Abstract

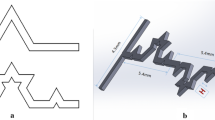

Micro-mixer is a device which is used to carry the mixing of two or more than two fluids. Any one dimension of it is in micrometer. Due to low Reynolds’ Number Micro-mixer design is challenge for the designers. To address this challenge, novel methods of mixing enhancement within micro-fluidic devices have been explored for a variety of applications. For Passive Micro-mixer mixing will be carried out with the help of geometry of the micro-mixer. In this study fabrication of a tree type Micro-mixer with Circular baffles using CO2 Laser machining is discussed. The Circular baffles are responsible for making diversion of flow of the fluid in Convergent & Divergent manner due to which proper mixing of fluids become possible. This type of micro-mixer is suitable for Bio-medical applications such as Urine testing, Blood testing, in preparation & in testing of Drugs. This paper focuses on design and fabrication of tree type Micro-mixer with Circular Baffles. The parametric study for CO2 laser machining by considering the speed and power as the control parameters and the depth as a performance measure for engraving different width micro channels is presented in this paper. The tree type Micro-mixer with Circular Baffles fabricated by CO2 laser machining is found to be suitable for master molds used in soft lithography process.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Klank H, Kutter JP, Geschke O (2000) CO2-Laser micromachining and back-end processing for rapid Production of PMMA-based microfluidic systems. La Chi 2:242–246

Das SS, Tilekar SD, Wangikar SS, Patowari PK (2017) Numerical and experimental study of passive fluids mixing in micro-channels of different configurations. Micros Technol 23:5977–5988

Seck HW, Patrick B, Michael W, Christopher W (2013) Investigation of mixing in a cross-shaped micromixer with static mixing elements for reaction kinetics studies. Sens Actua B 95:414–424

Gianni O, Mina R, Elisabetta B, Chiara G, Roberto M (2013) Water-ethanol mixing in T-shaped microdevices. Chem Eng Sci 95:174–183

Tsung-Han T, Dar-Sun L, Long-Sheng K, Ping-Hei C (2009) Rapid mixing between ferro-nanofluid and water in a semi-active Y-type micromixer. Sens Actua A 153:267–273

Wangikar SS, Patowari PK, Misra RD (2018) Numerical and experimental investigations on the performance of a serpentine microchannel with semicircular obstacles. Micros Technol 24:3307–3320

Gidde RR, Pawar PM, Ronge BP, Misal ND, Kapurkar RB, Parkhe AK (2018) Evaluation of the mixing performance in a planar passive micromixer with circular and square mixing chambers. Micros Technol 24:2599–2610

Zonghuan L, Jay McMahon HM, Barnard D, Shaikh TR, Mannella CA, Wagenknecht T, Toh-Ming L (2010) Passive microfluidic device for submilli second mixing. Sens Actua B 144:301–309

Gidde RR, Shinde AB, Pawar PM, Ronge BP (2018) Design optimization of a rectangular wave micromixer (RWM) using Taguchi based grey relational analysis (GRA). Micros Technol 24:3651–3666

Gidde RR, Pawar PM, Ronge BP, Shinde AB, Misal ND, Wangikar SS (2019) Flow field analysis of a passive wavy micromixer with CSAR and ESAR elements. Micros Technol 25:1017–1030

Gerlach A, Knebel G, Guber AE, Heckele M, Herrmann D, Muslija AS (2002) Microfabrication of single-use plastic microfluidic devices for high-throughput screening and DNA analysis. Micros Technol 7:265–268

Arshad A, Kwang-Yong K (2012) Passive split and recombination micromixer with convergent-divergent walls. Chem Eng J 203:182–192

Rotting O, Ropke W, Becker H, Gartner C (2010) Polymer microfabrication technologies. Micros Technol 8:32–36

Wangikar SS, Patowari PK, Misra RD (2017) Effect of process parameters and optimization for photochemical machining of brass and german silver. Mater Manuf Process 32:1747–1755

Wangikar SS, Patowari PK, Misra RD (2016) Parametric optimization for photochemical machining of copper using grey relational method. In: 1st Techno-societal, international conference on advanced technologies for societal applications. Springer, pp 933–943

Wangikar SS, Patowari PK, Misra RD (2018) Parametric optimization for photochemical machining of copper using overall evaluation criteria. Mater Tod Proc 5:4736–4742

Wangikar SS, Patowari PK, Misra RD, Misal ND (2019) Photochemical machining: a less explored non-conventional machining process. In: Non-conventional machining in modern manufacturing systems. IGI Global, pp 188–201

Kulkarni HD, Rasal AB, Bidkar OH, Mali VH, Atkale SA, Wangikar SS, Shinde AB (2019) Fabrication of micro-textures on conical shape hydrodynamic journal bearing. Int J Tre Eng Technol 36:37–41

Raut MA, Kale SS, Pangavkar PV, Shinde SJ, Wangikar SS, Jadhav SV, Kashid DT (2019) Fabrication of micro channel heat sink by using photo chemical machining. Int J New Technol Res 5:72–75

Patil PK, Kulkarni AM, Bansode AA, Patil MK, Mulani AA, Wangikar SS (2020) Fabrication of logos on copper material employing photochemical machining. Nov MIR Res J 5(6):70–73

Wangikar SS, Patowari PK, Misra RD, Gidde RR, Bhosale SB, Parkhe AK (2020) Optimization of photochemical machining process for fabrication of microchannels with obstacles. Mater Manuf Process. https://doi.org/10.1080/10426914.2020.1843674

Chavan NV, Bhagwat RM, Gaikwad SS, Shete SS, Kashid DT, Wangikar SS (2019) Fabrication & characterization of microfeatures on PMMA using CO2 laser machining. Int J Tre Eng Technol 36:29–32

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Gavali, S.R., Wangikar, S.S., Parkhe, A.K., Pawar, P.M. (2021). Fabrication of Tree Type Micro-Mixer with Circular Baffles Using CO2 Laser Machining. In: Pawar, P.M., Balasubramaniam, R., Ronge, B.P., Salunkhe, S.B., Vibhute, A.S., Melinamath, B. (eds) Techno-Societal 2020. Springer, Cham. https://doi.org/10.1007/978-3-030-69921-5_104

Download citation

DOI: https://doi.org/10.1007/978-3-030-69921-5_104

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-69920-8

Online ISBN: 978-3-030-69921-5

eBook Packages: EngineeringEngineering (R0)