Abstract

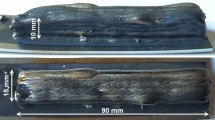

In this research, the manufacturing and characterization of a Sn-Al lead-free solder composite, reinforced with electric arc furnace dust, through an accumulative extrusion process was studied. To this end, one eutectic Sn-0.6Al solder alloy and three composite lead-free solders Sn-0.6Al/X%D (X = 0.5, 1, 1.5) were fabricated. The microstructure of the solders was investigated using x-ray diffraction (XRD) and a scanning electron microscope (SEM) equipped with an energy dispersion spectroscopy (EDS) detector. Thermal characteristics of the samples were investigated using differential scanning calorimetry (DSC). The wetting angle, density, electrical resistivity, microhardness, tensile strength and shear strength of the samples were also measured. The results of microstructural investigations indicated that the solder comprises the β-Sn phase and has a eutectic microstructure, and the increase in the number of accumulative extrusion passes results in a better, more uniform distribution of Al in the Sn matrix. The results of DSC tests showed a decrease in the melting point of the Sn-0.6Al solder alloy, which indicates successful alloying. The results showed that the contact angle of the Sn-0.6Al solder alloy with the substrate was 37° and the wetting angles of the Sn-0.6Al/X%D (X = 0.5, 1, 1.5) composite solders were 39°, 42° and 72°, respectively. Density measurements showed that, by fabrication of the Sn-0.6Al eutectic solder alloy, the density of the composite solder can be reduced by up to 18% compared to the Sn-37Pb alloy. Electrical resistivity measurements indicated that electrical resistivity of Sn-0.6Al/X%D (X = 0.5, 1, 1.5) composite solders was comparable to Sn-37Pb solder. Finally, mechanical test results showed that, by addition of 1% reinforcement particles, the microhardness, ultimate tensile strength and shear strength are improved.

Similar content being viewed by others

References

J. Tian, C. Hong, L. Hong, X. Yan, and P. Dai, J. Electron. Mater 48, 2685 (2019).

S. Menon, E. George, M. Osterman, and M. Pecht, J. Mater. Sci. Mater. Electron 26, 4021 (2015).

M. Abtew, and G. Selvaduray, Mater. Sci. Eng. R 27, 95 (2000).

A. Al-Ezzi, A. Al-Bawee, F. Dawood, and A.A. Shehab, J. Electron. Mater 48, 8089 (2019).

C.-J. Lee, K.D. Min, H.J. Park, J.-H. Kim, and S.-B. Jung, Electron. Mater. Lett 15, 693 (2019).

A. Sharma, D.E. Xu, J. Chow, M. Mayer, H.-R. Sohn, and J.P. Jung, Electron. Mater. Lett 11, 1072 (2015).

H.Y. Lee, A. Sharma, S.H. Kee, Y.W. Lee, J.T. Moon, and J.P. Jung, Electron. Mater. Lett 10, 997 (2014).

M.E. Alam, and M. Gupta, Electron. Mater. Lett 9, 575 (2013).

C. Wu, D.Q. Yu, C. Law, and L. Wang, Mater. Sci. Eng. R 44, 1 (2004).

K. Zeng, and K.-N. Tu, Mater. Sci. Eng. R 38, 55 (2002).

F. Guo, Composite lead-free electronic solders, in Lead-Free Electronic Solders, (Springer, 2006), pp. 129–145.

T. Laurila, V. Vuorinen, and M. Paulasto-Kröckel, Mater. Sci. Eng. R 68, 1 (2010).

H. Zhang, F. Sun, and Y. Liu, J. Mater. Sci. Mater. Electron 30, 340 (2019).

S.-M. Lee, J.-W. Yoon, and S.-B. Jung, J. Mater. Sci. Mater. Electron 27, 1105 (2016).

