Abstract

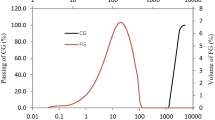

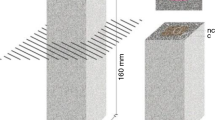

The use of alternative cements with lower CO2 emissions during production compared to ordinary Portland cement (PC) is only sustainable, if the durability and with it the service life of components and structures produced with them are not compromised. In this project, the carbonation resistance of mortars produced with calcium sulfoaluminate cement (CSA) and three different slag-based cements is studied in accelerated conditions and natural exposure. Additionally, the diffusion coefficients of oxygen (\(D_{{{\text{O}}_{2} }}\)) and carbon dioxide (\(D_{{{\text{CO}}_{2} }}\)) are measured (the latter one only on carbonated mortars) and the change in mortar porosity due to carbonation is determined. Mortar PC used as reference and mortar CSA display the lowest carbonation coefficients, both in accelerated conditions and natural exposure. The three systems based on slag display higher carbonation coefficients. After carbonation, the diffusion coefficient \(D_{{{\text{O}}_{2} }}\) is increased for all mortars except for mortar PC, whose total porosity is decreased as well, in contrast to all other mortars. The diffusion coefficients \(D_{{{\text{O}}_{2} }}\) and \(D_{{{\text{CO}}_{2} }}\) show a linear relationship in the carbonated mortars.

Similar content being viewed by others

References

Tuutti K (1982) Corrosion of steel in concrete. Svenska Forskningsinstitutet för cement och betong, Stockholm

Gonzalez JA, Andrade C (1982) Effect of carbonation, chlorides and relative ambient humidity on the corrosion of galvanized rebars embedded in concrete. Br Corros J 17:21–28

Papadakis VG, Vayenas CG, Fardis MN (1991) Physical and chemical characteristics affecting the durability of concrete. Mater J 88:186–196

Leemann A, Nygaard P, Kaufmann J, Loser R (2015) Relation between carbonation resistance, mix design and exposure of mortar and concrete. Cem Concr Compos 62:33–43

Leemann A, Moro F (2017) Carbonation of concrete: the role of CO2 concentration, relative humidity and CO2 buffer capacity. Mater Struct 50:30

Quillin K (2001) Performance of belite–sulfoaluminate cements. Cem Concr Res 31:1341–1349

Bakharev T, Sanjayan JG, Cheng YB (2001) Resistance of alkali-activated slag concrete to carbonation. Cem Concr Res 31:1277–1283

Puertas F, Palacios M, Vázquez T (2006) Carbonation process of alkali-activated slag mortars. J Mater Sci 41:3071–3082

Matschei T, Bellmann F, Stark J (2005) Hydration behaviour of sulphate-activated slag cements. Adv Cem Res 17:167–178

Hargis CW, Lothenbach B, Müller CJ, Winnefeld F (2017) Carbonation of calcium sulfoaluminate mortars. Cem Concr Compos 80:123–134

Bernal SA, Provis JL, Brice DG, Kilcullen A, Duxson P, van Deventer JS (2012) Accelerated carbonation testing of alkali-activated binders significantly underestimates service life: the role of pore solution chemistry. Cem Concr Res 42:1317–1326

Gartner E, Quillin K (2007) Low-CO2 cements based on calcium sulfoaluminates. Sustain Cem Concr Ind Nor Cem Assoc 16:95–105

Zhang L, Glasser FP (2005) Investigation of the microstructure and carbonation of CSA-based concretes removed from service. Cem Concr Res 35:2252–2260

Bin X, Xincheng P (1999) Study on durability of solid alkaline AAS cement. In: Second international conference alkaline cements and concretes, pp 101–108

Papadakis VG (2000) Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cem Concr Res 30:291–299

Rozière E, Loukili A, Cussigh F (2009) A performance based approach for durability of concrete exposed to carbonation. Constr Build Mater 23:190–199

Thomas MDA, Matthews JD, Haynes CA (2000) Carbonation of fly ash concrete. Spec Publ 192:539–556

De Ceukelaire L, Van Nieuwenburg D (1993) Accelerated carbonation of a blast-furnace cement concrete. Cem Concr Res 23:442–452

Chen CT, Ho CW (2013) Influence of cyclic humidity on carbonation of concrete. J Mater Civ Eng 25:1929–1935

