Abstract

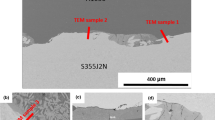

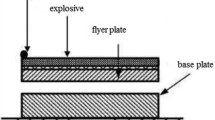

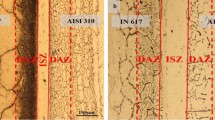

The effects of heat treatment on the microstructure and mechanical properties of intermetallic compounds in the interface of stainless steel 321 explosively bonded to aluminum 1230 were investigated in this study. Experimental investigations were performed by optical microscopy, scanning electron microscopy, and microhardness and shear tensile strength testing. Prior to heat treatment, increasing the stand-off distance between samples from 1 to 2.5 mm caused their interface to become wavy and the thickness of intermetallic layers to increase from 3.5 to 102.3 μm. The microhardness increased from HV 766 in the sample prepared at a stand-off distance of 1 mm to HV 927 in the sample prepared at a stand-off distance of 2.5 mm; in addition, the sample strength increased from 103.2 to 214.5 MPa. Heat treatment at 450°C for 6 h increased the thickness of intermetallic compound layers to 4.4 and 118.5 μm in the samples prepared at stand-off distances of 1 and 2.5 mm, respectively. These results indicated that increasing the duration and temperature of heat treatment decreased the microhardness and strength of the interface of explosively welded stainless steel 321−Al 1230 and increased the thickness of the intermetallic region.

Similar content being viewed by others

References

B.S. Zlobin, Explosion welding of steel with aluminum, Combust. Explos. Shock Waves, 38(2002), No. 3, p. 374.

R. Kacar and M. Acarer, An investigation on the explosive cladding of 316L stainless steel-din-P355GH steel, J. Mater. Process. Technol., 152(2009), No. 1, p. 91.

L. Tricarico, R. Spina, D. Sorgente, and M. Brandizzi, Effects of heat treatments on mechanical properties of Fe/Al explosion-welded structural transition joints, Mater. Des., 30(2009), No. 7, p. 2693.

G. Temizel and M. Özenbaş, Intermetallic phase formation at Fe−Al film interfaces, Turk. J. Eng. Environ. Sci., 31(2007), No. 2, p. 71.

S. Phengsakul and A. Rodchanarowan, Effect of thermal treatment on intermetallic phases of Fe/Al structural transition joints, Energy Procedia, 34(2013), p. 782.

A.A. Shtertser and B.S. Zlobin, Flows, strains, and the formation of joints in oblique collision of metal plates, J. Appl. Mech. Tech. Phys., 56 (2015), No. 5, p. 927.

M.K.G. Shiran, H. Bakhtiari, S.A. Akbari Mousavi, G. Khalaj, and S.M. Mirhashemi, Effect of stand-off distance on the mechanical and metallurgical properties of explosively bonded 321 austenitic stainless steel−1230 aluminum alloy tubes, Mater. Res., 20(2017), No. 2, p. 291.

A. Patterson, Fundamentals of Explosion Welding, ASM International, USA, 1993, p. 160.

A. Durgutlu, H. Okuyucu, and B. Gulenc, Investigation of effect of the stand-off distance on interface characteristics of explosively welded copper and stainless steel, Mater. Des., 29(2008), No. 7, p. 1480.

Y. Wang and K.S. Vecchio, Microstructure evolution in a martensitic 430 stainless steel−Al metallic-intermetallic laminate (MIL) composite, Mater. Sci. Eng. A, 643(2015), p. 72.

T.I. Khan, S.A. Rizvi, and K. Matsuura, The effect on wear behaviour of H13 tool steel surfaces modified using a tungsten arc heat source, Wear, 244(2000), No. 1-2, p. 154.

I. Samardžić, B. Mateša, and I. Kladarić, The influence of heat treatment on properties of three-metal explosion joint: AlMg−Al−steel, Metalurgija, 51(2012), No. 3, p. 353.

F. Findik, R. Yilmaz, and T. Somyurek, The effects of heat treatment on the microstructure and microhardness of explosive welding, Sci. Res. Essays, 6(2011), No. 19, p. 4141.

J. Lokaj, M. Turna, E. Jakubcek, and M. Benak, X-ray microanalysis of Al−austenitic steel boundary formed by explosion welding, Materiały Wysokoenergetyczne, 3(2011), p. 72.

ASTM E3-11: Standard Guide for Preparation of Metallographic Specimens, Philadelphia, 2012.

ASTM E407: Standard Practice for Microetching Metals and Alloys, Philadelphia, 2012.

ASTM E883-11: Standard Guide for Reflected-Light Photomicrography, Philadelphia, 2012.

ASTM B487-85: Standard Test Method for Measurement of Metal and Oxide Coating Thickness by Microscopical Examination of a Cross Section, Philadelphia, 2013.

ASTM D 3165-07: Standard Test Method for Strength Properties of Adhesives in Shear by Tension Loading of Single-Lap-Joint Laminated Assemblies, Philadelphia, 2014.

ASTM E384-11: Standard Test Method for Knoop and Vickers Hardness of Materials, Philadelphia, 2012.

S.A.A. Akbari Mousavi, M. Nourozpour, and A. Makki, Investigations on the explosive welding interface of Al−5083/Al−1250/sea steel three layer composite, J. Energetic Mater., 3(2008), No. 2, p. 11.

N. Kahraman and B. Gülenç, Microstructural and mechanical properties of Cu-Ti plates bonded through explosive welding process, J. Mater. Process. Technol., 169(2005), No. 1, p. 67.

M. Acarer, B. Gülenç, and F. Findik, Investigation of explosive welding parameters and their effects on microhardness and shear strength, Mater. Des., 24(2003), No. 8, p. 659.

L. Tricarico and R. Spina, Mechanical strength of Fe/Al structural transition joints subject to thermal loading, Arch. Mater. Sci. Eng., 37(2009), No. 2, p. 85.

S.A.A. Akbari Mousavi and P. Farhadi Sartangi, Effect of post-weld heat treatment on the interface microstructure of explosively welded titanium-stainless steel composite, Mater. Sci. Eng. A, 494(2008), No. 1-2, p. 329.

B. Crossland, Explosive Welding of Metals and Its Applications, Clarendon Press, 1982.

N. Kengkla and N. Tareelap, Role of intermetallic compound on crrosion of aluminium/steel transition joint used in naval applications, [in] The 1st Mae Fah Luang University International Conference, Thailand, 2012, p. 1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shiran, M.K.G., Khalaj, G., Pouraliakbar, H. et al. Effects of heat treatment on the intermetallic compounds and mechanical properties of the stainless steel 321–aluminum 1230 explosive-welding interface. Int J Miner Metall Mater 24, 1267–1277 (2017). https://doi.org/10.1007/s12613-017-1519-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-017-1519-x