Abstract

The performance of a pharmaceutical formulation, such as the drug (API) release rate, is significantly influenced by the properties of the materials used, the composition of the final product and the tablet compression process parameters. However, in some cases, the knowledge of these input parameters does not necessarily provide a reliable description or prediction of tablet performance. Therefore, the knowledge of tablet microstructure is desirable to understand such formulations. Commonly used analytical techniques, such as X-ray tomography and intrusion mercury porosimetry, are not widely used in pharmaceutical companies due to their price and/or toxicity, and therefore, efforts are made to develop a tool for fast and easy microstructure description. In this work, we have developed an image-based method for microstructure description and applied it to a model system consisting of ibuprofen and CaHPO4∙2H2O (API and excipient with different deformability). The obtained parameter, the quadratic mean of the equivalent diameter of the non-deformable, brittle excipient CaHPO4∙2H2O, was correlated with tablet composition, compression pressure and API release rate. The obtained results demonstrate the possibility of describing the tablet dissolution performance in the presented model system based on the microstructural parameter, providing a possible model system for compressed solid dosage forms in which a plastic component is present and specific API release is required.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

There are many steps in the process of making a tablet from the initial powder materials that affect the final performance of the tablet (frequently assessed by in vitro dissolution and disintegration, where the internal structure of the tablet inherently plays a very important role [1]). All of those steps can significantly alter the initially known input properties of the used materials. There is a significant dependence of the final tablet properties on compression process parameters, tablet composition and, of course, different characteristics of the used materials [2,3,4].

The input properties of the used materials/prepared tabletting mixture alone cannot usually sufficiently explain the final tablet disintegration, dissolution, tensile strength and other parameters [5, 6]. The input properties typically include the particle shape and size and, in more advanced cases, the viscoelastic [7] and surface properties of processed powders [8]. Such properties can be used to describe the drug release from particles or agglomerates [9]; however, they alone usually fail to predict the resulting tablet behaviour due to the complexity of the compression process as the force exerted on the tablet mixture by the compression punches leads first to the particle rearrangement within the matrix and eventually to their fragmentation, plastic or elastic deformation (changing the size and shape of individual particles) [10,11,12,13]. The dissolution profiles of the tablet may be substantially different from the starting particulate material, even if the disintegration limitations are avoided, as we recently reported [14]. Here, information about tablet microstructure can provide a better understanding of the tablet performance [6, 8], as it goes one step further from the input material particle properties and the compression parameters and aims to describe their combined result in the final dosage form. A great example here would be the significant tendency of needle-like particles to undergo fragmentation during compression [15,16,17]. For such materials, the input particle size will not be of significant use in predicting tablet behaviour.

Hence, designing a pharmaceutical tablet of desirable properties, especially of a desirable dissolution profile, is an intricate process since the particulate starting material properties change in many ways during the production process. Pharmaceutical tablet properties may be multi-correlated to properties of different powders, including active ingredients and excipients, and they can exhibit non-linear, non-monotonous or threshold-like behaviour in relation to compression parameters. Therefore, the traditional way of dissolution tuning is largely empirical, relying on a relatively large number of development batches even if sophisticated tools for the design of experiments are used because the number of variables in the factorial plan is large.

On the other hand, the effect of particle properties and compression parameters on the tablet microstructure is more straightforward as it depends only on the mechanical properties of the materials used. The microstructure can be evaluated by overall tablet density/porosity and pore size distribution often measured by the mercury intrusion porosimetry [18] or by material (and porosity) distribution within the tablet where X-ray microscopy [19, 20] and microtomography [5, 21] and different chemical imaging methods come in. The most common ones would be methods based on vibrational spectroscopy – near-infrared and Raman mapping [22, 23]; moreover, energy-dispersive X-ray spectroscopy based on scanning electron microscopy is also used frequently [6, 24, 25]. While different general behaviour patterns exist, depending on the deformability attributes of the formulation components (such as plastic, elastic and brittle) and their combinations, the combination of a plastically deformable drug and a non-deformable excipient is of special importance.

Since many of the recently discovered drugs suffer from poor water solubility, there is a significant increase in the formulation of such drug candidates into amorphous solid solutions and dispersions to increase the dissolution rate of the drug [26,27,28,29]. Particles of such drug formulations can, thanks to their relatively high polymer content then exhibit specific viscoelastic properties [30]. It can be presumed that such particles would be fairly well plastically deformable in general so that they can contribute to the formation of a specific tablet microstructure. The microstructure–dissolution relationship is again relatively straightforward as it no longer depends on the mechanical properties of the constituents.

Thus, separating the objective of understanding the relationship between tablet composition, compression parameters and the dissolution properties into two independent problems of the mechanical properties to microstructure correlation (MMC) and the microstructure to dissolution correlation (MDC) is a promising opportunity to streamline the formulation development and improve the understanding of underlying processes. The present study aims at demonstrating the potential of the aforementioned approach using the MMC and MDC analysis in a binary system comprising materials with different viscoelastic properties – a plastically deformable model drug combined with a hard, brittle excipient.

