Abstract

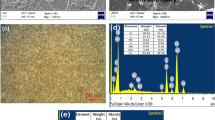

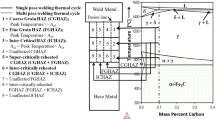

Steels 9-12% Cr, having the high creep rupture strength are advocated for the modern low polluting thermal power plants. In the present investigation, the P91 pipe weldments have been characterized for microstructural responses in as-welded, post-weld heat treatment (PWHT) and ageing conditions. The PWHT of welded samples were carried out at 760 °C for time of 2 h and ageing at 760 °C for 720 h and 1440 h, respectively. The effect of time has been studied on precipitates size, distribution of precipitates and grain sizes present in various zones of P91 steel weldments. The impact toughness and hardness variation of heat affected zone (HAZ) have also been studied in as-welded condition as well as at different heat treatment condition. A significant change was observed in grain size and precipitates size after each heat treatment condition. The maximum impact toughness of HAZ was obtained after PWHT at 760 °C for 2 h. The main phase observed in weld fusion zone in as-welded, PWHT and ageing conditions were M23C6, MX, M7C3, Fe-rich M3C and M2C. The unwanted Z-phase (NbCrN) was also noticed in weld fusion zone after ageing of 1440 h.

Similar content being viewed by others

References

H. Cerjak, P. Hofer, and B. Schaffernak, ISIJ Int. 39, 874 (1999).

F. Masuyama, ISIJ Int. 41, 612 (2001).

V. K. Sikka, C. T. Ward, and C. K. Thomas, Proceedings of International Conference on Ferritic Steels for High Temperature Applications (Ed. A.K. Khare), p. 65, ASM International, Ohio, USA (1983).

S. J. Sandersion, Proceeding of the ASM International Conference on on Ferritic Steels for High Temperature Applications (Ed. A.K. Khare), p. 85, ASM International, Ohio, USA (1983).

C. Coussment and A. Dhooge, Int. J. Pres. Ves. Pip. 45, 163 (1991).

S. Haribabu, A. Amarendra, R. Rajaraman, and C. S. Sundar, J. Phys. Conf. 443, 1 (2013).

B. Arivazhagan and M. Kamaraj, J. Manuf. Process. 15, 542 (2013).

B. Silwal, L. Li, A. Deceuster, and B. Griffiths, Weld. J. 92, 80 (2013).

C. Pandey, A. Giri, and M. M. Mahapatra, Mat. Sci. Eng. A 657, 173 (2016).

C. Pandey, A. Giri, and M. M. Mahapatra, Mat. Sci. Eng. A 664, 58 (2016).

C. Pandey and M.M. Mahapatra, P. I. Mech. Eng. E, DOI: 10.1177/0954408916656678 (2016).

T. Watanabe, M. Tabuchi, M. Yamazaki, H. Hongo, and T. Tanabe, Int. J. Pres. Ves. Pip. 83, 63 (2006).

B. Arivazhagan, S. Sundaresan, and M. Kamaraj, J. Mater. Process. Tech. 209, 5245 (2009).

J. A. Francis, W. Mazur, and H. K. D. H. Bhadeshia, Mater. Sci. Tech. 22, 1387 (2006).

Y. Wang, R. Kannan, and L. Li, Mater. Charact. 118, 225 (2016).

S. K. Albert, M. Matsui, T. Watanabe, H. Hongo, K. Kubo, and M. Tabuchi, Int. J. Pres. Ves. Pip. 80, 405 (2003).

D. J. Abson and J. S. Rothwell, Int. Mater. Rev. 58, 438 (2013).

K. Sawada, M. Bauer, F. Kauffmann, P. Mayr, and A. Klenk, Mat. Sci. Eng. A 527, 1417 (2010).

S. Spigrarelli and E. Quadrini, Mater. Design 23, 547 (2002).

M. E. Abd El-Azim, O. E. El-Desoky, H. Ruoff, F. Kauffmann, and E. Roos, J. Mater. Sci. Tech. 29, 1027 (2013).

M. L. Santella, R. W. Swinderman, R. W. Reed, and J. M. Tanzosh, M. L. Santella, R. W. Swinderman, R. W. Reed, and J. M. Tanzosh, EPRI Conference on 9Cr Materials Fabrication and Joining Technologies, p. 14–1, EPRI, California, USA (2001).

C. Pandey and M. M. Mahapatra, J. Mater. Eng. Perform. 25, 2761 (2016).

K. E. Dawson, G. J. Tatlock, K. Chi, and P. Barnard, Metall. Mater. Trans. A 44, 5065 (2013).

C. Pandey and M. M. Mahapatara, J. Mater. Eng. Perform. 25, 2195 (2016).

S. Paddea, J. A. Francis, A. M. Paradowaska, P. J. Bouchard, and I. A. Shibli, Mat. Sci. Eng. A 534, 663 (2012).

K. Sawada, T. Hara, M. Tabuchi, K. Kimura, and K. Kubushiro, Mater. Charact. 101, 106 (2015).

C. Pandey, A. Giri, and M. M. Mahapatra, Int. J. Steel Struct. 16, 333 (2016).

D. P. Singh, M. Sharma, and J. S. Gill, Int. J. Res. Mech. Eng. Tech. 3, 216 (2013).

M. Sireesha, S. K. Albert, and S. Sundaresan, J. Mater. Eng. Perform. 10, 320 (2001).

B. Arivazhagan and M. Vasudevan, J. Manuf. Process. 16, 305 (2014).

H. K. Danielsen and J. Hald, Mat. Sci. Eng. A 505(1-2), 169 (2009).

A. Golpayegani, H. O. Andren, H. Danielsen, and J. Hald, Mat. Sci. Eng. A 489, 310 (2008).

C. Hurtado-Noreña, C. A. Danón, M. I. Luppo, and P. Bruzzoni, Metall. Mater. Trans. A 46, 3972 (2015).

R. D. Peelamedu, R. Roy, and D. K. Agrawal, Mater. Lett. 55, 234 (2002).

F. Abe, M. Taneike, and K. Sawada, Int. J. Press. Vessel. Pip. 84, 3 (2007).

P. Mayr and H. Cerjak, T. Indian I. Metals 63, 131 (2010).

T. Kojima, K. Hayashi, and Y. Kajita, ISIJ Int. 35, 1284 (1995).

Z. Nishiyama, Martensitic Transformation, Academic Press, USA (1978).

K. Laha, K. S. Chanddravathi, P. Parameswaran, B. S. Rao, and S. L. Mannan, Metallurg. Mater. Trans. A 38(A), 58 (2007).

J. Onoro, J. Mater. Process. Technol. 180, 137 (2006).

C. Pandey and M. M. Mahapatara, Proc. 23rd International Conference on Processing and Fabrication of Advanced Materials, IIT Roorkee, India (2014).

C. Pandey and M. M. Mahapatara, T. Indian I. Metals 69, 1657 (2016).

J. Blach, L. Falat, and P. Sevc, Eng. Fail. Anal. 16, 1397 (2009).

C. Pandey, N. Saini, M. M. Mahapatra, and P. Kumar, Eng. Fail. Anal. 71, 131 (2017).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pandey, C., Giri, A., Mahapatra, M.M. et al. Characterization of microstructure of HAZs in as-welded and service condition of P91 pipe weldments. Met. Mater. Int. 23, 148–162 (2017). https://doi.org/10.1007/s12540-017-6394-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6394-5