Abstract

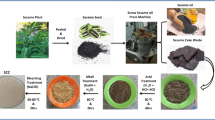

Every year, the food industry generates a large amount of waste, which prompts researchers to come up with a solution to efficiently manage the issue to support zero-waste concepts. After oil extraction, many oilseed cakes remain in the oil-processing industry as a waste. Converting this oilseed cake into value-added products would reduce environmental pollution and production costs. Oilseed cakes are high in fiber and contain a lot of non-starch polysaccharides. Azadirachta indica A. Juss neem oil cake (NOC) is a low-cost agricultural waste material produced during the oil extraction process of neem seeds. It is a dark brown powder that contains cellulose as well as other components such as hemicelluloses, proteins, and lipids. In this investigation, cellulose was extracted from the NOC, and comprehensive characterization was carried out. The polymer composite industry is in search of biofillers to incorporate with various matrices. As neem cake cellulose (NCC) is an entirely biodegradable material, it was considered for this study. To ensure its suitability in polymer composite industries, physicochemical, morphological, thermal, and spectroscopy analyses were carried out on NCC. Higher cellulose content (73.53%), better crystallinity (66.23%), lower density (1.59 g/cm3), considerable thermal stability (335.71 °C), kinetic activation energy (83.06 kJ/mol), particle size (17.93 µm), and good surface roughness (47.004 nm) make NCC suitable to be incorporated as a biofiller material in polymer matrices to manufacture eco-friendly composites.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.

References

Rangappa SM, Siengchin S, Parameswaranpillai J et al (2022) Lignocellulosic fiber reinforced composites: progress, performance, properties, applications, and future perspectives. Polym Compos 43:645–691. https://doi.org/10.1002/PC.26413

Miao C, Hamad WY (2013) Cellulose reinforced polymer composites and nanocomposites: a critical review. Cellulose 20:2221–2262. https://doi.org/10.1007/s10570-013-0007-3

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed Eng 44:3358–3393. https://doi.org/10.1002/anie.200460587

Somasundaram R, Rajamoni R, Suyambulingam I et al (2022) Utilization of discarded Cymbopogon flexuosus root waste as a novel lignocellulosic fiber for lightweight polymer composite application. Polym Compos 43:2838–2853. https://doi.org/10.1002/PC.26580

Divya D, Suyambulingam I, Sanjay MR, Siengchin S (2022) Suitability examination of novel cellulosic plant fiber from Furcraea selloa K. Koch peduncle for a potential polymeric composite reinforcement. Polym Compos 43:4223–4243. https://doi.org/10.1002/PC.26683

Thulasisingh A, Kannaiyan S, Pichandi K (2021) Cellulose nanocrystals from orange and lychee biorefinery wastes and its implementation as tetracycline drug transporter. Biomass Conv Bioref. https://doi.org/10.1007/s13399-020-01168-0

Ran Y, Elsayed M, Eraky M et al (2022) (2022) Sequential production of biomethane and bioethanol through the whole biorefining of rice straw: analysis of structural properties and mass balance. Biomass Convers Biorefin 1:1–13. https://doi.org/10.1007/S13399-022-02548-4

Indran S, Raj RE, Daniel BSS, Saravanakumar SS (2016) Cellulose powder treatment on Cissus quadrangularis stem fiber-reinforcement in unsaturated polyester matrix composites. J Reinf Plast Compos 35:212–227. https://doi.org/10.1177/0731684415611756

Sumesh KR, Kavimani V, Rajeshkumar G et al (2020) An investigation into the mechanical and wear characteristics of hybrid composites: influence of different types and content of biodegradable reinforcements. J Nat Fibers 00:1–13. https://doi.org/10.1080/15440478.2020.1821297

Alemdar A, Sain M (2008) Isolation and characterization of nanofibers from agricultural residues—wheat straw and soy hulls. Biores Technol 99:1664–1671. https://doi.org/10.1016/j.biortech.2007.04.029

Dube AM (2022) (2022) Isolation and characterization of cellulose nanocrystals from Ensete ventricosum pseudo-stem fiber using acid hydrolysis. Biomass Convers Biorefin 1:1–16. https://doi.org/10.1007/S13399-022-02987-Z

Barampouti EM, Christofi A, Malamis D, Mai S (2021) A sustainable approach to valorize potato peel waste towards biofuel production. Biomass Convers Biorefin 1:1–12. https://doi.org/10.1007/S13399-021-01811-4/FIGURES/6