Materials and Methods

In the presented study, directly compressed binary tablets comprised of ibuprofen and CaHPO4∙2H2O (of different compositions and compressed with different loads) were at the centre of attention. Model materials were chosen based on their mechanical properties. Ibuprofen represents well-deformable active substances; thus, it can represent any other plastically deformable API alone and also quite a wide range of formulations of various APIs into various solid dispersion systems. CaHPO4∙2H2O can, on the other hand, represent excipients that are non-deformable, quite hard and under higher pressure brittle [31]. Each one of the prepared tablet formulations was subjected to tablet microstructure analysis and dissolution testing, so these two performance parameters could be investigated in correlation with each other.

Materials

Two different batches of ibuprofen were used in this study (marked as Ibu I and Ibu II), both kindly provided by Zentiva, k.s., CZ in combination with CaHPO4∙2H2O (EmCompress®; JRS Pharma GmbH & Co., DE) for the model tablets preparation. One of the ibuprofen batches, Ibu I, was for some of the tested formulations milled, so its particle size was lower than with the two raw batches. Milling was performed using a planetary ball mill PM 100 CM (Retsch GmbH, DE) at 250 rpm for 15 min. This altered batch is further marked as Ibu Im. Since the importance of initial particle size and morphology of the input materials was taken into consideration, all four materials (CaHPO4∙2H2O and three ibuprofen variants) were characterised using a static light scattering system Mastersizer 3000 (Malvern Instruments, UK) for particle size distribution (Fig. 1). Scanning electron microscopy, SEM, (FE MIRA II LMU, Tescan s.r.o., CZ) was then used to describe and evaluate the particle morphology of these materials (Fig. 2).

Particle size distribution of the ibuprofen batches and complementary excipient for formulation preparation used in the presented study. Legend: grey – batch Ibu II (d90 = 367.6 µm), purple – batch Ibu I (d90 = 242.7 µm), orange – batch Ibu Im (milled) (d90 = 166.8 µm), green – excipient CaHPO4∙2H2O (d90 = 330.0 µm)

Tablet Composition and Preparation

Tablets were prepared from mixtures containing different amounts of CaHPO4∙2H2O and one of the three respective ibuprofen batches (Ibu I, Ibu Im, Ibu II). Homogenisation was done with a Turbula T2F mixer (Willy A. Bachhofen AG, CH) using 55 rpm for 5 min. Each of the mixtures was then subjected to compression with a compaction analyser GTP-1 (Gamlen Instruments, UK) equipped with the 5-mm diameter die under different compaction loads. The mixture weight added into the die was always adjusted, so all the resulting tablets had comparable geometry (height of 2.3 mm ± 15%). All of the tablet variants with the above-mentioned parameters prepared are summarised in Table I.

Tablet Microstructure Evaluation

The inner microstructure of tablets was evaluated in the form of a quadratic mean of area equivalent diameter (dAvg) of CaHPO4∙2H2O particles/aggregates on the tablet radial cross-section areas. Tablets were, for this purpose, incorporated into paraffin wax matrices and cut on rotary microtome RM2255 (Leica Mikro spol. s.r.o., CZ), so the resulting cross-sections are flat and smooth [32]. Samples prepared in this way were subsequently sputter coated with 2 nm of platinum (sputter coater Q150R ES, Quorum Technologies Ltd, UK) and analysed using the SEM with detection of back-scattered electrons (BSE). Here, the use of CaHPO4∙2H2O as an excipient in model binary formulations and also as the primary source of the microstructural data can be justified. Thanks to its chemical nature, CaHPO4∙2H2O provides a different contrast than ibuprofen during the BSE detection which is necessary for further image analysis. While the SEM-BSE was the most suitable method in the presented model system, other imaging methods such as scanning Raman spectroscopy or SEM-EDS could also be used for different systems as the input data for the subsequent image analysis, depending on the specifics and limitations of the tested systems.

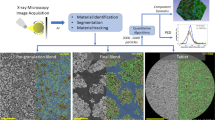

Image Analysis

The original SEM images of tablet cross-sections were subjected to image analysis using a simple script created in the Matlab® environment (Fig. 3). Its whole workflow is based on a greyscale thresholding thanks to the phase contrast of CaHPO4∙2H2O mentioned earlier. However, a few image adjustments had to be made with the original SEM picture, so the thresholding provides sensible results. Preceding the analysis, each picture was modified using a low-pass filter and contrast enhancement. Since the aim was to analyse the whole cross-section at once, the used magnification is rather low (40×) for such a purpose. It can cause the SEM-BSE pictures to have a horizontal brightness gradient. That is why the thresholding itself is eventually done separately for three vertical bands (left, middle and right) of the image and those three resulting segmentation masks are combined into one final mask only after a proper threshold setting for each one of them separately. From this final mask, where CaHPO4∙2H2O particles/aggregates are properly marked, a particle size distribution (PSD) is constructed, so the dAvg along with its coefficient of variation (dAvg CV) for each tested tablet variant can be calculated. The coefficient of variation is used to represent the sample polydispersity since the final result for each tablet is a mean size rather than a size distribution. To ensure the statistical significance of the results, as many pictures as necessary for the PSD to be constructed from at least 100 particles/aggregates are analysed for each tested tablet variant.

