Abstract

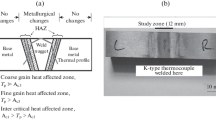

The inducement of this paper was the revelation of true microstructure-hardening relationship in heat affected zones (HAZs) of P91B steels. This work reports erroneous metallographic practices in revealing true microstructure and establishes prior austenite grain (PAG) hardening and softening phenomenon. Different HAZs were simulated having distinguished microstructural features. True microstructure of simulated and post-weld heat treatment (PWHT) samples were revealed completely and discussed with respect to microhardness indicating the degree of hardening. It was revealed that true microstructure features of sub-HAZs were governed by peak temperature, hold time at peak temperature, PAG size, and microhardness. The simulated samples showed different microstructural features on using different reagents/etchants. Rate of revealing microstructural features and degree of keying force influencing PAG size were observed to be dependent on peak temperature and hold time at peak temperature. However, true-microstructural features of furnace simulated and PWHT samples were independent of reagents’ composition. Degree of hardening varied due to the difference in solid solution strengthening and formation of second phases at a given peak temperature and hold time at peak temperature. In simulated samples, PAG softening was observed for coarse-grained HAZ (CGHAZ) after PWHT, while in furnace simulated samples, softening occurred in inter-critical HAZ (furnace simulated ICHAZ). Interpass temperature with second pass led to the formation of mixed PAGs and PAG hardening. This hardening was retained in inter-critically reheated CGHAZ after PWHT, whereas it was absent in super-critically reheated CGHAZ.

Similar content being viewed by others

References

M. Akhtar, A. Khajuria, Probing true creep-hardening interaction in weld simulated heat affected zone of P91 steels. J. Manuf. Process (2019, Accepted)

V. Sinha, E.J. Payton, M. Gonzales, R.A. Abrahams, B.S. Song, Delineation of prior austenite grain boundaries in a low-alloy high-performance steel. Met. Microstruct. Anal. 6, 610–618 (2017). https://doi.org/10.1007/s13632-017-0403-4

M. Akhtar, Metallurgical characterisation of simulated heat affected zone in boron modified P91 steel. Natl. Inst. Technol. Warangal (2017). https://doi.org/10.13140/RG.2.2.12593.68967/2

C.R. Simcoe, A.R. Elseo, G.K. Manning, Study of the effect of boron on the decomposition of austenite. JOM 7, 193–200 (1955). https://doi.org/10.1007/BF03377480

P. Mayr, Evolution of microstructure and mechanical properties of the heat affected zone in B-containing 9% chromium steels (Graz University of Technology, Austria, 2007)

A. Khajuria, M. Akhtar, R. Kumar, J. Swaminanthan, R. Bedi, D.K. Shukla, Effect of boron modified microstructure on impression creep behaviour of simulated multi-pass heat affected zone of P91 steel, in: S. Dutta, S.S. Chakraborty (Eds.), National Conference on Advanced Materials, Manufacturing and Metrology, CSIR-CMERI, Durgapur, Durgapur, 2018: pp. 150–157. https://doi.org/10.13140/rg.2.2.34633.24164/2

A. Khajuria, M. Pratap Singh, A. Raina, M. Akhtar, Improvement in productivity by application of a slat conveyor design in a steel rolling mill. Int. J. Res. Mech. Civ. Eng. 4, 5–12 (2018)

M. Akhtar, A. Khajuria, V.S. Kumar, R.K. Gupta, S.K. Albert, Evolution of microstructure during welding simulation of boron modified P91 steel. Phys. Met. Metallogr. 120, 672–685 (2019). https://doi.org/10.1134/S0015323019070052

M. Akhtar, A. Khajuria, R. Kumar, R. Bedi, Metallurgical investigations on dual heat cycled boron alloyed P91 ferritic/martensitic steel, in: Young Professionals of the International Institute of Welding, 2017, pp. 322–331

