Abstract

The functionalization of polymeric matrices through graft polymerization offers various advantages by providing new properties, allowing for additional chemical reactions that the matrix alone could not undergo or that would require drastic chemical conditions to occur. In this work, epoxy groups were incorporated through a graft polymer of poly(glycidyl methacrylate), using a prefunctionalization with peroxide groups in the polytetrafluoroethylene matrix through gamma radiation. These peroxide groups were subsequently used as radical chemical initiators in the graft polymerization reaction of glycidyl methacrylate. The graft polymerization reaction was studied based on the absorbed dose, monomer concentration, reaction time, and temperature.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The modification of polymeric materials has been the subject of study in recent decades as a new way to obtain materials with added value by providing specific properties, such as a physicochemical response to pH or temperature, as well as the introduction of catalytic or reactive sites.[1]

In this regard, various strategies have been developed to obtain new materials from polymeric matrices with low chemical reactivity. These methodologies include the use of energy sources such as plasma,[2] ultraviolet light,[3] and gamma rays,[4] capable of promoting the formation of free radicals or chemical functional groups such as hydroperoxides and peroxides in the presence of oxygen.[5] These groups act as chemical initiators in graft polymerization reactions since these act as a stable radical source, with hydroperoxides and peroxides being advantageous due to their greater chemical stability against free radicals generated directly, allowing them to be stored for later use.[6]

The use of high energy sources to promote graft polymerization reactions has advantages compared to those using chemical initiators, as the resulting polymers have a chemical composition without the presence of residues from chemical initiators. These residues could modify the final properties of the graft copolymer or trigger side effects when used in medical devices, as is the case with reactions using cerium (Ce4+), silver (Ag+), iron (Fe2+, Fe3+), etc. as a promoter of free radicals.[7]

In this context, PTFE has been widely used and is of great interest in various sectors such as medical, engineering, and the food industry due to its physicochemical and mechanical properties, including low chemical reactivity, high hydrophobicity, and notable resistance to abrasion and tensile strength.[8,9,10] Despite its outstanding properties, it can be modified by graft polymers capable of providing new physicochemical properties.[11,12] This allows for improving biocompatibility,[13] increasing hydrophilicity,[14] or adding value through subsequent chemical reactions aimed at incorporating specific properties such as enzymatic activity[15] or the presence of chelating groups[16] capable of removing heavy metal ions.

In this sense, PTFE has been surface modified with graft polymers and employed to load zinc oxide and silver nanoparticles or provide stimulus–response properties (pH- and thermo-responsiveness) by grafting polymers as 2-(diethylamino)ethyl methacrylate (DEAEMA), acrylic acid (AAc), N-isopropylacrylamide (NIPAAm), methyl methacrylate (MMA), and N-vinylimidazole (NVI).[17] From this perspective, PTFE has undergone surface modifications by introducing oxygenated hydrocarbon species using plasma treatment to enhance its hydrophilicity and thereby improve its hemocompatibility. Similarly, gamma radiation was employed to modify PTFE with hydroxyethyl methacrylate (HEMA), facilitating the loading and release of antimicrobial agents. This modification, accompanied by the alteration in surface hydrophilicity, has enabled the PTFE matrix to adsorb proteins, thereby enhancing its biocompatibility and expanding its potential applications, such as implants in the human body. These instances of surface modification highlight the capability to impart new properties to the PTFE matrix, which it would not naturally possess. For this purpose, glycidyl methacrylate has been used as a graft copolymer in various polymeric matrices, such as silicone rubber (SR),[18] poly(lactic) acid (PLA),[19] poly(propylene) (PP),[20] poly(vinylidene fluorine) (PVDF),[21] among others, to add value to the polymeric matrix through subsequent chemical reactions by opening the epoxy units under mild reaction conditions using nucleophilic reagents (Fig. 1),[22] incorporating new chemical agents through covalent bonds as a coating, and ensuring material integrity[6,15,23,24]

The objective of this study was to graft PGMA onto a PTFE matrix by forming hydroperoxide and peroxide groups, which were then used as chemical initiators in a "grafting from" type graft polymerization. Graft polymerization was studied in terms of absorbed dose, GMA concentration, reaction time, and temperature. The new graft materials were characterized by infrared spectroscopy (FTIR-ATR), thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), static contact angle, and swelling tests.