Illustrative workflow of image analysis performed on tablet cross-section areas (tablet from formulation EmC-IbuII 50-50 250 MPa). 45× mag. a Original SEM picture (lighter areas on the tablet cross-section indicate the regions where the excipient is present, which are measured during the image analysis, the darker areas belong to the API), b three vertical bands after low-pass filtering and contrast adjustment, c segmentation masks for three individual bands (here, the white areas indicate the regions of the excipient, CaHPO4∙2H2O), d combined segmentation mask, e partially transparent segmentation mask in colour on top of the original picture for visual control (excipient here shown in pink colour, API and background in green)

Moreover, image analysis of SEM pictures of the raw CaHPO4∙2H2O powder was done, where the clearly observable excipient particles were marked, so a similar particle size distribution to the one from tablet cross-section can be constructed and a comparable excipient dAvg parameter can be used for the tablet microstructure evaluation.

Dissolution Testing

Along with the microstructural characterisation, all prepared variants of tablets were subjected to dissolution testing, so the release profile and release rate of ibuprofen from model tablets can be described. Tests were performed using an apparatus with flow-through cells (USP 4) CE-7smart (Sotax AG, CH). The apparatus was equipped with small tablet cells (12 mm diameter, 32 mm height) with the use of glass beads to ensure laminar flow. Tablets were placed in a holder approximately halfway up the cell. Phosphate buffer (pH 6.8) at a flow rate of 6 mL/min was used as a dissolution medium, and the whole system was tempered to 37°C. The tests were performed using an open-loop configuration; the dissolution medium passed the cell only once, and the samples were collected during the whole sampling intervals which were capped at 1 min, 2 min, 3 min, 4 min, 5 min, 7 min, 10 min, 15 min, 20 min, 25 min, 35 min, 45 min and 60 min after the beginning of the test.

Sample Analysis

Collected samples were analysed for ibuprofen concentration on a UV/VIS spectrophotometer SPECORD 200 PLUS (Analytik Jena AG, DE). Analysis was done at two wavelengths, 234 nm and 264 nm, each with a separate calibration curve. Ibuprofen concentration in samples was then calculated based on the more suitable absorbance value measured at either one of the wavelengths. The concentration values were then used to construct dissolution profiles (in the form of immediate API concentration values plotted against time) for each tablet variant (illustratively in Fig. 4). Measurements were always done in triplicates. The relatively high and variable values of the API concentration observed at the beginning of the test (approximately the first 1% of the released API) are mostly caused by the individual tablet surface characteristics, including adhered particles of the API or excipients and the API domain distribution on the tablet surface. After this 1% is released, tablets provide a consistent matrix tablet-like character.

Limit Release Rate Calculation

Subsequently, the relative release rate (rrel, min−1) of the samples was calculated for each time point of the measurement according to Eq. (1).

where \(\dot{m}\) is the mass flow of the API from the immediately exposed tablet surface, m0 is the initial API dose, c is the immediate concentration in each sample and F stands for the flow rate of the dissolution medium [33].

The rrel values were then plotted against the amount of ibuprofen released from the tested tablet at the corresponding time points, so the limit release rate (rlim, -) of the API can be determined (Fig. 5). Its values are equal to the y-intercept of linear regression of relative release rate–released amount of ibuprofen dependency after the release rate became stable and not influenced by any surface inconsistencies and possible adhered particles of either API or the excipient on top of the tablet (typically where the amount of released API is already higher than 1%).

Illustrative limit release rate (rlim) calculation for three measurements performed with tablets EmC-IbuI 15-85 125 MPa. Tablet 1 (grey), linear regression equation: rrel, = −0.0006wIBU + 0.0014, R2 = 0.0787; tablet 2 (purple), linear regression equation: rrel, = −0.0021wIBU + 0.0014, R2 = 0.4345; tablet 3 (orange), linear regression equation: rrel, = −0.0035wIBU + 0.0016, R2 = 0.2192. A vertical dashed line marks the area with a steady release rate where the linear regression was applied

Results and Discussion

All of the prepared tablet variants with differing compositions and used compression pressure were subjected to analyses described in the “Materials and Methods” section in order to study their microstructural and dissolution properties and their respective relationship with the tablet composition and preparation, as well as their relationship with each other.

Mechanical Properties to Microstructure Correlation (MMC)

The first studied relationship was the one between the input material and process properties and the created tablet microstructure (mechanical properties to microstructure correlation, MMC), where the input material viscoelastic properties, the compression pressure and the tablet composition were taken into account.

