2001) Glucose repression of xylitol production in Candida tropicalis mixed-sugar fermentations. Biotechnol Lett 23:1663–1667

Lane D (1991) 16S/23S rRNA sequencing. In: Stackebrandt E, Goodfellow M (eds) Nucleic acid techniques in bacterial systematics. Wiley, New York, pp 115–175

Laopaiboon P, Thani A, Leelavatcharamas V, Laopaiboon L (2010) Acid hydrolysis of sugarcane bagasse for lactic acid production. Bioresour Technol 101:1036–1043

Lima LHA, das Gracas de Almeida Felipe M, Vitolo M, Torres FAG (2004) Effect of acetic acid present in bagasse hydrolysate on the activities of xylose reductase and xylitol dehydrogenase in Candida guilliermondii. Appl Microbiol Biotechnol 65:734–738

Maas R, Bakker R, Jansen M, Visser D, De Jong E, Eggink G, Weusthuis R (2008) Lactic acid production from lime-treated wheat straw by Bacillus coagulans: neutralization of acid by fed-batch addition of alkaline substrate. Appl Microbiol Biotechnol 78:751–758

Martinez A, Rodriguez M, Wells M, York S, Preston J, Ingram L (2001) Detoxification of dilute acid hydrolysates of lignocellulose with lime. Biotechnol Prog 17:287–293

Moldes A, Torrado A, Converti A, Dominguez J (2006) Complete bioconversion of hemicellulosic sugars from agricultural residues into lactic acid by Lactobacillus pentosus. Appl Biochem Biotechnol 135:219–227

Mussatto S, Teixeira J (2010) Lignocellulose as raw material in fermentation processes. In: Mendez-Vilas A (ed) Current research, technology and education topics in applied microbiology and microbial biotechnology, vol 2. Formatex Research Center, Badajoz, pp 897–907

Neureiter M, Danner H, Madzingaidzo L, Miyafuji H, Thomasser C, Bvochora J, Bamusi S, Braun R (2004) Lignocellulose feedstocks for the production of lactic acid. Chem Biochem Eng Q 18:55–64

Ou MS, Ingram LO, Shanmugam K (2011) L (+)-Lactic acid production from non-food carbohydrates by thermotolerant Bacillus coagulans. J Ind Microbiol Biotechnol 38:599–605

Patel M, Ou M, Ingram L, Shanmugam K (2004) Fermentation of sugar cane bagasse hemicellulose hydrolysate to L(+)-lactic acid by a thermotolerant acidophilic Bacillus sp. Biotechnol Lett 26:865–868

Patel M, Ou M, Ingram L, Shanmugam K (2005) Simultaneous saccharification and co-fermentation of crystalline cellulose and sugar cane bagasse hemicellulose hydrolysate to lactate by a thermotolerant acidophilic Bacillus sp. Biotechnol Prog 21:1453–1460

Patel M, Ou M, Harbrucker R, Aldrich H, Buszko M, Ingram L, Shanmugam K (2006) Isolation and characterization of acid-tolerant, thermophilic bacteria for effective fermentation of biomass-derived sugars to lactic acid. Appl Environ Microbiol 72:3228–3235

Rodríguez-Chong A, Alberto Ramírez J, Garrote G, Vázquez M (2004) Hydrolysis of sugar cane bagasse using nitric acid: a kinetic assessment. J Food Eng 61:143–152

Saha B (2003) Hemicellulose bioconversion. J Ind Microbiol Biotechnol 30:279–291

Tanaka K, Komiyama A, Sonomoto K, Ishizaki A, Hall S, Stanbury P (2002) Two different pathways for D-xylose metabolism and the effect of xylose concentration on the yield coefficient of L-lactate in mixed-acid fermentation by the lactic acid bacterium Lactococcus lactis IO-1. Appl Microbiol Biotechnol 60:160–167

Walton S, Bischoff K, van Heiningen A, Van Walsum G (2010) Production of lactic acid from hemicellulose extracts by Bacillus coagulans MXL-9. J Ind Microbiol Biotechnol 37:823–830

Wang L, Zhao B, Liu B, Yu B, Ma C, Su F, Hua D, Li Q, Ma Y, Xu P (2010) Efficient production of L-lactic acid from corncob molasses, a waste by-product in xylitol production, by a newly isolated xylose utilizing Bacillus sp. strain. Bioresour Technol 101:7908–7915

Yan L, Zhang H, Chen J, Lin Z, Jin Q, Jia H, Huang H (2009) Dilute sulfuric acid cycle spray flow-through pretreatment of corn stover for enhancement of sugar recovery. Bioresour Technol 100:1803–1808

Zhang D, Ong YL, Li Z, Wu JC (2012) Optimization of dilute acid-catalyzed hydrolysis of oil palm empty fruit bunch for high yield production of xylose. Chem Eng J 181–182:636–642

Acknowledgments

This work was supported by the Science and Engineering Research Council (SERC) of the Agency for Science, Technology and Research (A*STAR) under the Value-Added Chemicals from Lignocellulose (VACL) Program (SERC grant no. 0921590133; ICES/10-474A01, NUS/R-279-000-309-305). Thanks are given to Ms. Ong Yee Ling for help with preparing the EFB hydrolysate. All authors have agreed to submit this manuscript to the “Applied Microbiology and Biotechnology.”

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ye, L., Hudari, M.S.B., Zhou, X. et al. Conversion of acid hydrolysate of oil palm empty fruit bunch to L-lactic acid by newly isolated Bacillus coagulans JI12. Appl Microbiol Biotechnol 97, 4831–4838 (2013). https://doi.org/10.1007/s00253-013-4788-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-013-4788-y