Abstract

This study aimed to investigate the adsorption efficiency of Cd and Mn using natural sorbents—bentonite, zeolite and stabilized digested dewatered waste sludge. The main contributions of the scientific article are in adding to the scientific knowledge of the use of natural and waste sorbents in the removal of heavy metals from neutral mine effluents. Current studies mainly focus on metal removal by sorption using natural sorbents from acid mine drainage. This study investigates sorption in neutral mine drainage. The efficiency of the sorption process was evaluated using the following parameters: efficiency (%) of metal ion removal, Freudlich and Langmuir adsorption isotherm constant. The AES–ICP method (atomic emission spectrometry with inductively coupled plasma) was used for the initial metal analysis of the materials used. The atomic absorption spectrometry (AAS) method was used for the analysis of Cd and Mn in the sorption process. The maximum efficiency of Mn removal by bentonite at the end of the test was approximately 90%. The removal of Mn by zeolite was considerably lower—about 20% compared to the use of sludge—80%. Based on the sorption efficiency, the sludge was suitable for sorption. Much higher levels of Cd sorption were achieved using sludge compared to using natural bentonite and zeolite. The main novelty of the work lies in the sorption of metals using dewatered digested sludge. Previous studies have focused on metal sorption using activated sludge. Most previous studies focused on sorption from acid mine drainage. The novelty of this study is that we focused on the sorption of neutral mine drainages, which are typical for the location we are monitoring.

Similar content being viewed by others

Introduction

The industrial sector is the source of a large amount of wastewater that needs to be disposed of before being discharged into the environment [1]. Multiple damage to living systems can occur if the threshold is exceeded [2].

Cadmium (Cd) is one of the major pollutants, a non-essential metal that is harmful to organisms at relatively low concentrations of about 0.001–0.1 mg dm−3 [3, 4]. Cadmium [5] and Manganese (Mn) [6] occur as one of the heavy metals in mine effluents.

In general, mine drainage treatment aims to raise the pH while removing metals and sulphates before it is discharged into natural streams. The removal mechanisms for most metals in mine drainage are sorption and precipitation [7]. Current methods for the treatment of wastewater containing heavy metal ions are the ferrite method, chemical precipitation, electrochemical method, reverse osmosis method, ion exchange method, and adsorption methods [8].

Frequently used natural sorbents for heavy metal sorption include bentonites [9], zeolite [10] and sludge of wastewater treatment plants [11]. Bentonites for sorption have also been used in mixtures with other materials (Parrotia persica) to increase their efficiency [12]. Other materials with a confirmed Cd sorption effect include, for example, charcoal [13]. In addition to natural materials, by-products from production can be used for sorption [14].

In recent years, many readily economically available biosorption materials have been used and have shown promise as methods for heavy metal removal [15,16,17]. Waste digested activated sludge (WDAS) is also a waste material that can be used as a biosorbent for the purpose of metal removal. WDAS is produced in wastewater treatment plants where excess activated sludge is used to produce biogas in an anaerobic digester [18]. Activated sludge has been used in the past as a sorbent for heavy metals [19].

In the removal of metals from mine effluents by sorption, previous studies have mainly used natural sorbents due to their low cost [20,21,22,23,24,25,26,27]. We investigated the removal of Cd and Mn by adsorption using SDDS (stabilized digested dewatered sludge), bentonite, and zeolite. As a sorbent, it could find use in the treatment of mine drainage as opposed to landfilling. In other studies, The using zeolite, efficiencies of more than 89% were achieved for Cu [10, 28, 29], Fe [30], 47% for Cd [31] and for Mn ∼100% [24]. Using bentonite, the sorption was more than 89% for Fe [23, 32], the same for Cd [31] as well as for Mn [23], even according to another study a sorption of ∼100% was found for Mn [23]. Biosorption by activated sludge for heavy metals has also been studied in the past. Cd uptake by activated sludge has been confirmed to be greater than 95% [33]. Another study reported Cd sorption by activated sludge and a level of 50% [34]. Activated sludge was studied for Ni sorption (39.7%) [19] Sorption for Cd and Pb capture by activated sludge has also been carried out [35]. Biosorption isotherms show that Cd can be biosorbed up to more than 20,000-fold above water concentrations using free cells at 30 °C and pH 6.6 [36]. According to the study [37] activated sludge had a high biosorption capacity and equilibrium was reached in a short time with respect to copper, iron, manganese, zinc and chromium from landfill leachate.

The use of surplus sludge from wastewater treatment plants is very limited in Slovakia, e.g., due to its confirmed microplastic content [38]. The current regulatory framework for sewage sludge is set out in several instruments at EU level. However, these primarily focus on the waste dimension and not on the reuse of valuable resources [39]. The view of sludge use in Slovakia focuses mainly as a fertilizer. However, for its application on agricultural land as a fertilizer is bound by restrictions regulated by the Act of the National Assembly of the Slovak Republic No. 188/2003 Coll. and the subsequent Manual for the application of sewage sludge to agricultural land, issued by the Research Institute of Soil Science and Soil Protection, Bratislava. According to this manual from the law in question, the application of sewage sludge and bottom sediments is prohibited to agricultural land or forest land—the pH value of which is lower than 5.0; in the protection zone of water supply sources of I. degree and II. Grade I or II; with a slope above 12° if the groundwater level is less than 0.5 m from the soil surface (or other restrictions defined by law). The use of surplus sewage sludge, for example, also in sorption methods, is one of the paths towards a circular economy, which is currently being strongly emphasised throughout the European Union.

The above studies mainly focused on the removal of metals by sorption from acid mine drainage. In Slovakia, neutral mine drainage occur more often; therefore, this study focused on metal removal by neutral pH. Also limited use of SDDS as fertilizer brought us to search for its other use rather than its disposal. This study supplements information about adsorption of Cd and Mn from neutral mine drainage with natural sorbents and confirms possible use of SDDS for metal removal.