API Particle Properties and Their Influence on Tablet Microstructure

The model materials were specifically chosen to represent different groups of viscoelastic behaviour – ductile, deformable API and a non-deformable hard excipient prone to brittle fracture. Another reason behind the choice of these materials lies in their different contrast while subjected to the SEM-BSE analysis. The excipient, CaHPO4∙2H2O, provides higher intensity of the back-scattered electrons, leading to a brighter appearance on the produced images. In contrast, the API appears darker in the images, thanks to the lack of elements heavier than oxygen in its molecule. Lastly, if there are any pores or voids present on the tablet cross-section, they are generally seen in black in the original unprocessed images. After preparation of the first tablets (containing only ibuprofen batch Ibu II with the particle size distribution closest to the excipient one) and performing SEM imaging of them, an observation was made that the ductility of the API causes its particles to form continuous domains when subjected to compression (shown in a darker shade of grey in the following Figs. 6 and 7), in which the crystalline areas of excipient are spread (lighter shades of grey to white areas in Figs. 6 and 7). Following this fact, it was decided to prepare tablets with APIs having different particle size distributions (and shape to some extent) to see if the tablet microstructure will be somehow changed. For example, if the smaller API particles would be able to separate the excipient particles more efficiently within the tablet mass and how the size affects their ability of continuous domain creation. The first mentioned phenomenon, separation of excipient by the API particles differing in size, was evaluated on formulations having 25 wt.% of API, and it was compared with the use of tablets prepared with compaction pressure of 125 MPa (Fig. 6). The tabletting pressure was chosen to be the middle point of all the tested ones, so it allows a certain degree of manifestation of the particulate viscoelastic properties in the final tablet. SEM images show no significant difference in compact structure when the different particle size of API was used. Formation of the API continuous domains was best observable in tablets having the highest amount of API (in the presented study that would be tablets with 85 wt.% of ibuprofen, Fig. 7). Here, the tabletting pressure chosen for the illustration has a value of 62.5 MPa, since even at this low compression pressure the borders between the API particles are already very poorly or not distinguishable, as seen in the representative images in Fig. 7. The results were strongly comparable for all three API variants. From the SEM pictures presented in Figs. 6 and 7, it can be concluded that neither of those phenomena is manifesting excessively, and the influence of initial particle size and morphology is, in terms of the resulting tablet microstructure, negligible for well-deformable materials (in this case the API).

Use of Image Analysis in Tablet Microstructure Description

As mentioned in the corresponding part of the “Materials and Methods” section, the image analysis was put together in a way that the excipient, CaHPO4∙2H2O, is the primary source of tablet microstructural information. Besides the phase contrast advantage, the use of this particular excipient as a primary microstructural tablet descriptor is sensible also from a mechanical point of view since it does keep some structure inside the tablet in contrast with well-deformable ibuprofen, which creates a more or less uniform mass after being subjected to compression and does not leave significant space for pores, cracks etc.

The model tablet characteristics presented in this paper arose from the nature of used materials and their preparation process, which ultimately result in an atypical behaviour of such model tablets – fairly low or absent disintegration. This is another reason why to evaluate the microstructure based on the used excipient. Since it is insoluble, there is a certain correspondence with constitutional excipients used in matrix tablet production, where the insoluble matrix structure can be of great significance; hence, the evaluation of tablet microstructure in the form of a quadratic mean of the equivalent diameter (dAvg) of CaHPO4∙2H2O particles/aggregates present on the tablet cross-section area. The quadratic mean was chosen to provide representative information about the mean excipient size while taking the relationship between the particle/aggregate size and its area visible on the cross-section into account. Moreover, using dAvg of CaHPO4∙2H2O stems from the fact that the well-deformable API forms continuous domains when subjected to compression, in which the crystalline areas of excipient are spread. API domain characteristics are then dependent only on the mixture composition and homogeneity, and not on initial particle properties.

Process Setup Influence on Tablet Microstructure

Besides the input API particle size and morphology, the process parameter setup influence on the resulting tablet microstructure was evaluated. Compaction pressure was chosen as the independent variable here with the predetermined values of 62.5 MPa, 125 MPa and 250 MPa. The objective of this part was mostly about whether the presence of some amount of the ductile material (API) in the formulation will have the ability to suppress the excipient brittle fraction propensity and to what extent (to how high compression pressure values).

For the formulations where there is a high amount of ibuprofen present (Table II), its somehow fracture-protective function seems to manifest quite well. The values of the mean quadratic equivalent diameter of the CaHPO4∙2H2O particles in prepared tablets are close to its raw powder value of 127.6 ± 87.2 μm. There are two outliers between the values obtained from tablets (EmC-IbuII 15-85 250 MPa and EmC-IbuI 15-85 125 MPa) which can be caused by the span of the size distribution (as can also be observed with all of the other formulations and the pure excipient evaluated from the SEM pictures) and relatively lower number of evaluated particles. However, the protection from the brittle fracture works here, at least to some extent. With the decreasing amount of the API in the formulation, the formation of excipient aggregates within the tablet begins to complicate drawing definite conclusions about the brittle fracture protection provided by the ibuprofen particles. However, the differences in excipient particle/aggregate size within tablets prepared from certain formulations with differing compaction loads are rather low when the ibuprofen content in the formulation is higher than 15 wt.%, which suggests that the fracture-protective function might be possible even at loads between 15 and 85 wt.% of the deformable material in the tablet. For a complete data table, please see Supplementary Table III.