Sanjuàn MA, Andrade C, Cheyrezy M (2003) Concrete carbonation tests in natural and accelerated conditions. Adv Cem Res 15:171–180

Turcry P, Oksri-Nelfia L, Younsi A, Aït-Mokhtar A (2014) Analysis of an accelerated carbonation test with severe preconditioning. Cem Concr Res 57:70–78

Groves GW, Brough A, Richardson IG, Dobson CM (1991) Progressive changes in the structure of hardened C3S cement pastes due to carbonation. J Am Ceram Soc 74:2891–2896

Castellote M, Fernandez L, Andrade C, Alonso C (2009) Chemical changes and phase analysis of OPC pastes carbonated at different CO2 concentrations. Mater Struct 42:515–525

Thiery M, Dangla P, Belin P, Habert G, Roussel N (2013) Carbonation kinetics of a bed of recycled concrete aggregates: a laboratory study on model materials. Cem Concr Res 46:50–65

Bernal SA, de Gutierrez RM, Provis JL, Rose V (2010) Effect of silicate modulus and metakaolin incorporation on the carbonation of alkali silicate-activated slags. Cem Concr Res 40:898–907

SN EN 505 262/1 (2013) Betonbau—Ergänzende Festlegungen. SIA, Zürich

Franke B (1941) Bestimmung von Calciumoxyd und Calciumhydroxyd neben wasserfreiem und wasserhaltigem Calciumsilikat. Z Anorg Allg Ch 247:180–184

EN 1015-11 (1999) Methods of test for mortar for masonry. Determination of flexural and compressive strength of hardened mortar. CEN, Brussels

Goto S, Suenaga K, Kado T, Fukuhara M (1995) Calcium silicate carbonation products. J Am Ceram Soc 78:2867–2872

Kaufmann J, Loser R, Leemann A (2009) Analysis of cement-bonded materials by multi-cycle mercury intrusion and nitrogen sorption. J Colloid Interface Sci 336:730–737

Buenfeld NR, Okundi E (1998) Effect of cement content on transport in concrete. Mag Concr Res 50:339–351

Villani C, Loser R, West MJ, Di Bella C, Lura P, Weiss JW (2014) An inter lab comparison of gas transport testing procedures: oxygen permeability and oxygen diffusivity. Cem Concr Compos 53:357–366

Leemann A, Loser R, Münch B, Lura P (2017) Steady-state O2 and CO2 diffusion in carbonated mortars produced with blended cements. Mater Struct. https://doi.org/10.1617/s11527-017-1118-3

Leemann A, Pahlke H, Winnefeld F (2017) Carbonation resistance of mortar produced with alternative cements. In: 10th ACI/RILEM international Conference on cementitious materials and alternative binders for sustainable concrete, Montreal

Loser R, Leemann A (2016) An accelerated sulfate resistance test for concrete. Mater Struct 49:3445–3457

Mehta PK, Gjørv OE (1982) Properties of Portland cement concrete containing fly ash and condensed silica-fume. Cem Concr Res 12:587–595

Li S, Roy DM (1986) Investigation of relations between porosity, pore structure, and Cl- diffusion of fly ash and blended cement pastes. Cem Concr Res 16:749–759

Houst YF, Wittmann FH (1994) Influence of porosity and water content on the diffusivity of CO2 and O2 through hydrated cement paste. Cem Concr Res 24:1165–1176

Wierig HJ (1984) Longtime studies on the carbonation of concrete under normal outdoor exposure. In: Proceedings of the RILEM seminar on the durability of concrete structures under normal outdoor exposure, pp 239–49

Osborne GJ (1999) Durability of Portland blast-furnace slag cement concrete. Cem Concr Compos 21:11–21

Acknowledgements

The authors would like to thank J. Kaufmann for the MIP measurements and P. Lura for the critical review of the manuscript.

Funding

This study was not funded by external sources. It was conducted with Empa means (employer of all authors).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they do not have a conflict of interest.

Rights and permissions

About this article

Cite this article

Leemann, A., Pahlke, H., Loser, R. et al. Carbonation resistance of mortar produced with alternative cements. Mater Struct 51, 114 (2018). https://doi.org/10.1617/s11527-018-1239-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-018-1239-3