Materials and methods

Polytetrafluoroethylene (PTFE) films with a thickness of 100 µm were purchased from Goodfellow (England). These films were cut into pieces measuring 1 × 5 cm, then washed with methanol for 24 h and dried under vacuum until a constant weight was achieved. Glycidyl methacrylate (GMA), obtained from Sigma Aldrich, was purified via vacuum distillation. All solvents, including methanol, ethanol, dimethyl sulfoxide (DSMO), dimethylformamide (DMF), and toluene, were procured from J.T. Baker and used as received.

Synthesis of PTFE-g-GMA using the oxidative pre-irradiation method

PTFE films measuring 1 × 5 cm were placed inside an ampoule and exposed to gamma rays from a 60Co source at various radiation doses in the presence of oxygen from the air. Subsequently, 7 ml of GMA at different concentrations were introduced into the ampoule using solvents such as DMF, DMSO, and toluene. The air in the samples was eliminated through repeated freeze–thaw cycles using liquid nitrogen. The ampoule was then sealed and heated to temperatures ranging from 40 to 80°C for durations of 6 to 24 h. Following this, the samples were thoroughly washed with methanol to eliminate any homopolymer formed during the graft polymerization reaction. Finally, they were dried in a vacuum oven at 40ºC until a constant weight was achieved.

The graft percentage was calculated using the following equation (Eq. 1):

where \(\text{Wo}\) and \(\text{Wg}\), correspond to the initial and final weights of the samples.

Characterization

Structural characterization

Dry samples of both PTFE and PTFE-g-GMA films were examined using a Perkin-Elmer Spectrum 100 spectrometer (Norwalk, CT, USA) with 16 scans. The spectra were recorded over the range of 4000 to 650 cm−1. Data processing was carried out using the native software.

Thermal characterization

Samples of both PTFE and PTFE-g-GMA films were analyzed using TGA Q50 and DCS 2010 TA instruments from New Castle, DE, USA. Thermal properties were recorded over a temperature range of 25 to 800ºC. Thermal transitions within the range of 25 to 400ºC were investigated using a heating rate of 10ºC min−1 under a nitrogen flow of 100 cm3 min−1.

Contact angle and swelling degree

The contact angle of films with varying degrees of grafting was measured using a DSA 100 goniometer from Krüss GmbH, Germany. Distilled water droplets were placed at different locations on the surface of the dry, flat film. The contact angle formed was then measured by the native software at 0, 1, 5, and 10 min at room temperature.

The swelling properties of the films were evaluated in distilled water at 25ºC. The samples were initially dried until a constant weight was achieved, then introduced into distilled water, and their weights were recorded at established time intervals. Excess water was gently removed using a paddle and towel paper before weighing the samples. The swelling percentage was determined using the equation (Eq. 2):

where \(\text{Ws}\) and \(\text{Wd}\) are the weights of the swollen and dried films, respectively.

Results and discussion

Grafting of PTFE-g-GMA

The PTFE films were initially exposed to a gamma radiation source in the presence of air at different absorbed doses, generating free radicals through the degradation of the matrix. These free radicals reacted with the oxygen from the air, forming peroxides and hydroperoxides, which are chemically stable compared to free radicals and can be used as radical initiators in graft polymerization reactions, controlling the polymerization by variables such as the type of solvent, temperature, reaction time, and monomer concentration.

The hydroperoxides and peroxides in the PTFE film originate from the homolytic cleavage of covalent bonds within the polymer structure, which can also promote the formation of double bonds. However, based on the energies of C–C (370–420 kJ/mol) and C–F (480–520 kJ/mol) bonds,[25] the formation of radicals predominantly occurs in C–C bonds.[26] This facilitates a greater generation of peroxides and hydroperoxides from these bonds when free radicals react with oxygen and moisture in the air,[25] as illustrated in Fig. 2(a).