Grishkewich N, Mohammed N, Tang J, Tam KC (2017) Recent advances in the application of cellulose nanocrystals. Curr Opin Colloid Interface Sci 29:32–45

Kumar A, Gupta V, Gaikwad KK (2021) Microfibrillated cellulose from pine cone: extraction, properties, and characterization. Biomass Convers Biorefin 1:1–8. https://doi.org/10.1007/S13399-021-01794-2/FIGURES/6

Zuluaga R, Putaux JL, Restrepo A et al (2007) Cellulose microfibrils from banana farming residues: isolation and characterization. Cellulose 14:585–592. https://doi.org/10.1007/s10570-007-9118-z

Arumugam M, Manikandan DB, Mohan S et al (2022) (2022) Comprehensive metabolite profiling and therapeutic potential of black gram (Vigna mungo) pods: conversion of biowaste to wealth approach. Biomass Convers Biorefin 1:1–32. https://doi.org/10.1007/S13399-022-02806-5

Wang Z, Yao ZJ, Zhou J, Zhang Y (2017) Reuse of waste cotton cloth for the extraction of cellulose nanocrystals. Carbohydr Polym 157:945–952. https://doi.org/10.1016/j.carbpol.2016.10.044

Eixenberger D, Carballo-Arce AF, Vega-Baudrit JR et al (2022) Tropical agroindustrial biowaste revalorization through integrative biorefineries—review part II: pineapple, sugarcane and banana by-products in Costa Rica. Biomass Convers Biorefin 1:1–28. https://doi.org/10.1007/S13399-022-02721-9

Mora-Villalobos JA, Aguilar F, Carballo-Arce AF et al (2021) Tropical agroindustrial biowaste revalorization through integrative biorefineries—review part I: coffee and palm oil by-products. Biomass Convers Biorefin 2021:1–19. https://doi.org/10.1007/S13399-021-01442-9

Cardoen D, Joshi P, Diels L et al (2015) Agriculture biomass in India: part 1 Estimation and characterization. Resour Conserv Recycl 102:39–48. https://doi.org/10.1016/j.resconrec.2015.06.003

Ubando AT, Felix CB, Chen WH (2020) Biorefineries in circular bioeconomy: a comprehensive review. Bioresour Technol 299:122585. https://doi.org/10.1016/j.biortech.2019.122585

Moshi AAM, Ravindran D, Bharathi SRS et al (2020) Characterization of a new cellulosic natural fiber extracted from the root of Ficus religiosa tree. Int J Biol Macromol 142:212–221. https://doi.org/10.1016/j.ijbiomac.2019.09.094

Arul Marcel Moshi A, Ravindran D, Sundara Bharathi SR et al (2020) Characterization of natural cellulosic fiber extracted from Grewia damine flowering plant’s stem. Int J Biol Macromol 164:1246–1255. https://doi.org/10.1016/j.ijbiomac.2020.07.225

Arul Marcel Moshi A, Ravindran D, Sundara Bharathi SR et al (2020) Characterization of surface-modified natural cellulosic fiber extracted from the root of Ficus religiosa tree. Int J Biol Macromol 156:997–1006. https://doi.org/10.1016/j.ijbiomac.2020.04.117

Pardo RNC, Rojas GMA, Florez LM (2021) Thermal analysis of the physicochemical properties of organic waste to application in the compost process. Biomass Conv Bioref. https://doi.org/10.1007/s13399-021-01786-2

Huang G, Wu X, Hou Y, Cai J (2020) Sustainable porous carbons from garlic peel biowaste and KOH activation with an excellent CO2 adsorption performance. Biomass Convers Biorefin 10:267–276. https://doi.org/10.1007/S13399-019-00412-6/FIGURES/8

Upadhyay A, Lama JP, Tawata S (2013) Utilization of pineapple waste: a review. J Food Sci Technol Nepal 6:10–18. https://doi.org/10.3126/jfstn.v6i0.8255

Stahel WR (2016) The circular economy. Nature 531:435–438. https://doi.org/10.1038/531435a

Karakoti A, Soundhar A, Rajesh M et al (2019) Enhancement of mechanical properties of an epoxy composite reinforced with Hibiscuss sabdariffa var. Altissima fiber micro cellulose. Int J Recent Technol Eng 8:477–480. https://doi.org/10.35940/ijrte.B1093.0782S419

