Abstract

Silicon/carbon composites are promising alternatives to current graphite anodes in commercial lithium-ion batteries (LIBs) because of their high capacity and excellent safety. Nevertheless, the unsatisfactory fast-charging capability and cycle stability of Si/C composites caused by slow charge transport capability and huge volume change under industrial electrode conditions severely hamper their development. Here, a novel Si/C anode was fabricated by homogeneously depositing amorphous C-Si nanolayers on graphite (C-Si@graphite). C-Si nanolayers with uniformly dispersed sub-nanometer Si particles in 3D carbon skeleton significantly boost electron and Li-ion transport and efficiently relieve Si's agglomeration and volume change. As a result, the tailored C-Si@graphite electrodes show an excellent rate capacity (760.3 mAh·g−1 at 5.0C) and long cycle life of over 1000 cycles at 1.0C and 800 cycles at 2.0C under industrial electrode conditions. In addition, the assembled full cells (C-Si@graphite, anode; Li[Ni0.8Co0.1Mn0.1]O2, cathode) present superior fast-charging capability (240.4 Wh·kg−1, charging for 16.2 min, 3.0C) and long cycle life (80.7% capacity retention after 500 cycles at 1.0C), demonstrating the massive potential of C-Si@graphite for practical application.

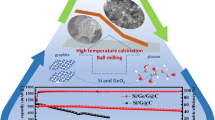

Graphical abstract

摘要

硅/碳(Si/C)复合材料具有高的容量和良好的安全性, 是目前商用锂离子电池中石墨阳极的 有希望的替代选择。然而, 在工业电极条件下, Si/C 复合电极的电荷传输能力差, 体积变 化大, 导致其快速充电能力和循环稳定性难以满足应用要求, 严重阻碍了其进一步发展。 在这里, 我们通过在石墨表面均匀沉积非晶态C-Si 纳米层制备了一种新型Si/C 阳极(CSi@graphite)。其中, 亚纳米Si 粒子在三维碳骨架中均匀分布构成C-Si 纳米层, 显著促 进了电子和锂离子的传输, 有效缓解了Si 的团聚和体积变化。

Similar content being viewed by others

References

Zhang YX, Wu BR, Mu G, Ma CW, Mu DB, Wu F. Recent progress and perspectives on silicon anode: synthesis and prelithiation for LIBs energy storage. J. Energy Chem. 2022;64:615. https://doi.org/10.1016/j.jechem.2021.04.013.

Chae SJ, Xu YB, Yi R, Lim HS, Velickovic D, Li XL, Li QY, Wang CM, Zhang JG. A micrometer-sized silicon/carbon composite anode synthesized by impregnation of petroleum pitch in nanoporous silicon. Adv. Mater. 2021;33(40):2103095. https://doi.org/10.1002/adma.202103095.

Li X, Zhang M, Yuan S, Lu C. Research progress of silicon/carbon anode materials for lithium-ion batteries: structure design and synthesis method. ChemElectroChem. 2020;7(21):4289. https://doi.org/10.1002/celc.202001060

Chen X, Chen Z, Ni Y, Wang L, Sun Y. Double-shell interphase design enabling suppressed side reactions for stable Si battery anode. Appl. Phys. Lett. 2022;121(12):123905. https://doi.org/10.1063/5.0117229

Chen X, Ge G, Wang W, Zhang B, Jiang J, Yang X, Li Y, Wang L, He X, Sun Y. In situ formation of ionically conductive nanointerphase on Si particles for stable battery anode. Sci. Chi. Chem 2021;64(8):1417. https://doi.org/10.1007/s11426-021-1023-4

An Y, Tian Y, Wei H, Xi B, Xiong S, Feng J, Qian Y. Porosity‐and graphitization‐controlled fabrication of nanoporous silicon@carbon for lithium storage and its conjugation with MXene for lithium‐metal anode. Adv. Funct. Mater. 2020;30(9):1908721. https://doi.org/10.1002/adfm.201908721

An W, Gao B, Mei S, Xiang B, Fu J, Wang L, Zhang Q, Chu P, Huo K. Scalable synthesis of ant-nest-like bulk porous silicon for highperformance lithium-ion battery anodes. Nat. Commun. 2019;10(1):1. https://doi.org/10.1038/s41467-019-09510-5

Wu H, Chan G, Choi JW, Ryu I, Yao Y, McDowell MT, Lee SW, Jackson A, Yang Y, Hu L, Cui Y. Stable cycling of double-walled silicon nanotube battery anodes through solid-electrolyte interphase control. Nat. Nanotechnol. 2012;7(5):310. https://doi.org/10.1038/nnano.2012.35

Chan CK, Peng H, Liu G, McIlwrath K, Zhang XF, Huggins RA, Cui Y. High-performance lithium battery anodes using silicon nanowires. Nat. Nanotechnol. 2008;3(1):31. https://doi.org/10.1038/nnano.2007.411