(a) Proposed PGMA graft mechanism on PTFE promoted by pre-irradiation oxidative, (b) effect of the solvent on the graft degree, (c) graft degree versus ration time, (d) effect of GMA concentration on the graft degree, (e) graft percentage versus absorbed dose, and (f) effect of temperature reaction on the graft degree.

The graft polymerization reaction was initially explored using both polar and non-polar solvents, including DMF, DMSO, and toluene. Initial findings regarding the graft degree revealed a more favorable outcome when toluene was employed as the solvent. This improvement was attributed to better monomer diffusion within the medium and enhanced interaction between the GMA monomer and the PTFE film. A graft degree of up to 41% was achieved with a monomer concentration of 30 v. %, in contrast to the polymerization conducted with DMF as the solvent, which exhibited a lower graft degree of up to 20.9%. This value is significantly lower than that obtained with toluene and DMSO, as depicted in Fig. 2(b). Consequently, toluene was selected as the preferred solvent for conducting the graft polymerization, with the investigation of variables such as absorbed doses, monomer concentration, time, and temperature reaction. The impact of these variables on the graft degree was substantial. In this context, the reaction time increased the graft percentage, reaching up to 262.6%. This rise in graft degree was attributed to the lengthening of the polymer graft chain. In this sense, the reaction time doesn’t create new chemical active sites (peroxides and hydroperoxides) but facilitates the growth of the polymer graft chain of PGMA [Fig. 2(c)]. Additionally, high graft degrees led to the loss of structural properties in the film.

On the other hand, the impact of monomer concentration on the graft degree yielded contrasting results. It demonstrated an initial rise in the graft degree, followed by a decline at higher monomer concentrations. The maximum degree reached was 124.8% with a monomer concentration of 40 v. %, decreasing to 29.6% at 50 v. %. This behavior was attributed to the self-polymerization of GMA monomer, as indicated by the graph in Fig. 2(d), which becomes benefited at monomer concentrations above 40 v. %. Other variables, such as absorbed doses, exhibited a similar trend, increasing the graft degree and reaching a graft percentage of 43.2% with an absorbed dose of 35 kGy. However, in this case, the increase in graft degrees is attributed to the high concentration of reactive sites (peroxides and hydroperoxides) provided by the absorbed dose [Fig. 2(e)].

Similarly, the reaction temperature showed an increase in the graft degree of PGMA [Fig. 2(f)]. This observed rise in the graft degree is caused by the rapid formation of free radicals as the temperature increases, leading to a swift formation of the graft polymer. Therefore, the increase in the reaction temperature only enhances the speed of graft polymerization, reaching the maximum polymerization rate at 70°C and remaining similar at higher temperatures. This suggests that the maximum reaction speed is attained starting from 70°C.

Characterization

Infrared spectroscopy (FTIR-ATR)

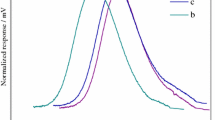

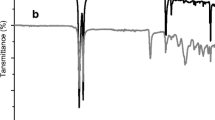

In the spectra of Fig. 3(a), the stretching of the C–H bond is observed at ~2999 cm−1, present in both PGMA and PTFE-g-GMA with a grafting of 71%. The absorption band at 1720 cm−1 represents the stretching of the carbonyl group C=O, standing out in the three grafted PTFE films and showing greater intensity in relation to the grafting degree. At 1446 cm−1, the vibration of the C-H bond in the methylene group -CH2- is associated. The band at 1254 cm−1 corresponds to the epoxy ring of PGMA and ester groups. The range from 1145 to 842 cm−1 coincides with the asymmetric and symmetric stretching of epoxy ring, respectively, of the C–O–C bond; and shows a bend at 757 cm−1 in the same bond.[27] Finally, the PTFE spectrum only shows vibrations associated with the C-F bond at 1201 and 1145 cm−1.[28]

(a) FTIR-ATR spectra of PTFE, PTFE-g-GMA films with different percentages of graft, and PGMA homopolymer, (b) DSC and (c) TGA of the PTFE, PTFE-g-GMA films with different percentages of graft and PGMA homopolymer, (d) Contact angle as a function of time at room temperature, (e) percentage of swelling as a function of immersion time in distilled water at room temperature.

