Abstract

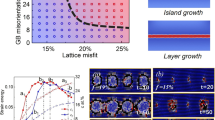

One of the recent advancements in the field of high temperature high strength aluminum alloys is the development of the Al-Sc-Zr alloy. The addition of Sc and Zr in the Aluminium matrix results in trialuminide precipitation that imparts excellent coarsening resistance, making the alloy suitable for high-temperature application. In the early stages of solid–solid phase transformations, the coherent microstructure is developed by maintaining the continuity between lattice planes and directions along the interface. These misfit strains significantly influence the shape and growth of trialuminides. The temperature dependency of misfit strain, which is often neglected in the theoretical simulations of precipitate phases, is considered in the present work to investigate microstructural evolution and resulting strain and concentration field distribution during trialuminide precipitation using the phase-field method. Also, an assessment of the precipitation kinetics during Al3X (X = Sc, Zr) growth in the Al matrix with the help of particle size and energy variation-time graph is also done to get an insight into the precipitation mechanism.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Knipling KE, Karnesky RA, Lee CP, et al (2010) Precipitation evolution in Al-0.1Sc, Al-0.1Zr and Al-0.1Sc-0.1Zr (at.%) alloys during isochronal aging. Acta Mater 58:5184–5195.

Costa S, Puga H, Barbosa J, Pinto AMP (2012) The effect of Sc additions on the microstructure and age hardening behaviour of as cast Al-Sc alloys. Mater Des 42:347–352.

Marquis EA, Seidman DN, Dunand DC (2003) Effect of Mg addition on the creep and yield behavior of an Al-Sc alloy. Acta Mater 51:4751–4760.

Knipling KE, Dunand DC, Seidman DN (2006) Criteria for developing castable, creep-resistant aluminum-based alloys - A review. Int J Mater Res 97:246–265.

Zhang JY, Gao YH, Yang C, et al (2020) Microalloying Al alloys with Sc: a review. Rare Met 39:636–650.

Souza PHL, Do Vale Quaresma JM, Silva De Oliveira CA (2017) Precipitation evolution and modeling of growth kinetics of L12-structured Al3Zr particles in Al-0.22Zr and Al-0.32Zr (wt.%) alloys isothermally aged. Mater Res 20:1600–1613.

Knipling KE, Dunand DC, Seidman DN (2006) Criteria for developing castable, creep-resistant aluminum-based alloys – A review. 97:

Novotny GM, Ardell AJ (2014) Precipitation of Al3Sc in Binary Al-Sc alloys Precipitation of Al 3 Sc in binary Al – Sc alloys. Mater Sci Eng A 5093:144–154

Knipling KE, Dunand DC, Seidman DN (2007) Nucleation and precipitation strengthening in dilute Al-Ti and Al-Zr alloys. Metall Mater Trans A Phys Metall Mater Sci 38:2552–2563.

Iwamura S, Miura Y (2004) Loss in coherency and coarsening behavior of Al3Sc precipitates. Acta Mater 52:591–600.

Liu S, Wang X, Zu Q, et al (2021) Significantly improved particle strengthening of Al–Sc alloy by high Sc composition design and rapid solidification. Mater Sci Eng A 800:140304.

Knipling KE, Dunand DC, Seidman DN (2008) Precipitation evolution in Al-Zr and Al-Zr-Ti alloys during aging at 450-600 °C. Acta Mater 56:1182–1195.

Knipling KE, Dunand DC, Seidman DN (2008) Precipitation evolution in Al-Zr and Al-Zr-Ti alloys during isothermal aging at 375-425 °C. Acta Mater 56:114–127.

Røyset J, Ryum N (2005) Some comments on the misfit and coherency loss of Al3Sc particles in Al-Sc alloys. Scr Mater 52:1275–1279.

Kamachali RD, Borukhovich E, Hatcher N, Steinbach I (2014) DFT-supported phase-field study on the effect of mechanically driven fluxes in Ni4Ti3 precipitation. Model Simul Mater Sci Eng 22:.

Steinbach I, Apel M (2006) Multi phase field model for solid state transformation with elastic strain. Phys D Nonlinear Phenom 217:153–160.

Seidman DN, Marquis EA, Dunand DC (2002) Precipitation strengthening at ambient and elevated temperatures of heat-treatable Al(Sc) alloys. Acta Mater 50:4021–4035.

Li DL, Chen P, Yi JX, et al (2009) Ab initio study on the thermal properties of the fcc Al3Mg and Al3Sc alloys. J Phys D Appl Phys 42:. 407

Tamim R, Mahdouk K (2018) Thermodynamic reassessment of the Al–Zr binary system. J Therm Anal Calorim 131:1187–1200.

Schwarze C, Gupta A, Hickel T, Darvishi Kamachali R (2017) Phase-field study of ripening and rearrangement of precipitates under chemomechanical coupling. Phys Rev B 95:1–14.

Clouet E, Sanchez JM, Sigli C (2002) First-principles study of the solubility of Zr in Al. Phys Rev B - Condens Matter Mater Phys 65:1–13.

Li DL, Chen P, Yi JX, et al (2010) Thermal properties of the FCC Al3Zr: First-principles study. Mater Sci Forum 650:313–319.

Kochetov M, Slawinski MA (2009) On obtaining effective transversely isotropic elasticity tensors. J Elast 94:1–13.

Guo W, Steinbach I, Somsen C, Eggeler G (2011) On the effect of superimposed external stresses on the nucleation and growth of Ni4Ti3 particles: A parametric phase field study. Acta Mater 59:3287–3296.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Sidhik, D., Sundar Daniel, B.S. (2023). Temperature Dependence of Lattice Misfit in Determining Microstructural Evolution of High Temperature High Strength Aluminium Alloys—A 3D Phase-Field Study. In: Broek, S. (eds) Light Metals 2023. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22532-1_71

Download citation

DOI: https://doi.org/10.1007/978-3-031-22532-1_71

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22531-4

Online ISBN: 978-3-031-22532-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)