Materials and methods

In the individual phases of the experiment, the values of metal concentrations were determined, from which the parameters of the adsorption process were gradually evaluated: efficiency (%) of metal ion removal, Freudlich and Langmuir adsorption isotherm constants.

Description of the sorbents and neutral mine drainage

Stabilized digested dewatered sludge was used in the study. Stabilized sludge was used specifically to remove pathogenic microorganisms that could cause hygienic complications when this sorbent is applied to the aquatic ecosystem. The sludge was dried and ground with a ball mill to a fraction below 200 µm.

Ground fine bentonite was used for better contact between the sorbent and the sample. Bentonite was obtained from the Kopernica site (Table 1). The bentonite was ball milled to a fraction below 200 µm.

Ground fine zeolite was used for better contact between the sorbent and the sample. The zeolite was ball milled to a fraction below 200 µm. Zeolite was obtained from Nižný Hrabovec (Table 1). The mineral composition of the zeolite used is Clinoptilolite 82–84% [40].

Neutral mine drainage was taken from the Voznická dedičná stôlňa adit—Central Slovakia. The average pH over 2 years in neutral mine drainage was 7.24. Aqueous solutions were used for sorption. The concentration of cadmium and manganese in them was modified with selected Cd and Mn salts for the needs of 5 input concentrations.

The selected input concentrations of cadmium and manganese solutions are related to the specific values of these metals in the monitored mine water. The measured values of Cd (0.025 mg k−1) and Mn (3.8 mg kg−1) in mine water from the Voznická dedičná stôlňa reach many times higher values than stated in Government Regulation No. 269/2010 Coll. (Cd: 0.08–0.25 μg·kg−3, Mn: 0.3 mg kg−1).

The interval of input concentrations for monitored heavy metals was also increased due to realistically possible situations in the environment during periods of drought and concentration of mine waters. The capacity of the sorbents will thus be reserved for sufficient sorption of metals in the monitored area.

Montmorillonite clays are layered silicates and are among the numerous inorganic supports for reagents used in organic synthesis [42]. Plagioclase is a solid solution of end members albite (NaAlSi3O8) and anorthite (CaAl2Si2O8), with minor substitution of K for Na [43]. Feldspars are a group of aluminosilicate minerals containing potassium, sodium and calcium, occasionally also barium, cesium and isomorphous compositions of these elements [44]. Feldspar is a valuable raw material in the production of glass, ceramics, fillers, enamelled frits and welding electrodes. Feldspar is the single most abundant mineral in the Earth’s crust and is associated with other silicate, titanium, and iron minerals [44].

Biotite is an important mineral in metamorphic rocks in a wide range of bulk compositions and metamorphic grades. One of the most interesting biotite substituents is Ti. This tetravalent cation is preferentially partitioned into biotite compared to other typical metapelitic silicate minerals and replaces octahedrally coordinated divalent or trivalent cations. [45]. Cristobalite is a high-temperature polymorph of silica stable in the temperature range (T) 1.470–1.705 °C, but also occurs outside its field of stability as a metastable phase [46]. Volcanic glass is surface-cooled lava. Lava is formed by rapid cooling, solid, liquid and gaseous inclusions can be preserved in it, which reflect the subsurface magmatic history of the lava [47].

Smectites are one of the largest and most important classes of the phyllosilicate clay mineral group. They are common in temperate soils and, because of their cation exchange capacities (CECs) and very high specific surface areas, tend to dominate the cation adsorption chemistry of these soils [48].

Kaolinite (Al2Si2O5 (OH)4) is a 1:1 layered clay mineral, meaning that the layer is made of two different sheets. The layer consists of a tetrahedral layer of silicon dioxide and an octahedral layer of aluminum oxide. They are linked through shared coordination oxygen atoms [49].

Clinoptilolite is one of the most widespread natural zeolites, widely distributed throughout the world and used for its ion exchange and adsorption properties [50].

First, the background concentrations of metals in the sorbents and the mine water were verified (Table 2). The concentrations of Mn and Cd in neutral mine water several times exceed their concentrations in sorbents. The mentioned metals were used in the experiment because the input analyzes showed the levels of these metals in the NMD in the same sampling area to be significant, some even like Cd, Cu, Mn exceeding the limit values, established by the Government Regulation No. 269/2010 Coll.

According to the OECD 301 F standard test, activated sludge was used as an inoculum for aerobic degradation. According to the OECD 311 standard test, digested sludge was used as inoculum for anaerobic degradation (Table 3).

Sorption of heavy metals

Adsorption experiments were carried out in closed Erlenmeyer flasks at laboratory temperature by mixing the sorbent with 100 cm3 of neutral mine drainage solution. Sorbent concentrations of 5 g·dm−3 were used in the experiment. The samples were periodically mixed at a constant speed (200 rpm) using an electromagnetic stirrer. Sorption was carried out at a laboratory temperature of 20 °C.

The sorption experiment was carried out in parallel samples. The first represented the input concentration. At minute intervals, sorption was gradually interrupted in individual samples. After stopping the sorption in a 100 ml sample, the solution was filtered, and the concentration of manganese/cadmium was determined in it. This experiment was repeated 6 times for the same input concentrations and the sorption results were averaged. 5 different inlet concentrations were achieved by adding manganese/cadmium salt to neutral mine drainage. In four of the five samples, the sorbent concentration was the same at 5 g·dm−3.

The measured values of c0 and ce were used to determine the percentage efficiency of metal ion removal, concentration values in time intervals of 30, 60, 90 and 120 min were used to obtain adsorption isotherms according to Freundlich and Langmuir and were compared in terms of suitability of the given type of isotherm.

The mentioned method is a standard method, which is used according to the pattern of other experimental studies, but with a change of conditions (mixing, input concentration, temperature), which can be changed variably. This is not a patented method. The initial concentrations were approximately 10; 12.5; 15.5; 20.0; 22.0 mg dm−3 for Mn sorption and 1.2; 2.3; 3; 4.2; 5.3 mg dm−3 for Cd sorption.