In the three spectra of PTFE-g-GMA, the signals corresponding to the vibration modes of both the PTFE matrix and the PGMA grafted polymer are distinguished, demonstrating that the matrix was functionalized by incorporating the epoxide functional groups of PGMA.

Thermal characterization

The DSC studies of the samples (PTFE and PTFE-g-GMA) presented in Fig. 3(b) were evaluated in the range between room temperature and 400°C, with a temperature ramp rate of 10°C min−1. The homopolymer shows a glass transition temperature (Tg) at 65°C,[29] additionally, the range from 200 to 350°C is attributed to the thermal decomposition of the PGMA. On the other hand, PTFE exhibits a thermal transition at 330°C, corresponding to its melting temperature (Tm) reported in the literature as 327°C.

For the three films (PTFE-g-GMA, 11%, 26%, 71%), the presence of grafting is demonstrated by obtaining degradation temperatures within the range described for PGMA (250–300°C). Furthermore, the presence of PGMA does not affect the melting temperature of PTFE, as even with a grafting of 71%, the temperature is similar to 330°C, indicating that the grafting was restricted to the surface of the material. Moreover, by exhibiting both transitions, the grafts adopt the characteristics of a semicrystalline or amorphous polymer, and the Tg of the PGMA graft decreases proportionally with the reduction in graft percentage.

Thermogravimetric studies (TGA) revealed a 10% mass loss for the homopolymer at 296°C, in contrast to 10% at 541°C for PTFE [Fig. 3(c)]. The higher thermal stability exhibited by PTFE is attributed to the highly stable C–F bonds in the material. The PTFE film shows a single decomposition temperature (Td) at 579°C.[30] In contrast, the homopolymer exhibits two decomposition stages: the first at 254°C, with a mass loss of nearly 5%, and the second at 372°C, with a 60% weight loss. The first decomposition is attributed to the volatile products formed throughout depolymerization of PGMA, followed by the decomposition of the ester along with the cleavage of the main chain.

Regarding the PTFE-g-GMA films, a trend was observed in which, as the grafting percentage increases, the decomposition temperature decreases. Therefore, the grafting degree of PGMA affects the thermal stability of the PTFE-g-GMA film. However, the thermal stability of the PGMA graft is superior compared to the PGMA homopolymer. This increased stability is attributed to the covalent bonds of PGMA with the PTFE matrix, which has a higher decomposition temperature, with the exception of the PTFE-g-GMA film at 71%, as shown in Table I. In this film, a 10% weight loss is observed, similar to that of the homopolymer. However, as the grafting degree decreases, so does the temperature, showing a behavior similar to that of PTFE.

Contact angle and swelling

The contact angle was evaluated on PTFE-g-GMA films with graft percentages of 26% and 71%, and compared with the PTFE film as a reference, considered a hydrophobic material according to the literature, with a contact angle of 110° and a surface energy of 19 dyn/cm. These background details align with the results obtained, as the PTFE film showed an average contact angle of 103.1°. On the other hand, the PTFE-g-GMA film with a graft of 26% presented a contact angle of 90°, indicating a decrease in hydrophobicity, and the film with a graft of 71% showed a hydrophilic character with a contact angle of 74.6° [Fig. 3(d)].

Additionally, the contact angle of the samples was recorded at different times, where no significant change was observed for the PTFE film. These results contrast with the PTFE-g-GMA films, which showed a decrease in the contact angle over time, with an average difference between the initial value of 11.5° and 12.9° for graft percentages of 26% and 71%, respectively, at a time of 10 min. These results suggest that modified PTFE films do not maintain a hydrophobic character and tend to become wetter over time.

The swelling tests allowed for a detailed examination of the affinity of the new materials for water, a crucial factor in the biocompatibility of materials intended for medical purposes. The PTFE-g-GMA films were immersed in distilled water at room temperature, showing an increase in their degree of swelling until reaching a maximum swelling value when their water absorption capacity was exhausted.

