Abstract

In a lyophilized protein/disaccharide system, the ability of the disaccharide to form a homogeneous mixture with the protein and to slow the protein mobility dictates the stabilization potential of the formulation. Human serum albumin was lyophilized with sucrose or trehalose in histidine, phosphate, or citrate buffer. 1H T1 relaxation times were measured by solid-state NMR spectroscopy and were used to assess the homogeneity and mobility of the samples after zero, six, and twelve months at different temperatures. The mobility of the samples decreased after 6 and 12 months storage at elevated temperatures, consistent with structural relaxation of the amorphous disaccharide matrix. Formulations with sucrose had lower mobility and greater stability than formulations with trehalose.

Similar content being viewed by others

Introduction

Protein-based drugs are established as a significant therapeutic modality for the treatment of numerous diseases (1). Some proteins are unstable in solution, and protein degradation can cause a loss of safety or efficacy (2, 3). One method to increase the storage stability is to lyophilize the protein in the presence of a disaccharide (4, 5). Disaccharides act as both a cryoprotectant during the lyophilization process and as a stabilizer for long-term stability (6, 7).

Sucrose and trehalose are the most common disaccharide excipients used for lyophilization, but it is difficult to predict whether sucrose or trehalose will provide better stability for a given protein at a given storage condition. Many studies have directly compared the long-term stability of proteins lyophilized with sucrose or trehalose with conflicting results (8). Zografi and co-workers showed that sucrose was a better stabilizer to human growth hormone (hGH) when compared to trehalose in lyophilized formulations stored at 40 or 50 °C in sealed vials with protein:disaccharide ratios of 1:6 (9). At higher temperatures such as 60 °C, or higher relative humidities such as 11%, it has been shown that trehalose was a better stabilizer to hGH (9) and a monoclonal antibody (10). Other direct comparisons of the stability of proteins lyophilized with sucrose or trehalose are summarized by Fang et al. (8). The effectiveness of a disaccharide to stabilize a protein during long-term storage relies on its ability to slow the mobility of the protein. Amorphous systems are mobile on at least two timescales, corresponding to α-relaxation and β-relaxation processes. α-relaxation processes are slower and are related to the proximity of the storage temperature to the glass transition temperature (Tg). In the case of sucrose and trehalose, the Tg of trehalose (~ 110 °C) is higher than that of sucrose (~ 60 °C), (11) suggesting that trehalose may be a better stabilizer because typical storage temperatures are further below the Tg. Despite sucrose having a lower Tg, Pikal and co-workers reported that hGH stability was approximately a factor of two better when lyophilized with sucrose than when lyophilized with trehalose (12). In another study, α-relaxation of lyophilized sucrose and trehalose were measured by isothermal microcalorimetry and the mobility of the sucrose was greater (13). Later, the same group concluded that the proximity of the storage temperature to the Tg cannot be used to predict protein stability and suggested that fast dynamics (β-relaxation processes) may be controlling the stability differences between the formulations (12).

Neutron backscattering can be used to measure βfast relaxation (mobility on ns timescale) of a lyophilized system. Cicerone et al. demonstrated that there was a linear relationship between disaccharide mass fraction and mean squared displacement of hydrogen atoms (< u2 >) in three lyophilized globular protein/disaccharide glasses. The authors then compiled the data from several studies where protein degradation rate was determined as a function of disaccharide mass fraction, and converted the disaccharide mass fraction to < u2 > using the linear relationship determined for the three lyophilized globular protein/disaccharide glasses. A linear relationship between degradation rate and < u2 > −1 was observed for eleven proteins in disaccharide glasses at various temperatures indicating that βfast relaxation is a good indicator of protein stability (14). However, neutron backscattering is not routinely used due to limited instrument availability and long analysis times. One study has been done which utilized the fluorescence red edge effect to derive a < u2 > surrogate in amorphous samples with an added fluorescence probe molecule (15). In glycerol, lyophilized trehalose, and lyophilized sucrose model systems, the method showed reasonable agreement with < u2 > measured with neutron backscattering, but the method did not agree well with < u2 > measured with neutron backscattering at very low temperatures.

Solid-state nuclear magnetic resonance (ssNMR) spectroscopy measures local mobility through proton spin-lattice relaxation times (1H T1) and is a practical and available analytical technique. 1H T1 measures mobility on timescales comparable to neutron backscattering (βfast relaxation) (16). ssNMR can also measure spin-lattice relaxation times in the rotating frame (1H T1ρ), which measure mobility at lower frequencies. Several reports in literature have attempted to correlate protein mobility measured by ssNMR with protein stability. Yoshioka et al. lyophilized β-galactosidase with various weight fractions of trehalose, sucrose or stachyose and measured T1ρ and aggregation rate (17). It was shown that sucrose slowed the local mobility more when compared to trehalose or stachyose. The authors concluded that the order of the ability of the excipient to decrease the local mobility was the same as the order of their ability to decrease aggregation rate. Additionally, it was shown that an increase in weight fraction of excipient increased the ability of the excipient to slow local mobility. Separovic et al. lyophilized recombinant human deoxyribonuclease type 1 (DNAse), insulin, and lysozyme without stabilizers (18). Lyophilized proteins were then stored at a range of relative humidities for 5 – 6 days. After equilibration, mobility was measured by ssNMR 1H T1 and 1H T1ρ relaxation times, and samples were stored for 60 days. The 1H T1 of protein molecules decreased with an increasing water content, likely due to changes in hydrogen bonding and the dynamics of the protein’s surface groups. The authors report that a decrease in 1H T1 relaxation time is associated with aggregation and loss of enzymatic activity. Lam et al. lyophilized lysozyme with trehalose or lactose and measured 1H T1 and 1H T1ρ relaxation times (19). The addition of either trehalose or lactose caused the 1H T1 of the lysozyme to increase. At lysozyme:excipient ratios of 8:2, both excipients formed a homogeneous matrix with the protein, indicated by similar 1H T1 values of the lysozyme and excipient. At lysozyme:excipient ratios of 2:8, trehalose formed a homogeneous matrix, but lactose crystallized and phase separated, which was measured by an increase in 1H T1 of the lactose. Samples which showed phase separation in ssNMR 1H T1 relaxation times also showed decrease in activity and increase in aggregation.

