Abstract

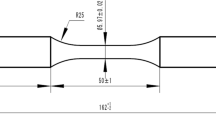

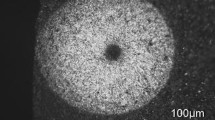

The effects of specimen geometry on the fatigue behavior of SAE 4320 steel carburized at 927 °C were evaluated with two sets of cantilever bend specimens, one set machined with square edges and one set machined with round edges. The specimens with square edges exhibited a 13% lower fatigue limit. In comparison to the rounded samples, the lower fatigue limit in the square-edged samples was attributed to the presence of a higher volume fraction of retained austenite in the sample corners and a lower surface residual compressive stress. As a result of the differences in residual stress, preferential crack initiation sites existed in the square-edged samples at a location approximately 200 to 900 ώm from the square edge. The implications of this study on laboratory analyses of the bending fatigue performance of carburized gear steels are discussed.

Similar content being viewed by others

References

R.E. Cohen, P.J. Haagensen, D.K. Matlock, and G. Krauss, “Assessment of Bending Fatigue Limits for Carburized Steel,“ SAE Technical Paper Series No. 910140, 1991.

K.D. Jones and G. Krauss, “Effects of High-Carbon Corners on Microstructure and Fatigue of Partial Pressure Carburized Steel,” inHeat Treatment ’ 79, The Metals Society, London, 1979, p 188–193.

K.D. Jones and G. Krauss, “Microstructure and Fatigue of Partial Pressure Carburized SAE 8620 and EX 24 Steels,“J. Heat Treating, Vol 1 (No. 1), 1979, p 64–71.

K.A. Erven, D.K. Matlock, and G. Krauss, “Effect of Sulfur on Bending Fatigue of Carburized Steel,”J. Heat Treating, Vol 9, 1991, p 27–35.

J.L. Pacheco and G. Krauss, “Microstructure and High Bending Fatigue Strength in Carburized Steel,” inCarburizing: Processing and Performance, G. Krauss, Ed., ASM International, 1989, p 191–237.

R. Sieber, “Bending Fatigue Performance of Carburized Gear Steels,” SAE Technical Paper Series No. 920533, 1992.

H. Brugger and G. Kraus, “Influence of Ductility on the Behavior of Carburizing Steel During Static and Dynamic Bend Testing,”Archiv. Eisenhüttenwesen, Vol 32, 1961, p 529–539.

T.B. Cameron and D.E. Diesburg, “The Significance of the Impact Fracture Strength of a Carburized Steel,” inCase-Hardened Steels: Microstructural and Residual Stress Effects, D.E. Diesburg, Ed., The Metallurgical Society of AIME, 1984, p 17–32.

R.A. DePaul, “Impact Fatigue Resistance of Carburized Gear Steels—Development of a Testing Machine and Evaluation of Initial Test Results,”Mater. Res. Stand., Mar, 1970, p 15–17, 54, 56–57.

R.A. DePaul, “High Cycle and Impact Fatigue Behavior of Some Carburized Gear Steels,”Met. Eng. Quart., Nov, 1970, p 25–29.

J.J. deBarbadillo, “The Effect of Impact Fatigue Prestressing on the High Cycle Fatigue Resistance of Carburized Gear Steels,” SAE Technical Paper Series No. 730142, 1973.

D.E. Diesburg and G.T. Eldis, “Fracture Resistance of Various Carburized Steels,”Metall. Trans. A, Vol 9, Nov 1978, p 1561–1571.

K.A. Erven, “The Effects of Sulfur and Titanium on Bending Fatigue Performance of Carburized Steels,” M.S. thesis No. T-3849, Colorado School of Mines, July 1990.

C.J. Van Tyne and K.A. Erven, “Finite Element Modelling of Carburizing Using a Commercial Code,” in preparation. Presentation summarized in J.E. Morral and A.D. Romig, Jr., “Computer Programs for Modeling Diffusion-Controlled Processes,” JOM, Feb 1992, p 12–14.

R.E. Peterson,Stress Concentration Factors, John Wiley & Sons, 1974, p 98.

Residual Stress Measurements by X-Ray Diffraction, SAE J784a, 2nd ed., 1971.

A.W. Brewer, K.A. Erven, and G. Krauss, “Etching and Image Analysis of Prior Austenite Grain Boundaries in Hardened Steels,”Materials Characterization, Vol 27, 1991, p 53–56.

G. Krauss, “The Microstructure and Fracture of a Carburized Steel,”Metall. Trans. A, Vol 9, 1978, p 1527–1535.

H.K. Obermeyer and G. Krauss, “Toughness and Intergranular Fracture of a Simulated Carburized Case in EX-24 Type Steel,”J. Heat Treating, Vol 1 (No. 3), 1980, p 31–39.

T. Ando and G. Krauss, “The Effect of Phosphorus Content on Grain Boundary Cementite Formation in AISI52100 Steel,”Metall. Trans. A, Vol 12, 1981, p 1283–1290.

D. J. Wulpi,How Components Fail, American Society for Metals, 1966.

R.S. Hyde, R.E. Cohen, D.K. Matlock, and G. Krauss, “Bending Fatigue Crack Characterization and Fracture Toughness of Gas Carburized SAE 4320 Steel,” SAE Technical Paper Series No. 920534, 1992.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Cohen, R.E., Matlock, D.K. & Krauss, G. Specimen edge effects on bending fatigue of carburized steel. JMEP 1, 695–703 (1992). https://doi.org/10.1007/BF02649251

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02649251