Abstract

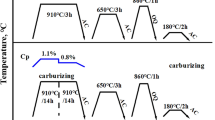

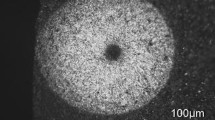

Rotating bending fatigue properties of the gear steel 16CrMnH have been investigated after carburized and re-austenitized at different temperatures with 18-30% of retained austenite in the carburized case. It was found that the fatigue life tended to increase from 105 to 107 cycles with the decrease of the stress amplitude in the range of 1200-1000 MPa. The fatigue limits were higher than 1000 MPa, independent of the fraction of retained austenite. The retained austenite in the carburized case did not transform into martensite after fatigue tests, but the hardness in the carburized case was increased presumably as a result of cyclic hardening of retained austenite. The fatigue limits of the carburized specimens were in good agreement with the calculated values based on the case hardness measured after fatigue tests. Observations of the fracture surfaces of the fatigue specimens showed that the fatigue crack initiated at the non-metallic inclusions or the matrix in the carburized case with a depth of no more 0.6 mm from the surface. Thus, a good fitting of S–N curves could be obtained by taking into consideration of the case hardness after cyclic hardening as well as the non-inclusion sizes.

Similar content being viewed by others

References

G. Parrish, Carburizing: Microstructures and Properties, (ASM International, Materials Park, OH, ASM, 1999)

G. Krauss, The Microstructure and Fracture of a Carburized Steel, Metall. Mater. Trans. A, 1978, 9(11), p 1527–1535.

K.J. Pang and H. Yuan, Mechanical Behavior and Fatigue Performance of Carburized Steel Specimens, Appl. Mech. Mater., 2016, 853, p 72–76.

S. Hao, H. Lin, R.R. Binomiemi, D.M.G. Combs, and G. Fett, A Multi-scale Model of Intergranular Fracture and Computer Simulation of Fracture Toughness of a Carburized Steel, Comput. Mater. Sci., 2010, 48, p 241–249.

T. Cameron, D.E. Diesburg, and C.M. Kim, Fatigue and Overload Fracture of Carburized Steels, J. Met., 2013, 35, p 37–41.

R.H. Richman and R.W. Landgraf, Some Effects of Retained Austenite on the Fatigue Resistance of Carburized Steel, Metall. Mater. Trans. A, 1975, 6, p 955–964.

R.W. Neu and H. Sehitoglu, Stress-induced Transformation in a Carburized Steel-Experiments and Analysis, Acta Metall. Mater., 1992, 40, p 2257–2268.

V.F. Da Silva, L.F. Canale, D. Spinelli, W.W. Bose-Filho, and O.R. Crnkovic, Influence of Retained Austenite on Short Fatigue Crack Growth and Wear Resistance of Case Carburized Steel, J. Mater. Eng. Perf., 1999, 8, p 543–548.

J. Yamabe and T. Matsui, Influences of Hardness, Defect Size and Retained Austenite on Fatigue Strength at N=107 for Carburized Steels, J. Soc. Mater. Sci. Japan, 2007, 56, p 236–243.

M. Zaccone and G. Krauss, Fatigue and Strain Hardening of Simulated Case Microstructure in Carburized Steels, Int. J. Fatigue, 1990, 12, p 226.

A. Inada, H. Yaguchi, and T. Inoue, The Effects of Retained Austenite on the Fatigue Properties of Carburized Steels, in Eighth International Congress on Heat Treatment of Materials, (Japan Technical Information Service Tokyo, Kyoto, Japan, 1992) p 409–412

B.A. Shaw, F.B. Abudaia, and J.T. Evans, Characterization of Retained Austenite in Case Carburized Gears and Its Influence on Fatigue Performance, in 20th ASM Heat Treating Society (St. Louis, MO), (ASM International, 2000) p 62–69

D. Jeddi, H. Sidhom, D. Ghihlione, and H.P. Lieurade, Role of the Cyclic Stability of Retained Austenite in Fatigue Performance of Carburized 14NiCr11 Steel, J. Mater. Eng. Perf., 2005, 14(1), p 37–49.

D. Jeddi, H. Sidhom, and H.P. Lieurade, Effect of Retained Austenite on High Cycle Fatigue Behavior of Carburized 14NiCr11 Steel, Int. Conf. Exp. Mech. Proc. of SPIE, 2008, 7375, p 73751J–1.

