Abstract

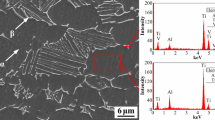

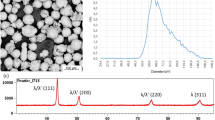

This study aims to investigate the impact of substrate preheating on the cracking and wear resistance of laser-clad T-800 alloy coatings on DD5 single-crystal alloy substrates. Two different conditions, namely non-preheated (22 °C) and preheated (300 °C), were employed to deposit T-800 alloy coatings on the surface of DD5 single-crystal alloy using laser cladding technology. The experimental results reveal that substrate preheating at 300 °C reduces the degree of variation in microstructure morphology within each region of the coating. This reduction effectively mitigates the internal stresses caused by the difference in solidification rates of the various parts of the coating, thereby preventing coating cracking. Additionally, the presence of Ni in the DD5 substrate enhances the dilution effect on the coating. Compared to the non-preheated condition, the preheated condition increases the Ni content in the primary Laves phase, secondary spherical Laves phase, and Co-based solid solution of the coating by 6.6%, 7.5%, and 14.8%, respectively, and the Co, Cr, Mo, and Si contents were all reduced. Consequently, this reduces the primary Laves phase and secondary spherical Laves phase precipitation and further inhibits coating cracking. The crack defects within the coating in the non-preheated condition of the substrate weakened its wear resistance. Despite a 13.6% reduction in coating microhardness attributed to preheating of the substrate, the high hardness properties of the T-800 alloy coating were preserved. Moreover, the internal hard Laves phase structure was more diffusely distributed in the softer Co-based solid solution, resulting in improved wear resistance through increased anti-adhesion ability and resistance to hard particles intrusion. Specifically, the preheated coating shows a 14.0% reduction in average coefficient of friction, a 37.9% reduction in mass loss. The wear mechanisms observed in the coatings include abrasive wear, adhesive wear, and oxidative wear.

Similar content being viewed by others

Data availability

The authors affirm that all data, findings, and conclusions presented in this paper are accurate and unbiased to the best of our knowledge. We have included all relevant references and sources for this research as per academic norms, and have made every effort to ensure transparency and honesty throughout the publication process.

References

C. Ming, G. Qiang, G. Xingjun, G. Yadong, Z. Minglei, Z. Tao, and C. Minghui, Plastic Deformation Mechanism of Running-in Subsurface of Nickel-Based Single-Crystal Superalloy, Int. J. Adv. Manuf. Technol., 2023, 128(11-12), p 4961-4979.

B. Hongyou, X. Xiaowen, L. Weijun, X. Fei, and W. Huiru, Control of Dendrite Epitaxial Growth and Microstructure Characteristics of Laser Deposition Repaired DD5 Alloy, Infrared Laser Eng., 2023, 52(05), p 138-150.

B. Hongyou, D. Tengda, W. Shijie, L. Ying, W. Wei, and Y. Guang, Microstructure and Wear Properties of Laser Deposition Repaired DZ125 Alloy, Rare Metal Mater. Eng., 2020, 49(06), p 2039-2045.

S. Ci, J. Liang, J. Li, Y. Zhou, and X. Sun, Microstructure and Tensile Properties of DD32 Single Crystal Ni-Base Superalloy Repaired by Laser Metal Forming, J. Mater. Sci. Technol., 2020, 45(10), p 23-34.

X.W. Xu, H.Y. Bian, W.J. Liu, W. Wang, and F. Xing, Microstructure and Properties of the Tribaloy T-800 Coating Fabricated by Laser Cladding on the DZ125 Superalloy, J. Therm. Spray Technol., 2023, 32(7), p 2112-2122.

Y. Liu, Y. Wang, X. Yang, P. Peng, J. Xie, H.K. Benno Park, Y.H. Joo, I.W. Jeong, T.H. Sung, and L. Xu, Research on Microstructure and Properties of Ti-Based Coating Prepared by Laser Cladding on Titanium Alloy: Simulation and Experiment, J. Mater. Res. Technol., 2022, 20, p 3667-3682.