S. Sulaiman, Structure of properties of the heat affected zone of P91 creep resistant steel, University of Wollongong, 2007. http://ro.uow.edu.au//theses/777

G.F. Vander Voort, Metallography Principles and Practice (ASM International, Materials Park, 1999)

A. Sauveur, The metallography and heat treatment of iron and steel, Sauveur and Boylston Metallurgical Engineers, 1918

F. Abe, M. Tabuchi, S. Tsukamoto, T. Shirane, Microstructure evolution in HAZ and suppression of type IV fracture in advanced ferritic power plant steels. Int. J. Press. Vessel. Pip. 87, 598–604 (2010). https://doi.org/10.1016/j.ijpvp.2010.08.005

C.R. Das, A.K. Bhaduri, S. Lakshmi, S. Chakravarty, S.K. Kar, S.K. Albert, Influence of boron and nitrogen on microstructure and hardness of heat-affected zone of modified 9Cr–1Mo steel—Gleeble simulation study. Weld. World. 59, 513–519 (2015). https://doi.org/10.1007/s40194-015-0226-3

M. Yanet, Z. Mónica, Microstructure characterization of heat affected zone in single pass welding in 9Cr-1Mo steels. Proc. Mater. Sci. 8, 904–913 (2015). https://doi.org/10.1016/j.mspro.2015.04.151

B.A. Shassere, Y. Yamamoto, S.S. Babu, Toward improving the type IV cracking resistance in Cr-Mo steel weld through thermo-mechanical processing. Metall. Mater. Trans. A 47A, 2188–2200 (2016). https://doi.org/10.1007/s11661-016-3387-9

C. Panait, W. Bendick, A. Fuchsmann, J.Besson Gourgues-Lorenzon, Study of the microstructure of the grade 91 steel after more than 100,000 h of creep exposure at 600 & #xB0;C. Int. J. Press. Vessel. Pip. 87, 326–335 (2010). https://doi.org/10.1016/j.ijpvp.2010.03.017

P. Agyakwa, Creep and microstructural development in P91 weldments at elevated temperature, University of Nottingham, 2004. http://eprints.nottingham.ac.uk/11759/1/417207.pd

M. Łomozik, E. Tasak, Physical simulation and numerical modelling of X10CrMoVNb 9.10 (P91) steel repair welding, in 8th Liege Conference Materials Advance Power Engineering Liege, Belgium, n.d. https://doi.org/10.13140/rg.2.1.5015.5920

M. Mallik, Effect of microstructure on the indentation creep behaviour of 2-25Cr-1Mo and its comparison with modified 9Cr-1Mo ferritic steel, National Institute of Technology Rourkela, 2011

Y. Wang, L. Li, Microstructure evolution of fine: grained heat—affected zone in type IV failure of P91 welds. Weld. J. 95, 27–36 (2016)

Y. Wang, R. Kannan, L. Li, Characterization of as-welded microstructure of heat-affected zone in modified 9Cr–1Mo–V–Nb steel weldment. Mater. Charact. 118, 225–234 (2016). https://doi.org/10.1016/J.MATCHAR.2016.05.024

H. Hongo, M. Tabuchi, T. Watanabe, Type IV creep damage behavior in grade 91 steel welded joints. Metall. Mater. Trans. A 43, 1163–1173 (2012). https://doi.org/10.1007/s11661-011-0967-6

J. Oñoro, Weld metal microstructure analysis of 9-12% Cr steels. Int. J. Press. Vessel. Pip. 83, 540–545 (2006). https://doi.org/10.1016/j.ijpvp.2006.03.005

C. Hurtado-Noreña, C.A. Danón, M.I. Luppo, P. Bruzzoni, Evolution of minor phases in a 9PctCr steel: Effect of tempering temperature and relation with hydrogen trapping. Metall. Mater. Trans. A 46A, 3972–3988 (2015). https://doi.org/10.1007/s11661-015-3045-7

