Abstract

This study aims to examine the influence of untreated coal waste (UCW) and treated coal waste (TCW) as supplementary cementitious materials (SCMs) on the environmental, mechanical, durability, and microstructural characteristics of mortar mixes. UCW preparation procedure consists of sequential steps of crushing and grinding. Afterward, UCW is thermally activated through incinerating at 750 °C to be promoted to TCW. Experimental work includes mixing mortar mixtures by partially replacing cement with the coal waste binders (UCW and TCW) at different incorporation levels of 4, 8, 12, and 16% of cement weight. Toxicity characteristic leaching procedure (TCLP) test was applied to investigate the environmental impacts of coal wastes. TCLP test results pointed out that heavy metals including manganese, cadmium, lead, and chromium could successfully entrap in the cement matrix. The compressive and flexural strengths as mechanical characteristics of mortar mixtures were determined at 3, 7, 28, 90, and 180 curing days. Moreover, the mortar specimens were immersed in 3% sulfuric acid (H2SO4) for 60 and 150 days. Durability results showed that the H2SO4 attack resistance of binary cement mortars containing 4% coal waste binders performed better than the plain mortar. Based on the scanning electron microscopy (SEM) images, ettringite was found as the main hydration product of binary cement after 28 days; however, the existence of calcium silicate hydrate (CSH) and calcium hydroxide (Ca(OH)2) in the cement matrix after 90 days explains the more compact microstructure attained by using coal waste as cement replacement materials compared to control mixtures.

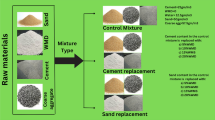

Graphic abstract

Similar content being viewed by others

References

Abdel-Gawwad H A, Metwally K A, Tawfik T A, Mohammed M S, Hassan H S, Heikal M, El-Kattan I M (2021) Evaluating the performance of high volume fly ash-blended-cement mortar individually containing nano-and ultrafine micro-magnesia. J Build Eng: 102129

Adhikari K, Mal U (2021) Evaluation of contamination of manganese in groundwater from overburden dumps of Lower Gondwana coal mines. Environ Earth Sci 80(1):1–15

Argane R, Benzaazoua M, Hakkou R, Bouamrane A (2016) A comparative study on the practical use of low sulfide base-metal tailings as aggregates for rendering and masonry mortars. J Cleaner pro 112:914–925

Ardejani FD, Shokri BJ, Bagheri M, Soleimani E (2010) Investigation of pyrite oxidation and acid mine drainage characterization associated with Razi active coal mine and coal washing waste dumps in the Azad shahr–Ramian region, northeast Iran. Environ Earth Sci 61(8):1547–1560

Afrakoti M T P, Choobbasti A J, Ghadakpour M, Kutanaei S S (2020) Investigation of the effect of the coal wastes on the mechanical properties of the cement-treated sandy soil. Contr Build Mater 239:117848

Ameli A, Babagoli R, Norouzi N, Jalali F, Mamaghani F P (2020) Laboratory evaluation of the effect of coal waste ash (CWA) and rice husk ash (RHA) on performance of asphalt mastics and Stone matrix asphalt (SMA) mixture. Contr Build Mater 36:117557

Avila-López U, Almanza-Robles JM, Escalante-García JI (2015) Investigation of novel waste glass and limestone binders using statistical methods. Contr Build Mater 82:296–303

Chen MC, Wang K, Xie L (2013) Deterioration mechanism of cementitious materials under acid rain attack. Eng Fail Anal 27:272–285

Dos Santos CR, Do Amaral Filho JR, Tubino RMC, Schneider IAH (2013) Use of coal waste as fine aggregates in concrete paving blocks. Geomater 03:54–59

Disfani MM, Arulrajah A, Bo MW, Sivakugan N (2012) Environmental risks of using recycled crushed glass in road applications. J Cleaner Prod 20(1):170–179

Duan P, Yan C, Zhou W, Luo W, Shen C (2015) An investigation of the microstructure and durability of a fluidized bed fly ash–metakaolin geopolymer after heat and acid exposure. Mater Des 74:125–137

Engbert A, Plank J (2021) Impact of sand and filler materials on the hydration behavior of calcium aluminate cement. J Amer Ceramic Soc 104(2):1067–1075

Fakhri M, Saberi KF (2016) The effect of waste rubber particles and silica fume on the mechanical properties of Roller Compacted Concrete Pavement. J Cleaner Prod 129:521–530

Ferraz E, Andrejkovičová S, Velosa AL, Silva AS, Rocha F (2014) Synthetic zeolite pellets incorporated to air lime–metakaolin mortars: Mechanical properties. Contr Build Mater 69:243–252

Filimonov AM, Rogozin OA, Firsov DG, Kuzminova YO, Sergeev SN, Zhilyaev AP, Evlashin SA (2021) Hardening of additive manufactured 316l stainless steel by using bimodal powder containing nanoscale fraction. Mater 14(1):115

Frías M, De Rojas MS, García R, Valdés AJ, Medina C (2012) Effect of activated coal mining wastes on the properties of blended cement. Cem Concr Compos 34(5):678–683

Gouran A, Aghel B, Nasirmanesh F (2021) Biodiesel production from waste cooking oil using wheat bran ash as a sustainable biomass. Fuel 295:120542

Hesami S, Modarres A, Soltaninejad M, Madani H (2016) Mechanical properties of roller compacted concrete pavement containing coal waste and limestone powder as partial replacements of cement. Contr Build Mater 111:625–636

Karimaei M, Dabbaghi F, Sadeghi-Nik A, Dehestani M (2020) Mechanical performance of green concrete produced with untreated coal waste aggregates. Contr Build Mater 233:117264

