Abstract

The electrochemical properties of the passive film formed on surface-modified 301 stainless steel (SS) were examined in the present study. After surface treatment, the passive film analysis was carried out via X-ray photoelectron spectroscopy (XPS) technique, while the surface microstructure of the samples was examined by scanning electron microscope analysis. With Cr 2p, Fe 2p, O 1s, Ni 2p, and C 1s as the principal spectra in the passive film, the Cr 2p spectrum shows two major peaks at 574.3 eV and 583.8 eV corresponding to Cr 2p3/2 (Cr in the metallic state) and Cr 2p1/2, respectively. The Fe 2p spectrum has two major peaks of 707.1 and 720.1 eV corresponding to Fe 2p3/2 (Fe in metallic state) and Fe 2p1/2 peaks, respectively, while the binding energies of 853.3 and 875.1 eV for the Ni 2p spectrum correspond to nickel in the metallic state. The XPS spectra revealed a higher percentage of Cr in the passive film of the treated 301 SS when compared with other elements. From the polarization results, the treated 301 SS possessed a lower corrosion current density of 1.401 mA/cm2 and higher corrosion potential of − 0.085 V.

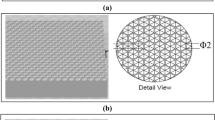

Graphical abstract

Similar content being viewed by others

Data availability

The data that support the findings of this study are available on request from the author.

References

Y. Lu, X. Liu, L. Wang, J. Yang, H. Xu, J. Ocean. Limnol. (2022). https://doi.org/10.1007/s00343-021-1168-9

Y. Lin, J. Lu, L. Wang, T. Xu, Q. Xue, Acta Mater. 54, 5599 (2006)

M.A.M. Ibrahim, S.S. Abd El Rehim, M.M. Hamza, Mater. Chem. Phys. 115, 80–85 (2009)

N.R. Tao, M.L. Sui, J. Lu, K. Lu, Nanostruct. Mater 11, 433 (1999)

X. Wu, N. Tao, Y. Hong, B. Xu, J. Lu, K. Lu, Acta Mater. 50, 2075 (2002)

Z.C. Wang, F. Di-Franco, A. Seyeux, S. Zanna, V. Maurice, P. Marcus, J. Electrochem. Soc. 166, C3376–C3388 (2019)

C. Dang, T.O. Olugbade, S. Fan, H. Zhang, L.L. Gao, J. Li, Y. Lu, Vacuum 156, 310–316 (2018)

C. Dang, Y. Yao, T.O. Olugbade, L. Li, L. Wang, Thin Solid Films 653, 107–112 (2018)

H. Zu, K. Chau, T.O. Olugbade, L. Pan, D.H. Chow, L. Huang, L. Zheng, W. Tong, X. Li, Z. Chen, X. He, R. Zhang, J. Mi, Y. Li, B. Dai, J. Wang, J. Xu, K. Liu, J. Lu, L. Qin, J. Mater. Sci. Technol. 63, 145–160 (2021)

T.E. Abioye, I.S. Omotehinse, I.O. Oladele, T.O. Olugbade, T.I. Ogedengbe, World J. Eng. 17, 87–96 (2020)

T.E. Abioye, T.O. Olugbade, T.I. Ogedengbe, J. Emerg. Trends Eng. Appl. Sci. 8, 225 (2017)

T.O. Olugbade, O.O. Omoniyi, B.O. Omiyale, J. Inst. Eng. (India): Ser. D 103, 141–147 (2022)

K. Wang, N.R. Tao, G. Liu, J. Lu, K. Lu, Acta. Mater. 54, 5281 (2006)

T. Olugbade, Data Brief 25, 104033 (2019)

T. Balusamy, S. Kumar, T.S.N. Sankara Narayanan, Corros. Sci. 52, 3826–3834 (2010)

T. Balusamy, T.S.N. Sankara Narayanan, K. Ravichandran, I.S. Park, M.H. Lee, Corros. Sci. 74, 332–344 (2013)

T.O. Olugbade, Anal. Lett. 54, 1055–1067 (2021)