Formulation and Process Impact on Microstructure

The resulting tablet microstructure was eventually evaluated as a function of tablet composition and compression pressure. In Fig. 8, there is the mean size of CaHPO4∙2H2O particles/aggregates on the tablet cross-section plotted against tablet composition. The particle size of raw excipient powder, evaluated in the same manner as in the tablet cross-section analysis, is depicted in the graph for comparison (cross mark). The measured excipient size increases with its increasing amount in the formulation which is connected with the used evaluation method. Size is evaluated based on excipient regions observable on tablet cross-section, so the higher the amount of excipient, the higher the propensity to evaluate aggregates, preferably to individual particles and the higher the variance of resulting size between different used compression loads. As for the different ibuprofen batches (different point mark shapes) with different particle characteristics used for tablet preparation, there do not seem to be major differences in the resulting tablet microstructure evaluated from the excipient point of view. It corresponds with the previous findings about the initial API particle size influence on tablet microstructure (“API Particle Properties and Their Influence on Tablet Microstructure”) and the observed phenomenon of ibuprofen’s well deformability and creation of larger domains with non-distinguishable primary particles after submission to pressure. Moreover, a larger drop between the resulting sizes is observable between the formulations having 40 vol.% and 50 vol.% amount of ibuprofen which can be pointing to a certain threshold-like behaviour of this particular material combination, which is associated with the steep change of the system characteristics as the percolating (continuous) phase of the microstructure changes from excipient to the drug.

CaHPO4∙2H2O quadratic mean equivalent diameter as a function of tablet composition. Used ibuprofen batch: ■ Ibu II, ● Ibu I, ▲ Ibu Im. Used compression pressure: white – 62.5 MPa, grey – 125 MPa, black – 250 MPa (data points for tablets containing ibuprofen batch Ibu II compressed with 62.5 MPa may not be visible as they are overlapped by data points obtained at higher tabletting pressures)

The compression pressure used for tablet production (as the key process parameter) was found not to have a significant influence (shown in Fig. 8 via different point mark fillings on the tablet microstructure evaluated by the methodology used in this article). This corresponds to and confirms the earlier discussed high deformable propensity of ibuprofen during tablet compression, where nearly maximum deformation is obtained even for low compression pressure.

Formulation and Process Impact on Dissolution

As for microstructure, the atypical behaviour of the resulting tablets (low or no disintegration) also leads to the description of the API release in a non-standard way. The resulting parameter obtained from dissolution is, for the purposes of this work, the value of the limit release rate (rlim) of ibuprofen. The use of rlim arose from the API plastic character and also from the fact that the used excipient creates non-disintegrable compacts. Thanks to these tablet properties, the dissolution of the drug can be considered comparable to intrinsic dissolution [34, 35] in its early-developed forms [36].

Firstly, the limit release rate (rlim) was, analogous to the tablet microstructure, evaluated as a function of tablet composition and compression pressure (Fig. 9). The overlook of the experimental data plot is quite similar to the dependency of tablet microstructure on composition. It suggests that the lower the amount of API in the formulation, the faster the dissolution. It can be thanks to the general nature of the tested model tablets. As only model binary mixtures were used (instead of the complex tablet formulation), there was not any extensive disintegration happening during the performed tests. This phenomenon thus can be explained by the higher relative surface area for ibuprofen available for dissolution in formulations having higher amounts of CaHPO4∙2H2O, thanks to lower ibuprofen domain size within the tablet and possibly also higher structural porosity created by the excipient. The limit release rate is significantly more dependent on tablet composition in these faster-dissolving formulations (with an ibuprofen amount lower than 50 vol.%) than in the formulations where API is the major component, which can also be presented as some form of threshold-like behaviour as seen by the microstructural characterisation of model tablets. In correspondence with the previous results for excipient mean size, the used compression load or ibuprofen initial particle characteristics are not significantly influencing the release rate of the API from model tablets either.

Ibuprofen limit release rate as a function of tablet composition. Used ibuprofen batch: ■ Ibu II, ● Ibu I, ▲ Ibu Im. Used compression pressure: white – 62.5 MPa, grey – 125 MPa, black – 250 MPa (data points for tablets containing ibuprofen batch Ibu II compressed with 62.5 MPa may not be visible as they are overlapped by data points obtained at higher tabletting pressures)

Microstructure to Dissolution Correlation (MDC)

Eventually, both the tablet microstructural characteristic in the form of CaHPO4∙2H2O dAvg and ibuprofen rlim were correlated (MDC, Fig. 10). The idea was to collect the combined influences of the mechanical properties of the input materials (particle size and viscoelastic behaviour) into the tablet microstructure parametrization (dAvg of CaHPO4∙2H2O, MMC) and see its subsequent relationship with the tablet performance (API dissolution rlim, MDC). Here, the tendencies for threshold-like behaviour described in “Mechanical Properties to Microstructure Correlation (MMC)” and “Formulation and Process Impact on Dissolution” sections are mutually compensated, and the drug release rate proves to be a strong function of the given tablet microstructure. It can be well characterised merely by the CaHPO4∙2H2O dAvg parameter irrespective of the tablet composition (ibuprofen amount in the formulation and initial particle size and morphology) and preparation method (applied compression load) in the form of linear dependency (Fig. 10c; Eq. (2)).