D.R. Jara, 9–12% Cr heat resistant steels: alloy design, TEM characterisation of microstructure evolution and creep response at 650°C (Ruhr-Universität Bochum, Bochum, 2011)

T. Vuherer, M. Dunder, L. Milovic, M. Zrilic, I. Samardzic, Microstructural investigation of heat-affected zone of simulated welded joint of P91 steel. Metalurgija 52, 317–320 (2013)

V. Gaffard, Experimental study and modelling of high temperature creep flow and damage behaviour of 9Cr1Mo-NbV steel weldments, Institut polytechnique de Grenoble (Grenoble Institute of Technology), 2004

Y.-Q. Peng, T.-C. Chen, T.-J. Chung, S.-L. Jeng, R.-T. Huang, L.-W. Tsay, Y.-Q. Peng, T.-C. Chen, T.-J. Chung, S.-L. Jeng, R.-T. Huang, L.-W. Tsay, Creep rupture of the dimulated HAZ of T92 steel compared to that of a T91 steel. Materials (Basel) 10, 139 (2017). https://doi.org/10.3390/ma10020139

T.H. Hsiao, T.C. Chen, S.L. Jeng, T.J. Chung, L.W. Tsay, Effects of simulated microstructure on the creep rupture of the modified 9Cr-1Mo steel. J. Mater. Eng. Perform. 25, 4317–4325 (2016). https://doi.org/10.1007/s11665-016-2270-6

G.F. Vander Voort, E.P. Manilova, Hints for imagining phases in steels. Adv. Mater. Process. 163, 32–37 (2005)

R.L. Bish, The action of Fry’s reagent on steel. Metallography 12, 147–151 (1979). https://doi.org/10.1016/0026-0800(79)90043-0

M. Akhtar, A. Khajuria, J.K. Sahu, J. Swaminathan, R. Kumar, R. Bedi, S.K. Albert, Phase transformations and numerical modelling in simulated HAZ of nanostructured P91B steel for high temperature applications. Appl. Nanosci. 8, 1669–1685 (2018). https://doi.org/10.1007/s13204-018-0854-1

M. Akhtar, A. Khajuria, V.S. Kumar, R.K. Gupta, S.K. Albert, Microstructure evolution in modelling welding of ferrite/martensite steel modified by boron. Phys. Met Met Sci. 120, 731–745 (2019). https://doi.org/10.1134/S0015323019070052. (in Russian)

V.T. Paul, S. Saroja, M. Vijayalakshmi, Microstructural stability of modified 9Cr–1Mo steel during long term exposures at elevated temperatures. J. Nucl. Mater. 378, 273–281 (2008). https://doi.org/10.1016/j.jnucmat.2008.06.033

Acknowledgements

Modassir is very much thankful to his M.Tech mentor, Dr. T. Jayakumar, DRDO Chair (Prof. S. Bhagavantam Chair), DMRL, Hyderabad. Authors are thankful to Director, CSIR-NML, Jamshedpur, Dr. I. Chattoraj for allowing to carry out the experimental work like Gleeble simulations, microhardness testing and microscopy techniques. Dr. Saroja Saibaba, Scientist-H, IGCAR Kalpakkam for nice discussions and suggestions; Director, IGCAR Kalpakkam for providing materials. Modassir would like to thank Dr. Sandip Ghosh Chowdhury, Chief Scientist, CSIR-NML, Jamshedpur for providing metallography facility. Modassir is also thankful for Dr. C. Vanitha, Associate Professor, NIT Warangal and Dr. Asit Kumar Khanra, Associate Professor, NIT Warangal for motivation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akhtar, M., Khajuria, A. Probing True Microstructure-Hardening Relationship in Simulated Heat Affected Zone of P91B Steels. Metallogr. Microstruct. Anal. 8, 656–677 (2019). https://doi.org/10.1007/s13632-019-00573-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-019-00573-w