Soma Sundaram Pillai R, Rajamoni R, Suyambulingam I et al (2021) Synthesis and characterization of cost-effective industrial discarded natural ceramic particulates from Cymbopogon flexuosus plant shoot for potential polymer/metal matrix reinforcement. Springer, Berlin Heidelberg

Jabbar A, Militký J, Wiener J et al (2017) Nanocellulose coated woven jute/green epoxy composites: characterization of mechanical and dynamic mechanical behavior. Compos Struct 161:340–349. https://doi.org/10.1016/j.compstruct.2016.11.062

Sumesh K, Kavimani V, Rajeshkumar G, Indran S, Khan A (2022) Mechanical, water absorption and wear characteristics of novel polymeric composites: Impact of hybrid natural fibers and oil cake filler addition. J Ind Textiles 51(4_suppl):5910S–5937S. https://doi.org/10.1177/1528083720971344

Mysiukiewicz O, Sałasińska K, Barczewski M, Szulc J (2020) The influence of oil content within lignocellulosic filler on thermal degradation kinetics and flammability of polylactide composites modified with linseed cake. Polym Compos 41:4503–4513. https://doi.org/10.1002/PC.25727

Elshaarani MT, Yaakob Z, Dahlan KZM, Mohammad M (2013) Jatropha deoiled cake filler-reinforced medium-density polyethylene biocomposites: effect of filler loading and coupling agent on the mechanical, dynamic mechanical and morphological properties. Polym Compos 34:746–756. https://doi.org/10.1002/PC.22479

Palanikumar V, Narayanan V, Vajjiram S (2018) Experimental investigation of mechanical and viscoelastic properties of Acacia Nilotica filler blended polymer composite. Polym Compos 39:2535–2546. https://doi.org/10.1002/PC.24238

Abu-Jdayil B, Mourad AH, Hassan M (2018) Development of polymeric heat insulators based on emirati red shale filler: thermal and physical properties. Polym Compos 39:E1463–E1473. https://doi.org/10.1002/PC.24356

Barman A, Shrivastava NK, Khatua BB, Ray BC (2015) Green composites based on high-density polyethylene and Saccharum spontaneum: effect of filler content on morphology, thermal, and mechanical properties. Polym Compos 36:2157–2166. https://doi.org/10.1002/PC.23126

Indran S, Edwin Raj RD, Daniel BSS, Binoj JS (2018) Comprehensive characterization of natural Cissus quadrangularis stem fiber composites as an alternate for conventional FRP composites. J Bionic Eng 15:914–923. https://doi.org/10.1007/s42235-018-0078-9

Razali NAM, Mohd Sohaimi R, Othman RNIR, Abdullah N, Demon SZN, Jasmani L, Yunus WMZW, Ya’acob WMHW, Salleh EM, Norizan MN, Halim NA (2022) Comparative study on extraction of cellulose fiber from rice straw waste from chemo-mechanical and pulping method. Polymers 14(3):387. https://doi.org/10.3390/polym14030387

Sheltami RM, Abdullah I, Ahmad I et al (2012) Extraction of cellulose nanocrystals from mengkuang leaves (Pandanus tectorius). Carbohydr Polym 88:772–779. https://doi.org/10.1016/j.carbpol.2012.01.062

Jenish I, Veeramalai Chinnasamy SG, Basavarajappa S et al (2020) Tribo-mechanical characterization of carbonized coconut shell micro particle reinforced with Cissus quadrangularis stem fiber/epoxy novel composite for structural application. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1838988

Rajeshkumar G, Hariharan V, Indran S et al (2020) Influence of sodium hydroxide (NaOH) treatment on mechanical properties and morphological behaviour of Phoenix sp. fiber/epoxy composites. J Polym Environ 29:765–774. https://doi.org/10.1007/s10924-020-01921-6

Manimekalai G, Kavitha S, Divya D et al (2021) Characterization of enzyme treated cellulosic stem fiber from Cissus quadrangularis plant: an exploratory investigation. Curr Res Green Sustain Chem 4:100162. https://doi.org/10.1016/j.crgsc.2021.100162