Determination of SDDS

The dry matter was determined according to STN EN 12880—characterization of sludge. Determination of substance content and water content. he sample is dried up under determined conditions (103 °C ± 2 °C) to constant weight. The content of dry matter in the sample is calculated from the difference of the sample weight before and after drying up.

NH4+ was determined according to the standard STN ISO 7150. Ammonia is determined by reacting in an alkaline environment with sodium tetraiodomercury to form oxydimercurium iodide, as a slightly soluble yellow–brown compound, which is determined spectrophotometrically under the conditions of determination (STN ISO 7150-1).

NO3− was determined according to the standard STN ISO 7890—determination of nitrates. Nitrates are determined in a water sample after nitration with salicylic acid, in an environment of concentrated sulfuric acid, spectrophotometrically at a wavelength of λ = 415 nm (STN ISO 7890-3).

PO43− was determined according to standard STN EN 10304—determination of dissolved anions by ionic liquid chromatography. Phosphates react in an H2SO4 environment under the catalytic effect of antimony salts with ammonium molybdate to form a heteropolyacid, while the yellow complex is reduced by ascorbic acid to a phosphomolybdenum blue solution, which is suitable for determination by absorption spectrophotometry (STN EN 10304-1).

Cl− was determined according to the standard STN ISO 9297—determination of chlorides. Argentometric determination with chromate indicator (Mohr’s method). Chlorides are determined by titration with a measuring solution of AgNO3 (pH 6.5–10.5) to form slightly soluble silver chloride. The end of the titration is indicated by K2CrO4, which forms a slightly soluble silver chromate precipitate with Ag+ ions. At the equivalence point, an orange–brown precipitate of silver chromate forms (STN ISO 9297).

SO42− was determined according to STN ISO 9280—determination of sulfates. Gravimetric method with barium chloride. Sulfate ions react in a weakly acidic environment with Ba2+ ions to form a very poorly soluble barium sulfate precipitate. The precipitate is collected quantitatively on filter paper, washed thoroughly with hot distilled water, dried at 105 °C, calcined and weighed.

Metals were determined according to STN ISO 8288—determination of cobalt, nickel, copper, zinc, cadmium and lead—flame atomic absorption spectrometric methods. A GBC 933 AA flame atomic absorption spectrometer (GBC; Dandenong, Australia) was used for the determination of metals in the sludge. The AAS method is suitable for the determination of metals in water, for the elemental analysis of soils and soil leachates, sediments, sludge, waste, oils, food, etc. It enables the determination of a wide range of elements in solution (e.g., Na, K, Mg, Ca, V, Cr, Mn, Fe, Co, Ni, Cu, Pb). AAS is a method for determining solutions, i.e., each solid sample must first be decomposed. The weight and type of decomposition, which partially affect the detection limits, are chosen according to the type of material and the purpose of the analysis. The determination possibilities, similar to other methods, are further conditioned by the sensitivity of the device, the type of matrix, the concentration of the analyte in the monitored material, the salinity of the solution, etc. The solutions must be stabilized with acids (2–5% HNO3, HCl) during collection, according to the required determinations and according to the usual recommendation.

Determination of heavy metal concentration

Metal concentrations were determined by atomic absorption spectrometry (AAS). For the determination of metals, we used an AAS AVANTA Σ flame atomization spectrometer (GBC Scientific). A hollow cathode lamp with a supply current of 3.00 mA was used as the radiation source. Air/acetylene was used as the flame type at flow rates of 11.50 dm3·min−1 for air and 1.10 dm3·min−1 for acetylene. The relative errors of the AAS measurements were less than 5%. The instrument operation as well as the evaluation of the results was carried out with the GBC Avanta software ver. 2.0.

Determination of heavy metal concentrations of sorbents and neutral mine drainage

The AES–ICP atomic emission spectrometry with inductively coupled plasma method was used to determine copper, manganese, iron, lead, cadmium, and aluminum and zinc.

Solid samples were mineralized by decomposition using aqua regia (DIN EN 16174 Digestion of aqua regia soluble fractions of elements), then they were determined on an ICP–AES Varian 725 device (ISO 22036 Soil quality—determination of trace elements in extracts of soil by inductively coupled plasma–atomic emission spectrometers).

Calculations

Adsorption capacity

From the measured concentrations, the adsorption capacity at equilibrium (qe), the amount of metal adsorbed per unit sorbent at time t (qt), and the percent removal efficiency of Mn2+ and Cd2+ ions from the solution (Ads. %) were calculated.

The adsorption capacity at equilibrium and at time t, respectively, was calculated according to the following equation: [29]

where c0 is the initial concentration of ions in solution (mg dm−3), ce is the equilibrium concentration of ions in solution or the concentration of ions in solution at time t (mg dm−3), V is the volume of solution (dm−3), m is the mass of adsorbent added (g) and qe is amount of adsorbed heavy metal per unit sorbent mass (mg g−1).

Percentage of metal ion removal efficiency

The percentage removal efficiency of metal ions from the solution was calculated according to the following equation [29]:

Experiments focusing on the adsorption of Mn and Cd were carried out with natural unmodified adsorbents and waste-stabilized digested dewatered sludge in a closed system under constant stirring of the suspension at laboratory temperature. We monitored the progress of sorption depending on the sorbent used.

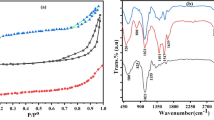

Freundlich and Langmuir adsorption isotherms

To express the dependence of the adsorbed amount of a metal ion on its equilibrium concentration in solution, Freundlich and Langmuir’s isotherms were constructed for all adsorbents used. The isotherms were evaluated at 5 input concentrations.

Freundlich adsorption isotherm

The effect of initial metal concentration on adsorption is described by adsorption isotherms. Several empirical and semiempirical relationships have been proposed for the analytical expression of the isotherms, of which either the Freundlich or Langmuir isotherm is the most suitable for adsorption from solutions (Table 4).