Mensink et al. lyophilized Immunoglobulin G (IgG) with trehalose, inulin, and dextran, measured 1H T1 at time zero, and measured aggregation rate by size exclusion chromatography (SEC) at extended timepoints (20). IgG lyophilized with trehalose exhibited the longest 1H T1 relaxation time and the greatest stability after storage at 50 °C. When IgG was lyophilized with 70 kDa dextran, the protein and excipient phase separated, despite remaining amorphous. The protein also had a much shorter 1H T1 relaxation time, and the stability was comparable to IgG lyophilized without a stabilizer. Samples containing lower molecular dextran and inulin had 1H T1 relaxation times that correlated with the relative stability of the protein formulations, where samples with longer 1H T1 relaxation times had better stability. All other excipients used resulted in relatively poor stability when compared to trehalose.

One challenge of the Mensink study was that the only excipient that was studied that is relevant to protein formulations was trehalose. In addition, relaxation times were only measured on the initial samples, and samples that were stored would have undergone structural relaxation, presumably leading to longer relaxation times. There was also no comparison of sucrose to trehalose in that study. While it has been well established that sucrose is a better stabilizer than trehalose, it has not been shown that trehalose would have a shorter relaxation time, and therefore higher mobility compared to sucrose. The purpose of this study is threefold: 1) compare the 1H T1 relaxation times of sucrose and trehalose upon initial formulation to determine if the 1H T1 relaxation time of sucrose is longer than the 1H T1 relaxation time; 2) to determine if the 1H T1 relaxation times of sucrose and trehalose increase upon storage at different temperatures in the presence of protein, indicating that structural relaxation has occurred in the system; 3) to determine if different buffer systems have a significant impact upon the 1H T1 relaxation times and/or stability under various storage conditions.

ssNMR was used to determine the 1H T1 relaxation times of lyophilized human serum albumin (HSA) samples containing either sucrose or trehalose and with either phosphate, histidine, or citrate buffer. Stability data was compared to the ssNMR 1H T1 relaxation times. Specifically, samples were lyophilized and stored at -20 °C, 4 °C, 37 °C, or 56 °C for 12 months. Relative sample stability was correlated with the 1H T1 relaxation time of the disaccharide at time zero, where HSA/sucrose samples were both more stable than HSA/trehalose samples during storage and had a longer 1H T1 relaxation time. 1H T1 relaxation times increased during storage, indicating that the sample mobility decreased due to structural relaxation occurring in the samples. Although multiple buffers were studied, the specific buffer used had little effect on the stability of the HSA compared to the disaccharide used and the storage temperature.

Materials & Methods

Sample Preparation

Albumin (20% (w/v)) from clinical grade product was exhaustively dialysed into high purity deionised water (NIBSC media services) using 8 kDa dialysis tubing (Spectrum, Thermo Fisher, Hemel Hempstead, UK) at 2–8 °C over a period of 44 h to remove all existing excipients. After dialysis, the final protein concentration was approximately 11.1% (w/v) based on OD280 nm absorbance.

The protein solution prepared above was formulated to a final concentration of 5% (w/v) protein, 5% (w/v) sucrose (USP/Ph Eur grade, Merck Life Science Uk Ltd, Gillingham, UK), and either 15 mM histidine, 15 mM sodium phosphate or 15 mM sodium citrate (pH 7). Another formulation with 5% (w/v) trehalose (highest analytical grade, Merck Life Science Uk Ltd, Gillingham, UK) in place of sucrose was also prepared for the sodium phosphate formulation. 0.25 mg/mL of 1-13C labeled malonic acid (Sigma Aldrich Ltd., Poole, UK) was added as a probe molecule to measure microenvironment pH changes between formulations (21,22,23). 3 mL of each formulation were dispensed into eight 10 mL vials (VC005-20C 10 mL, Schott, Adelphi Tubes, Haywards Heath, UK), and vials were semi-stoppered with 20 mm diameter halobutyl igloo closures.

Thermal Analysis

Freeze drying microscopy was performed on a Linkam FDCS 196 stage with liquid nitrogen cooling and programmable heating using Linkam control software and an Olympus BK51 microscope with plane polarised lighting (Linkam Scientific Ltd, Epsom, UK). A solution with known collapse temperature (5% trehalose in water, - 30 °C) was used to confirm instrument calibration. 3—5 µL of each of the sucrose formulations were tested by pipetting into a quartz crucible and trapping the droplet under a 13 mm coverslip. The droplet was frozen to -50 °C at 10 °C/min. Pressure was reduced to < 100 µbar, and then the temperature was increased at 5 °C/min until the collapse was observed. Collapse temperature can be found in the Supporting Information Table S1.

