Abstract

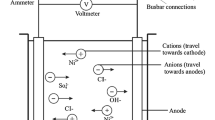

This study reports the influence of surface texturing patterns (circular dimples, hexagonal dimples, and hexagonal spots) on corrosion behaviour, manufactured by µ-plasma additive manufacturing (MPAM) process on Ni45–Ti55 alloy for offshore, food processing, and biomedical applications. Corrosion studies were done by electrochemical potentiodynamic polarization in Hank’s solution (pH value 7.4) and seawater (pH value 8.1). Tafel extrapolation, electrochemical impedance spectroscopy (EIS), and open circuit potential showed a significant difference in corrosion behaviour among the surface textured hexagonal dimples, hexagonal spots, and circular dimple samples. The EIS and Tafel extrapolation in Hank’s solution showed that circular dimples surface textured sample depicted better corrosion resistance potential (Rp) as 55 Ω, corrosion potential (Ecorr) as − 0.56 V, and corrosion current density (icorr) as 0.15 A/cm2, followed by hexagonal dimples and hexagonal spots. The present study indicated advantage of surface texturing on corrosion resistance improvement of Ni45–Ti55 alloy.

Similar content being viewed by others

Data Availability

Authors understand that our manuscript and associated personal data will be shared with Research Square for the delivery of the author dashboard.

References

Vishnoi M, Kumar P, and Murtaza Q, Surf Interfaces 27 (2021) 101463. https://doi.org/10.1016/j.surfin.2021.101463

Zhou Y, Shao T, and Yin L, Trans Indian Inst Met (2024). https://doi.org/10.1007/s12666-023-03245-0

Vignesh G, and Barik D, Trans Indian Inst Met 47 (2022) 565. https://doi.org/10.1007/s40799-022-00570-9

Menci G, Demir A G, Waugh D G, Lawrence J, and Previtali B, Appl Surf Sci 30 (2019) 175. https://doi.org/10.1016/j.apsusc.2019.05.111

Kim B S, Chung W Y, Rhee M, and Lee S, Trans Indian Inst Met 18 (2012) 1023. https://doi.org/10.1007/s12540-012-0483-2

Costa M, Miranda A, Bartolomeu F, et al., J Mater Sci Technol 114 (2022) 120. https://doi.org/10.1016/j.jmst.2021.11.014

Meng R, Deng J, Duan R, Liu Y, and Zhang G, Opt Laser Technol 109 (2019) 401. https://doi.org/10.1016/j.optlastec.2018.08.020

Guzmán-Nogales R, Estupiñán-López F, Gaona-Tiburcio C, Lopez-Botello O E, Ramírez-Rodríguez J G, and Zambrano-Robledo P C, Materials. 14 (2021) 4509. https://doi.org/10.3390/ma14164509

Sun Y, and Haruman E, Corr Sci 53 (2011) 4131. https://doi.org/10.1016/j.corsci.2011.08.021

Loto C A, Popoola A P, Fayomi O S, and Loto R T, Int. J. Electrochem. Sci. 7 (2012) 3787. https://doi.org/10.1016/S1452-3981(23)13997-6

Ahmad S, Sharma H, Agrawal A, and Joshi S S, Trans Indian Inst Met 6 (2021) 775. https://doi.org/10.1007/s41403-021-00244-9

Eisenhauer D, Sai H, Matsui T, Köppel G, Rech B, and Becker C, Opt Exp 26 (2018) 498. https://doi.org/10.1364/OE.26.00A498

Hales T C, Discrete Comput Geom 25 (2001) 1. https://doi.org/10.1007/s004540010071

Triantaphyllou A, Giusca C L, Macaulay G D, Roerig F, Hoebel M, Leach R K, Tomita B, and Milne K A, Surf Topogr: Metrol Prop 3 (2015) 024002. https://doi.org/10.1088/2051-672X/3/2/024002

Arya P K, Kumar P, Negi B S, Jain N K, and Sathiaraj D, J Alloys Compd 984 (2024) 173980. https://doi.org/10.1016/j.jallcom.2024.173980

Li Y H, and Li J H, Trans Indian Inst Met 76 (2023) 945. https://doi.org/10.1007/s12666-022-02803-2

Resnina N, Palani I A, Belyaev S, et al., Trans Indian Inst Met (2023). https://doi.org/10.1007/s12666-023-03193-9

Arya P K, Jain N K, Sathiaraj D, and Patel V, J Mater Res Technol 28 (2024) 3526. https://doi.org/10.1016/j.jmrt.2023.12.271

Rafi H K, Karthik N V, Gong H, Starr T L, and Stucker B E, J Mater Eng Perform 22 (2013) 3872. https://doi.org/10.1007/s11665-013-0658-0

Dai N, Zhang L C, Zhang J, Zhang X, Ni Q, Chen Y, Wu M, and Yang C, Corr Sci 111 (2016) 703. https://doi.org/10.1016/j.corsci.2016.06.009

Moghadas S M, Yeganeh M, Zaree S R, and Eskandari M, Surf Topogr: Metrol Prop 10 (2022) 025012. https://doi.org/10.1088/2051-672X/ac6c42

Zhao C, Bai Y, Zhang Y, Wang X, Xue J, and Wanga H, Mater Des 209 (2021) 109999. https://doi.org/10.1016/j.matdes.2021.109999

Acknowledgements

The research described in this paper was made possible by the resources and facilities of the Additive and Micromanufacturing Lab (AMAL), the Department of Mechanical Engineering at IIT Indore. The authors gratefully acknowledge the laboratory’s support.

Funding

Authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed equally to all aspects of the research and manuscript preparation.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bankar, P.S., Rao, P.K.V., Sawant, M.S. et al. Investigations on Corrosion Behaviour of Surface Texturing on Ni45Ti55 Alloy Manufactured Using µ-Plasma Additive Manufacturing Process. Trans Indian Inst Met (2024). https://doi.org/10.1007/s12666-024-03326-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12666-024-03326-8