Abstract

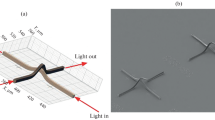

An apparatus for 3D laser printing by the two-photon polymerization technique using a scheme for spatiotemporal focusing of femtosecond laser radiation is described. The system, which is based on available components) allows the formation of 3D centimeter-size structures with the micron resolution in all directions; this is its main advantage over other systems, including commercial ones. When creating the apparatus, a minimum number of optical and optomechanical components were used, thus significantly increasing the accessibility of such apparatuses in various laboratories. This apparatus can be used to manufacture 3D structures for various purposes, including scaffold structures for tissue-engineering tasks.

Similar content being viewed by others

REFERENCES

Awad, A., Fina, F., Goyanes, A., Gaisford, S., and Basit, A.W., Int. J. Pharm., 2020, vol. 586, p. 119594. https://doi.org/10.1016/j.ijpharm.2020.119594

Kruth, J.P., Wang, X., Laoui, T., and Froyen, L., Assem. Autom., 2003, vol. 23, no. 4, p. 357. https://doi.org/10.1108/01445150310698652

Schmidleithner, C. and Kalaskar, D.M., Stereolithography, IntechOpen, 2018, vol. 32, p. 137. https://doi.org/10.5772/intechopen.78147

Bártolo, P.J., Stereolithography: Materials, Processes and Applications, Springer Science & Business Media, 2011.

Fernández-Pradas, J.M., Colina, M., Serra, P., Dominguez, J., and Morenza, J.L., Thin Solid Films, 2004, vols. 453–454, p. 27. https://doi.org/10.1016/j.tsf.2003.11.154

Orimi, H.E., Kolkooh, S.S.H, Hooker, E., Narayanswamy, S., Larrivée, B., and Boutopoulos, C., Sci. Rep., 2020, vol. 10, no. 1, p. 9730. https://doi.org/10.1038/s41598-020-66565-x

Willis, D.A. and Grosu, V., Appl. Phys. Lett., 2005, vol. 86, no. 24, p. 244103. https://doi.org/10.1038/s41598-020-66565-x

Kuznetsov, A.I., Kiyan, R., and Chichkov, B.N., Opt. Express, 2010, vol. 18, no. 20, p. 21198. https://doi.org/10.1038/s41598-020-66565-x

Mezel, C., Souquet, A., Hallo, L., and Guillemot, F., Biofabrication, 2010, vol. 2, no. 1, pp. 1–7. https://doi.org/10.1088/1758-5082/2/1/014103

Antoshin, A.A., Churbanov, S.N., Minaev, N.V., Zhang, D., Zhang, Y., Shpichka, A.I., and Timashev, P.S., Bioprinting, 2019, vol. 15, p. e00052. https://doi.org/10.1016/j.bprint.2019.e00052

Yusupov, V., Churbanov, S., Churbanova, E., Bardakova, K., Antoshin, A., Evlashin, S., Timashev, P., and Minaev, N., Int. J. Bioprint., 2020, vol. 6, no. 3, p. 1. https://doi.org/10.18063/ijb.v6i3.271

Yusupov, V.I., Gorlenko, M.V., Cheptsov, V.S., Minaev, N.V., Churbanova, E.S., Zhigarkov, V.S., Chutko, E.A., Evlashin, S.A., Chichkov, B.N., and Bagratashvili, V.N., Laser Phys. Lett., 2018, vol. 15, no. 6, p. 065604. https://doi.org/10.1088/1612-202X/aab5ef

Gorlenko, M.V., Chutko, E.A., Churbanova, E.S., Minaev, N.V., Kachesov, K.I., Lysak, L.V., Evlashin, S.A., Cheptsov, V.S., Rybaltovskiy, A.O., Yusupov, V.I., Zhigarkov, V.S., Davydova, G.A., Chichkov, B.N., and Bagratashvili, V.N., J. Biol. Eng., 2018, vol. 12, no. 1, p. 27. https://doi.org/10.1186/s13036-018-0117-4

Minaev, N.V., Epifanov, E.O., and Yusupov, V.I., Instrum. Exp. Tech., 2021, vol. 64, no. 3, pp. 464–467. https://doi.org/10.1134/S0020441221020147