Figure 3(e) illustrates the swelling kinetics of the films, showing an increase with the increase in the degree of PGMA grafting. This is because the PTFE matrix is hydrophobic, and its modification reduces its repulsion to water. The PTFE-g-GMA film with a graft of 11% exhibited a low swelling percentage, while films with grafts of 26% and 71% showed a more notable change, absorbing most of the water during the first 2 h of immersion and reaching equilibrium within 3 h. Although, in general, low swelling percentages were obtained, the film with the highest graft, PTFE-g-GMA at 71% of graft, reaches a swelling limit of 3.55%, close to that of PGMA, which is 3.74%.

Conclusion

The graft copolymerization of PGMA onto PTFE films was successfully executed using the oxidative pre-irradiation method. Precise control of the graft percentage was achieved by manipulating various factors, including the absorbed dose, monomer concentration, reaction time, and temperature, resulting in a graft percentage ranging from 10 to 241%. These factors not only governed the graft percentage but also enabled control over the formation of homopolymer and matrix degradation. Furthermore, thermal studies demonstrated that the graft polymerization was carried out superficially on the PTFE film, exhibiting the thermal transitions and matrix degradation without considerable changes as well as the PGMA graft.

The modification of PTFE with PGMA (PTFE-g-GMA) induced notable alterations in the contact angle and swelling properties of the matrix, changing from hydrophobic to hydrophilic. This transformation was evident in the initial average contact angle, which changed from 103.3° to 61.5° within 10 mins, with a graft percentage of 71% and maximum swelling of 3.5%. In conclusion, these results pave the way for subsequent chemical modifications in a coating form, enhancing the material with added value and a hydrophilic character, a crucial aspect for materials with potential medical applications.

Data availability

Not applicable.

References

S.K. Nemani, R.K. Annavarapu, B. Mohammadian, A. Raiyan, J. Heil, Md.A. Haque, A. Abdelaal, H. Sojoudi, Surface modification of polymers: methods and applications. Adv. Mater. Inter. 5, 1801247 (2018). https://doi.org/10.1002/admi.201801247

E.M. Liston, L. Martinu, M.R. Wertheimer, Plasma surface modification of polymers for improved adhesion: a critical review. J. Adhes. Sci. Technol. 7, 1091–1127 (1993). https://doi.org/10.1163/156856193X00600

I. Ul Ahad, A. Bartnik, H. Fiedorowicz, J. Kostecki, B. Korczyc, T. Ciach, D. Brabazon, Surface modification of polymers for biocompatibility via exposure to extreme ultraviolet radiation. J. Biomed. Mater. Res. 102, 3298–3310 (2014). https://doi.org/10.1002/jbm.a.34958

A. Ramos-Ballesteros, V.H. Pino-Ramos, F. López-Saucedo, G.G. Flores-Rojas, E. Bucio, γ-rays and ions irradiation, in Surface modification of polymers. ed. by J. Pinson, D. Thiry (Wiley, Hoboken, 2019), pp.185–209

A. Chapiro, Radiation induced grafting. Radiat. Phys. Chem. 1977(9), 55–67 (1977). https://doi.org/10.1016/0146-5724(77)90072-3

G.G. Flores-Rojas, F. López-Saucedo, J.E. López-Barriguete, T. Isoshima, M. Luna-Straffon, E. Bucio, Polypropylene films modified by grafting-from of ethylene glycol dimethacrylate/glycidyl methacrylate using γ-rays and antimicrobial biofunctionalization by schiff bases. MRS Commun. 8, 168–177 (2018). https://doi.org/10.1557/mrc.2018.14

A. Bhattacharya, Grafting: a versatile means to modify polymerstechniques, factors and applications. Prog. Polym. Sci. 29, 767–814 (2004). https://doi.org/10.1016/j.progpolymsci.2004.05.002

