Abstract

Modern thermal power plant operating on fossil fuels has to be highly efficient and should emit low levels of CO2. One of possible ways to fulfil these requirements is to increase thermal power plant peak service temperature. P92 steel enables service temperature of up to 650 °C. It is stronger, more resistant to creep and enables higher service temperature than P91. During welding of steam boiler components made of P92, it is important to consider proper preheating, welding and post-weld heat treatment parameters in order to avoid cracks and diminish sensitivity to creep in service.

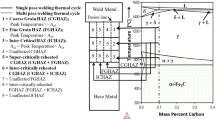

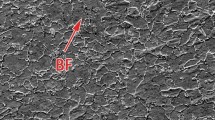

The research focused on analysis of simulated heat-affected zone (HAZ) microstructures and distribution of carbides. The FG HAZ (fine-grain heat-affected zone) (Tmax is 950 °C) is the most problematic when it comes to occurrence of type IV cracks, as in this zone, the average representation of carbides on PAGB is 72%, while the average representation of carbides on PAGB in the P21 steel is 58%. After the heat treatment, maximum hardness is recorded in the CG HAZ (coarse-grain heat-affected Zone) (Tmax is 1300 °C), where the values reached 248 HV, which was below the maximum allowable value of 250 HV. Other areas of HAZ expressed the values from 218 to 227 HV. Charpy impact test at service temperatures of 650 °C showed that the CG HAZ was the most critical immediately after welding as the energy for crack initiation was 30 J. However, after obligatory post-weld heat treatment, FG HAZ appeared to be more problematic than CG HAZ, so this research showed that the crack initiation energy value increased due to the fine-grain microstructure, yet the crack propagation energy reduced.

Similar content being viewed by others

References

Khalaj G, Pouraliakbar H, Jandaghi MR, Gholami A (2017) Microalloyed steel welds by HF-ERW technique: novel PWHT cycles, microstructure evolution and mechanical properties enhancement. Int J Press Vessel Pip 152:15–26. https://doi.org/10.1016/j.ijpvp.2017.04.003

Shiran MKG, Khalaj G, Pouraliakbar H, Jandaghi M, Bakhtiari H, Shirazi M (2017) Effects of heat treatment on the intermetallic compounds and mechanical properties of the stainless steel 321–aluminum 1230 explosive-welding interface. Int J Min Met Mater 24(11):1267–1277. https://doi.org/10.1007/s12613-017-1519-x

Ennis PJ, Czyrska-Filemonowicz A (2003) Recent advances in creep-resistant steels for power plant applications. Sadhana 28(3-4):709–730. https://doi.org/10.1007/BF02706455

Hesam Pouraliakbar, Mohsen Hamedi, Amir Hossein Kokabi, Ali Nazari, » Designing of CK45 carbon steel and AISI 304 stainless steel dissimilar welds«, Mater Res, 17 (2014) 1, 106–114, https://doi.org/10.1590/S1516-14392013005000170

Ennis PJ (2006) The creep rupture behaviour and steam oxidation resistance of P92 weldments. Materials at high temperatures 23(3-4):187–193. https://doi.org/10.1179/mht.2006.013

Vaillant JC, Vandenberghe B, Hahn B, Heuser H, Jochum C (2008) T/P23, 24, 911 and 92: New grades for advanced coal-fired power plants-properties and experience. Int J Pres Ves Pip 85(1-2):38–46. https://doi.org/10.1016/j.ijpvp.2007.06.011

Vuherer T, Dunđer M, Milović LJ, Zrilić M, Samardžić I (2013) Microstructural investigation of the heat-affected zone of simulated welded joint of P91 steel. Metalurgy 52(3):317–320

Richardot D, Vaillant JC, Arbab A, Bendick W (2000) The T92/P92 Book, Vallourec-Mannesmann tubes

Yatomi M, Fuji A, Tabuchi M, Hasegawa Y, Kobayashi KI, Yokobori T, Yokobori T, Yokobori T (2010) Evaluation of creep crack growth rate of P92 welds using fracture mechanics Parameters. J Press Vessel Technol 132(4):132–140. https://doi.org/10.1115/1.4001522