The Freundlich isotherm is usually valid for physical adsorption and for adsorption on heterogeneous surfaces with different active sites. It can be expressed by the relation: [51]

To verify that the experimental data fit this isotherm, the relation is linearized: [51]

where kf (mg g−1) is a constant related to the adsorption capacity and n is an empirical parameter expressing the adsorption intensity, which varies with the heterogeneity of the adsorbent.

Langmuir adsorption isotherm

The Langmuir isotherm is usually valid for chemisorption or electrostatic adsorption, where only a monomolecular layer is formed on the adsorbent surface and all active centers are equivalent. The Langmuir isotherm is expressed by the relation [51]:

or in the linearized form: [51]

where qm (mg g−1) gives the maximum monolayer adsorption capacity and b is the equilibrium constant dependent on the sorption energy.

RMSE

RMSE is the most natural finite-sample approximation of the standard error, which is closely related with standard deviation. For scalar unbiased estimators, it is actually the most natural finite-sample approximation of standard deviation of estimation error. Since standard deviation is an important parameter for probabilistic analysis, RMSE is useful for probabilistic analysis in the scalar case [52].

RMSE is expressed by the by formula: [53]

where yi is the actual value for the ith observation, \(\hat{y}_{i}\) is the predicted value for the ith observation, N is the number of observations.

Results and discussion

The parameters of adsorption isotherms present the ability and conditions for the sorption of individual sorbents. The selected parameters are also used for mutual comparison between sorbents. These findings can then be confronted with the adsorption capacity of the monolayer qm, as shown in Table 4.

Table 4 indicates that the experimental data better fit the Freundlich adsorption isotherm model. The coefficients of determination R2 have higher values and the root mean square error are also more favorable, they acquire much lower values.

Based on the obtained parameter n, which is an indicator of nonlinearity, it can be concluded that almost all isotherms are nonlinear (n → 1 is the value for a linear isotherm) (Table 5). This nonlinearity can be due to several causes, such as heterogeneity of sorption sites or adsorbate–adsorbent interaction. Cd was observed to be more prominent in occupying adsorption positions compared to Mn.

From the parameters of the Langmuir isotherm, we determined the values of qm, which characterize the maximum amount of adsorbed metal per unit mass of the adsorbent, assuming the formation of an adsorption monolayer on the surface. As can be seen in the comparison, for Cd the highest measured adsorption capacity is 3.143 mg g−1 in zeolite adsorbent, Mn has the highest values observed in bentonite 3.894 mg g−1 and sludge 4.200 mg g−1.

The fitting of the Langmuir isotherm was carried out according to the above equations at time t120—the end of the experiment. We assumed that at the end of the experiment, after 120 min of sorption, the trends of the isotherm curves would reach a steady-state character, which would be indicative of a state of reaching equilibrium. In some cases, the fitting of the Langmuir isotherm at t120 corresponded to a linear trend (e.g., bentonite—Mn; zeolite—Mn; sludge—both Cd and Mn. In other cases, the fitting of the isotherms at t120 resulted in very low R2, e.g., for Cd sorption using zeolite.

The fitting of the Freundlich isotherm also took place at time t120—at the end of the sorption experiment. In this case, the R2 refers to a more linear trend than was the case for the Langmuir adsorption isotherms. In addition, when fitting the Freundlich isotherms at time t120, some deviations in the real versus linearized values were observed. However, these deviations were much smaller than for the fitting of the Langmuir isotherms at time t120. In the case of Mn sorption, the highest value of adsorption capacity qm was observed when sludge was used–4.200 mg g−1. The bentonite level for Mn sorption reached a similar value, on the other hand, qm when zeolite was used was in the low range–0.611 mg g−1. The highest sorption intensity for Mn sorption was observed when sludge was used.

The maximum monolayer capacity for Cd sorption was generally maintained at low values for bentonite and SDDS. The highest sorption intensity for Cd sorption was observed using SDDS. The equilibrium constant dependent on the sorption energy reached the highest values when excess dewatered sludge was used. The highest value of kf, which is also related to adsorption capacity, was observed to be the highest for Mn sorption using SDDS and Cd sorption using zeolite.

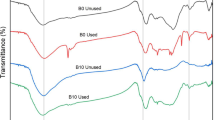

Metal removal depending on contact time

Monitoring the kinetics of the sorption process is necessary from the point of view of the overall picture of the sorption progress. It is important to observe when sorption starts or at what time the process equilibrium of sorption occurs. The amount of metal ion adsorbed at the contact time is a reflection of the maximum adsorption capacity achieved by the adsorbent under operating conditions. Sorption was carried out within 120 min (Figs. 1, 2, 3, 4, 5 and 6). The metal was measured at an interval of 30 min. Average (2 ± SD; standard deviation) was used to express the uncertainty of six measurements.

The analysis of the influence of the contact time on the adsorption efficiency indicates that Cd reaches an equilibrium value at 120 min for all used adsorbents, Mn is preferably sorbed on bentonite at a lower time—90 min.

Lower initial concentrations of metals in solutions generally occupy sorption sites much earlier, except for zeolite, where the fastest adsorption efficiency was observed at the highest initial concentration used. From the point of view of the contact time of the solution with the adsorbent, sludge is a suitable sorbent for Cd, bentonite is more suitable for Mn. As a sorbent, zeolite is probably unstable over time, its adsorption capacity is not exhausted in experiments.

Metal removal depending on the initial concentration

The percentage of Mn removal was evaluated in the concentration range of 8–22 mg dm−3 and Cd removal in the concentration range approximately of 1–5 mg dm−3 (Figs. 7, 8). The removal efficiency is compared after 120 min of sorption uniformly for all sorbents, for both Cd and Mn.

The adsorption efficiency greatly increases by increasing the time of contact between pollutants and adsorbent due to the increase of interaction time between active sites of chelation and metals. Normally, at the beginning of the adsorption, the removal efficiency occurs quickly and then increases gradually. This occurs because of the availability of the free active sites at initial adsorption that are gradually occupied with time by chelated metals [58]. After 120 min, equilibrium starts to occur in the solutions, probably due to the filling monolayer.