Karimipour A (2020) Effect of untreated coal waste as fine and coarse aggregates replacement on the properties of steel and polypropylene fibres reinforced concrete. Mech Mater 150:103592

Khan H A, Castel A, Khan M S, Mahmood A H (2019) Durability of calcium aluminate and sulphate resistant Portland cement based mortars in aggressive sewer environment and sulfuric acid. Cem Concr Res 124:105852

Khater HM, Ghareib M (2020) Optimization of geopolymer mortar incorporating heavy metals in producing dense hybrid composites. J Build Eng 32:01684

Kočí V, Maděra J, Jerman M, Žumár J, Koňáková D, Čáchová M, Černý R (2016) Application of waste ceramic dust as a ready-to-use replacement of cement in lime-cement plasters: an environmental-friendly and energy-efficient solution. Clean Technol Environ Policy 18(6):1725–1733

Li SS, Liu H, Bharath MS, Zhang SX, Cheng X (2020a) Variation in the sulfate attack resistance of iron rich-phosphoaluminate cement with mineral admixtures subjected to a Na2SO4 solution. Constr Build Mater 230:116817

Li X, Ma Y, Shen X, Zhong Y, Li Y (2020b) Study of hydration and microstructure of mortar containing coral sand powder blended with SCMs. Mater 13(19):4248

Liu R, Yang Y, Zhao X, Pang B (2021) Quantitative phase analysis and microstructural characterization of Portland cement blends with diatomite waste using the Rietveld method. J Mater Sci 56(2):1242–1254

Mejia-Ballesteros JE, Savastano H Jr, Fiorelli J, Rojas MF (2019) Effect of mineral additions on the microstructure and properties of blended cement matrices for fibre-cement applications. Cem Con Comp 98:49–60

Moayedi H, Aghel B, Nguyen H, Rashid ASA (2019) Applications of rice husk ash as green and sustainable biomass. J Cleaner Prod 237:117851

Modarres A, Hesami S, Soltaninejad M, Madani H (2018) Application of coal waste in sustainable roller compacted concrete pavement-environmental and technical assessment. Int J Pave Eng 19(8):748–761

Nguyen H, Kunther W, Gijbels K, Samyn P, Carvelli V, Illikainen M, Kinnunen P (2021) On the retardation mechanisms of citric acid in ettringite-based binders. Cem Con Res 140:106315

Parghi A, Shahria Alam M (2016) Effects of curing regimes on the mechanical properties and durability of polymer-modified mortars–an experimental investigation. J Sus Cem-Based Mater 5(5):324–347

Pitarch AM, Reig L, Tomás AE, Forcada G, Soriano L, Borrachero MV, Monzó JM (2021) Pozzolanic activity of tiles, bricks and ceramic sanitary-ware in eco-friendly Portland blended cements. J Cleaner Prod 279:123713

Sakir S, Raman SN, Safiuddin M, Kaish ABM, Mutalib AA (2020) Utilization of by-products and wastes as supplementary cementitious materials in structural mortar for sustainable construction. Sustain 12(9):3888

Sata V, Sathonsaowaphak A, Chindaprasirt P (2012) Resistance of lignite bottom ash geopolymer mortar to sulfate and sulfuric acid attack. Cem Con Comp 34(5):700–708

Scrivener K L, Young J F (Eds.) (1997) Mechanisms of chemical degradation of cement-based systems. CRC Press

Shamsaei M, Khafajeh R, Aghayan I (2019) Laboratory evaluation of the mechanical properties of roller compacted concrete pavement containing ceramic and coal waste powders. Clean Technol Environ Policy 21(3):707–716

Shirin MS, Islam MM, Kumruzzaman M (2020) Stabilization of coal mine waste and its practical application as a road subgrade. Amer J Traf Trans Eng 5(5):51–56

Statista. (2021) [online] Available at: https://www.statista.com/statistics/263980/forecast-of-global-carbon-dioxide-emissions/

Taha Y, Benzaazoua M, Edahbi M, Mansori M, Hakkou R (2018) Leaching and geochemical behavior of fired bricks containing coal wastes. J Environ Manag 209:227–235

Tironi A, Trezza MA, Scian AN, Irassar EF (2013) Assessment of pozzolanic activity of different calcined clays. Cem Conc Comp 37:319–327

USEPA, (1992) Method 1311 – toxicity characteristic leaching procedure [online]. US EPA. Available from: http://www.epa.gov/sw-846/pdfs/1311.pdf

USEPA (2018) Greenhouse Gas Emissions [online]. US EPA. Available from: https://www.epa.gov/ghgemissions/overview-greenhouse-gases

Usman J, Sam AM (2017) Acid resistance of palm oil fuel ash and metakaolin ternary blend cement mortar. Sustain Environ Res 27(4):181–187

Vafaei M, Allahverdi A, Dong P, Bassim N, Mahinroosta M (2021) Resistance of red clay brick waste/phosphorus slag-based geopolymer mortar to acid solutions of mild concentration. J Build Eng 34:102066

Wang R, Wang PM, Li XG (2005) Physical and mechanical properties of styrene–butadiene rubber emulsion modified cement mortars. Cem Con Res 35(5):900–906

Yaghubpour A, Hakkakzadeh B (2010) Environmental effects of the Zarand coal mines and coal washing plant in Kerman Province, Southeast Iran. Mineral Mag

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Soltaninejad, M., Soltaninejad, M., K, F.S. et al. Environmental-friendly mortar produced with treated and untreated coal wastes as cement replacement materials. Clean Techn Environ Policy 23, 2843–2860 (2021). https://doi.org/10.1007/s10098-021-02204-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-021-02204-x