Abstract

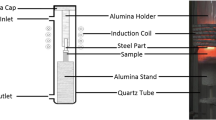

Low-density, open-cell nickel base superalloy foams have been synthesized by a high-rate, electron beam-directed vapor deposition process and their mechanical properties evaluated. The deposition process uses an open-cell polymer foam template upon which is deposited a metal alloy coating. The electron beam evaporated flux was entrained in a rarefied transonic gas jet and propagated along the flow stream lines through the polymer structure. After vapor deposition, the polymer template was removed by low-temperature thermal decomposition. The resultant ultralightweight metal foams consisted of a three-dimensional open cell, reticulated structure possessing hollow triangular ligaments with relative densities of <3%. Their mechanical integrity was increased by either pressureless or transient liquid phase sintering. The mechanical properties of these ultralightweight metal foams were comparable to theoretical predictions for open-cell, reticulated foams.

Similar content being viewed by others

References

M.F. Ashby, A.G. Evans, N.A. Fleck, L.J. Gibson, J.W. Hutchinson, and H.N.G. Wadley, Metal Foams: A Design Guide (Butterworth Heinemann, Oxford, U.K., 2000).

M.F. Ashby, Metall. Trans. A, 14, 1755 (1983).

L.J. Gibson, Mater. Sci. Eng. A 110, 1 (1989).

L.J. Gibson and M.F. Ashby, Cellular Solids: Structure and Properties, 2nd ed. (Cambridge University Press, Cambridge, U.K., 1997).

A.G. Evans, J.W. Hutchinson, and M.F. Ashby, Prog. Mater. Sci. 43, 171 (1998).

A.G. Evans, J.W. Hutchinson, and M.F. Ashby, Curr. Opin. Solid State Mater. Sci. 3, 288 (1998).

T.J. Lu and C. Chen, Acta Mater. 47, 1469 (1999).

X. Wang and T.J. Lu, J. Acoust. Soc. Am. 106, 756 (1999).

T.J. Lu, A. Hess, and M.F. Ashby, J. Appl. Phys. 85, 7528 (1999).

T.J. Lu, H.A. Stone, and M.F. Ashby, Acta Mater 46, 3619 (1998).

T.J. Lu, Int. J. Heat Mass Transfer 42, 2031 (1999).

D.D. Walz, Method of Making an Inorganic Reticulated Foam Structure, U.S. Patent 3 616 841 (2 November 1971).

J.R. Brannan, A.S. Bean, A.J. Vaccaro, and J.J. Stewart, Continuous Electroplating of Conductive Foams, U.S. Patent 4 978 431 (18 December 1990).

J.R. Brannan, A.S. Bean, A.J. Vaccaro, and J.J. Stewart, Continuous Electroplating of Conductive Foams, U.S. Patent 5 098 544 (24 March 1992).

J.R. Brannan, A.J. Vaccaro, and J.P. Healy, High Density, High Capacity Battery Electrode, U.S. Patent 5 374 491 (20 December 1994).

W.A. Pruyn, Metal Foam, U.S. Patent 5 503 941 (2 April 1996).

W.A. Pruyn, Method for the Production of a Metal Foam, U.S. Patent 5 584 983 (17 December 1996).

A.J. Vaccaro, J.S. Gregg, D.W. Gibbons, J.R. Brannan, G.R. Pohto, and J.M. Hinden, Continuously Electroplated Foam of Improved Weight Distribution, U.S. Patent 5 804 053 (8 September 1998).

R.A. Clyde, Method of Plating Metal Uniformly on and Throughout Porous Structures, U.S. Patent 3 900 646 (19 August 1975).

J. Babjak, V.A. Ettel, and V. Paserin, Method of Forming Nickel Foam, U.S. Patent 4 957 543 (18 September 1990).

R.B. Kaplan, H.O. Pierson, R.H. Tuffias, and B.E. Williams, High Temperature Resistant Reticulated Foam Structures and Process, U.S. Patent 5 154 970 (13 October 1992).

G. Perugini and E. Marcaccioli, Process for the Preparation of Metallic and/or Metal-Ceramic and/or Ceramic Sponges, U.S. Patent 4 076 888 (28 February 1978).

E. Pinkhasov, Method of Making Open Pore Structures, U.S. Patent 4 975 230 (4 December 1990).

E. Pinkhasov, Method of Making Open Pore Structures, U.S. Patent 5 011 638 (30 April 1991).

S. Schiller, U. Heisig, and S. Panzer, Electron Beam Technology (Verlag Technik, GmbH, Berlin, Germany, 1995).

J.F. Groves and H.N.G. Wadley, Composites B 28, 57 (1997).

D.D. Hass, H.N.G. Wadley, and Parrish, P.A., J. Vac. Sci. Technol. B 13, 183 (1998).

J.F. Groves, Ph.D. Dissertation, University of Virginia (1998).

H.N.G. Wadley and J.F. Groves, Directed Vapor Deposition of Electron Beam Evaporant, U.S. Patent 5 534 314 (9 July 1996).

INCO Alloys International Inc., Product Data Sheet (1994).

H.K. Kohl and K. Peng, J. Nucl. Mater. 101, 243 (1981).

G.K. Dey, S. Albert, D. Srivastava, M. Sundararaman, and P. Mukhopadhyay, Mater. Sci. Eng. A, 119, 175 (1989).

K.K. Cushnie and S.T. Campbell, Process for Removal of Polymer Foams from Nickel-Coated Substrates, U.S. Patent 5 735 977 (7 April 1998).

B.A Movchan and A.V. Demchishin, Phys. Met. Metallogr. 28, 83 (1969).

J.V. Sanders, in Chemisorption and Reacting on Metal Film, edited by J.R. Anderson (Academic Press, New York, 1971).

J.A. Thornton, J. Vac. Sci. Technol. 11, 666 (1974).

K.A. Thornton, Annu. Rev. Mater. Sci. 7, 239 (1977).

Y.G. Yang, R.A. Johnson, and H.N.G. Wadley, Acta Mater. 45, 1455 (1997).

J.M. Howe, Interfaces in Materials: atomic structure, thermodynamics and kinetic of solid-vapor, solid-liquid and solid-solid interfaces (John Wiley & Sons, Inc., New York, 1997).

J.W. Cahn and J.E. Hilliard, J. Chem. Phy. 28, 258 (1958).

R.M. German, Powder Metallurgy Science (Metal Powder Industries Federation, Princeton, NJ, 1984).

R.M. German, Liquid Phase Sintering (Plenum Press, New York, 1985).

Powder Diffraction File, Card No. 4-850, International Center for Diffraction Data (1993).

A.E. Simone and L.J. Gibson, Acta Mater. 46, 3929 (1998).

J.L. Grenestedt, J. Mech. Phys. Solids 46, 29 (1998).

R. Gradinger and F.G. Rammerstorfer, Acta Mater. 47, 143 (1999).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Queheillalt, D.T., Hass, D.D., Sypeck, D.J. et al. Synthesis of open-cell metal foams by templated directed vapor deposition. Journal of Materials Research 16, 1028–1036 (2001). https://doi.org/10.1557/JMR.2001.0143

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2001.0143