The concentration-dependent decrease in Mn removal efficiency was similar to that observed with zeolite and bentonite. Sorption using sludge was approximately 60% higher compared to zeolite. This indicates that digested sludge is a better adsorbent for Mn removal than zeolite. The experiment did not confirm a direct dependence between the input concentration and the percentage of Cd removal efficiency. Therefore, it is necessary to experimentally determine the optimum level of input concentration and not rely on the application of a mathematical relationship (linear or otherwise). The results confirmed decreasing levels of Cd removal from increasing concentrations of this metal ion in the solution. However, the level of sorption is several times higher than that of using bentonite and zeolite. We can conclude that SDDS could be used as an effective low-cost sorbent for metal removal.

Also, with increasing initial concentration of metal in solution metal removal efficiency slightly decreased. According to Tahoon et al. [58] above a particular initial concentration, ions with an equal amount of adsorption locations are available, which therefore decreases their elimination adsorption capacity.

Pradas et al. [59] studied the sorption of cadmium using natural and activated bentonite. The maximum monolayer adsorption capacity qm using natural bentonite reached 3.32 mg g−1 and 4.54 mg g−1, respectively. The level of equilibrium constant B was at 1.61 and 1.86 dm3 mg−1 [59]. These values are much higher than ours—qm 0.068 mg g−1 and B 0.083. Alexander et al. present the sorption capacity of natural bentonite at 1.4 and 2.4 for input Cd concentrations of 10 and 50 mg dm−3, respectively [60]. Again, as in the previous case, a lower average value was obtained by our experiment. The differences with the compared studies may be due to the length of the test or to the particular composition of the bentonite used.

Using zeolite, Rao et al. [61] determined Cd adsorption intensities of 4.382 and 3.690. The sorption intensity n in this study was approximately 1.4. Rao et al. performed their sorption at 30 °C, which may have increased the sorption intensity. Therefore, one possible way to increase the sorption intensity may be to increase the temperature (within observed and controlled levels, of course). The Langmuir adsorption isotherm was found to be unsuitable for evaluating Cd sorption using zeolite. Therefore, it will not be considered in this study.

Hu et al. [62] tested Cd sorption on dewatered sludge from a wastewater treatment plant. By constructing the Langmuir isotherm, a qm of 28.336 mg g−1 was obtained. By treating the sludge, they achieved an improvement in qm with the addition of 0.125 mol dm−3 NaOH; 0.25 mol dm−3 NaOH; 2·5 mol dm−3 NaOH; 7.5 mol dm−3 NaOH qm at the level of 85.232 mg g−1; 70.336 mg g−1; 86.128 mg g−1; 108.192 mg g−1. In our case, a much lower monolayer capacity was obtained. By Freundlich isotherm using sludge, Hu et al. achieved a sorption intensity n of 3.25 and an adsorption capacity kf of 28 mg g−1. The sorption intensity in this case was comparable to our experiments. In contrast, the sorption capacity Kf was again incomparably lower compared to the study of Hu et al. We assume that the above differences were due to the heterogeneous composition of the sludge. Therefore, as we can see, the sorption properties are incomparable for different sludge types in terms of their chemistry.

Pradas et al. using natural bentonite achieved % Cd removal of 99.3–100% [59]. By our sorption, much lower values were achieved. It should be justified that Pradas et al. heat-treated their bentonite to a temperature of 110 °C. Furthermore, in Prads’ study, sorption lasted 72 h, i.e., 36 times longer than in our case. At the same time, the concentration of added bentonite was 100 g dm−3 in Pradas’ study, which is 20 times higher than in our experiment.

The adsorption time is related to the amount of sorbent used, its preparation and also to the conditions of the experiment—static or dynamic adsorption, nature of mixing—turbulence, laminarity.

Different input concentrations did not significantly affect the level of Cd removal using bentonite. Equally low levels of Cd(II) removal were observed using zeolite. A removal level of 9% was found in this experiment. Compared to both natural sorbents, the removal level of Cd(II) using SDDS in this study was much higher and reached about 20%. Zhai et al. in their study [63] confirmed the removal of Cd(II) using a sorbent from sewage sludge at a level of 68% (70 min; sorbent 50 g dm−3; pH 5.8; temperature 25 °C). With all three sorbents, a gradual increase in Cd(II) removal was observed in this study within 2 h of sorption. For bentonite and SDDS, it was observed that the highest level of Cd(II) removal was found at the lowest concentration. The reason for this fact may be the filling of the sorption capacity of both sorbents, after which desorption began to occur. On the contrary, desorption did not occur with zeolite, as the highest level of Cd(II) removal was observed in the case of the highest input concentration.

With bentonite, a drop in metal removal was observed already at the level of 2232 g dm−3. From the above results the finding that bentonite and SDDS are sensitive to higher concentrations of Cd and tend to re-release the metal into the solution at higher concentrations. In all three cases, the sorption took place gradually for 120 min without a sudden acceleration or deceleration of the sorption.

Much higher levels of metal removal were found for Mn(II) removal. The highest level was observed when using SDDS, when we achieved removal at the input concentration of 9.531 mg dm−3 at the level of 88.4%. A very close level of Mn(II) removal—84.4% was observed when bentonite was used at an input metal concentration of 9.747 mg dm−3. The removal of Mn(II) by zeolite was much lower—the maximum level of removal was 20.4% compared to both remaining sorbents. Moreover, with zeolite, the cessation of sorption was observed after 1 h of adsorption. Sorption stopped at the level of 10.7%. Bentonite showed the highest increase in Mn(II) removal at all five inlet concentrations between 30 and 60 min of sorption, while zeolite and SDDS showed a much smoother increase in sorbed metal over 2 h. All three sorbents proved to be sensitive to the sorption of the given metal, as a decrease in removal—desorption was observed at higher input concentrations of Mn(II).

