Abstract

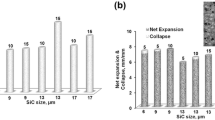

Fabrication of NiTi intermetallic foams using the self-propagating, high-temperature synthesis (SHS) process was investigated. Weighed amounts of powders taken from an equimolar mixture of Ni and Ti powders along with 0.5, 1, and 1.5 wt pct of different foaming agents were cold pressed to form cylindrical compacts 10 mm in diameter, 20 mm in height, and 7 to 8 g in weight. A novel, induction-assisted ignition method was used for indirect heating and igniting the compressed mixtures at one end. As a result of intensive exothermic reaction between Ni and Ti and decomposition of foaming agents and liberation of gases, highly porous products were obtained. Characterization of the products was carried out using X-ray diffraction (XRD) and a scanning electron microscope equipped with an energy-dispersive spectroscope (SEM-EDS). The main phase in the products was detected to be B2(NiTi) with minor amounts of NiTi2 as the secondary phase. Other undesirable phases, such as Ni4Ti3 and Ni3Ti, were not detected. The effect of type and percentage of foaming agent on the formation and distribution of pores within the products was studied. Final products with porosities up to ~ 80 vol pct were obtained by adding foaming agent. Under the conditions of this study, CaH2 proved to be the most effective foaming agent considering its ability to generate a uniform distribution of pores, while TiH2 was not considered favorable due to its decomposition at relatively low temperatures. In general, the addition of foaming agents in amounts higher than 1wt pct is not recommended; due to the endothermic nature of thermal decomposition reactions of foaming agents, excessive use of these agents can result in suppression of the exothermic reaction.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

References

J. Jani, M. Leary, A. Subic, and M.A. Gibson: Mater. Des. 2014, 65, 1078–1113.

M. Whitney, S.F. Corbin, and R.B. Gorbet: Acta Mater., 2008, vol. 56, pp. 559–70.

Z. Abdullah, R. Razali, I. Subuki, M.A. Omar, and M.H. Ismail: Adv. Mater. Res., 2016, vol. 1133, pp. 269–74.

D. Zhou, Y. Gao, M. Lai, H. Li, B. Yuan, and M. Zhu: J. Bionic Eng., 2015, vol. 12, pp. 575–82.

M. Kaya and O. Cakmak: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 1499–1503.

F. Mohammadi, M. Kharaziha, and A. Ashrafi: Met. Mater. Int., 2019, vol. 25 (3), pp. 617–26.

C. Wen, X. Yu, W. Zeng, S. Zhao, L. Wang, G. Wan, S. Huang, H. Grover, and Z. Chen: AIMS Mater. Sci., 2018, vol. 5, pp. 559–90.

S.O.R. Sheykholeslami, J. Khalil-Allafi, and L. Fathyunes: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 5878–87.

A. Bansiddhi, T.D. Sargeant, S.I. Stupp, and D.C. Dunand: Acta Biomater., 2008, vol. 4, pp. 773–82.

P. Salvetr, Z. Pecenova, A. Školáková, and P. Novák: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 1524–27.

M.H. Elahinia, M. Hashemi, M. Tabesh, and S.B. Bhaduri: Progr. Mater. Sci., 2012, vol. 57, pp. 911–46.

B.Y. Li, L.J. Rong, Y.Y. Li, and V.E. Gjunter: Acta Mater., 2000, vol. 48, pp. 3895–3904.

Y.H. Li, L.J. Rong, and Y.Y. Li: J. Alloys Compd., 2001, vol. 325, pp. 259–62.

B.Y. Li, L.J. Rong, Y.Y. Li, and V.E. Gjunter: Metall. Mater. Trans. A, 2000, 31A, 1867–71.

C.L. Yeh and W.Y. Sung: J. Alloy Compd., 2004, vol. 376, pp. 79–88.

K. Khanlari, M. Ramezani, P. Kelly, P. Cao, and T. Neitzert: Intermetallics, 2018, vol. 100, pp. 32–43.

H. Li, B. Yuan, Y. Gao, C.Y. Chung, and M. Zhu: J. Mater. Sci., 2009, vol. 44, pp. 875–81.

G. Tosun, L. Ozler, M. Kaya, and N. Orhan: J. Alloys Compd., 2009, vol. 487, pp. 605–11.

X. Ma, H. Xie, J. Qu, Q. Song, Z. Ning, H. Zhao, and H. Yin: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 940–49.