Modulated Differential Scanning Calorimetry (mDSC) was performed on a TA Instruments Q2000 DSC with autosampler and cooling accessory. (TA Instruments, Wilmslow, UK) 80 µL of each sample was added to a high-volume hermetic steel pan. Freezing was at maximum rate (nominally 10°C/min) to -90 °C and the samples were held isothermally for 10 min. The sample was then ramped to 25 °C at 3 °C/min with a modulation of 1 °C/min. Glass transitions/eutectics were calculated using Universal Analysis Software (TA Instruments, Wilmslow, UK). Glass transition temperature (midpoint) of maximally freeze concentrated solution (Tg’) are tabulated in the Supporting Information Table S1.

Lyophilization

Glass transition temperature of the maximally freeze concentrated solution (Tg’) and the collapse temperature (Tc) by freeze dry microscopy were measured for each of the sucrose formulations to determine the shelf temperature for primary drying which would not result in cake collapse. Tg’ and Tc can be found in the Supporting Information in Table S1.

Vials were loaded into a single freeze dryer run on a Telstar LyoBeta 15 freeze dryer (Telstar Azbil spA, Terrassa, Spain). Samples were frozen by ramping the shelf to -40 °C at 1 °C/min. Samples were held for 2 h at -40 °C to ensure the solution in all vials was frozen and the ice crystallization was complete. Primary drying was started by reducing the pressure to 200 µbar and raising the shelf temperature to -20 °C. Samples were held at these conditions for 30 h. By this point, two thermocouples placed in vials near the front of the vial pack had shown inflection, although comparative vapour pressure measurement still indicated a difference between Pirani gauge and baratron capacitance manometer measurements. Secondary drying was begun by ramping the shelf temperature to 25 °C at 0.125 °C/min, and the pressure was reduced to 50 µbar. Samples were held at these conditions for 8 h. The thermocouple profiles indicated only a small lag during the ramping phase and equilibration at the shelf temperature during most of secondary drying. The vials were then backfilled with dry nitrogen to atmospheric pressure. The vials were stoppered in situ and sealed with aluminium crimp closures.

All lyophilized samples were pharmaceutically elegant well-formed cakes with no apparent collapse. Photographs of the lyophilized formulations are shown in Fig. S1 in the Supporting Information. Residual moisture contents ranged from 0.27 to 0.38% (w/w) after lyophilization. Headspace oxygen levels were < 0.15% and suggest that headspace gases should not adversely impact storage.

Residual Moisture Analysis

Residual moisture in the lyophilised cakes at time zero was measured by coulometric Karl Fischer (KF) titration (A1-Envirosciences, Blyth, UK.). Residual moisture was not measured at extended time points because the vial headspace was backfilled with dry nitrogen after the lyophilization cycle, and vials were sealed with aluminum crimp caps. In a drybag (Pyramid, Cole Parmar, London UK) with RH < 10%, a single vial of each product was distributed between three 4 mL HPLC autosampler vials (Thermo Fisher Ltd, Loughborough, UK). Vials were capped with screw caps with a polytetrafluoroethylene (PTFE) membrane seal. Samples were then analyzed on an automated KF system based upon the AquaFast (A1 Envirosciences Ltd, Blyth, UK) with a CA-200 coulometer (Mitsubishi, supplied by A1 Envirosciences) and a GX-270 robotic sampler (Gilson, supplied by A1 Envirosciences). Mitsubishi cathode and anode reagents were used (Aquamicron, Mitsubishi, supplied by A1 Envirosciences) and a check solution of known water content was used to check performance on each assay (Aquamicron P, Mitsubishi). The moisture content of empty vials was measured and used as a blank subtraction for the freeze-dried materials. The mean of three determinations with CV was reported for each sample. Residual moisture content can be found in Table S2 in the Supporting Information.

Oxygen Headspace Analysis

Frequency-modulated spectroscopy at 760 nm (FMS 760, Lighthouse Instruments, Charlottesville, VA, USA) was used as a non-destructive method to measure residual oxygen in the headspace gas on three vials of each freeze dried formulation. Calibration was performed with NIST traceable oxygen standards (0% and 20%) in identical 10 mL vials. Oxygen headspace data can be found in Table S2 in the Supporting Information.

Stability Studies

Samples were stored at -20 °C, 4 °C, 37 °C, and 56 °C for up to 12 months. At 6 and 12 months, samples were removed for analysis either by SEC to assess aggregation, or by ssNMR to determine 1H T1 relaxation times.

HPLC SEC Analysis

HPLC SEC was performed according to the Ph Eur SEC HPLC method (2.2.30, Ph Eur 9th Ed., Strasbourg, France; Council of Europe 2019). Samples were reconstituted to 3 mL with deionised water and then assayed by loading approximately 100 µL of 0.2 µm filtered sample injection volume onto a Thermo Ultimate 3000 HPLC (Thermo Fisher, Hemel Hempstead, UK) with a disodium hydrogen phosphate, sodium dihydrogen phosphate, sodium chloride, sodium azide buffer as mobile phase and with isocratic elution on a TSKgel G3000SWXL column (7.8 × 300 mm, I.D. x length) at 0.5 mL/min. Protein molecular size distribution was assessed by OD280nm and compared to a non-lyophilized albumin control preparation.