Our results indicate that SDDS could be a promising low-cost adsorbent for the removal of Mn and Cd from neutral mine drainage. According to Gu [64], it is possible to achieve Cd removal by adsorption using activated sludge at the level of 99.74%. When thinking about cadmium and manganese removal we need to take into account not only the dosage of adsorbent but also contact time and the possibility of bacteria interference, which could strengthen removal efficiency.

Conclusion

Based on the tests performed, stabilized digested dewatered sludge appears as a good low-cost sorbent for Cd and Mn removal. However, when comparing with other studies, usually for effective removal longer contact time is needed, from 4 to 8 h up to 72 h. Differences in metal sorption may be due to different sorbent compositions or other test conditions (thermal and chemical pre-treatment of the sorbent). Mn sorption results using zeolite according to other studies are comparable to our results. Comparable sorption results were found for sorption using sludge compared to bentonite, and even better when using zeolite. Much higher levels of Cd sorption were achieved using sludge compared to using natural bentonite and zeolite. To improve the sorption, the sorbent dosage needs to be increased and at the same time, the contact time should be extended. As manganese-oxidizing bacteria could contribute to both Mn and Cd removal, in next study should be investigated if they are naturally occurring in mine drainage or digested sludge and how to support their activity for better heavy metals uptake.

Availability of data and materials

The authors confirm that the data supporting the findings of this study are available within the article [and/or] its additional materials.

References

Saadi R, Saadi Z, Fazaeli R, Fard NE (2015) Monolayer and multilayer adsorption isotherm models for sorption from aqueous media. Korean J Chem Eng 32:787–799. https://doi.org/10.1007/s11814-015-0053-7

Luo C, Liu C, Wang Y et al (2011) Heavy metal contamination in soils and vegetables near an e-waste processing site, south China. J Hazard Mater 186:481–490. https://doi.org/10.1016/j.jhazmat.2010.11.024

Alkorta I, Hernández-Allica J, Becerril JM et al (2004) Recent findings on the phytoremediation of soils contaminated with environmentally toxic heavy metals and metalloids such as zinc, cadmium, lead, and arsenic. Rev Environ Sci Biotechnol 3:71–90. https://doi.org/10.1023/B:RESB.0000040059.70899.3d

Tang X, Zeng G, Fan C et al (2018) Chromosomal expression of CadR on Pseudomonas aeruginosa for the removal of Cd(II) from aqueous solutions. Sci Total Environ 636:1355–1361. https://doi.org/10.1016/j.scitotenv.2018.04.229

Gray NF (1998) Acid mine drainage composition and the implications for its impact on lotic systems. Water Res 32:2122–2134. https://doi.org/10.1016/S0043-1354(97)00449-1

Das PK (2018) Phytoremediation and nanoremediation: emerging techniques for treatment of acid mine drainage water. Def Life Sci J. https://doi.org/10.14429/dlsj.3.11346

Skousen J, Zipper CE, Rose A et al (2017) Review of passive systems for acid mine drainage treatment. Mine Water Environ 36:133–153. https://doi.org/10.1007/s10230-016-0417-1

Wang Q, Zhu S, Xi C, Zhang F (2022) A review: adsorption and removal of heavy metals based on polyamide-amines composites. Front Chem 10:814643. https://doi.org/10.3389/fchem.2022.814643

Gitari WM (2014) Attenuation of metal species in acidic solutions using bentonite clay: implications for acid mine drainage remediation. Toxicol Environ Chem 96:201–217. https://doi.org/10.1080/02772248.2014.923426

Balintova M, Holub M, Singovszka E (2012) Study of iron, copper and zinc removal from acidic solutions by sorption. Chem Eng Trans 28:175–180. https://doi.org/10.3303/CET1228030

Frišták V, Pipiška M, Horník M et al (2013) Sludge of wastewater treatment plants as Co2+ ions sorbent. Chem Pap 67:265–273. https://doi.org/10.2478/s11696-012-0244-1

Ntwampe IO (2023) Adsorption efficiency of bentonite clay and Parrotia persica during acid mine drainage treatment for the removal of turbid material. Mine Water Environ 42:348–357. https://doi.org/10.1007/s10230-023-00936-4

Strugała-Wilczek A, Stańczyk K, Bebek K (2020) Comparison of metal adsorption from aqueous solutions on coal and char remaining after in-situ underground coal gasification (UCG). Mine Water Environ 39:369–379. https://doi.org/10.1007/s10230-020-00677-8

Kaartinen T, Laine-Ylijoki J, Ahoranta S et al (2017) Arsenic removal from mine waters with sorption techniques. Mine Water Environ 36:199–208. https://doi.org/10.1007/s10230-017-0450-8

Ahad RIA, Goswami S, Syiem MB (2017) Biosorption and equilibrium isotherms study of cadmium removal by Nostoc muscorum meg 1: morphological, physiological and biochemical alterations. 3Biotech. 7:1–2. https://doi.org/10.1007/s13205-017-0730-9

Bailey SE, Olin TJ, Bricka RM, Adrian DD (1999) A review of potentially low-cost sorbents for heavy metals. Water Res 33:2469–2479. https://doi.org/10.1016/S0043-1354(98)00475-8

Kratochvil D, Volesky B (1998) Advances in the biosorption of heavy metals. Trends Biotechnol 16:291–300. https://doi.org/10.1016/S0167-7799(98)01218-9

Appels L, Baeyens J, Degrève J, Dewil R (2008) Principles and potential of the anaerobic digestion of waste-activated sludge. Prog Energy Combust Sci 34:755–781. https://doi.org/10.1016/j.pecs.2008.06.002

Arican B, Gokcay CF, Yetis U (2002) Mechanistics of nickel sorption by activated sludge. Process Biochem 37:1307–1315. https://doi.org/10.1016/S0032-9592(02)00015-8

Aguiar AO, Duarte RA, Ladeira ACQ (2013) The application of MnO2 in the removal of manganese from acid mine water. Water Air Soil Pollut 224:1690. https://doi.org/10.1007/s11270-013-1690-2