E. Dhanumalayan, G.M. Joshi, Performance properties and applications of polytetrafluoroethylene (PTFE)—a review. Adv. Compos. Hybrid Mater. 1, 247–268 (2018). https://doi.org/10.1007/s42114-018-0023-8

S. Reichman, A. Ulus, E. Peled, PTFE-based solid polymer electrolyte membrane for high-temperature fuel cell applications. J. Electrochem. Soc. 154, B327 (2007). https://doi.org/10.1149/1.2429046

S.K. Biswas, K. Vijayan, Friction and wear of PTFE — a review. Wear 158, 193–211 (1992). https://doi.org/10.1016/0043-1648(92)90039-B

C. Wang, J.-R. Chen, Studies on surface graft polymerization of acrylic acid onto PTFE film by remote argon plasma initiation. Appl. Surf. Sci. 253, 4599–4606 (2007). https://doi.org/10.1016/j.apsusc.2006.10.014

J. Chen, M. Asano, T. Yamaki, M. Yoshida, Preparation of sulfonated crosslinked PTFE–poly(Alkyl Vinyl Ether) membranes for polymer electrolyte membrane fuel cells by radiation processing. J. Membr. Sci. (2005). https://doi.org/10.1016/j.memsci.2005.02.005

T. Chandy, G.S. Das, R.F. Wilson, G.H.R. Rao, Use of plasma glow for surface-engineering biomolecules to enhance bloodcompatibility of dacron and PTFE vascular prosthesis. Biomaterials 21, 699–712 (2000). https://doi.org/10.1016/S0142-9612(99)00231-8

H. Song, H. Yu, L. Zhu, L. Xue, D. Wu, H. Chen, Durable hydrophilic surface modification for PTFE hollow fiber membranes. React. Funct. Polym. 114, 110–117 (2017). https://doi.org/10.1016/j.reactfunctpolym.2017.03.010

G.G. Flores-Rojas, V.H. Pino-Ramos, F. López-Saucedo, A. Concheiro, C. Alvarez-Lorenzo, E. Bucio, Improved covalent immobilization of lysozyme on silicone rubber-films grafted with poly(ethylene glycol dimethacrylate-co-glycidylmethacrylate). Eur. Polym. J. 95, 27–40 (2017). https://doi.org/10.1016/j.eurpolymj.2017.07.040

H. Yoo, S.-Y. Kwak, Surface functionalization of PTFE membranes with hyperbranched poly(amidoamine) for the removal of Cu2+ ions from aqueous solution. J. Membr. Sci. 448, 125–134 (2013). https://doi.org/10.1016/j.memsci.2013.07.052

F. López-Saucedo, G.G. Flores-Rojas, B. Magariños, A. Concheiro, C. Alvarez-Lorenzo, E. Bucio, Radiation grafting of poly(methyl methacrylate) and poly(vinylimidazole) onto polytetrafluoroethylene films and silver immobilization for antimicrobial performance. Appl. Surf. Sci. 473, 951–959 (2019). https://doi.org/10.1016/j.apsusc.2018.12.229

G.G. Flores-Rojas, E. Bucio, Radiation-grafting of ethylene glycol dimethacrylate (EGDMA) and glycidyl methacrylate (GMA) onto silicone rubber. Radiat. Phys. Chem. 127, 21–26 (2016). https://doi.org/10.1016/j.radphyschem.2016.05.015

W. Yang, F. Dominici, E. Fortunati, J.M. Kenny, D. Puglia, Melt free radical grafting of glycidyl methacrylate (GMA) onto fully biodegradable poly(lactic) acid films: effect of cellulose nanocrystals and a masterbatch process. RSC Adv. 5, 32350–32357 (2015). https://doi.org/10.1039/C5RA00894H

O.M. Jazani, H. Rastin, K. Formela, A. Hejna, M. Shahbazi, B. Farkiani, M.R. Saeb, An investigation on the role of GMA grafting degree on the efficiency of PET/PP-g-GMA reactive blending: morphology and mechanical properties. Polym. Bull. 74, 4483–4497 (2017). https://doi.org/10.1007/s00289-017-1962-x