L. Zhu, P. Xue, Q. Lan, G. Meng, Y. Ren, Z. Yang, P. Xu, and Z. Liu, Recent Research and Development Status of Laser Cladding: A Review, Opt. Laser Technol., 2021, 138, 106915.

T. Durejko, M. Łazińska, J. Dworecka-Wójcik, S. Lipiński, R.A. Varin, and T. Czujko, The Tribaloy T-800 Coatings Deposited by Laser Engineered Net Shaping (LENS(TM)), Materials (Basel), 2019, 12(9), p 1366. (in Eng)

E. Díaz, J.M. Amado, J. Montero, M.J. Tobar, and A. Yáñez, Comparative Study of Co-Based Alloys in Repairing Low Cr-Mo Steel Components by Laser Cladding, Phys. Procedia, 2012, 39, p 368-375.

S.T. Nyadongo, S.L. Pityana, and E.O. Olakanmi, Isothermal Oxidation Performance of Laser Cladding Assisted with Preheat (LCAP) Tribaloy T-800 Composite Coatings Deposited on EN8, Coatings, 2021, 11(7), p 843.

H. Bo, W. Chen, S. Changqing, Y. Guang, W. Xiangming, and S. Yadong, Effect of Substrate Preheating on Microstructure and Properties of Laser-Deposited TA15/GH4169 Composite Structure, Chin. J. Lasers, 2020, 47(01), p 82-88.

W. Cheng, W. Wei, D. Shijie, G. Penghui, and G. Yuan, Preparation and Tribological Properties of Fe-based Wear-Resistant Coating by Laser Cladding, Chin. J. Lasers, 2022, 49(22), p 137-147.

J. Przybylowicz and J. Kusinski, Laser Cladding and Erosive Wear of Co-Mo-Cr-Si Coatings, Surf. Coat. Technol., 2000, 125(1-3), p 13-18.

L. Shangping, L. Heli, C. Xu, and Z. Xie, Microstructure and High-Temperature Fretting Wear Behavior of T800 Alloy in Casting and Cladding State, Rare Metal Mater. Eng., 2013, 42(03), p 603-606.

Z. Yong, D.Q. Xie, Y. Liu, L.D. Shen, S.C. Jiang, F. Xing, L.L. Chang, and Z.J. Tian, Validation of Cr6Fe18Mo in Tribaloy T-800 Coating Fabricated by Induction Heating Assisted Laser Cladding, J. Alloy. Compd., 2023, 944, 169195.

B. Hongyou, Z. Xiangpeng, Q. Shen, W. Shijie, Y. Guang, Q. Lanyun, and W. Wei, Effect of Substrate Preheating on Property of GH4169 Alloys Repaired by Laser Deposition, Chin. J. Lasers, 2016, 43(07), p 98-103.

B. Hongyou, L. Yang, L. Ying, Y. Guang, Q. Lanyun, W. Wei, and H. Shuanglong, Effects of Induction Preheating on Microstructure and Residual Stress of Laser Deposition Repair TA15 Titanium Alloy, Infrared Laser Eng., 2016, 45(07), p 60-65.

K. Qi, Y. Yang, G. Hu, X. Lu, and J. Li, Thermal Expansion Control of Composite Coatings on 42CrMo by Laser Cladding, Surf. Coat. Technol., 2020, 397, 125983.

C. Lee, H. Park, J. Yoo, C. Lee, W. Woo, and S. Park, Residual Stress and Crack Initiation in Laser Clad Composite Layer with Co-Based Alloy and WC Plus NiCr, Appl. Surf. Sci., 2015, 345, p 286-294.

P.B. Kadolkar, T.R. Watkins, J.T.M. De Hosson, B.J. Kooi, and N.B. Dahotre, State of Residual Stress in Laser-deposited Ceramic Composite Coatings on Aluminum Alloys, Acta Mater., 2007, 55(4), p 1203-1214.

H. Suoxia, R. Chengxiang, W. Chao, Z. Jiangkun, Z. Duo, and Z. Haoqiang, A Review of Crack Generation and Suppression in Laser Cladding Layer, Mater. Rep., 2021, 35(S1), p 352-356.

W. Ran, W. Yuling, J. Fulin, and Y. Fazhan, Effect of Substrate Preheating on Crack Sensitivity of Al2O3-ZrO2 Ceramic Coating Prepared by Laser Cladding, Surf. Technol., 2022, 51(03), p 342-352.

