Abstract

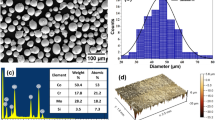

In this study, the effect of Y2O3 addition on the quality, microstructure, and microhardness of multi-track laser-cladded Ti-6Al-4V coating using coaxial powder feeding was investigated. These parameters were characterised via dye penetration, x-ray diffractometry, scanning electron microscopy, energy dispersive spectrometry, electron probe microanalysis, microhardness measurements, and ball-on-disc tribometer. It is observed that Y2O3 addition improved the coating quality by completely eliminating the formation of pores in multi-tracked Ti-6Al-4V coatings. The microstructure of the coating without and with Y2O3 primarily consists of acicular martensite (α′-Ti). Furthermore, the continuity of original β-Ti grain boundary is broken by the introduction of Y2O3. In addition, the Y2O3 is adsorbed and pinned at the original β-Ti grain boundaries resulting in the refinement of the β-Ti grains. It is believed that the refinement in the original β-Ti grains occurs via inhibition of the movement of the grain solid–liquid interface through dragging action. This phenomenon hinders grain growth by acting as a heterogeneous nucleus rather than increasing nucleation rate because it exhibits high lattice misfit degree. Compared with the coating without the Y2O3, the microhardness and wear stability of the Y2O3-supplemented coating was improved because of grain boundary strengthening, fine-grained strengthening, addition of high hardness Y2O3, and elimination of pores.

Similar content being viewed by others

References

P. Singh, H. Pungotra, and N.S. Kalsi, On the Characteristics of Titanium Alloys for the Aircraft Applications, Mater. Today, 2017, 4(8), p 8971–8982

N. Kherrouba, D. Carron, M. Bouabdallah et al., Effect of Solution Treatment on the Microstructure, Micromechanical Properties, Kinetic Parameters of the β → α Phase Transformation During Continuous Cooling of Ti-6Al-4V Titanium Alloy, J. Mater. Eng. Perform., 2019, 28, p 6921–6930

S.Y. Liu and Y.C. Shin, Additive Manufacturing of Ti6Al4V Alloy: A Review, Mater. Des., 2019, 164, p 107552

M. Yamaguchi, H. Inui, and K. Ito, High-Temperature Structural Intermetallics, Acta Mater., 2000, 48(1), p 307–322

B.K.C. Ganesh, W. Sha, N. Ramanaiah et al., Effect of Shotpeening on Sliding Wear and Tensile Behavior of Titanium Implant Alloys, Mater. Des., 2014, 56, p 480–486

X.D. Ren, W.F. Zhou, F.F. Liu et al., Microstructure Evolution and Grain Refinement of Ti-6Al-4V Alloy by Laser Shock Processing, Appl. Surf. Sci., 2016, 363, p 44–49

J.H. Yao, Y. Wang, G.L. Wu et al., Growth Characteristics and Properties of Micro-arc Oxidation Coating on SLM-produced TC4 Alloy for Biomedical Applications, Appl. Surf. Sci., 2019, 479, p 727–737

Y.N. Liu, R.L. Sun, W. Niu et al., Effects of CeO2 on Microstructure and Properties of TiC/Ti2Ni Reinforced Ti-Based Laser Cladding Composite Coatings, Opt. Lase. Eng., 2019, 120, p 84–94

J.M. Wilson, C. Piya, Y.C. Shin et al., Remanufacturing of Turbine Blades by Laser Direct Deposition with Its Energy and Environmental Impact Analysis, J. Clean. Prod., 2014, 80, p 170–178

R. Cottam and M. Brandt, Laser Cladding of Ti-6Al-4V Powder on Ti-6Al-4V Substrate: Effect of Laser Cladding Parameters on Microstructure, Phys. Proc., 2011, 12, p 323–329

Y.R. Choi, S.D. Sun, Q. Liu et al., Influence of Deposition Strategy on the Microstructure and Fatigue Properties of Laser Metal Deposited Ti-6Al-4V Powder on Ti-6Al-4V Substrate, Int. J. Fatigue, 2020, 130, p 105236

M. Nabhani, S.R. Reza, and M. Barekat, Corrosion Study of Laser Cladded Ti-6Al-4V Alloy in Different Corrosive Environments, Eng. Fall. Anal., 2019, 97, p 234–241