Jenish I, Veeramalai Chinnasamy SG, Basavarajappa S et al (2020) Tribo-mechanical characterization of carbonized coconut shell micro particle reinforced with Cissus quadrangularis stem fiber/epoxy novel composite for structural application. J Nat Fibers 00:1–17. https://doi.org/10.1080/15440478.2020.1838988

Divya D, Jenish I, Raja S (2022) Comprehensive characterization of Furcraea selloa K. Koch peduncle fiber-reinforced polyester composites—effect of fiber length and weight ratio. Adv Mater Sci Eng 2022:1–10. https://doi.org/10.1155/2022/8099500

Iyyadurai J, Gandhi VCS, Suyambulingam I, Rajeshkumar G (2021) Sustainable development of Cissus quadrangularis stem fiber/epoxy composite on abrasive wear rate. Journal of Natural Fibers 00:1–13. https://doi.org/10.1080/15440478.2021.1982819

Gandhi VCS, Jenish I, Indran S, Rajan DY (2022) Mechanical and thermal analysis of Cissus quadrangularis stem fiber/epoxy composite with micro-red mud filler composite for structural application. Trans Indian Inst Met 75:737–747. https://doi.org/10.1007/s12666-021-02478-1

Sari NH, Suteja, Ilyas RA, et al (2021) Characterization of the density and mechanical properties of corn husk fiber reinforced polyester composites after exposure to ultraviolet light. Funct Compos Struct 3. https://doi.org/10.1088/2631-6331/ac0ed3

Sumesh KR, Kavimani V, Rajeshkumar G et al (2021) Effect of banana, pineapple and coir fly ash filled with hybrid fiber epoxy based composites for mechanical and morphological study. J Mater Cycles Waste Manag 23:1277–1288. https://doi.org/10.1007/s10163-021-01196-6

Muthu chozharajan B, Indran S, Divya D et al (2020) Mechanical and thermal properties of Chloris barbata flower fiber /epoxy composites: effect of alkali treatment and fiber weight fraction. J Nat Fibers 00:1–14. https://doi.org/10.1080/15440478.2020.1848703

Bano S, Negi YS (2017) Studies on cellulose nanocrystals isolated from groundnut shells. Carbohydr Polym 157:1041–1049. https://doi.org/10.1016/j.carbpol.2016.10.069

Raja S, Rajesh R, Indran S et al (2021) Characterization of industrial discarded novel Cymbopogon flexuosus stem fiber: a potential replacement for synthetic fiber. J Ind Text. https://doi.org/10.1177/15280837211007507

Penjumras P, Rahman RBA, Talib RA, Abdan K (2014) Extraction and characterization of cellulose from durian rind. Agric Agric Sci Procedia 2:237–243. https://doi.org/10.1016/j.aaspro.2014.11.034

Babu BG, Princewinston D, Saravanakumar SS et al (2022) Investigation on the physicochemical and mechanical properties of novel alkali-treated Phaseolus vulgaris fibers. J Nat Fibers 19:770–781. https://doi.org/10.1080/15440478.2020.1761930

Ait Benhamou A, Kassab Z, Boussetta A et al (2022) Beneficiation of cactus fruit waste seeds for the production of cellulose nanostructures: extraction and properties. Int J Biol Macromol 203:302–311. https://doi.org/10.1016/j.ijbiomac.2022.01.163

Suksaeree J, Nawathong N, Anakkawee R, Pichayakorn W (2017) Formulation of polyherbal patches based on polyvinyl alcohol and hydroxypropylmethyl cellulose: characterization and in vitro evaluation. AAPS PharmSciTech 18:2427–2436. https://doi.org/10.1208/s12249-017-0726-0

Heinze T, Camacho Gómez JA, Haucke G (1996) Synthesis and characterization of the novel cellulose derivative dansyl cellulose. Polym Bull 37:743–749. https://doi.org/10.1007/BF00295772

Kocaman S, Karaman M, Gursoy M, Ahmetli G (2017) Chemical and plasma surface modification of lignocellulose coconut waste for the preparation of advanced biobased composite materials. Carbohydr Polym 159:48–57. https://doi.org/10.1016/j.carbpol.2016.12.016

Kocaman S, Ahmetli G (2020) Effects of various methods of chemical modification of lignocellulose hazelnut shell waste on a newly synthesized bio - based epoxy composite. J Polym Environ 28:1190–1203. https://doi.org/10.1007/s10924-020-01675-1