Akbari Dehkharghani A (2019) Exfoliated graphitic carbon nitride for the fast adsorption of metal ions from acid mine drainage: a case study from the sungun copper mine. Mine Water Environ 38:335–341. https://doi.org/10.1007/s10230-018-0561-x

Farsi A, Javid N, Malakootian M (2019) Investigation of adsorption efficiency of Cu2+ and Zn2+ by red soil and activated bentonite from acid copper mine drainage. Desalin Water Treat 144:172–184

Masindi V, Gitari MW, Tutu H, DeBeer M (2015) Efficiency of ball milled South African bentonite clay for remediation of acid mine drainage. J Water Process Eng 8:227–240. https://doi.org/10.1016/j.jwpe.2015.11.001

Motsi T (2010) Remediation of acid mine drainage using natural zeolite. D_ph, University of Birmingham

Motsi T, Rowson NA, Simmons MJH (2009) Adsorption of heavy metals from acid mine drainage by natural zeolite. Int J Miner Process 92:42–48. https://doi.org/10.1016/j.minpro.2009.02.005

Orakwue EO, Asokbunyarat V, Rene ER et al (2016) Adsorption of Iron(II) from acid mine drainage contaminated groundwater using coal fly ash, coal bottom ash, and bentonite clay. Water Air Soil Pollut 227:74. https://doi.org/10.1007/s11270-016-2772-8

Wulandari E, Hidayat AE, Moersidik SS (2020) Comparison of copper adsorption effectivity in acid mine drainage using natural zeolite and synthesized zeolite. IOP Conf Ser: Earth Environ Sci 473:012143. https://doi.org/10.1088/1755-1315/473/1/012143

Feng G, Ma J, Zhang X et al (2019) Magnetic natural composite Fe3O4-chitosan@bentonite for removal of heavy metals from acid mine drainage. J Colloid Interface Sci 538:132–141. https://doi.org/10.1016/j.jcis.2018.11.087

Balintova M, Holub M, Stevulova N et al (2014) Sorption in acidic environment—biosorbents in comparison with commercial adsorbents. Chem Eng Trans 39:625–630. https://doi.org/10.3303/CET1439105

Varvara S, Popa M, Bostan R, Damian G (2013) Preliminary considerations on the adsorption of heavy metals from acidic mine drainage using natural zeolite. J Environ Prot Ecol 14:1506–1514

Mokgehle TM, Gitari WM, Tavengwa NT (2019) Synthesis of di-carboxylic acid functionalized zeolites from coal fly ash for Cd (II) removal from acid mine drainage using column studies approach. J Environ Chem Eng 7:103473. https://doi.org/10.1016/j.jece.2019.103473

Enslin F, van der Mey L, Waanders F (2010) Acid leaching of heavy metals from bentonite clay, used in the cleaning of acid mine drainage. J S Afr Inst Min Metall 110:187–191

Gourdon R, Rus E, Bhende S, Sofer SS (1990) Mechanism of cadmium uptake by activated sludge. Appl Microbiol Biotechnol 34:274–278. https://doi.org/10.1007/BF00166795

Sterritt RM, Lester JN (1981) The influence of sludge age on heavy metal removal in the activated sludge process. Water Res 15:59–65. https://doi.org/10.1016/0043-1354(81)90182-2

Wang X, Xia S, Chen L et al (2006) Biosorption of cadmium(II) and lead(II) ions from aqueous solutions onto dried activated sludge. J Environ Sci 18:840–844. https://doi.org/10.1016/S1001-0742(06)60002-8

Gourdon R, Rus E, Bhende S, Sofer SS (1990) A comparative study of cadmium uptake by free and immobilized cells from activated sludge. J Environ Sci Health Part A Environ Sci Eng Toxicol 25:1019–1036. https://doi.org/10.1080/10934529009375614

Çeçen F, Gürsoy G (2001) Biosorption of heavy metals from landfill leachate onto activated sludge. J Environ Sci Health, Part A 36:987–998. https://doi.org/10.1081/ESE-100104126

Sewage sludge fertilizers contain alarming amounts of microplastics, a new study says. In: ODPADY-PORTAL.SK. https://www.odpady-portal.sk/Dokument/103272/hnojiva-zo-splaskoveho-kalu-obsahuju-znepokojujuce-mnozstvo-mikroplastov-hovori-nova-studia.aspx. Accessed 25 Dec 2023

The time has come to look at sewage sludge as a valuable resource. In: VODA-PORTAL.SK. https://www.voda-portal.sk/Dokument/nastal-cas-aby-sme-sa-na-kaly-z-cov-pozerali-ako-na-cenny-zdroj-101138.aspx. Accessed 25 Dec 2023

VSK Pro-Zeo—Treatment, processing and packaging of zeolite. In: VSK Pro-Zeo. https://www.vskpro-zeo.sk/. Accessed 10 Jan 2023

Deliova J, Adamcova R, Ottner F, Wriessning K (2015) Comparison of bentonite BKT to the bentonite K45 from the Kopernica deposit. Vydavatelstvo Univerzity Komenskeho, Slovakia, p 1741

Nasreen A (2001) Montmorillonite. Synlett 2001:1341–1342. https://doi.org/10.1055/s-2001-16061

Bersani D, Aliatis I, Tribaudino M et al (2018) Plagioclase composition by Raman spectroscopy. J Raman Spectrosc 49:684–698. https://doi.org/10.1002/jrs.5340

Zhang Y, Hu Y, Sun N et al (2018) Systematic review of feldspar beneficiation and its comprehensive application. Miner Eng 128:141–152. https://doi.org/10.1016/j.mineng.2018.08.043

Henry DJ, Guidotti CV (2002) Titanium in biotite from metapelitic rocks: temperature effects, crystal-chemical controls, and petrologic applications. Am Miner 87:375–382. https://doi.org/10.2138/am-2002-0401

Pagliari L, Dapiaggi M, Pavese A, Francescon F (2013) A kinetic study of the quartz–cristobalite phase transition. J Eur Ceram Soc 33:3403–3410. https://doi.org/10.1016/j.jeurceramsoc.2013.06.014