Ibuprofen limit release rate dependence on CaHPO4∙2H2O particle/aggregate size in prepared tablets for ibuprofen batch (a) Ibu II, (b) Ibu I and Ibu Im, (c) all tested tablets. ■ Ibu II, ● Ibu I, ▲ Ibu Im. Used compression pressure: white – 62.5 MPa, grey – 125 MPa, black – 250 MPa. Ibuprofen content in formulation: red – 15 wt.%, orange – 20 wt.%, purple – 25 wt.%, aqua – 35 wt.%, green – 50 wt.%, blue – 85 wt.%. Linear dependency of the limit release rate on the tablet microstructural parameter, CaHPO4∙2H2O dAvg (- - -), with the equation of rlim = 5.54 dAvg + 9.99, R2 = 0.8881

It can be argued that microstructure, which is determined by the material properties, is not the only or the most important factor affecting dissolution since physicochemical properties, such as hydrophilicity, pKa and the physical form of the API, also significantly impact the dissolution behaviour. However, the effect of those parameters could be captured via an experiment involving pure API, such as the intrinsic dissolution rate test. When such an experiment precedes the use of the proposed methodology, the simplifications made can be seen as reasonable within the tested system.

In practice, the MMC to MDC approach can work together with the traditional methods used for a better understanding of dissolution behaviour, such as disintegration tests and different types of tablet imaging and input material imaging (Raman, SEM, SEM-EDS). The major area of application would probably be in the scope of new formulation development (especially for complicated systems containing, i.e. API in the form of an amorphous dispersion system), as well as troubleshooting and dissolution profile fine-tuning. Considering the poor disintegration of tested tablets, the application of the obtained results could lie in the area of disintegrated tablet fragments more likely than in the tablets as whole dosage forms. More specifically, the surface of the model tablets, when compared with the surface of disintegrated tablet fragments of the corresponding composition, can lead to the prediction of the drug release from such fragments and, subsequently, of the whole disintegrating tablet in question.

The additional directing parameter of the drug release from the whole tablet would then be the amount of disintegrant used for tablet preparation and its different modes of incorporation into the tablet microstructure [37].

Conclusions

The studied system of plastic API (ibuprofen) and brittle excipient (CaHPO4∙2H2O) was used as a model to illustrate the potential of separating a formulation study into MMC and MDC parts. The direct relationship between the ibuprofen variant used, tablet composition and tablet compression parameters was difficult to analyse due to the mutually combined effects of those parameters. The MMC approach allows documenting the tablet microstructure through the excipient particle/aggregate size. This approach revealed that different combinations of the parameters can lead to similar microstructure and a threshold-like behaviour was observed when tablet microstructure (CaHPO4∙2H2O dAvg) and drug release rate (ibuprofen rlim) were evaluated separately. MDC approach, which considers the drug release rate to be a function of the tablet microstructure, successfully described the drug release rate only as a function of excipient particle/aggregate size in the tablet as a single microstructure descriptor and the influence of input particle size and other parameters on the dissolution beyond their effects already identified by MMC proved rather insignificant. The used system can thus provide a general understanding of compressed solid dosage forms in which the plastic API component is formulated with a hard excipient with a propensity to brittle fracture under higher compression pressures. For example, solid dispersions prepared from poorly soluble drugs with polymers can belong to the plastic API component category, and their formulation can benefit from the presented results and proposed methodology.

Data Availability

The data generated and analyzed in the study are included in this article. Any additional supportive data are available on request from the corresponding author.

Abbreviations

- MMC:

-

mechanical properties to microstructure correlation

- MDC:

-

microstructure to dissolution correlation

References

Zhang S, Stroud PA, Zhu A, Johnson MJ, Lomeo J, Burcham CL, et al. Characterizing the impact of spray dried particle morphology on tablet dissolution using quantitative X-ray microscopy. Eur J Pharm Sci. 2021;165:105921. https://doi.org/10.1016/j.ejps.2021.105921.

Fichtner F, Rasmuson Å, Alderborn G. Particle size distribution and evolution in tablet structure during and after compaction. Int J Pharm. 2005;292(1):211–25. https://doi.org/10.1016/j.ijpharm.2004.12.003.

Sinka IC, Motazedian F, Cocks ACF, Pitt KG. The effect of processing parameters on pharmaceutical tablet properties. Powder Technol. 2009;189(2):276–84. https://doi.org/10.1016/j.powtec.2008.04.020.

Markl D, Strobel A, Schlossnikl R, Botker J, Bawuah P, Ridgway C, et al. Characterisation of pore structures of pharmaceutical tablets: a review. Int J Pharm. 2018;538(1–2):188–214. https://doi.org/10.1016/j.ijpharm.2018.01.017.