O. Yilmaz, N. Gindy, and J. Gao, A Repair and Overhaul Methodology for Aeroengine Components, Robot. Com-Int. Manuf., 2010, 26(2), p 190–201

R.D. Zhu, Z.Y. Li, X.X. Li et al., Microstructure and Properties of the Low-Power-Laser Clad Coatings on Magnesium Alloy with Different Amount of Rare Earth Addition, Appl. Surf. Sci., 2015, 353, p 405–413

Y.H. Zhao, S. Jie, and J.F. Li, Effect of Rare Earth Oxide on the Properties of Laser Cladding Layer and Machining Vibration Suppressing in Side Milling, Appl. Surf. Sci., 2014, 321, p 387–395

Y.S. Tian, C.Z. Chen, L.X. Chen et al., Effect of RE Oxides on the Microstructure of the Coatings Fabricated on Titanium Alloys by Laser Alloying Technique, Scr. Mater., 2006, 54(5), p 847–852

M.M. Quazi, M.A. Fazal, A.S.M.A. Haseeb et al., Effect of Rare Earth Elements and Their Oxides on Tribo-mechanical Performance of Laser Claddings: A Review, J. Rare Earth, 2016, 34(6), p 549–564

J.P. Qu, C.J. Zhang, J.C. Han et al., Microstructural Evolution and Mechanical Properties of Near α-Ti Matrix Composites Reinforced by Hybrid (TiB + Y2O3) with Bimodal Size, Vacuum, 2017, 144, p 203–206

A.K. Das, S.M. Shariff, and A.R. Choudhury, Effect of Rare Earth Oxide (Y2O3) Addition on Alloyed Layer Synthesized on Ti-6Al-4V Substrate with Ti + SiC + h-BN Mixed Precursor by Laser Surface Engineering, Tribol. Int., 2016, 95, p 35–43

J. Li, X. Luo, and G.J. Li, Effect of Y2O3 on the Sliding Wear Resistance of TiB/TiC-Reinforced Composite Coatings Fabricated by Laser Cladding, Wear, 2014, 310(1–2), p 72–82

W.J. Lu, L. Xiao, D. Xu et al., Microstructural Characterization of Y2O3 in In Situ Synthesized Titanium Matrix Composites, J. Alloys Compd., 2007, 433(1–2), p 140–146

A. Li, S. Ma, Y.J. Yang et al., Microstructure and Mechanical Properties of Y2O3 Reinforced Ti6Al4V Composites Fabricated by Spark Plasma Sintering, J. Alloys Compd., 2018, 768, p 49–56

H. Mustafa, M. Mezera, D.T.A. Matthews et al., Effect of Surface Roughness on the Ultrashort Pulsed Laser Ablation Fluence Threshold of Zinc and Steel, Appl. Surf. Sci., 2019, 488, p 10–21

H.C. Man, S. Zhang, F.T. Cheng et al., In Situ Synthesis of TiC Reinforced Surface MMC on Al6061 by Laser Surface Alloying, Scr. Mater., 2002, 46(3), p 229–234

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24(8), p 981–988

T. Ungár, S. Ott, P.G. Sanders et al., Dislocations, Grain Size and Planar Faults in Nanostructured Copper Determined by High Resolution x-Ray Diffraction and a New Procedure of Peak Profile Analysis, Acta Mater., 1998, 46(10), p 3693–3699

M. Bellardita, A.D. Paola, B. Megna et al., Determination of the Crystallinity of TiO2 Photocatalysts, J. Photochem. Photobiol. A Chem., 2018, 367, p 312–320

J.H. Yang, S.L. Xiao, Y.Y. Chen et al., Effects of Nano-Y2O3 Addition on the Microstructure Evolution and Tensile Properties of a Near-α Titanium Alloy, Mater. Sci. Eng. A, 2019, 761, p 137977

S. Roy, S. Suwas, S. Tamirisakandala et al., Development of Solidification Microstructure in Boron-Modified Alloy Ti-6Al-4V-0.1B, Acta Mater., 2011, 59(14), p 5494–5510

T. Ahmed and H.J. Rack, Phase Transformations During Cooling in α + β Titanium Alloys, Mater. Sci. Eng. A, 1998, 243(1–2), p 206–211