S.J. Lim, I.H. Shin, Graft copolymerization of GMA and EDMA on PVDF to hydrophilic surface modification by electron beam irradiation. Nucl. Eng. Technol. 52, 373–380 (2020). https://doi.org/10.1016/j.net.2019.07.018

M. Fallah-Mehrjardi, A.R. Kiasat, K. Niknam, Nucleophilic ring-opening of epoxides: trends in β-substituted alcohols synthesis. J IRAN CHEM SOC 15, 2033–2081 (2018). https://doi.org/10.1007/s13738-018-1400-5

S. Kiyohara, M. Sasaki, K. Saito, K. Sugita, T. Sugo, Amino acid addition to epoxy-group-containing polymer chain grafted onto a porous membrane. J. Membr. Sci. 109, 87–92 (1996). https://doi.org/10.1016/0376-7388(95)00186-7

E.M. Muzammil, A. Khan, M.C. Stuparu, Post-polymerization modification reactions of poly(glycidyl methacrylate)s. RSC Adv. 7, 55874–55884 (2017). https://doi.org/10.1039/C7RA11093F

R. Li, G. Wu, Y. Hao, J. Peng, M. Zhai, Radiation degradation or modification of poly(Tetrafluoroethylene) and natural polymers, in radiation technology for advanced materials. (Elsevier, Amsterdam, 2019), pp.141–182

A. Oshima, H. Horiuchi, A. Nakamura, S. Kobayashi, A. Terui, A. Mino, R. Shimura, M. Washio, Trapped radical behavior of electron beam irradiated polytetrafluoroethylene fine powder at various temperatures. Sci. Rep. 11, 10907 (2021). https://doi.org/10.1038/s41598-021-90462-6

T. Çaykara, F. Çakar, S. Demirci, A new type of poly(glycidyl methacrylate) microbeads with surface grafted iminodiacetic acid: synthesis and characterization. Polym. Bull. 61, 311–318 (2008). https://doi.org/10.1007/s00289-008-0958-y

H. Wang, Y. Wen, H. Peng, C. Zheng, Y. Li, S. Wang, S. Sun, X. Xie, X. Zhou, Grafting polytetrafluoroethylene micropowder via in situ electron beam irradiation-induced polymerization. Polymers 10, 503 (2018). https://doi.org/10.3390/polym10050503

Y. Miyashita, Y. Yamada, N. Kimura, H. Suzuki, M. Iwata, Y. Nishio, Phase structure of chitin/poly(glycidyl methacrylate) composites synthesized by a solution coagulation/bulk polymerization method. Polymer 38, 6181–6187 (1997). https://doi.org/10.1016/S0032-3861(97)00174-2

A.N. García, N. Viciano, R. Font, Products obtained in the fuel-rich combustion of PTFE at high temperature. J. Anal. Appl. Pyrol. 80, 85–91 (2007). https://doi.org/10.1016/j.jaap.2007.01.004

Acknowledgments

Thanks to M. Sc. G. Cedillo from the Materials Research Institute, UNAM, Mr. M. Cruz-Villafañe, Ph. D. B. Leal-Acevedo, M. Sc. J. Gutiérrez-Romero, and M. Sc. M.J. Rodríguez-Albarrán from Nuclear Sciences Institute, for their technical assistance.

Funding

This work was supported by the Dirección General de Asuntos del Personal Académico (DGAPA), Universidad Nacional Autónoma de México under Grant IN204223, University of Guadalajara under PROSNI 2022, and CONAHCyT postdoctoral fellowship provided to G. G. Flores-Rojas (CVU 407270).

Author information

Authors and Affiliations

Contributions

All authors contributed equally to this work.

Corresponding authors

Ethics declarations

Conflict of interest

Authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ibarra-Cervantes, T.B.S., Flores-Rojas, G.G., Mendizabal, E. et al. PTFE-g-GMA graft copolymer synthesis promoted by oxidative gamma-rays method and characterization. MRS Communications (2024). https://doi.org/10.1557/s43579-024-00573-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/s43579-024-00573-0