Solid-State Nuclear Magnetic Resonance Spectroscopy (ssNMR)

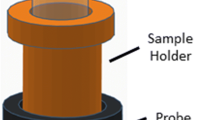

ssNMR data at 0 and 6 months were acquired using a Tecmag Apollo spectrometer operating at 100.6 MHz for 13C (9.4 T static magnetic field). 12 month data was acquired using a Bruker Avance spectrometer operating at 100.505 MHz for 13C. In a drybox (RH < 3%), lyophilized powders were packed into zirconia rotors and sealed with Kel-F endcaps (Revolution NMR, LLC, Fort Collins, CO). All experiments were performed at room temperature using a double resonance magic angle spinning (MAS) probe. All 13C spectra were acquired under MAS (24) at 4 kHz, using ramped-amplitude cross-polarization (CP) (25), total sideband suppression (TOSS) (26), and SPINAL-64 1H decoupling (27). An approximately 4 µs 1H 90º pulse, and a 2 ms contact time were used in all experiments. 3-Methylglutaric acid was used as an external chemical shift standard and to optimize spectrometer settings (28).

1H T1 relaxation times were measured using a saturation recovery experiment through 13C observation. A saturation recovery experiment is a pseudo 2D NMR experiment where the 13C spectrum is plotted against a variably delay time. 90º pulses were used to saturate the magnetization, followed by a variable pulse delay to allow the magnetization to recover back to equilibrium. After Fourier transform, a peak from each sample component was identified (25 ppm HSA, 75 ppm disaccharide, 176 ppm malonic acid) based on high intensity and minimal overlap with other system components. The chosen peaks were then integrated over the full width at half maximum, and the areas were plotted against the delay time. Equation 1 was fit to the data using KaleidaGraph (Synergy Software, Reading, PA)

where M is the area of the chosen peak, t is the variable delay time, M0 is an amplitude parameter from the fit, and T1 is the spin-lattice relaxation time in the laboratory frame. 1H T1 relaxation times are reported with error values that reflect the goodness-of-fit of Eq. 1 to the data.

Results

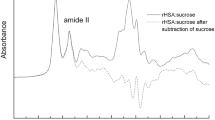

Figure 1 shows two representative spectra of lyophilized formulations using phosphate buffer, one containing HSA, sucrose, and malonic acid, and a second containing HSA, trehalose, and malonic acid. The original purpose of including 13C labeled malonic acid was to measure microenvironment pH changes between buffers (21,22,23). However, sensitivity precluded an accurate measure of pH change between samples, so the samples served as duplicates for each data set. Although malonic acid was present in all samples, it will not be discussed further. Broad peaks indicate that the sample is amorphous after lyophilization. The highlighted region from 72.5—77.5 ppm was used for 1H T1 determination of the sucrose or trehalose, and the highlighted region from 22.5—27.5 ppm was used for 1H T1 determination of the HSA.

ssNMR 1H T1 relaxation times can be used to determine if a sample is homogeneous, as well as the degree of molecular mobility present in the sample. Sample homogeneity is determined by measuring and comparing the 1H T1 relaxation times of the protein and disaccharide. Due to spin diffusion, magnetization is transferred between neighboring nuclei at a rate given by the spin diffusion constant. The distance over which spin diffusion occurs is related to the relaxation time by Eq. 2 (29,30,31).

where L is the distance of spin diffusion, D is the diffusion coefficient, which is assumed to be 10–12 cm2/s (29) and T is the 1H T1 relaxation time. Because 1H T1 is typically on the order of 1—5 s for protein/disaccharide systems, spin diffusion occurs over approximately 20 – 50 nm. Spin diffusion results in magnetization transfer between nearby nuclei, resulting in a relaxation time that is a weighted average of the nuclei in the distance over which spin diffusion occurs. If the sample is homogeneous, the protein and disaccharide will have the same 1H T1 relaxation times. If the sample is inhomogeneous, where the degree of inhomogeneity is greater than 20–50 nm, then the 1H T1 relaxation times of each component are not averaged and will correspond to the values of the two independent components. Samples that are partially inhomogeneous will have 1H T1 relaxation values that are different for the protein and disaccharide, but the values will be closer than that found for the two independent components. Homogeneity on a smaller domain size could be assessed in a similar way using 1H T1ρ relaxation times, however 1H T1ρ relaxation times were not measured here because it has been shown that values do not correlate with protein stability (19).

Table I shows 1H T1 relaxation times for Pure HSA, sucrose, and trehalose, as well as lyophilized HSA and sucrose or trehalose in either histidine, sodium phosphate or sodium citrate buffer. Shortly after lyophilization, HSA by itself had a 1H T1 relaxation time of 1.01 s, lyophilized sucrose had a 1H T1 relaxation time of 3.34 s, and lyophilized trehalose had a 1H T1 relaxation time of 3.95 s. 1H T1 relaxation time values were approximately 2 s for all formulations. This is consistent with an average relaxation time of a 1:1 mixture of HSA and sucrose or trehalose. The 1H T1 relaxation time of each component in each formulation is approximately the same, indicating that all samples are homogeneous on an approximately 20—50 nm domain. Samples prepared using sucrose in histidine, sodium phosphate or sodium citrate buffers have the same 1H T1 relaxation time for each component, suggesting that changing the buffer and any potential changes in microenvironment pH do not affect the 1H T1 relaxation time. The only noticeable difference between the formulations in Table I is that the 1H T1 relaxation time of each sample component is higher when sucrose was used as a stabilizer when compared to when trehalose was used as a stabilizer.