H. Tan, M.L. Guo, A.T. Clare et al., Microstructure and Properties of Ti-6Al-4V Fabricated by Low-Power Pulsed Laser Directed Energy Deposition, J. Mater. Sci. Technol., 2019, 35(9), p 2027–2037

X.L. Zhao, S.J. Li, M. Zhang et al., Comparison of the Microstructures and Mechanical Properties of Ti-6Al-4V Fabricated by Selective Laser Melting and Electron Beam Melting, Mater. Des., 2016, 95, p 21–31

B.A. Obadele, P.A. Olubambi, A. Andrews et al., Electrochemical Behaviour of Laser-Clad Ti6Al4V with CP Ti in 0.1 M Oxalic Acid Solution, J. Alloys Compd., 2015, 646, p 753–759

J. Kumar, A.V. Rao, S.G.S. Raman et al., Creep-Fatigue Damage Simulation at Multiple Length Scales for an Aeroengine Titanium Alloy, Int. J. Fatigue, 2018, 116, p 505–512

F. Weng, C.Z. Chen, and H.J. Yu, Research Status of Laser Cladding on Titanium and Its Alloys: A Review, Mater. Des., 2014, 58, p 412–425

J.J. Yang, H.C. Yu, Y. Jie et al., Formation and Control of Martensite in Ti-6Al-4V Alloy Produced by Selective Laser Melting, Mater. Des., 2016, 108, p 308–318

C.J. Zhang, F.T. Kong, S.L. Xiao et al., Evolution of Microstructure and Tensile Properties of In Situ Titanium Matrix Composites with Volume Fraction of (TiB + TiC) Reinforcements, Mater. Sci. Eng. A, 2012, 548, p 152–160

Z.Y. Zhao, G.F. Wang, Y.L. Zhang et al., Microstructure Evolution and Mechanical Properties of Ti-6Al-4V Alloy Prepared by Multipass Equal Channel Angular Pressing, J. Mater. Eng. Perform., 2020, 29, p 905–913

C. Guo, Z.R. Yu, C. Liu et al., Effects of Y2O3 Nanoparticles on the High-Temperature Oxidation Behavior of IN738LC Manufactured by Laser Powder Bed Fusion, Corros. Sci., 2020, 171, p 108715

T.S. Deng, S. Li, Y.Q. Liang et al., Effects of Scandium and Silicon Addition on the Microstructure and Mechanical Properties of Ti-6Al-4V Alloy, J. Mater. Res. Technol., 2020, 9(3), p 5676–5688

B.L. Bramfitt, The Effect of Carbide and Nitride Additions on the Heterogeneous Nucleation Behavior of Liquid Iron, Metall. Mater. Trans. B, 1970, 1(7), p 1987–1995

Y.R. Li, J.M. Wang, and J.Y. Wang, Theoretical Investigation of Phonon Contributions to Thermal Expansion Coefficients for Rare Earth Monosilicates RE2SiO5 (RE = Dy, Ho, Er, Tm, Yb and Lu), J. Eur. Ceram. Soc., 2020, 40(7), p 2658–2666

C.G.D. Andrés, F.G. Caballero, C. Capdevila et al., Application of Dilatometric Analysis to the Study of Solid–Solid Phase Transformations in Steels, Mater. Charact., 2002, 48(1), p 101–111

H. Attar, K.G. Prashanth, A.K. Chaubey et al., Comparison of Wear Properties of Commercially Pure Titanium Prepared by Selective Laser Melting and Casting Processes, Mater. Lett., 2015, 142, p 38–41

M.X. Shen, B. Li, Z.N. Zhang et al., Abrasive Wear Behavior of PTFE for Seal Applications Under Abrasive-Atmosphere Sliding Condition, Friction, 2020, 8(4), p 755–767

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Number 51905536) and the Fundamental Research Funds for the Central Universities of China (Grant Numbers 3122019084 and 3122018D013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, T., Xiao, H., Zhang, Z. et al. Effect of Y2O3 Addition on Microstructural Characteristics and Microhardness of Laser-Cladded Ti-6Al-4V Alloy Coating. J. of Materi Eng and Perform 29, 8221–8235 (2020). https://doi.org/10.1007/s11665-020-05316-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05316-5