Abstract

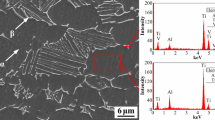

The effects of heat treatment on the microstructure, microhardness, nanohardness and wear resistance of Tribaloy 400 coatings prepared by laser cladding on 304 stainless steel were studied in this paper. The results show that the microstructures of Tribaloy 400 laser cladding layer are cobalt matrix dendrites and eutectic structure. After the heat treatment at 1250 °C for 1 h, the eutectic structure disappears and the strip-like Laves phase is formed on the Co matrix. Meanwhile, the hardness is obviously improved. After the heat treatment at 1250 °C for 1 h and then 900 °C for 4 h, a small amount of ε-Co appears, the strip-like Laves phases become coarser and blunter, and some of the strip structures combine together to form blocky structures, and the hardness is decreased. The wear resistance of the samples at 600 °C is better than that at RT since the hardness of the Laves phase increases with the rise in temperature.

Similar content being viewed by others

References

R. Vilar, Laser Cladding, J. Laser Appl., 1999, 11, p 64–79

G.J. Xu, W.J. Yang, Z.X. Hang, X.Y. Liu, H.L. Chi, and X.S. Ou, Performance of Clad Layer Using Mixed Powder of Stellite 6 and VC, J. Mech. Eng., 2017, 53, p 165–170

Q. Sun, Z.Y. Li, Y.Q. Zhang, L.Q. Yang, C.K. Liu, and K.Q. Cheng, Microstructure and Properties of Laser Cladding Al–TiC Coating on AZ91D Magnesium Alloy, Surf. Technol., 2017, 47, p 40–44

L. Sexton, S. Lavin, and G. Byrne, Laser Cladding of Aerospace Materials, J. Mater. Process. Technol., 2002, 122, p 63–68

C. Navas, M. Cadenas, J.M. Cuetos, and J. de Damborenea, Microstructure and Sliding Wear Behaviour of Tribaloy T-800 Coatings Deposited by Laser Cladding, Wear, 2006, 260, p 838–846

J.R. Davis, Nickel, Cobalt, and Their Alloys, ASM International, Materials Park, 2000, p 343–370

W. Betteridge, Cobalt and Its Alloys, Halsted Press, New York, 1982, p 30–52

R. Liu, M.X. Yao, P.C. Patnaik, and X.J. Wu, Effects of Heat Treatment on Mechanical and Tribological Properties of Cobalt-Base Tribaloy Alloys, J. Mater. Eng. Perform., 2005, 14, p 634–640

A. Halstead and R.D. Rawlings, The Fracture Behavior of Two Co-Mo-Cr-Si Wear-Resistant Alloys, J. Mater. Sci., 1985, 20, p 1248–1256

G. Bolelli and L. Lusvarghi, Heat Treatment Effects on the Tribological Performance of HVOF Sprayed Co-Mo-Cr-Si Coatings, J. Therm. Spray Technol., 2006, 15, p 802–810

M.J. Tobar, J.M. Amado, C. Álvarez, A. García, A. Varela, and A. Yáñez, Characteristics of Tribaloy T-800 and T-900 Coatings on Steel Substrates by Laser Cladding, Surf. Coat. Technol., 2008, 202, p 2297–2301

A. Mostafaei, Y. Behnamian, Y.L. Krimer, E.L. Stevens, J. Li, L. Luo, and M. Chmielus, Effect of Solutionizing and Aging on the Microstructure and Mechanical Properties of Powder Bed Binder Jet Printed Nickel-Based Superalloy 625, Mater. Des., 2016, 111, p 482–491

W. Xiong, Q.M. Zhang, Q. Xia, and L. Guo, Effect of Heat Treatment on the Microstructure and Properties of Laser Cladding Alloy, Appl. Laser, 2013, 33, p 233–238

A. Halstead and R.D. Rawlings, Structure and Hardness of Co-Mo-Cr-Si Wear-Resistant Alloys (Tribaloys), J. Mater. Sci., 1984, 18, p 491–500

M.X. Ren and B.S. Li, Hardness and Elastic Modulus of Microcastings by Nanoindentation, J. Chin. Nonferrous Metals, 2008, 18, p 231–236

H.M. Jiang and G.J. Zhang, Research of the Microstructure and Wear Resistance of Laser Cladding Cobalt-Based Alloy Layer over Stell Surface, Appl. Laser, 2012, 32, p 289–293

X.W. Zou, Q. Ma, and J.G. Jia, Research Developments of Laves Phase High Temperature Structural Silicides, Mater. Rev., 2008, 22, p 85–88

K. Yan, C.J. Chen, and M. Zhang, Microstructure and Properties of Laser Additive Manufacturing and Tempered H13 Steel, J. Chin. Surf. Eng., 2017, 30, p 134–142

Acknowledgments

The authors are gratefully acknowledged financial support from open fund from State Key Laboratory of Advanced Processing and Recycling of Non-ferrous Metals, Lanzhou University of Technology (SKLAB02014006), Suzhou Science and Technology Bureau (Grant Nos. SYG201231 and SYG201642). And Jiangsu province 333 talent project (BRA2017098), open fund for Jiangsu Key Laboratory of Advanced Manufacturing Technology (HGAMTL-1701) are also appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, J., Chen, C., Zhang, M. et al. The Effects of Heat Treatment on Microstructure and Mechanical Properties of Tribaloy 400 Coatings Deposited by Laser Cladding. J. of Materi Eng and Perform 27, 6339–6348 (2018). https://doi.org/10.1007/s11665-018-3762-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3762-3