Sample Storage and Mobility

Figure 2 shows the disaccharide 1H T1 relaxation time of samples that were stored at -20 ºC, 4 ºC, 37 ºC, and 56 ºC for 6 months. Two basic trends can be observed from the data shown in Fig. 2. First, samples that were stored at higher temperatures generally had a longer 1H T1 relaxation time. The HSA/sucrose/histidine sample had more variation in 1H T1 relaxation times but followed the general trend of increasing with storage temperature. Second, the 1H T1 relaxation time for the trehalose samples were consistently lower than the sucrose samples.

Figure 3 shows the disaccharide 1H T1 relaxation time of samples that were stored at 4 ºC and 37 ºC for 12 months. The same trend that the 1H T1 relaxation time of the HSA/sucrose samples was longer than the 1H T1 relaxation time of the HSA/trehalose sample observed in Fig. 2 can also be seen in Fig. 3. After 12 months, the increase in 1H T1 relaxation time with increasing storage temperature is less than the corresponding increase in 1H T1 relaxation time after 6 months, however the 1H T1 relaxation time of all samples after 12 months of storage is longer than the 1H T1 relaxation time after 6 months.

The concept of samples stored at a higher temperature having a longer 1H T1 relaxation time is consistent with the fact that structural relaxation occurs in these samples. Structural relaxation refers to the decrease in free volume of a sample as molecules rearrange over time. A denser sample likely has stronger intermolecular interactions, such as hydrogen bonding (32). Pikal and co-workers observed structural relaxation occurring in protein formulations, where structural relaxation is observed by a non-reversible endothermic event at the glass transition temperature (Tg) in a differential scanning calorimetry experiment (33). Pyszczynski found that the 1H T1 relaxation time of lyophilized trehalose increased from about 4.6 s to about 7.1 s after storage for 24 h at 20 °C below the Tg of trehalose (34). The increase in the 1H T1 relaxation time as a function of storage temperature in Figs. 2 and 3 is entirely consistent with the samples undergoing structural relaxation. The 1H T1 relaxation times in Fig. 2 are consistently shorter than 1H T1 relaxation times shown in Fig. 3, which corresponds to 6 months of storage vs 12 months, where longer storage times result in increased 1H T1 relaxation times due to structural relaxation to a denser state or a state with fewer highly mobile states.

Stability Data on Storage

Size exclusion chromatography was used to measure stability of lyophilized HSA systems stored at -20 ºC, 4 ºC, and 37 ºC and 56 ºC for 90 days, 190 days, and 401 days. In size exclusion chromatography, the peaks corresponding to monomer and the peaks corresponding to higher molecular weight species (dimer, trimer, and larger aggregates) are separated in a chromatogram. The relative area of each peak corresponds to the amount of each species in the sample. Percent monomer remaining is a measure of the physical stability of the protein.

Figure 4 shows HSA monomer percent for sucrose formulations lyophilized from histidine, phosphate, and citrate buffers at 91 days, 192 days, and 401 days and at storage temperatures of -20 ºC, 4 ºC, and 37 ºC and 56 ºC. At storage temperatures of -20 ºC, 4 ºC, and 37 ºC, HSA monomer content remained above 94% for up to 401 days, although the samples stored at 37 ºC showed a slight decrease in monomer content. After storage at 56 ºC, HSA monomer content decreased to approximately 90–92%. At storage temperatures of -20 ºC, 4 ºC, and 37 ºC, buffer effects on the HSA stability were minimal, however after storage at 56 ºC for 1 month, the effect of buffer became apparent with the greatest HSA stability occurring when the formulation prepared in histidine buffer, followed by citrate buffer and then phosphate buffer.

Figure 5 shows HSA monomer percent for sucrose and trehalose formulations lyophilized from phosphate buffer at 91 days, 192 days, and 401 days for storage temperatures of -20 ºC, 4 ºC, and 37 ºC and 56 ºC. At -20 ºC and 4 ºC, monomer content remained approximately 95% for both sucrose and trehalose formulations. At 37 ºC and 56 ºC, monomer content is higher for sucrose containing formulations when compared to trehalose formulations, where a significant difference can be seen between the sucrose and trehalose formulations at 56 ºC and 12-months stability. Trehalose loses more than twice the monomer content when compared to sucrose.

Discussion

Correlation of 1H T1 Relaxation Times with Protein Stability

The results from this study are consistent with the results found by Mensink et al., where the samples with the longest 1H T1 relaxation time also had the greatest stability (20). In the Mensink study, structural variability between the excipients was very high, and inulin and dextran are not typical lyophilization excipients, making it harder to show that longer 1H T1 relaxation times are correlated with higher stability in samples lyophilized with commonly used excipients sucrose and trehalose. In both the Mensink study and in this study, very little degradation was observed for the proteins lyophilized with a disaccharide at 90 days. In this study, samples were stored for over 400 days and a clear difference was observed between the degradation rates of HSA lyophilized with either sucrose or trehalose. The 1H T1 relaxation time of the HSA/sucrose system was consistently longer than that of the HSA/trehalose system, consistent with also having greater stability.

