Abstract

The aim of this work was to evaluate the effect of different heat treatment routes on the microstructure and sliding wear resistance of Inconel 718 alloy deposited by laser cladding on an AISI 316 L stainless steel substrate. Three heat treatment conditions were tested: double aged, solubilized and double aged, and homogenized, solubilized and double aged. These conditions were compared between each other and the as built samples. Both as built and double aged conditions presented a dendritic microstructure. The solubilized and double aged samples exhibited a recrystallized characteristic, however still containing a dendritic structure. While the homogenized, solubilized and double aged samples reveled equiaxial grains with the total replacement of the dendrites. Regarding the top and cross-section hardness, the heat-treated claddings were superior (about 65% higher) when compared to the as built condition. The friction coefficient for all conditions were statistically equal, however the solubilized and double aged and homogenized, solubilized and double aged conditions showed better results of wear loss (about 25% lower) when compared to the as built condition, whereas the double aged condition displayed statistically equal results in relation to the others. The wear mechanisms were predominantly adhesive for the as built conditions, adhesive and abrasive for the double aged and mostly abrasive for the solubilized and double aged and homogenized, solubilized and double aged samples. The results presented confirmed the need for heat treatment to improve the hardness of the coating and, in addition, it can be concluded that the different heat treatment routes did not have significant impacts on wear resistance. Therefore, from the conditions tested in this study it is possible to assume that the double aged route is the most suitable, for the point of view of wear resistance.

Similar content being viewed by others

Data Availability Statements

All data generated or analyzed during this study are included in this published article.

References

Holmberg, K., Kivikytö-Reponen, P., Härkisaari, P., Valtonen, K., Erdemir, A.: Global energy consumption due to friction and wear in the mining industry. Tribol. Int. 115, 116–139 (2017). doi:https://doi.org/10.1016/j.triboint.2017.05.010

Ramesh, C.S., Devaraj, D.S., Keshavamurthy, R., Sridhar, B.R.: Slurry erosive wear behaviour of thermally sprayed Inconel-718 coatings by APS process. Wear. 271, 1365–1371 (2011). doi:https://doi.org/10.1016/j.wear.2011.01.057

Pacheco, J.T., da Silva, L.J., Barbetta, L.D., Ferreira, H.S., Veiga, M.T., Forni, R., Teixeira, M.F.: Laser Cladding of Stellite-6 on AISI 316 L Austenitic Stainless Steel: Empirical-Statistical Modeling and Parameter Optimization. Lasers Manuf. Mater. Process. 2020, doi:https://doi.org/10.1007/s40516-020-00132-0

Kopliku, A., Mendez, C. 316 Stainless steel instrument tubing in marine applications - localized corrosion problems and solutions. In Proceedings of the NACE Corrorion Conference; Houston, Tex, USA, 2010

Quintino, L.: Overview of coating technologies. In: Surface Modification by Solid State Processing, pp. 1–24. Elsevier (2014)

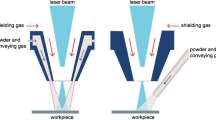

Vilar, R.: Laser cladding. J. Laser Appl. 11, 64–79 (1999). doi:https://doi.org/10.2351/1.521888

LAWRENCE, J.: Advances in Laser Material Processing - Techonology, Research and Applications. In Advances in Laser Materials Processing; Elsevier, 2018; pp. 1–22 ISBN 9780857092649

Donachie, M.J., Donachie, S.J. A Technical Guide SUPERALLOYS; 2002; ISBN 0871707497

Kuo, C.-M., Yang, Y.-T., Bor, H.-Y., Wei, C.-N., Tai, C.-C.: Aging effects on the microstructure and creep behavior of Inconel 718 superalloy. Mater. Sci. Eng. A. 510 – 511, 289–294 (2009). doi:https://doi.org/10.1016/j.msea.2008.04.097

Special metals: INCONEL alloy 718 2014, 1–27

Huang, L., Cao, Y., Zhang, J., Gao, X.: Effect of heat treatment on the microstructure evolution and mechanical behaviour of a selective laser melted Inconel 718 alloy. Journal of Alloys and Compounds (2021), doi:https://doi.org/10.1016/j.jallcom.2021.158613

Farber, B., Small, K.A., Allen, C., Causton, R.J., Nichols, A., Simbolick, J., Taheri, M.L.: Correlation of mechanical properties to microstructure in Inconel 718 fabricated by Direct Metal Laser Sintering. Mater. Sci. Eng. 712, 539–547 (2018). doi:https://doi.org/10.1016/j.msea.2017.11.125

ASTM E348-17 Standard Test Method of Microindentation Hardness of Materials: Annu. B. ASTM Stand. 14, 1–24 (2002). doi:https://doi.org/10.1520/E0384-17

SAE AMS5383 Nickel Alloy, Corrosion and: Heat-Resistant, Investment Castings, 52.5Ni - 19Cr - 3.0Mo - 5.1Cb(Nb) - 0.90Ti - 0.60Al - 18Fe, Vacuum Melted Homogenization and Solution Heat Treated 2007

SAE AMS5663 Nickel Alloy, Corrosion and: Resistant, H. Bars, Forgings, and Rings 52.5Ni 19Cr 3.0Mo 5.1Cb 0.90Ti 0.50Al 19Fe, Consumable Electrode or Vacuum Induction Melted 1775°F (968°C) Solution and Precipitation Heat Treated (2016)