T. Ochi, M. Kubota, and Y. Tanaka, Effect of Austenite Grain Size on the Fatigue Crack Growth and Arrest Behavior of Carburized Steel, Tetsu-to-Hagane, 2011, 97, p 592–596.

R. Ramasamy, S. Sivathanu, V. Neelakandan, T. Ganesan, and P.C. Rao, Influence of Retained Austenite on Fatigue Performance of Carburized Gears. SAE Technical Paper, 2019-28-0102. https://doi.org/10.4271/2019-28-0102

F.Z. Li and C.Z. Li, The Influence of Heat Treatment after Carburizing and Retained Austenite in the Carburized Layer on the Strength and Toughness of Steel, Trans. Heat Treat. Metals, 1985, 6(2), p 59–68.

S. Roy and S. Sundararajan, The Effect of Heat Treatment Routes on the Retained Austenite and Tribomechanical Properties of Carburized AISI 8620 Steel, Surf. Coat. Technol., 2016, 308, p 236–243.

A. Benselya, D. Senthilkumara, D. Mohan Lala, G. Nagarajana, and A. Rajaduraib, Effect of Cryogenic Treatment on Tensile Behavior of Case Carburized Steel-815M17, Mater. Character., 2007, 58, p 485–491.

P. Baldissera and C. Delprete, Effects of Deep Cryogenic Treatment on Static Mechanical Properties of 18NiCrMo5 Carburized Steel, Mater. Des., 2009, 30, p 1435–1440.

E. Szpunar and J. Bielanik, Influence of Retained Austenite on Propagation of Fatigue Crack in Carburized Cases of Toothed Elements, Heat Treat., 1984, 85, p 39.1.

K. Murakami, S. Kodama, and S. Konuma, Quantitative Evaluation of Effects of Non-metallic Inclusions on Fatigue Strength of High Strength Steels. I. Basic Fatigue Mechanism and Evaluation of Correlation Between the Fatigue Fracture Stress and the Size and Location of Non-metallic Inclusions, Int. J. Fatigue, 1989, 11, p 291–298.

L. Ma, M.Q. Wang, J. Shi, W.J. Hui, and H. Dong, Influence of Niobium Microalloying on Fatigue Properties of Case Hardening Steels, Mater. Sci. Eng. A., 2008, A498, p 258–265.

Y. Liu, M.Q. Wang, J. Shi, W.J. Hui, G. Fan, and H. Dong, Fatigue Properties of Two Case Hardening Steels after Carburization, Int. J. Fatigue, 2009, 31(2), p 292–299.

B. Jo, S. Sharifimehr, Y. Shim, and A. Fatemi, Cyclic Deformation and Fatigue Behavior of Carburized Automotive Gear Steel and Predictions Including Multiaxial Stress States, Int. J. Fatigue, 2017, 100, p 454–465.

F. Yin and A. Fatemi, Fatigue Behavior and Life Predictions of Case-Hardened Steels, Fat. Fract. Eng. Mater. Struct., 2009, 32, p 197–213.

W. Chen, X.F. He, W.C. Yu, J. Shi, M.Q. Wang, and K.F. Yao, Characterization of Microstructure and Hardness Distribution of Case carburized Gear Steel, Micron, 2021, 2, p 103028.

W. Chen, X.F. He, W.C. Yu, M.Q. Wang, and K.F. Yao, Microstructure Hardness, and Tensile Properties of Vacuum Carburizing Gear Steel, Metals, 2021, 11, p 300.

X.Y. Zhu and J.F. Xi, Study on Cyclic Hardening of Carbon Steel under High Cycle Fatigue, J. Mech. Strength, 1991, 13, p 35–37.

Y. Furuya, Specimen Size Effects on Gigacycle Fatigue Properties of High-strength Steel under Ultrasonic Fatigue Testing, Scr. Mater., 2008, 58, p 1014–1017.

T. Ochi, S. Kozawa, and M. Kubota, Crack Propagation Behavior and Change of Residual Stress on the Process of Bending Fatigue Test of Carburized Steel, Tetsu-to-Hagane, 2011, 97, p 486–492.

Acknowledgments

The authors would like to thank financial support by National Key Research and Development Program of China under the Project No. 2016YFB0300102.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, W., He, X., Yu, W. et al. Rotating Bending Fatigue Properties of Case Carburized Steel with Different Fractions of Retained Austenite. J. of Materi Eng and Perform 32, 7960–7968 (2023). https://doi.org/10.1007/s11665-022-07683-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07683-7