Abstract

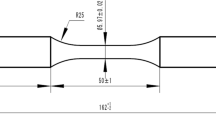

Bending fatigue test was performed on carburized gears made of different low-carbon hardenable steels such as 20CrMo, 20MnCr5, and SAE 8620. Hardness assessment and microstructure examination were conducted to confirm the homogeneity of phase presence and absence of network carbides and decarburization. Stress levels were chosen to find the fatigue limit of the different carburized gear materials. Fatigue life of the component can be predicted at various stress level with available test data by using Weibull distribution, which is suitable for random failure data. By fitting this failure data at various stress level, actual fatigue strength of the component can be calculated at different reliability. Reliable fatigue design for three different materials are predicted and compared, which disclosed SAE 8629 as superior.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Handschuh RF, Krantz TL, Lerch BA, Burke CS (2007) Investigations of low cycle bending fatigue of AISI 9310 steel spur gears. ASME PTD

Fernandes PJL (1996) Tooth Bending fatigue failures in gears. Eng Fail Anal 3(3):219–225

Ramasamy R, Sivathanu S, Neelakandan V, Ganesan T et al (2019) Influence of retained austenite on fatigue performance of carburized gears. SAE Technical Paper 2019–28–0102. https://doi.org/10.4271/2019-28-0102

Conrado E, Gorla C, Davoli P, Boniardi M (2017) A comparison of bending fatigue strength of carburized and nitrided gears for industrial applications. Eng Fail Anal 78:41–54

Lin H, Fett GA Binoniemi RR (2003) Bending fatigue life analysis of carburized components using strain life and fracture mechanics approaches. SAE World Congress Detroit, Michigan March 3–6, 2003

Singh A (2002) The nature of initiation and propagation S-N curves at and below the endurance limit. Fatigue Fract Eng Mater Struct 25(1):79–90

Masuyama T, Inoue K, Yamanaka M, Kitamura K, Saito T (2002) Evaluation of bending strength of carburized gears based on inferential identification of principal surface layer defects. JSME Int J Ser C 45:794–801

Tobie T, Oster P, Höhn B-R (2003) Systematic investigations on the influence of case depth on the pitting and bending strength of case carburized gears. In: ASME international design engineering technical conferences and computers and information in engineering conference. American Society of Mechanical Engineers, Chicago, Illinois, USA, pp 111–119

Yang Q (1996) Fatigue test and reliability design of gears. Int J Fatigue 18(3):171–177

Montgomery DC, Runger GC (2011) Applied statistics and probability for engineers. Wiley, pp 118–144

Zhang J, Zhang Q, Xu Z-Z, Gwi-Su-Shin, Lyu S (2013) A study on the evolution of bending fatigue strength of 20CrMoH gear. Int J Precis Eng Manuf 14(8):1339–1343

Devendran S, Ramasamy R, Neelakandan V et al (2019) Failure assessment using accelerated testing on IC engine’s starter motor for reliability improvement. Life Cycle Reliab Saf Eng 8:175–181. https://doi.org/10.1007/s41872-019-00076-1

Bain LJ, Engelhard M (1991) Statistical analysis of reliability and life testing models: theory and methods, 2nd edn. Mercel Dekker, New York

Acknowledgements

Authors would like to thank M/s Sona Comstar Automotive Technologies for giving opportunity and financial support to present the work in ICALMS 2K20-CMR technical campus.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Ramasamy, R., Durairaj, S.R.N., Ganesan, T., Rao, P.C. (2020). Reliability Design for Bending Fatigue Strength of Carburized Gears of Low-Carbon Case Hardenable Steels 20CrMo, 20MnCr5, and SAE 8620. In: Praveen Kumar, A., Dirgantara, T., Krishna, P.V. (eds) Advances in Lightweight Materials and Structures . Springer Proceedings in Materials, vol 8. Springer, Singapore. https://doi.org/10.1007/978-981-15-7827-4_53

Download citation

DOI: https://doi.org/10.1007/978-981-15-7827-4_53

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-7826-7

Online ISBN: 978-981-15-7827-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)