Mensink et al. showed a linear relationship between 1H T1 relaxation time and aggregation rate per square root of time for various IgG/excipient systems. For example, after 90 days of storage, samples that lost approximately 20% monomer content showed a difference in 1H T1 relaxation time of the protein of about 1 s when compared to the 1H T1 relaxation time of the protein in a sample that lost approximately 0% monomer content (3.3 s vs 4.3 s, respectively). Samples that lost approximately 65% monomer content showed a difference in 1H T1 relaxation times of about 3.3 s (1 s vs 4.3 s).

It is possible to plot the degradation rate obtained in this study on the same graph shown in the Mensink study (Fig. 6). The 1H T1 relaxation time differences need to be scaled by approximately 2.22 because of the different protein to sugar ratios (12:88 in Mensink study, 50:50 in this study). This is based upon measured 1H T1 relaxation times in our laboratory for sucrose and for trehalose, and for measured 1H T1 relaxation times of 50:50 mixtures of HSA and sucrose/trehalose (35). The loss of monomer content in the trehalose sample was approximately 13% after 90 days at 56 ºC, which would correspond to a difference in 1H T1 relaxation time of about 0.5 s. Multiplying this by the scaling factor of 2.22 results in a decrease in 1H T1 relaxation time of 0.29 s. The loss of monomer content in the sucrose sample was approximately 3% after 90 days at 56 ºC, which would correspond to a difference in 1H T1 relaxation time of about 0.15 s. Multiplying this by the scaling factor of 2.22 results in a decrease in 1H T1 relaxation time of 0.09 s. This is consistent with the approximately 0.2 s difference between the 1H T1 relaxation time between the HSA/sucrose and HSA/trehalose samples. Several assumptions were made in performing these calculations, such as that the scaling factor for 1H T1 relaxation times was valid, that 1H T1 relaxation time comparisons can be made across different excipients (at least different carbohydrate excipients), and that the scaling factor for percent degradation is valid. Both the direction and the magnitude of the changes in 1H T1 relaxation time are consistent with what would be expected based upon the data from the Mensink study.

Correlation of 1H T1 Relaxation Data with Storage Time/Temperature

In the Mensink study, 1H T1 relaxation times were only measured at time zero and not after storage. The 1H T1 relaxation data showed that samples stored at higher temperatures had a longer 1H T1 relaxation time, consistent with the fact that samples are undergoing structural relaxation. As structural relaxation occurs, the disaccharide matrix can better protect the protein because it has less mobility (16). Structural relaxation may also help to explain why the degradation rate depends on the square root of time instead of being linear with time. In the absence of structural relaxation, the degradation rate would be closer to linear instead of depending upon the square root of time.

One explanation for sucrose being a better stabilizer for HSA than trehalose is the ability for sucrose to undergo greater levels of structural relaxation during storage. The Tg of sucrose is approximately 45 ºC lower than the Tg of trehalose, so storage temperatures were closer to the Tg of sucrose than to the Tg of trehalose. When storage temperature is sufficiently below Tg, mobility is lowered to a level where structural relaxation cannot occur as quickly. If storage temperature is sufficient for structural relaxation, the system can become less mobile and more stable over time. The increase in the 1H T1 relaxation time shown in Figs. 2 and 3, which indicates a decrease in mobility, suggests structural relaxation has occurred.

All samples showed greater than 80% monomer at even the longest storage times and highest temperatures, as shown in Figs. 4 and 5. 1H T1 relaxation times for all samples shown in Table I are very similar for all formulations which is consistent with the fact that they are all good stabilizers and maintain high monomer content over storage.

Impact of Buffer on Protein Stability

Initially, the purpose of utilizing three different buffers (histidine, citrate, and phosphate) in this study was to study the effect of microenvironment pH on the stability of HSA. However, sensitivity issues inherent to ssNMR prohibited accurate measurement of changes in microenvironment pH. At storage temperatures of -20 ºC and 4 ºC minimal difference is shown between the stability of the HSA as a function of the buffer used. At 56 ºC, a small difference in stability is shown, with the greatest stability provided by histidine, followed by citrate, followed by phosphate. In this study, degradation is dominated by the storage conditions and the disaccharide used. At time zero, 1H T1 relaxation times are very similar between samples (approximately 2 s) and we are reluctant to make a conclusion correlating mobility measured by 1H T1 relaxation time and stability in samples with different buffers. It is possible that the difference in stabilization provided by the three buffers is not due to mobility, but other factors, such as microenvironment pH. This continues to be an area of ongoing research that we are pursuing.

Conclusions

Lyophilized HSA/sucrose formulations were more stable and had longer 1H T1 relaxation times than HSA/trehalose formulations. 1H T1 relaxation times increased with increasing storage temperature after 6 months of storage. After 12 months, 1H T1 relaxation times were longer than 1H T1 relaxation times at 6 months but did not further increase at higher storage temperatures. HSA/trehalose samples were more than twice as unstable when compared to HSA/sucrose samples when stored at 56 ºC. The difference in the 1H T1 relaxation times between HSA/sucrose and HSA/trehalose samples are consistent with results found in a study by Mensink et al. and the increase in 1H T1 relaxation times upon storage at high temperatures is consistent with structural relaxation occurring in the samples.