Saint J, Morcrette M, Larcher D, Laffont L, Beattie S, Pérès JP, Talaga D, Couzi M, Tarascon, JM. Towards a fundamental understanding of the improved electrochemical performance of silicon-carbon composites. Adv. Funct. Mater. 2007;17(11):1765. https://doi.org/10.1002/adfm.200600937

Kong X, Zheng Y, Wang Y, Liang S, Cao G, Pan A. Necklace-like Si@C nanofibers as robust anode materials for high performance lithium ion batteries. Sci.Bull. 2019;64(4):261. https://doi.org/10.1016/j.scib.2019.01.015

Zhang M, Zhang T, Ma Y, Chen Y. Latest development of nanostructured Si/C materials for lithium anode studies and applications. Energy Stor. Mater. 2016;4:1. https://doi.org/10.1016/j.ensm.2016.02.001

Buqa H, Goers D, Holzapfel M, Spahr ME, Novák P. High rate capability of graphite negative electrodes for lithium-ion batteries. J. Electrochem. Soc. 2005;152(2):A474. https://doi.org/10.1149/1.1851055

Kim N, Chae S, Ma J, Ko M, Cho J. Fast-charging high-energy lithium-ion batteries via implantation of amorphous silicon nanolayer in edgeplane activated graphite anodes. Nat. Commun. 2017;8(1):1. https://doi.org/10.1038/s41467-017-00973-y

Ma J, Sung J, Hong J, Chae S, Kim N, Choi SH, Nam G, Son Y, Kim SY, Ko M, Cho J. Towards maximized volumetric capacity via porecoordinated design for large-volume-change lithium-ion battery anodes. Nat. Commun. 2019;10(1):1. https://doi.org/10.1038/s41467-018-08233-3

Simonneau A, Oestreich M. Formal SiH4 chemistry using stable and easy-to-handle surrogates. Nature Chem. 2015;7(10):816. https://doi.org/10.1038/nchem.2329

Han M, Mu Y, Yuan F, Liang J, Jiang T, Bai X, Yu J. Vertical graphene growth on uniformly dispersed sub-nanoscale SiOx/N-doped carbon composite microspheres with a 3D conductive network and an ultra-low volume deformation for fast and stable lithium-ion storage. J. Mater. Chem. A. 2020;8(7):3822. https://doi.org/10.1039/C9TA12554J

Hishiyama Y, Irumano H, Kaburagi Y, Soneda Y. Structure, Raman scattering, and transport properties of boron-doped graphite. Phys. Rev. B. 2001;63(24):245406. https://doi.org/10.1103/PhysRevB.63.245406

Li Z, Li J, Cui J, Qiu H, Yang G, Zheng S, Yang J. Dispersion and parallel assembly of sulfonated graphene in waterborne epoxy anticorrosion coatings. J. Mater. Chem. A. 2019;7(30):17937. https://doi.org/10.1039/C9TA03995C

Li Z, Lin Z, Han M, Mu Y, Yu P, Zhang Y, Yu J. Flexible electrospun carbon nanofibers/silicone composite films for electromagnetic interference shielding, electrothermal and photothermal applications. Chem. Eng. J. 2021;420:129826. https://doi.org/10.1016/j.cej.2021.129826

Wang Z, Yao Q, Neumann C, Börrnert F, Renner J, Kaiser U, Turchanin A, Zandvliet JW, Eigler S. Identification of semiconductive patches in thermally processed monolayer oxo-functionalized graphene. Angew. Chem. Int. Ed. 2020;59(32):13657. https://doi.org/10.1002/anie.202004005

Shang H, Zuo Z, Yu L, Wang F, He F, Li Y. Low-temperature growth of all-carbon graphdiyne on a silicon anode for high-performance lithium-ion batteries. Adv. Mater. 2018;30(27):1801459. https://doi.org/10.1002/adma.201801459

Karuppiah S, Keller C, Kumar P, Jouneau PH, Aldakov D, Ducros JB, Lapertot G, Chenevier P, Haon C. A scalable silicon nanowires-grownon-graphite composite for high-energy lithium batteries. ACS Nano 2020;14(9):12006. https://doi.org/10.1021/acsnano.0c05198

Miao J, Thompson CV. Kinetic study of the initial lithiation of amorphous silicon thin film anodes. J.Electrochem.Soc. 2018;165(3):A650. https://doi.org/10.1149/2.1011803jes

Chae S, Park S, Ahn K, Nam G, Lee T, Sung J, Kim N, Cho J. Gas phase synthesis of amorphous silicon nitride nanoparticles for high-energy LIBs. Energy Environ. Sci. 2020;13(4):1212. https://doi.org/10.1039/C9EE03857D