Schomberg AK, Diener A, Wünsch I, Finke JH, Kwade A. The use of X-ray microtomography to investigate the microstructure of pharmaceutical tablets: potentials and comparison to common physical methods. Int J Pharm: X. 2021;3:100090. https://doi.org/10.1016/j.ijpx.2021.100090.

Gupta S, Omar T, Muzzio FJ. SEM/EDX and Raman chemical imaging of pharmaceutical tablets: a comparison of tablet surface preparation and analysis methods. Int J Pharm. 2022;611:121331. https://doi.org/10.1016/j.ijpharm.2021.121331.

Paul S, Sun CC. Dependence of friability on tablet mechanical properties and a predictive approach for binary mixtures. Pharm Res. 2017;34(12):2901–9. https://doi.org/10.1007/s11095-017-2273-5.

Sun CC. Microstructure of tablet—pharmaceutical significance, assessment, and engineering. Pharm Res. 2017;34(5):918–28. https://doi.org/10.1007/s11095-016-1989-y.

Petrů J, Zámostný P. Analysis of drug release from different agglomerates using a mathematical model. Dissolution Technol. 2014;21(4):40–7.

Patel S, Kaushal AM, Bansal AK. Compression physics in the formulation development of tablets. Crit Rev Ther Drug Carrier Syst. 2006;23(1):1–65. https://doi.org/10.1615/critrevtherdrugcarriersyst.v23.i1.10.

Tanner T, Antikainen O, Ehlers H, Yliruusi J. Introducing a novel gravitation-based high-velocity compaction analysis method for pharmaceutical powders. Int J Pharm. 2017;526(1):31–40. https://doi.org/10.1016/j.ijpharm.2017.04.039.

Antikainen O, Yliruusi J. Determining the compression behaviour of pharmaceutical powders from the force–distance compression profile. Int J Pharm. 2003;252(1):253–61. https://doi.org/10.1016/S0378-5173(02)00665-8.

Skelbæk-Pedersen AL, Vilhelmsen TK, Wallaert V, Rantanen J. Investigation of the effects of particle size on fragmentation during tableting. Int J Pharm. 2020;576:118985. https://doi.org/10.1016/j.ijpharm.2019.118985.

Zámostný P, Drahozal M, Švehla O, Römerová S, Marinko N. Drug release from carrier systems comprising meloxicam crystals formed by impregnation-evaporation. Crystals. 2023;13(3):527.

Šimek M, Grünwaldová V, Kratochvíl B. Hot-stage microscopy for determination of API fragmentation: comparison with other methods. Pharm Dev Technol. 2016;21(5):583–9. https://doi.org/10.3109/10837450.2015.1026608.

Penkavova V, Kulaviak L, Ruzicka MC, Puncochar M, Grof Z, Stepanek F, et al. Compression of anisometric granular materials. Powder Technol. 2019;342:887–98. https://doi.org/10.1016/j.powtec.2018.10.031.

Penkavova V, Kulaviak L, Ruzicka MC, Puncochar M, Zamostny P. Breakage of anisometric rod-shaped particles. Part Sci Technol. 2018;36(4):432–7. https://doi.org/10.1080/02726351.2017.1347969.

Khorasani M, Amigo JM, Sonnergaard J, Olsen P, Bertelsen P, Rantanen J. Visualization and prediction of porosity in roller compacted ribbons with near-infrared chemical imaging (NIR-CI). J Pharm Biomed Anal. 2015;109:11–7. https://doi.org/10.1016/j.jpba.2015.02.008.

Jia W, Yawman PD, Pandya KM, Sluga K, Ng T, Kou D, et al. Assessing the interrelationship of microstructure, properties, drug release performance, and preparation process for amorphous solid dispersions via noninvasive imaging analytics and material characterization. Pharm Res. 2022. https://doi.org/10.1007/s11095-022-03308-9.

Zhu A, Mao C, Luner PE, Lomeo J, So C, Marchal S, et al. Investigation of quantitative X-ray microscopy for assessment of API and excipient microstructure evolution in solid dosage processing. AAPS PharmSciTech. 2022;23(5):117. https://doi.org/10.1208/s12249-022-02271-3.

Gioumouxouzis CI, Katsamenis OL, Fatouros DG. X-ray microfocus computed tomography: a powerful tool for structural and functional characterisation of 3D printed dosage forms. J Microsc. 2020;277(3):135–9. https://doi.org/10.1111/jmi.12798.

Zeng Q, Wang L, Wu S, Fang G, Liu H, Li Z, et al. Dissolution profiles prediction of sinomenine hydrochloride sustained-release tablets using Raman mapping technique. Int J Pharm. 2022;620:121743. https://doi.org/10.1016/j.ijpharm.2022.121743.

Gupta S, Igne B, Omar T, Román-Ospino AD, Hausner D, Muzzio F. Multi-layer Raman chemical mapping to investigate the effect of API particle size and blending shear rate on API domain sizes in pharmaceutical tablets. Int J Pharm. 2022;624:122052. https://doi.org/10.1016/j.ijpharm.2022.122052.