B. Shi, T. Li, Z. Guo, X. Zhang, and H. Zhang, Selecting Process Parameters of Crack-Free Ni60A Alloy Coating Prepared by Coaxial Laser Cladding, Opt. Laser Technol., 2022, 149, 107805.

J.B. Lin, C.J. Chen, M. Zhang, and S.Q. Wang, The Effects of Heat Treatment on Microstructure and Mechanical Properties of Tribaloy 400 Coatings Deposited by Laser Cladding, J. Mater. Eng. Perform., 2018, 27(12), p 6339-6348.

H.F. Lu, W.L. Li, E.W. Qin, C.W. Liu, S.Y. Liu, W.L. Zhang, and S.H. Wu, The Gradient Microstructure and High-Temperature Wear Behavior of the CoCrMoSi Coating by Laser Cladding, J. Therm. Spray Technol., 2021, 30(4), p 968-976.

C. Zhikun, L. Min, Z. Dechang, M. Wenyou, L. Fuhai, C. Xingchi, and K. Xiaojun, Microstructure and Wear Resistance of Laser Cladding NiCrWB Alloy Coating on Cu Substrate, Tribology, 2010, 30(04), p 344-349.

X. Xu, H. Bian, W. Liu, F. Xing, B. Song, K. Chen, and A. Liu, Effect of Laser Energy Density on the Microstructure and Properties of Tribaloy T-800 Coating Fabricated by Laser Cladding on the DZ125 Alloy, Mater. Today Commun., 2023, 37, 107459.

F. Weng, H. Yu, J. Liu, C. Chen, J. Dai, and Z. Zhao, Microstructure and Wear Property of the Ti5Si3/TiC Reinforced Co-Based Coatings Fabricated by Laser Cladding on Ti-6Al-4V, Opt. Laser Technol., 2017, 92, p 156-162.

Y. Yongqiang, L. Chen, S. Jingyi, L. Jia, and X. Huanhuan, Influence of Vacuum Environment and Substrate Preheating on the Organization and Properties of Laser Cladding WC-Reinforced Nickel-Based Alloy Coatings, Mater. Mech. Eng., 2020, 44(05), p 49-53.

X. Zhang, J. Zhang, and J. Ding, Effect of the Additive Graphene Oxide on Tribological Properties of WC-Co Cemented Carbide, Int. J. Refract. Met. Hard Mater., 2022, 109, 105962.

J. Yao, Y. Ding, R. Liu, Q. Zhang, and L. Wang, Wear and Corrosion Performance of Laser-clad Low-carbon High-molybdenum Stellite Alloys, Opt. Laser Technol., 2018, 107, p 32-45.

G. Bolelli, V. Cannillo, L. Lusvarghi, M. Montorsi, F.P. Mantini, and M. Barletta, Microtissue and Tribological Comparison of HVOF-Sprayed and Post-treated M-Mo-Cr-Si (M = Co, Ni) Alloy Coatings, Wear, 2007, 263, p 1397-1416.

M.S.K.K.Y. Nartu, T.B. Torgerson, S.A. Mantri, R. Banerjee, and T.W. Scharf, Directed Energy Deposition of Ni-Al-Cr-C Composites: Microstructural Evolution During Solidification and Wear, Addit. Manuf., 2021, 42, p 102000.

Acknowledgments

The authors would like to thank the National Natural Science Foundation of China (52375456) and the Liaoning “BaiQianWan Talents Program” (LNBQW 2020B0050), for financially supporting this study under.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors unequivocally declare that we have no conflict of interest related to this research. We have not received any financial support or other forms of compensation from any individuals or organizations that could influence the results of this study. Furthermore, we have no affiliations with any commercial entities that may pose a conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guangtai, Z., Weijun, L., Hongyou, B. et al. Effect of Substrate Preheating on Cracking and Wear Resistance of Laser-Cladded Tribaloy T-800 Coatings on DD5 Single-Crystal Alloy. J Therm Spray Tech 33, 1027–1039 (2024). https://doi.org/10.1007/s11666-024-01748-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-024-01748-w