T.I. Ogedengbe, T.O. Olugbade, O. Olagunju, Br. J. Appl. Sci. Technol. 10, 1–11 (2015)

N.R. Tao, J. Lu, K. Lu, Mater. Sci. Forum 579, 91–108 (2008)

T.O. Olugbade, J. Lu, Anal. Lett. 52, 2454–2471 (2019)

H.Q. Sun, Y.N. Shi, M.X. Zhang, K. Lu, Acta Mater. 55, 975 (2007)

T.O. Olugbade, J. Lu, Nano Mater. Sci. 2, 3–31 (2020)

T.O. Olugbade, O.T. Ojo, B.O. Omiyale, E.O. Olutomilola, B.J. Olorunfemi, J. Braz. Soc. Mech. Sci. Eng. 43, 421 (2021)

T. Mohammed, T.O. Olugbade, I. Nwankwo, J. Sci. Res. Rep. 10, 1–9 (2016)

T. Olugbade, J. Lu, in Twelfth International Conference on Fatigue Damage of Structural Materials, Cape Cod, Hyannis (2018)

T.O. Olugbade, Corros. Rev. 38, 473–488 (2020)

Z.J. Zheng, Y. Gao, Y. Gui, M. Zhu, Corros. Sci. 54, 60–67 (2012)

T.O. Olugbade, T.E. Abioye, P.K. Farayibi, N.G. Olaiya, B.O. Omiyale, T.I. Ogedengbe, Anal. Lett. 54, 1588–1602 (2021)

H.W. Chang, P.M. Kelly, Y.N. Shi, M.X. Zhang, Surf. Coat. Technol. 206, 3970–3980 (2012)

T.O. Olugbade, B.O. Omiyale, O.T. Ojo, J. Mater. Eng. Perform. 31, 1707–1727 (2022)

T.O. Olugbade, E.O. Olutomilola, B.J. Olorunfemi, Corros. Rev. (2022). https://doi.org/10.1515/corrrev-2021-0072

T. Olugbade, J. Lu, in International Conference on Nanostructured Materials (NANO 2020) Australia, vol. 117 (2020)

T.O. Olugbade, Chem. Afr. 5, 333–340 (2022)

T. Olugbade, C. Liu, J. Lu, Adv. Eng. Mater. 21, 1900125 (2019)

I.S. Zhidkov, A.I. Kukharenko, A.V. Makarov, R.A. Savrai, N.V. Gavrilov, S.O. Cholakh, E.Z. Kurmaevs, Surf. Coat. Technol. 386, 125492 (2020)

N. Chung, Spectroscopy 33, 28–34 (2018)

L. Ma, F. Wiame, V. Maurice, P. Marcus, Corros. Sci. 140, 205–216 (2018)

B. Adrien, D. Thomas, D. Nadège, N. Eric, D. Julien, L. Lydia, B. Christine, Surf. Interfaces 22, 100874 (2021)

S. Detriche, S. Vivegnis, J.F. Vanhumbeeck, A. Felten, P. Louette, F. Renner, J. Delhalle, Z. Mekhalif, J. Electron Spectrosc. Relat. Phenom. 243, 146970 (2020)

R. Natarajan, N. Palaniswamy, M. Natesan, V.S. Muralidharan, Open Corros. J. 2, 114–124 (2009)

Z. Duan, F. Arjmand, L. Zhang, H. Abe, J. Nucl. Sci. Technol. 53, 1435–1446 (2016)

M.S. Qurashi, Y. Cui, J. Wang, N. Dong, J. Bai, Y. Wu, P. Han, Int. J. Electrochem. Sci. 14, 10642–10656 (2019)

Acknowledgments

The author appreciates the support of the Centre for Advanced Structural Materials (CASM), Hong Kong SAR, as regards the SMAT technique.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author reports no conflict of interest.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Olugbade, T.O. Passive film analysis and corrosion study of steel type 301 after mechanical deformation. MRS Advances 7, 886–891 (2022). https://doi.org/10.1557/s43580-022-00327-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43580-022-00327-x