References

Martins AC, Oshiro MY, Albericio F, de la Torre BG, Pereira GJV, Gonzaga RV. Trends and perspectives of biological drug approvals by the FDA: a review from 2015 to 2021. Biomedicines. 2022;10(9):2325. https://doi.org/10.3390/biomedicines10092325.

Arakawa T, Prestrelski SJ, Kenney WC, Carpenter JF. Factors affecting short-term and long-term stabilities of proteins. Adv Drug Deliv Rev. 1993;10(1):1–28. https://doi.org/10.1016/0169-409X(93)90003-M.

Krause ME, Sahin E. Chemical and physical instabilities in manufacturing and storage of therapeutic proteins. Curr Opin Biotechnol. 2019;60:159–67. https://doi.org/10.1016/j.copbio.2019.01.014.

Carpenter JF, Chang BS, Garzon-Rodriguez W, Randolph TW. Rational design of stable lyophilized protein formulations: theory and practice. In Carpenter JF, Manning MC, editors. Rational design of stable protein formulations: theory and practice. Boston, MA: Springer US; 2002. pp. 109–133. https://doi.org/10.1007/978-1-4615-0557-0_5.

Chang JFC, Byeong S. Lyophilization of protein pharmaceuticals. In Biotechnology and biopharmaceutical manufacturing, processing, and preservation. CRC Press; 1996.

Chang L, Shepherd D, Sun J, Ouellette D, Grant KL, Tang X, et al. Mechanism of protein stabilization by sugars during freeze-drying and storage: native structure preservation, specific interaction, and/or immobilization in a glassy matrix? J Pharm Sci. 2005;94(7):1427–44. https://doi.org/10.1002/jps.20364.

Chang L, Pikal MJ. Mechanisms of protein stabilization in the solid state. J Pharm Sci. 2009;98(9):2886–908. https://doi.org/10.1002/jps.21825.

Fang R, Obeidat W, Pikal MJ, Bogner RH. Evaluation of predictors of protein relative stability obtained by solid-state hydrogen/deuterium exchange monitored by FTIR. Pharm Res. 2020;37(9):168. https://doi.org/10.1007/s11095-020-02897-7.

Hill JJ, Shalaev EY, Zografi G. The importance of individual protein molecule dynamics in developing and assessing solid state protein preparations. J Pharm Sci. 2014;103(9):2605–14. https://doi.org/10.1002/jps.24021.

Li Y, Williams TD, Schowen RL, Topp EM. Characterizing protein structure in amorphous solids using hydrogen/deuterium exchange with mass spectrometry. Anal Biochem. 2007;366(1):18–28. https://doi.org/10.1016/j.ab.2007.03.041.

Roe KD, Labuza TP. Glass transition and crystallization of amorphous trehalose-sucrose mixtures. Int J Food Prop. 2005;8(3):559–74. https://doi.org/10.1080/10942910500269824.

Pikal MJ, Rigsbee D, Roy ML, Galreath D, Kovach KJ, Wang B, et al. Solid state chemistry of proteins: II. The correlation of storage stability of freeze‐dried human growth hormone (hGH) with structure and dynamics in the glassy solid. J Pharm Sci. 2008;97(12):5106–5121. https://doi.org/10.1002/jps.21374.

Liu J, Rigsbee DR, Stotz C, Pikal MJ. Dynamics of pharmaceutical amorphous solids: the study of enthalpy relaxation by isothermal microcalorimetry. J Pharm Sci. 2002;91(8):1853–62. https://doi.org/10.1002/jps.10181.

Cicerone MT, Douglas JF. β-Relaxation governs protein stability in sugar-glass matrices. Soft Matter. 2012;8(10):2983–91. https://doi.org/10.1039/C2SM06979B.

Qian KK, Grobelny PJ, Tyagi M, Cicerone MT. Using the fluorescence red edge effect to assess the long-term stability of lyophilized protein formulations. Mol Pharm. 2015;12(4):1141–9. https://doi.org/10.1021/mp500641f.

Cicerone MT, Pikal MJ, Qian KK. Stabilization of proteins in solid form. Adv Drug Deliv Rev. 2015;93:14–24. https://doi.org/10.1016/j.addr.2015.05.006.

Yoshioka S, Miyazaki T, Aso Y, Kawanishi T. Significance of local mobility in aggregation of β-Galactosidase lyophilized with trehalose, sucrose or stachyose. Pharm Res. 2007;24(9):1660–7. https://doi.org/10.1007/s11095-007-9296-2.

Separovic F, Lam YH, Ke X, Chan H-K. A solid-state NMR study of protein hydration and stability. Pharm Res. 1998;15(12):1816–21. https://doi.org/10.1023/A:1011993620177.

Lam Y-H, Bustami R, Phan T, Chan H-K, Separovic F. A solid-state NMR study of protein mobility in lyophilized protein-sugar powders. J Pharm Sci. 2002;91(4):943–51. https://doi.org/10.1002/jps.10089.

Mensink MA, Nethercott MJ, Hinrichs WLJ, van der VoortMaarschalk K, Frijlink HW, Munson EJ, Pikal MJ. Influence of miscibility of protein-sugar lyophilizates on their storage stability. AAPS J. 2016;18(5):1225–32. https://doi.org/10.1208/s12248-016-9937-7.