Minaev, N.V., Antonov, E.N., Minaeva, S.A., and Churbanov, S.N., Prib. Tekh. Eksp., 2019, no. 1, p. 150. https://doi.org/10.1134/S003281621901018X

Minaev, N.V., Mironov, A.V., Minaeva, S.A., Mironova, O.A., Syachina, M.A., Krumins, E., Howdle, S., and Popov, V.K., Instrum. Exp. Tech., 2020, vol. 63, no. 2, pp. 288–290. https://doi.org/10.1134/S0020441220020116

Nguyen, A.K. and Narayan, R.J., Mater. Today, 2017, vol. 20, no. 6, p. 314. https://doi.org/10.1016/j.mattod.2017.06.004

LaFratta, C.N. and Baldacchini, T., Micromachines, 2017, vol. 8, no. 4, pp. 1–25. https://doi.org/10.3390/mi8040101

Obata, K., El-Tamer, A., Koch, L., Hinze, U., and Chichkov, B.N., Light: Sci. Appl., 2013, vol. 2, pp. 8–11. https://doi.org/10.1038/lsa.2013.72

Cheng, Y., Sugioka, K., Midorikawa, K., Masuda, M., Toyoda, K., Kawachi, M., and Shihoyama, K., Opt. Lett., 2003, vol. 28, no. 1, p. 55. https://doi.org/10.1364/ol.28.000055

Kaplin, V.S., Glagolev, N.N., Shashkova, V.T., Matveeva, I.A., Shershnev, I.V., Zarkhina, T.S., Solovi-eva, A.B., Minaev, N.V., Aksenova, N.A., Shavkuta, B.S., Kopylov, A.S., Kuznetsova, D.S., Timashev, P.S., Shpichka, A.I., and Bezrukov, E.A., Polymers (Basel), 2020, vol. 12, no. 11, p. 1. https://doi.org/10.3390/polym12112525

Demina, T., Bardakova, K., Minaev, N., Svidchenko, E., Istomin, A., Goncharuk, G., Vladimirov, L., Grachev, A., Zelenetskii, A., Timashev, P., and Akopova, T., Polymers (Basel), 2017, vol. 9, no. 12, p. 302. https://doi.org/10.3390/polym9070302

He, F., Cheng, Y., Lin, J., Ni, J., Xu, Z., Sugioka, K., and Midorikawa, K., New J. Phys., 2011, vol. 13, p. 083014. https://doi.org/10.1088/1367-2630/13/8/083014

He, F., Xu, H., Cheng, Y., Ni, J., Xiong, H., Xu, Z., Sugioka, K., and Midorikawa, K., Opt. Lett., 2010, vol. 35, no. 7, p. 1106. https://doi.org/10.1364/OL.35.001106

Vitek, D.N., Adams, D.E., Johnson, A., Tsai, P.S., Backus, S., Durfee, C.G., Kleinfeld, D., and Squier, J.A., Opt. Express, 2010, vol. 18, no. 17, p. 18086. https://doi.org/10.1364/OE.18.018086

Chu, W., Tan, Y., Wang, P., Xu, J., Li, W., Qi, J., and Cheng, Y., Adv. Mater. Technol., 2018, vol. 3, no. 5, p. 1. https://doi.org/10.1002/admt.201700396

Tan, Y., Chu, W., Wang, P., Li, W., Qi, J., Xu, J., Wang, Z., and Cheng, Y., Phys. Scr., 2019, vol. 94, no. 1, p. 015501. https://doi.org/10.1088/1402-4896/aaec99

ACKNOWLEDGMENTS

We are grateful to P.I. Zharikov for his help in assembling the experimental system.

Funding

This study was supported by the Russian Science Foundation, grant no. 19-75-00108.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Seferov

Rights and permissions

About this article

Cite this article

Epifanov, E.O., Migal, E.A., Potemkin, F.V. et al. An Apparatus for Forming Three-Dimensional Structures by the Method of Two-Photon Femtosecond Polymerization with Simultaneous Spatiotemporal Focusing. Instrum Exp Tech 64, 891–897 (2021). https://doi.org/10.1134/S0020441221060026

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020441221060026