Fitriani F, Aprilia S, Arahman N et al (2021) Isolation and characterization of nanocrystalline cellulose isolated from pineapple crown leaf fiber agricultural wastes using acid hydrolysis. Polymers (Basel) 13(23):4188. Published 2021 Nov 30. https://doi.org/10.3390/polym13234188

Li M, He B, Zhao L (2019) Isolation and characterization of microcrystalline cellulose from Cotton Stalk Waste. Bioresources 14:3231–3246. https://doi.org/10.15376/biores.14.2.3231-3246

Abdul Rahman NH, Chieng BW, Ibrahim NA, Abdul Rahman N (2017) Extraction and characterization of cellulose nanocrystals from tea leaf waste fibers. Polymers (Basel) 9(11):588. Published 2017 Nov 7. https://doi.org/10.3390/polym9110588

Perumal AB, Nambiar RB, Sellamuthu PS et al (2022) Extraction of cellulose nanocrystals from areca waste and its application in eco-friendly biocomposite film. Chemosphere 287:132084. https://doi.org/10.1016/j.chemosphere.2021.132084

Ahuja D, Kaushik A, Singh M (2018) Simultaneous extraction of lignin and cellulose nanofibrils from waste jute bags using one pot pre-treatment. Int J Biol Macromol 107:1294–1301. https://doi.org/10.1016/j.ijbiomac.2017.09.107

Harini K, Ramya K, Sukumar M (2018) Extraction of nano cellulose fibers from the banana peel and bract for production of acetyl and lauroyl cellulose. Carbohydr Polym 201:329–339. https://doi.org/10.1016/j.carbpol.2018.08.081

Gabriel T, Belete A, Syrowatka F et al (2020) Extraction and characterization of celluloses from various plant byproducts. Int J Biol Macromol 158:1248–1258. https://doi.org/10.1016/j.ijbiomac.2020.04.264

Sumesh KR, Kanthavel K, Kavimani V (2020) Peanut oil cake-derived cellulose fiber: Extraction, application of mechanical and thermal properties in pineapple/flax natural fiber composites. Int J Biol Macromol 150:775–785. https://doi.org/10.1016/j.ijbiomac.2020.02.118

Reddy KO, Uma Maheswari C, Muzenda E et al (2016) Extraction and characterization of cellulose from pretreated ficus (peepal tree) leaf fibers. J Nat Fibers 13:54–64. https://doi.org/10.1080/15440478.2014.984055

Reddy KO, Maheswari CU, Dhlamini MS et al (2018) Extraction and characterization of cellulose single fibers from native african napier grass. Carbohydr Polym 188:85–91. https://doi.org/10.1016/j.carbpol.2018.01.110

Nagarajan KJ, Balaji AN, Kasi Rajan ST, Ramanujam NR (2020) Preparation of bio-eco based cellulose nanomaterials from used disposal paper cups through citric acid hydrolysis. Carbohydr Polym 235:115997. https://doi.org/10.1016/j.carbpol.2020.115997

Harini K, Chandra Mohan C (2020) Isolation and characterization of micro and nanocrystalline cellulose fibers from the walnut shell, corncob and sugarcane bagasse. Int J Biol Macromol 163:1375–1383. https://doi.org/10.1016/j.ijbiomac.2020.07.239

Nagarajan KJ, Sanjay MR, Raghav GR, Anish Khan (2022) Extraction of cellulose nanocrystals from red banana peduncle agro‐waste and application in environmentally friendly biocomposite film. Polym Compos 43(8):4942–4958.

Midhun Dominic CD, Raj V, Neenu KV et al (2022) Chlorine-free extraction and structural characterization of cellulose nanofibers from waste husk of millet (Pennisetum glaucum). Int J Biol Macromol 206:92–104. https://doi.org/10.1016/j.ijbiomac.2022.02.078

Collazo-Bigliardi S, Ortega-Toro R, Chiralt Boix A (2018) Isolation and characterisation of microcrystalline cellulose and cellulose nanocrystals from coffee husk and comparative study with rice husk. Carbohydr Polym 191:205–215. https://doi.org/10.1016/j.carbpol.2018.03.022

Julie Chandra CS, George N, Narayanankutty SK (2016) Isolation and characterization of cellulose nanofibrils from arecanut husk fibre. Carbohydr Polym 142:158–166. https://doi.org/10.1016/j.carbpol.2016.01.015