H. Sun, Y. Chan, and F. Wu, J. Mater. Sci. Mater. Electron 26, 5129 (2015).

J. Bath, Lead-Free Soldering Standards. Springer, 271 (2007)

T. Lee, W. Choi, K.-N. Tu, J. Jang, S. Kuo, J. Lin, D. Frear, K. Zeng, and J. Kivilahti, J. Mater. Res 17, 291 (2002).

S.-Y. Hwang, J.-W. Lee, and Z.-H. Lee, J. Electron. Mater 31, 1304 (2002).

J. Wasynczuk, and G. Lucey, NEPCON WEST 3, 1245 (1992).

T. Cheng, Y. Zhang, W.Y. Lai, and W. Huang, Adv. Mater 27, 3349 (2015).

K.-S. Kim, B.-G. Park, H. Kim, H.-S. Lee, and S.-B. Jung, Curr. Appl Phys 15, S36 (2015).

M.E. Alam, and M. Gupta, Development of extremely ductile lead-free Sn-Al solders for futuristic electronic packaging applications J. Electron. Mater 10, 515 (2014).

A. Sharma, A.K. Srivastava, and B. Ahn, Mater. Res. Express 6, 056520 (2019).

X. Zhong, and M. Gupta, Appl. Phys 41, 095403 (2008).

S. Nai, J. Wei, and M. Gupta, Thin Solid Films 504, 401 (2006).

F. Guo, J. Lee, T. Hogan, and K. Subramanian, J. Mater. Res 20, 364 (2005).

ASTM, F. 756-00. Standard practice for assessment of hemolytic properties of materials. West Conshohocken, PA: ASTM International, (2000)

W. Xing, X. Yu, H. Li, L. Ma, W. Zuo, P. Dong, W. Wang, and M. Ding, J. Alloys Compd 695, 574 (2017).

S. Hassan, K. Ho, and M. Gupta, Mater. Lett 58, 2143 (2004).

L.Y. Aguirre-Perales, I.-H. Jung, and R.A. Drew, Acta Mater 60, 759 (2012).

M.M. Salleh, A.M. Al-Bakri, M. Zan, F. Somidin, and N.F.M. Alui, Mater Sci. Eng. A 556, 633 (2012).

X. Liu, Y. Han, H. Jing, J. Wei, and L. Xu, Mater. Sci. Eng. A 562, 25 (2013).

M.S. Maa, A.M. Al-Bakri, H. Kamarudin, M. Bnhussain, and F. Somidin, Phys Procedia 22, 299 (2011).

Y. Tang, Y. Pan, and G. Li, J. Mater. Sci. Mater. Electron 24, 1587 (2013).

S.-Y. Chang, C.-F. Chen, S.-J. Lin, and T.Z. Kattamis, Electrical resistivity of metal matrix composites Acta Mater 51, 6291 (2003).

M. Gupta, G. Karunasiri, and M. Lai, Mater. Sci. Eng. A 219, 133 (1996).

D. Lloyd, Int. Mater. Rev. 39, 1 (1994).

S.U. Reddy, N. Srikanth, M. Gupta, and S.K. Sinha, Adv. Eng. Mater 6, 957 (2004).

A. El-Daly, W. Desoky, T. Elmosalami, M. El-Shaarawy, and A. Abdraboh, Mater. Des 65, 1196 (2015).

H.K. Rafi, T.L. Starr, and B.E. Stucker, Int. J. Adv. Manuf. Technol 69, 1299 (2013).

R. Sayyadi, and H. Naffakh-Moosavy, Mater. Sci. Eng. A 735, 367 (2018).

N. Hansen, Acta Metall 25, 863 (1977).

D. Dunand, and A. Mortensen, Acta Metall. Mater 39, 127 (1991).

Z. Szaraz, Z. Trojanova, M. Cabbibo, and E. Evangelista, Mater. Sci. Eng. A 462, 225 (2007).

H. Mavoori, and S. Jin, J. Electron. Mater 27, 1216 (1998).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zamani Bakhtiarvand, N., Taherizadeh, A., Maleki, A. et al. Manufacturing and Characterization of Sn-0.6Al Lead-Free Composite Solder Using Accumulative Extrusion Process. J. Electron. Mater. 50, 6372–6385 (2021). https://doi.org/10.1007/s11664-021-09143-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-021-09143-9