Li FS, Wu YS, Chou J, Wu NL. A dimensionally stable and fast-discharging graphite–silicon composite Li-ion battery anode enabled by electrostatically self-assembled multifunctional polymer-blend coating. ChemComm. 2015;51(40):8429–31. https://doi.org/10.1039/C4CC09825K

Li Z, Yuan F, Han M, Yu J. Atomic-scale laminated structure of O-doped WS2 and carbon layers with highly enhanced ion transfer for fast–charging lithium-ion batteries. Small. 2022:2202495. https://doi.org/10.1002/smll.202202495

Fang G, Wu Z, Zhou J, Zhu C, Cao X, Lin T, Chen Y, Wang C, Pan A, Liang S. Observation of pseudocapacitive effect and fast ion diffusion in bimetallic sulfides as an advanced sodium‐ion battery anode. Adv. Energy. Mater. 2018;8(19):1703155. https://doi.org/10.1002/aenm.201703155

Zhao G, Zhang Y, Yang L, Jiang Y, Zhang Y, Hong W, Tian Y, Zhao H, Hu J, Zhou L, Hou H, Ji X, Mai L. Nickel chelate derived NiS2 decorated with bifunctional carbon: an efficient strategy to promote sodium storage performance. Adv. Funct. Mater. 2018;28(41):1803690. https://doi.org/10.1002/adfm.201803690

Zhao ZJ, Chao YG, Wang F, Dai JY, Qin YF, Bao XB, Yang Y, Guo SJ. Intimately coupled WS2 nanosheets in hierarchical hollow carbon nanospheres as the high-performance anode material for lithium-ion storage. Rare Met. 2022;41(4):1245. https://doi.org/10.1007/s12598-021-01850-w

Ke CZ, Liu F, Zheng ZM, Zhang HH, Cai MT, Li M, Yan QZ, Chen HX, Zhang QB. Boosting lithium storage performance of Si nanoparticles via thin carbon and nitrogen/phosphorus co-doped two-dimensional carbon sheet dual encapsulation. Rare Met. 2021;40(6):1347. https://doi.org/10.1007/s12598-021-01716-1

Wang, JT; Lu, SG; Wang, Y; Huang, B; Yang, JY; Tan, A.Improvement of cycle behavior of Si/Sn anode composite supported by stable Si-OC skeleton. Rare Met. 2022;41(5):1647–1651. https://doi.org/10.1007/s12598-014-0377-1

Ko M, Chae S, Ma J, Kim N, Lee HW, Cui Y, Cho J. Scalable synthesis of silicon-nanolayer-embedded graphite for high-energy lithium-ion batteries. Nat. Energy. 2016;1(9):1. https://doi.org/10.1038/nenergy.2016.113

Zhao J, Li Y, Yang G, Jiang K, Lin H, Ade H, Ma W, Yan H. Efficient organic solar cells processed from hydrocarbon solvents. Nat. Energy. 2016;1(2):1. https://doi.org/10.1038/nenergy.2015.27

Shao R, Zhu F, Cao Z, Zhang Z, Dou M, Niu J, Zhu B, Wang F. Heteroatom-doped carbon networks enabling robust and flexible silicon anodes for high energy Li-ion batteries. J. Mater. Chem. A. 2020;8(35):18338. https://doi.org/10.1039/D0TA06647H

Han M, Li J, Yu J. Microspheres integrating Ti2O3 nanocrystals, carbon matrix, and vertical graphene enable fast ion transport for fast-charging lithium-ion batteries. J. Energy Stor. 2021;43:103179. https://doi.org/10.1016/j.est.2021.103179

El-Khodary SA, Subburam G, Zou BB, Wang J, Qiu JX, Liu XH, Ng DHL, Wang S, Lian JB. Mesoporous silica anchored on reduced graphene oxide nanocomposite as anode for superior lithium-ion capacitor. Rare Met. 2022;41(2):368. https://doi.org/10.1007/s12598-021-01788-z

Li H, Chen Z, Kang Z, Liu W, Chen Y. High-density crack-resistant Si-C microparticles for lithium ion batteries. Energy Stor. Mater. 2023;56:40. https://doi.org/10.1016/j.ensm.2022.12.045

Ma J, Sung J, Lee Y, Son Y, Chae S, Kim N, Choi S, Cho J. Strategic pore architecture for accommodating volume change from high Si content in lithium-ion battery anodes. Adv. Energy. Mater. 2020;10(6):1903400. https://doi.org/10.1002/aenm.201903

Acknowledgements

This study was financially supported by Guangdong Basic and Applied Basic Research Foundation (No. 2020A1515110762).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, ZW., Han, MS. & Yu, J. Sub-nanometer structured silicon-carbon composite nanolayers armoring on graphite for fast-charging and high-energy-density lithium-ion batteries. Rare Met. 42, 3692–3704 (2023). https://doi.org/10.1007/s12598-023-02395-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02395-w