Joy J, Jose C, Varanasi SB et al (2016) Preparation and characterization of poly(butylene succinate) bionanocomposites reinforced with cellulose nanofiber extracted from Helicteres isora plant. J Renew Mater 4:351–364. https://doi.org/10.7569/JRM.2016.634128

Reddy JP, Rhim JW (2018) Extraction and characterization of cellulose microfibers from agricultural wastes of onion and garlic. J Nat Fibers 15:465–473. https://doi.org/10.1080/15440478.2014.945227

Prabhu Stalin JRR, Jenish I, Indran S (2014) Tribological charecterization of carbon epoxy composite materials with particulate silane treated SiC fillers. Adv Mat Res 984–985:331–335. https://doi.org/10.4028/www.scientific.net/AMR.984-985.331

Sundaram RS, Rajamoni R, Suyambulingam I, Isaac R (2021) Comprehensive characterization of industrially discarded cymbopogon flexuosus stem fiber reinforced unsaturated polyester composites: effect of fiber length and weight fraction. J Nat Fibers 00:1–16. https://doi.org/10.1080/15440478.2021.1944435

Zhao H, Kwak JH, Conrad Zhang Z et al (2007) Studying cellulose fiber structure by SEM, XRD, NMR and acid hydrolysis. Carbohyd Polym 68:235–241. https://doi.org/10.1016/j.carbpol.2006.12.013

Senthil Muthu Kumar T, Rajini N, Obi Reddy K et al (2018) All-cellulose composite films with cellulose matrix and Napier grass cellulose fibril fillers. Int J Biol Macromol 112:1310–1315. https://doi.org/10.1016/j.ijbiomac.2018.01.167

Kouadri I, Satha H (2018) Extraction and characterization of cellulose and cellulose nanofibers from Citrullus colocynthis seeds. Ind Crops Prod 124:787–796. https://doi.org/10.1016/j.indcrop.2018.08.051

Nagarajan KJ, Ramanujam NR, Sanjay MR, Siengchin S, Surya Rajan B, Sathick Basha K, ..., Raghav GR (2021) A comprehensive review on cellulose nanocrystals and cellulose nanofibers: Pretreatment, preparation, and characterization. Polym Compos 42(4):1588–1630

Bahloul A, Kassab Z, El Bouchti M, Hannache H, Oumam M, El Achaby M (2021) Micro-and nano-structures of cellulose from eggplant plant (Solanum melongena L) agricultural residue. Carbohydr Polym 253:117311

Agarwal UP, Ralph SA, Baez C et al (2017) Effect of sample moisture content on XRD-estimated cellulose crystallinity index and crystallite size. Cellulose 24:1971–1984. https://doi.org/10.1007/s10570-017-1259-0

Kim SH, Lee CM, Kafle K (2013) Characterization of crystalline cellulose in biomass: Basic principles, applications, and limitations of XRD, NMR, IR, Raman, and SFG. Korean J Chem Eng 30:2127–2141. https://doi.org/10.1007/s11814-013-0162-0

Khan MN, Rehman N, Sharif A et al (2020) Environmentally benign extraction of cellulose from dunchi fiber for nanocellulose fabrication. Int J Biol Macromol 153:72–78. https://doi.org/10.1016/j.ijbiomac.2020.02.333

Jiang F, Lo HY (2015) Cellulose nanocrystal isolation from tomato peels and assembled nanofibers. Carbohydr Polym 122:60–68. https://doi.org/10.1016/j.carbpol.2014.12.064

Chen Q, Xiong J, Chen G, Tan T (2020) Preparation and characterization of highly transparent hydrophobic nanocellulose film using corn husks as main material. Int J Biol Macromol 158:781–789. https://doi.org/10.1016/j.ijbiomac.2020.04.250

Kassab Z, Abdellaoui Y, Salim MH et al (2020) Micro- and nano-celluloses derived from hemp stalks and their effect as polymer reinforcing materials. Carbohydr Polym 245:116506. https://doi.org/10.1016/j.carbpol.2020.116506

Kassab Z, Ben youcef H, Hannache H, El Achaby M (2019) Isolation of cellulose nanocrystals from various lignocellulosic materials: physico-chemical characterization and Application in Polymer Composites Development. Mater Today Proc 13:964–973. https://doi.org/10.1016/j.matpr.2019.04.061