Yin L, Wang J, Chen X, Liu C, Siddiquee AN, Wang G, Yao Z (2018) Microstructures and their distribution within HAZ of X80 pipeline steel welded using hybrid laser-MIG welding. Weld World 62(4):721–727. https://doi.org/10.1007/s40194-018-0582-x

Fotovvati B, Wayne SF, Lewis G, Asadi E (2018) A review on melt-pool characteristics in laser welding of metals. Adv Mater Sci Eng 2018:18–18. https://doi.org/10.1155/2018/4920718

Pouraliakbar H, Khalaj M-j, Nazerfakhari M, Khalaj G (2015) Artificial neural networks for hardness prediction of HAZ with chemical composition and tensile test of X70 pipeline steels. J Iron Steel Res Int 22(5):446–450. https://doi.org/10.1016/S1006-706X(15)30025-X

Allen DJ, Harvey B, Brett SJ (2007) FOURCRACK - An investigation of the creep performance of advanced high alloy steel welds. Int J Pres Ves Pip 84(1/2):104–113. https://doi.org/10.1016/j.ijpvp.2006.09.010

Abe F, Tabuchi M, Tsukamoto S, Shirane T (2010) Microstructure evolution in HAZ and suppression of type IV fracture in advanced ferritic power plant steels. Int J Pres Ves Pip 87(11):598–604. https://doi.org/10.1016/j.ijpvp.2010.08.005

Chen X, Chen X, Xu H, Madigan B (2015) Monte Carlo simulation and experimental measurements of grain growth in the heat affected zone of 304 stainless steel during multipass welding. Int J Adv Manuf Technol 80(5-8):1197–1211. https://doi.org/10.1007/s00170-015-7024-3

Khorrami MS, Mostafaei MA, Pouraliakbar H, Kokabi AH (2014) Study on microstructure and mechanical characteristics of low-carbon steel and ferritic stainless steel joints. Mater Sci Eng A 608:35–45. https://doi.org/10.1016/j.msea.2014.04.065

Shirana MKG, Khalajb G, Pouraliakbarc H, Jandaghic MR, Dehnavia AS, Haimd Bakhtiar (2018) Multilayer Cu/Al/Cu explosive welded joints: characterizing heat treatment effect on the interface microstructure and mechanical properties. J Manuf Process 35:657–663. https://doi.org/10.1016/j.jmapro.2018.09.014

Pouraliakbar H, Jandaghi MR (2018) Mechanistic insight into the role of severe plastic deformation and post-deformation annealing in fracture behavior of Al-Mn-Si alloy. Mech Mater 122:145–158. https://doi.org/10.1016/j.mechmat.2018.04.002

Pouraliakbar H, Jandaghi MR, Heidarzadeh A, Jandaghi MM (2018) Constrained groove pressing, cold-rolling, and post-deformation isothermal annealing: consequences of their synergy on material behavior. Mater Chem Phys 206:85–93. https://doi.org/10.1016/j.matchemphys.2017.12.010

Bertram LA (1996) A Digital Rykalin Function for Welding. Report No. SAND-97-8225. Albuquerque and Livermore - Sandia National Labs, Livermore, CA, United States

Rykalin NN (1952) Die Wärmegrundlagen des Schweissvorganges, Verlag Technik (Pohl H. ed), Berlin, Germany

Tabuchi M, Kondo M, Watanabe T, Hongo H, Yin F, Abe F (2004) Improvement of Type IV Cracking resistance of 9Cr heat resisting steel weldment by boron addition. Acta Metall Sin 17(4):331–337

Albert SK, Kondo M, Tabuchi M, Yin FX, Sawada K, Abe F (2005) Improving the creep properties of 9Cr-3 W-3Co-NbV steels and their weld joints by the addition of boron. Metal Mater Trans A 36(2):333–343

Kimura M, Yamaguchi K, Hayakawa M, Kobayashi K, Kanazawa K (2006) Microstructures of creep-fatigued 9-12% Cr ferritic heat-resisting steels. Int J Fatigue 28:300–308. https://doi.org/10.1016/j.ijfatigue.2005.04.013

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dunđer, M., Vuherer, T., Samardžić, I. et al. Analysis of heat-affected zone microstructures of steel P92 after welding and after post-weld heat treatment. Int J Adv Manuf Technol 102, 3801–3812 (2019). https://doi.org/10.1007/s00170-019-03513-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03513-8