Nasedkin VV, Boyarskaya RV (1982) Minerals in volcanic-glass pores. Int Geol Rev. https://doi.org/10.1080/00206818209451048

Kloprogge JT, Komarneni S, Amonette JE (1999) Synthesis of smectite clay minerals: a critical review. Clays Clay Miner 47:529–554. https://doi.org/10.1346/CCMN.1999.0470501

Detellier C (2018) Functional kaolinite. Chem Rec 18:868–877. https://doi.org/10.1002/tcr.201700072

Mastinu A, Kumar A, Maccarinelli G et al (2019) Zeolite clinoptilolite: therapeutic virtues of an ancient mineral. Molecules 24:1517. https://doi.org/10.3390/molecules24081517

www.cosmotron.sk ICS s r o-, Zvolene S lesnícka a drevárska knižnica pri T univerzite vo Hodnotenie rizík vybraných kovových prvkov vo vodách. https://www.library.sk/arl-sldk/sk/detail-sldk_un_epca-0020016-Hodnotenie-rizik-vybranych-kovovych-prvkov-vo-vodach/. Accessed 26 Jan 2024

Li XR, Zhao Z (2006) Evaluation of estimation algorithms part I: incomprehensive measures of performance. IEEE Trans Aerosp Electron Syst 42:1340–1358. https://doi.org/10.1109/TAES.2006.314576

Wang W, Lu Y (2018) Analysis of the mean absolute error (MAE) and the root mean square error (RMSE) in assessing rounding model. IOP Conf Ser: Mater Sci Eng 324:012049. https://doi.org/10.1088/1757-899X/324/1/012049

Fernández-Nava Y, Ulmanu M, Anger I et al (2011) Use of granular bentonite in the removal of mercury (ii), cadmium (ii) and lead (ii) from aqueous solutions. Water Air Soil Pollut 215:239–249. https://doi.org/10.1007/s11270-010-0474-1

Chen Y-G, Ye W-M, Yang X-M et al (2011) Effect of contact time, pH, and ionic strength on Cd(II) adsorption from aqueous solution onto bentonite from Gaomiaozi, China. Environ Earth Sci 64:329–336. https://doi.org/10.1007/s12665-010-0850-6

Barkat M, Chegrouche S, Mellah A et al (2014) Application of Algerian bentonite in the removal of cadmium (ii) and chromium (vi) from aqueous solutions. J Surf Eng Mater Adv Technol 4:210–226. https://doi.org/10.4236/jsemat.2014.44024

Merrikhpour H, Jalali M (2013) Comparative and competitive adsorption of cadmium, copper, nickel, and lead ions by Iranian natural zeolite. Clean Technol Environ Policy 15:303–316. https://doi.org/10.1007/s10098-012-0522-1

Tahoon MA, Siddeeg SM, Salem Alsaiari N et al (2020) effective heavy metals removal from water using nanomaterials: a review. Processes 8:645. https://doi.org/10.3390/pr8060645

Pradas EG, Sánchez MV, Cruz FC et al (1994) Adsorption of cadmium and zinc from aqueous solution on natural and activated bentonite. J Chem Technol Biotechnol 59:289–295. https://doi.org/10.1002/jctb.280590312

Alexander JA, Surajudeen A, Aliyu E-NU et al (2017) Multi-metals column adsorption of lead(II), cadmium(II) and manganese(II) onto natural bentonite clay. Water Sci Technol 76:2232–2241. https://doi.org/10.2166/wst.2017.391

Purna Chandra Rao G, Satyaveni S, Ramesh A et al (2006) Sorption of cadmium and zinc from aqueous solutions by zeolite 4A, zeolite 13X and bentonite. J Environ Manag 81:265–272. https://doi.org/10.1016/j.jenvman.2005.11.003

Hu J-L, He X-W, Wang C-R et al (2012) Cadmium adsorption characteristic of alkali modified sewage sludge. Biores Technol 121:25–30. https://doi.org/10.1016/j.biortech.2012.06.100

Zhai Y, Wei X, Zeng G et al (2004) Study of adsorbent derived from sewage sludge for the removal of Cd2+, Ni2+ in aqueous solutions. Sep Purif Technol 38:191–196. https://doi.org/10.1016/j.seppur.2003.11.007

Gu H, Lin W, Sun S et al (2021) Calcium oxide modification of activated sludge as a low-cost adsorbent: preparation and application in Cd(II) removal. Ecotoxicol Environ Saf 209:111760. https://doi.org/10.1016/j.ecoenv.2020.111760

Acknowledgements

The research presented in this paper is an outcome of project Comprehensive research of determinants for ensuring environmental health (ENVIHEALTH), ITMS 313011T721 supported by the Operational. Programme Integrated Infrastructure (OPII) funded by the ERDF and research contract KEGA 009TU Z-4/2022.

Funding

This work was supported by Comprehensive research of determinants for ensuring environmental health (ENVIHEALTH), ITMS 313011T721 supported by the Operational. Programme Integrated Infrastructure (OPII) funded by the ERDF and by research contract KEGA 009TU Z-4/2022.

Author information

Authors and Affiliations

Contributions

Conceptualization, VP and JP; methodology, AĎ; investigation, JS; statistical analysis, MS; writing—original draft preparation, DS; writing—review and editing, MM; visualization, VP and JP; supervision, MS. All authors reviewed the manuscript. All authors have agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Consent to participate was obtained from all individual participants included in the study.

Consent for publication

Consent to publish was obtained from all individual participants included in the study. Informed consent was obtained from all individual participants included in the study.

Competing interests

The authors have no relevant competing interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Prepilková, V., Poništ, J., Ďuricová, A. et al. Adsorption of Cd and Mn from neutral mine effluents using bentonite, zeolite, and stabilized dewatered sludge. Environ Sci Eur 36, 100 (2024). https://doi.org/10.1186/s12302-024-00911-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12302-024-00911-y