Du Y, Li J, Xu W, Cote A, Lay-Fortenbery A, Suryanarayanan R, Su Y. Solid-state NMR spectroscopy to probe state and phase transitions in frozen solutions. Mol Pharm. 2023;20(12):6380–90. https://doi.org/10.1021/acs.molpharmaceut.3c00764.

Li M, Koranne S, Fang R, Lu X, Williams DM, Munson EJ, Bhambhani A, Su Y. Probing microenvironmental acidity in lyophilized protein and vaccine formulations using solid-state NMR spectroscopy. J Pharm Sci. 2021;110(3):1292–301. https://doi.org/10.1016/j.xphs.2020.11.017.

Lay-Fortenbery A, Su Y, Munson EJ. Utilizing solid-state NMR spectroscopy to assess properties of lyophilized formulations. In: Jameel F, editor. Principles and practices of lyophilization in product development and manufacturing; AAPS Advances in the Pharmaceutical Sciences Series. Cham: Springer International Publishing; 2023. pp. 291–306. https://doi.org/10.1007/978-3-031-12634-5_16.

Andrew ER, Bradbury A, Eades RG. Removal of dipolar broadening of nuclear magnetic resonance spectra of solids by specimen rotation. Nature. 1959;183(4678):1802–3. https://doi.org/10.1038/1831802a0.

Pines A, Gibby MG, Waugh JS. Proton-enhanced NMR of dilute spins in solids. J Chem Phys. 1973;59(2):569–90. https://doi.org/10.1063/1.1680061.

Dixon WT, Schaefer J, Sefcik MD, Stejskal EO, McKay RA. Total suppression of sidebands in CPMAS C-13 NMR. J Magn Reson 1969. 1982;49(2):341–345. https://doi.org/10.1016/0022-2364(82)90199-8.

Fung BM, Khitrin AK, Ermolaev K. An improved broadband decoupling sequence for liquid crystals and solids. J Magn Reson. 2000;142(1):97–101. https://doi.org/10.1006/jmre.1999.1896.

Barich DH, Gorman EM, Zell MT, Munson EJ. 3-Methylglutaric acid as a 13C solid-state NMR standard. Solid State Nucl Magn Reson. 2006;30(3):125–9. https://doi.org/10.1016/j.ssnmr.2006.06.001.

Bovey F, Mirau P. NMR of Polymers, 1st ed.. Academic Press; 1996.

Lagassé HAD, Alexaki A, Simhadri VL, Katagiri NH, Jankowski W, Sauna ZE, et al. Recent advances in (Therapeutic Protein) drug development. F1000Res. 2017;6:113. https://doi.org/10.12688/f1000research.9970.1.

Pham TN, Watson SA, Edwards AJ, Chavda M, Clawson JS, Strohmeier M, Vogt FG. Analysis of amorphous solid dispersions using 2D solid-state NMR and 1H T1 relaxation measurements. Mol Pharm. 2010;7(5):1667–91. https://doi.org/10.1021/mp100205g.

Green JE, Sitaula R, Fowler A, Toner M, Bhowmick S. Enthalpic relaxation of convective desiccated trehalose-water glasses. Thermochim Acta. 2007;453(1):1–8. https://doi.org/10.1016/j.tca.2006.10.014.

Luthra SA, Hodge IM, Pikal MJ. Effects of annealing on enthalpy relaxation in lyophilized disaccharide formulations: mathematical modeling of DSC curves. J Pharm Sci. 2008;97(8):3084–99. https://doi.org/10.1002/jps.21186.

Pyszczynski S. Understanding transformations of trehalose in the solid state. Ph.D. Dissertation, University of Kansas, Lawrence, KS; 2013.

Tower CW, Lay-Fortenbery A, Su Y, Munson EJ. Homogeneity and mobility as stability predictors in lyophilized formulations. International Society of Lyophilization and Freeze Drying Midwest Conference; 2022.

Funding

No external funding was used.

Author information

Authors and Affiliations

Contributions

• Ashley Lay-Fortenbery

Conception/design of work, data collection and analysis

• Cole W. Tower

Data collection and analysis, drafting the article

• Ernest Ezeajughi

Data collection and analysis

• Julie Calahan

Data collection and analysis

• Chinwe Duru

Data collection and analysis

• Paul Matejtschuk

Conception/design of work, data analysis and interpretation

• Eric J. Munson

Conception/design of work, data analysis and interpretation

Corresponding authors

Ethics declarations

Conflict of Interest

Eric Munson is a partial owner of Kansas Analytical Services, a company that provides solid-state services to the pharmaceutical industry. The results presented here are from his academic work, and no data from Kansas Analytical Services is shown here. Authors from MHRA declare no commercial or other conflicts of interest. The MHRA is an arm’s length body of the UK Government Department of Health.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lay-Fortenbery, A., Tower, C.W., Ezeajughi, E. et al. Predicting the Stability of Lyophilized Human Serum Albumin Formulations Containing Sucrose and Trehalose Using Solid-State NMR Spectroscopy: Effect of Storage Temperature on 1H T1 Relaxation Times. AAPS J 26, 40 (2024). https://doi.org/10.1208/s12248-024-00900-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12248-024-00900-2