Zhong, C., Kittel, J., Gasser, A., Schleifenbaum, J.H.: Study of nickel-based super-alloys Inconel 718 and Inconel 625 in high-deposition-rate laser metal deposition. Opt. Laser Technol. 109, 352–360 (2019). doi:https://doi.org/10.1016/j.optlastec.2018.08.003

Zhong, C., Biermann, T., Gasser, A., Poprawe, R.: Experimental study of effects of main process parameters on porosity, track geometry, deposition rate, and powder efficiency for high deposition rate laser metal deposition. J. Laser Appl. 27, 042003 (2015). doi:https://doi.org/10.2351/1.4923335

Jelvani, S., Shoja Razavi, R., Barekat, M., Dehnavi, M.R., Erfanmanesh, M.: Evaluation of solidification and microstructure in laser cladding Inconel 718 superalloy. Opt. Laser Technol. 2019, 120, doi:https://doi.org/10.1016/j.optlastec.2019.105761

Zhang, D., Niu, W., Cao, X., Liu, Z.: Effect of standard heat treatment on the microstructure and mechanical properties of selective laser melting manufactured Inconel 718 superalloy. Mater. Sci. Eng. A. 644, 32–40 (2015). doi:https://doi.org/10.1016/j.msea.2015.06.021

Feng, K., Liu, P., Li, H., Sun, S., Xu, S., Li, J.: Microstructure and phase transformation on the surface of Inconel 718 alloys fabricated by SLM under 1050°C solid solution + double ageing. Vacuum. 145, 112–115 (2017). doi:https://doi.org/10.1016/j.vacuum.2017.08.044

Zhong, C., Chen, J., Linnenbrink, S., Gasser, A., Sui, S., Poprawe, R.: A comparative study of Inconel 718 formed by High Deposition Rate Laser Metal Deposition with GA powder and PREP powder. Mater. Des. 107, 386–392 (2016). doi:https://doi.org/10.1016/j.matdes.2016.06.037

Weng, F., Yu, H., Chen, C., Liu, J., Zhao, L., Dai, J.: Effect of process parameters on the microstructure evolution and wear property of the laser cladding coatings on Ti-6Al-4V alloy. J. Alloys Compd. 2016, doi:https://doi.org/10.1016/j.jallcom.2016.09.071

da Silva, L.J., D’Oliveira, A.S.C.M.: NiCrSiBC coatings: Effect of dilution on microstructure and high temperature tribological behavior. Wear. 350 – 351, 130–140 (2016). doi:https://doi.org/10.1016/j.wear.2016.01.015

Vasudev, H., Thakur, L., Singh, H., Bansal, A.: Erosion behaviour of HVOF sprayed Alloy718-nano Al2O3 composite coatings on grey cast iron at elevated temperature conditions. Surf. Topogr. Metrol. Prop. 2021, 9, doi:https://doi.org/10.1088/2051-672X/ac1c80

Singh, G., Vasudev, H., Bansal, A., Vardhan, S.: Influence of heat treatment on the microstructure and corrosion properties of the Inconel-625 clad deposited by microwave heating. Surf. Topogr. Metrol. Prop. 2021, 9, doi:https://doi.org/10.1088/2051-672X/abfc61

Vasudev, H., Thakur, L., Singh, H., Bansal, A.: An investigation on oxidation behaviour of high velocity oxy-fuel sprayed Inconel718-Al2O3 composite coatings. Surf. Coatings Technol. 393, 125770 (2020). doi:https://doi.org/10.1016/j.surfcoat.2020.125770

Zhong, C., Gasser, A., Kittel, J., Wissenbach, K., Poprawe, R.: Improvement of material performance of Inconel 718 formed by high deposition-rate laser metal deposition. Materials and Design (2016), 98, 128?134, doi:https://doi.org/10.1016/j.matdes.2016.03.006

Karabulut, Y., Tascioglu, E., Kaynak, Y.: Heat treatment temperature-induced microstructure, microhardness and wear resistance of Inconel 718 produced by selective laser melting additive manufacturing. Optik (Stuttg). 2019, 163907, doi:https://doi.org/10.1016/j.ijleo.2019.163907

Sun, W., Tan, A.W., Jia, D., King, Y., Win, N., Bhowmik, A. Tribological behavior of cold sprayed Inconel 718 coatings at room and elevated temperatures. Surf. Coat. Technol.: 2020, 385, doi:https://doi.org/10.1016/j.surfcoat.2020.125386

Thirugnanasambantham, K.G., Natarajan, S.: Mechanistic studies on degradation in sliding wear behavior of IN718 and Hastelloy X superalloys at 500°C. Tribol. Int. 101, 324–330 (2016). doi:https://doi.org/10.1016/j.triboint.2016.04.016

Calvin Samuel, S., Arivarasu, M., Ram Prabhu, T.: High temperature dry sliding wear behaviour of laser powder bed fused Inconel 718. Addit. Manuf. 34, 101279 (2020). doi:https://doi.org/10.1016/j.addma.2020.101279

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Moura Filho, O.C., Pacheco, J.T., Veiga, M.T. et al. Effect of Different Heat Treatment Routes on the Tribological Behavior of the Inconel 718 Alloy Deposited on Aisi 316 L by Laser Cladding. Lasers Manuf. Mater. Process. 9, 241–256 (2022). https://doi.org/10.1007/s40516-022-00166-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-022-00166-6