El Achaby M, El Miri N, Hannache H et al (2018) Production of cellulose nanocrystals from vine shoots and their use for the development of nanocomposite materials. Int J Biol Macromol 117:592–600. https://doi.org/10.1016/j.ijbiomac.2018.05.201

Prado KS, Spinacé MAS (2019) Isolation and characterization of cellulose nanocrystals from pineapple crown waste and their potential uses. Int J Biol Macromol 122:410–416. https://doi.org/10.1016/j.ijbiomac.2018.10.187

Kassab Z, Abdellaoui Y, Salim MH, El Achaby M (2020) Cellulosic materials from pea (Pisum Sativum) and broad beans (Vicia Faba) pods agro-industrial residues. Mater Lett 280:128539. https://doi.org/10.1016/j.matlet.2020.128539

Hu Y, Hamed O, Salghi R et al (2017) Extraction and characterization of cellulose from agricultural waste Argan press cake. Cellul Chem Technol 51:263–272. https://doi.org/10.1016/j.matpr.2021.07.030

Kassab Z, El Achaby M, Tamraoui Y et al (2019) Sunflower oil cake-derived cellulose nanocrystals: extraction, physico-chemical characteristics and potential application. Int J Biol Macromol 136:241–252. https://doi.org/10.1016/j.ijbiomac.2019.06.049

Nabili A, Fattoum A, Passas R et al (2014) Extraction and characterization of cellulose from date palm seeds ( Phoenix dactylifera L.). Cellul Chem Technol 50:9–10

Lin Q, Huang Y, Yu W (2021) Effects of extraction methods on morphology, structure and properties of bamboo cellulose. Ind Crops Prod 169:113640. https://doi.org/10.1016/j.indcrop.2021.113640

Wang Z, Qiao X, Sun K (2018) Rice straw cellulose nanofibrils reinforced poly(vinyl alcohol) composite films. Carbohydr Polym 197:442–450. https://doi.org/10.1016/j.carbpol.2018.06.025

Kumar A, Singh Negi Y, Choudhary V, Kant Bhardwaj N (2020) Characterization of cellulose nanocrystals produced by acid-hydrolysis from sugarcane bagasse as agro-waste. J Mater Phys Chem 2:1–8. https://doi.org/10.12691/jmpc-2-1-1

Rehman N, Alam S, Amin NU et al (2018) Ecofriendly isolation of cellulose from eucalyptus lenceolata: a Rehman, N., Alam, S., Amin, N. U., Mian, I., & Ullah, H. (2018). Ecofriendly isolation of cellulose from eucalyptus lenceolata: A novel approach. Int J Polym Sci 2018. https://doi.org/10.1155/2018/8381501

Krishnamachari P, Hashaikeh R, Tiner M (2011) Modified cellulose morphologies and its composites; SEM and TEM analysis. Micron 42:751–761. https://doi.org/10.1016/j.micron.2011.05.001

Mtibe A, Linganiso LZ, Mathew AP et al (2015) A comparative study on properties of micro and nanopapers produced from cellulose and cellulose nanofibres. Carbohyd Polym 118:1–8. https://doi.org/10.1016/j.carbpol.2014.10.007

Trache D, Donnot A, Khimeche K et al (2014) Physico-chemical properties and thermal stability of microcrystalline cellulose isolated from Alfa fibres. Carbohyd Polym 104:223–230. https://doi.org/10.1016/j.carbpol.2014.01.058

Acknowledgements

First author acknowledges the Rohini College of Engineering and Technology, Shiv Kumar—copyeditor, and RadoChemMAX, Nagercoil for providing research lab facilities to carry out his research work.

Author information

Authors and Affiliations

Contributions

Rantheesh J: conceptualization, investigation, methodology, writing—original draft, visualization, and data curation. S. Indran: resources, formal analysis, validation, writing—review and editing, project administration, and supervision. S. Raja: visualization and supported for data interpretation. Suchart Siengchin: resources and complete analysis of the work with technical correction.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rantheesh J, Indran S, Raja S et al. Isolation and characterization of novel micro cellulose from Azadirachta indica A. Juss agro-industrial residual waste oil cake for futuristic applications. Biomass Conv. Bioref. 13, 4393–4411 (2023). https://doi.org/10.1007/s13399-022-03467-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03467-0