Carlton R. Image analysis of EDS and backscatter SEM images of pharmaceutical tablets. Microsc Microanal. 2010;16(S2):662–3. https://doi.org/10.1017/s1431927610061283.

Scoutaris N, Vithani K, Slipper I, Chowdhry B, Douroumis D. SEM/EDX and confocal Raman microscopy as complementary tools for the characterization of pharmaceutical tablets. Int J Pharm. 2014;470(1):88–98. https://doi.org/10.1016/j.ijpharm.2014.05.007.

Boetker JP, Savolainen M, Koradia V, Tian F, Rades T, Müllertz A, et al. Insights into the early dissolution events of amlodipine using UV imaging and Raman spectroscopy. Mol Pharm. 2011;8(4):1372–80. https://doi.org/10.1021/mp200205z.

Slámová M, Školáková T, Školáková A, Patera J, Zámostný P. Preparation of solid dispersions with respect to the dissolution rate of active substance. J Drug Deliv Sci Technol. 2020;56:101518. https://doi.org/10.1016/j.jddst.2020.101518.

Školáková T, Slámová M, Školáková A, Kadeřábková A, Patera J, Zámostný P. Investigation of dissolution mechanism and release kinetics of poorly water-soluble tadalafil from amorphous solid dispersions prepared by various methods. Pharmaceutics. 2019;11(8):383.

Shi Q, Li F, Yeh S, Moinuddin SM, Xin J, Xu J, et al. Recent advances in enhancement of dissolution and supersaturation of poorly water-soluble drug in amorphous pharmaceutical solids: a review. AAPS PharmSciTech. 2021;23(1):16. https://doi.org/10.1208/s12249-021-02137-0.

Partheniadis I, Toskas M, Stavras F-M, Menexes G, Nikolakakis I. Impact of Hot-melt-extrusion on solid-state properties of pharmaceutical polymers and classification using hierarchical cluster analysis. Processes. 2020;8(10):1208.

Tanner T, Antikainen O, Ehlers H, Blanco D, Yliruusi J. Examining mechanical properties of various pharmaceutical excipients with the gravitation-based high-velocity compaction analysis method. Int J Pharm. 2018;539(1):131–8. https://doi.org/10.1016/j.ijpharm.2018.01.048.

Šimek M, Grünwaldová V, Kratochvíl B. A new way of solid dosage form samples preparation for SEM and FTIR using microtome. Pharm Dev Technol. 2014;19(4):411–6. https://doi.org/10.3109/10837450.2013.788515.

Slámová M, Prausová K, Epikaridisová J, Brokešová J, Kuentz M, Patera J, et al. Effect of co-milling on dissolution rate of poorly soluble drugs. Int J Pharm. 2021;597:120312. https://doi.org/10.1016/j.ijpharm.2021.120312.

Wood JH, Syarto JE, Letterman H. Improved holder for intrinsic dissolution rate studies. J Pharm Sci. 1965;54(7):1068. https://doi.org/10.1002/jps.2600540730.

Bergström CAS, Box K, Holm R, Matthews W, McAllister M, Müllertz A, et al. Biorelevant intrinsic dissolution profiling in early drug development: fundamental, methodological, and industrial aspects. Eur J Pharm Biopharm. 2019;139:101–14. https://doi.org/10.1016/j.ejpb.2019.03.011.

Parrott EL, Wurster DE, Higuchi T. Investigation of drug release from solids*. I. Some factors influencing the dissolution rate. J Am Pharm Assoc (Scientific ed). 1955;44(5):269–73. https://doi.org/10.1002/jps.3030440505.

Tomas J, Dvořák J, Dammer O, Štěpánek F. Frequency analysis of stress relaxation patterns reveals the effect of formulation and process history on tablet disintegration. Powder Technol. 2021;379:438–46. https://doi.org/10.1016/j.powtec.2020.10.081.

Acknowledgements

Technical and scientific support was provided by The Parc (Pharmaceutical Applied Research Center).

Funding

Open access publishing supported by the National Technical Library in Prague. This work was supported by the grant of Specific university research – grant No A2_FCHT_2023_034. The data for this work were measured on an instrument that was co-funded by the European Union in the “Infrastructure for Chemical Education for Practice” project (reg. no. CZ.02.2.67/0.0/0.0/18_057/0013355).

Author information

Authors and Affiliations

Contributions

Simona Römerová: conceptualization, investigation, data curation, methodology, validation, visualisation, writing – original draft, writing – review and editing. Ondřej Dammer: conceptualization, methodology, validation, writing – review and editing, supervision. Petr Zámostný: conceptualization, methodology, validation, writing – review and editing, supervision.

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

ESM 1

(DOCX 17.2 KB)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Römerová, S., Dammer, O. & Zámostný, P. Development of an Image-based Method for Tablet Microstructure Description and Its Correlation with API Release Rate. AAPS PharmSciTech 24, 199 (2023). https://doi.org/10.1208/s12249-023-02658-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-023-02658-w