Y. Arakawa, M. Kobashi, and N. Kanetake: Materials, 2012, vol. 5, pp. 1267–74.

S.K. Sadrnezhaad, S.H. Katiraei, and A. Ghasemi: Int. J. Adv. Des. Manuf. Technol., 2014, vol. 7, pp. 1–7.

P. Novák, L. Mejzlíková, A. Michalcová, J. Čapek, P. Beran, and D. Vojtěch: Intermetallics, 2013, vol. 42, pp. 85–91.

P. Novák, T. Veselý, I. Marek, P. Dvořák, V. Vojtěch, P. Salvetr, M. Karlik, P. Haušild, and J. Kopeček: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 932–38.

M. Kaya, N. Orhan, and G. Tosun: Curr. Opin. Solid State Mater. Sci., 2010, vol. 14, pp. 21–25.

J.L. Xu, L.Z. Bao, A.H. Liu, X.F. Jin, J.M. Luo, Z.C. Zhong, and Y.F. Zheng: J. Alloys Compd., 2015, vol. 645, pp. 137–42.

A. Baran and M. Polanski: J. Alloys Compd., 2018, vol. 750, pp. 863–70.

X. Zhao, H. Sun, L. Lan, J. Huang, H. Zhang, and Y. Wang: Mater. Lett., 2009, vol. 63, pp. 2402–04.

S.A. Hosseini, M. Alizadeh, A. Ghasemi, and M.A. Meshkot: J. Mater. Eng. Perform., 2013, vol. 22, pp. 405–09.

G. Chen, P. Cao, and N. Edmonds: Mater. Sci. Eng. A, 2013, vol. A582, pp. 117–25.

S. Wu, X. Liu, K.W.K. Yeung, T. Hu, Z. Xu, J.C.Y. Chung, and P.K. Chu: Acta Biomater., 2011, vol. 7, pp. 1387–97.

Y. Arakawa, M. Kobashi, and N. Kanetake: J. Jpn. Inst. Met., 2010, vol. 75, pp. 379–85.

C.L. Chu, C.Y. Chung, P.H. Lin, and S.D. Wang: Mater. Sci. Eng. A, 2004, vol. 366A, pp. 114–19.

P. Salvetr, A. Školáková, C. Hudrisier, P. Novák, and D. Vojtěch: Materials, 2018, vol. 11, pp. 689–700.

P. Rittmayer and U. Wieltelmann: Ullmann’s Encyclopedia of Industrial Chemistry, B. Elvers, ed., Wiley-VCH, Weinheim, 2012, pp. 103–32.

A.F. Holleman and E. Wiberg: Inorganic Chemistry, 1st ed., N. Wiberg, ed., Walter de Gruyter-Academic Press, Berlin, 2001, pp. 270–73.

J. Blamey, E.J. Anthony, J. Wang, and P.S. Fennell: Progr. Energy Combust. Sci., 2010, vol. 36, pp. 260–79.

D. Yang, J. Chen, H. Wang, J. Jiang, and A. Ma: J. Mater. Sci. Technol., 2015, vol. 31, pp. 361–68.

H.C. Yi and J.J. Moore: Scripta Metall., 1988, vol. 22, pp. 1889–92.

M. Thier, M. Hiihner, E. Kobus, D. Drescher, and C. Bourauel: Mater. Charact., 1991, vol. 27, pp. 133–40.

A. Foroozmehr, A. Kermanpur, F. Ashrafizadeh, and Y. Kabiri: Mater. Sci. Eng. A, 1991, vol. 528A, pp. 7952–55.

J. Frenzel, E.P. George, A. Dlouhy, C. Somsen, M.F.X. Wagner, and G. Eggeler: Acta Mater., 2010, vol. 58, pp. 3444–58.

P. Salvetr, T. Kubatik, D. Pignol, and P. Novák: Metall. Mater. Trans. B, 2017, 48B, 772–78.

A. Školáková, P. Novák, P. Salvetr, H. Moravec, V. Šefl, D. Deduytsche, and C. Detavernier: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 3559–69.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted February 28, 2019.

Rights and permissions

About this article

Cite this article

Kalantari, H., Adeli, M. & Aboutalebi, M.R. Investigation of the Effect of Foaming Agent on the Fabrication of NiTi Foams Using the Self-Propagating, High-Temperature Synthesis Process. Metall Mater Trans B 50, 2566–2573 (2019). https://doi.org/10.1007/s11663-019-01700-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01700-2