Abstract

A high-performance gas sensor operating at room temperature is always favourable since it simplifies the device fabrication and lowers the operating power by eliminating a heater. Herein, we fabricated the ammonia (NH3) gas sensor by using Au nanoparticle-decorated TiO2 nanosheets, which were synthesized via two distinct processes: (1) preparation of monolayer TiO2 nanosheets through flux growth and a subsequent chemical exfoliation and (2) decoration of Au nanoparticles on the TiO2 nanosheets via hydrothermal method. Based on the morphological, compositional, crystallographic, and surface characteristics of this low-dimensional nano-heterostructured material, its temperature- and concentration-dependent NH3 gas-sensing properties were investigated. A high response of ~ 2.8 was obtained at room temperature under 20 ppm NH3 gas concentration by decorating Au nanoparticles onto the surface of TiO2 nanosheets, which generated oxygen defects and induced spillover effect as well.

Similar content being viewed by others

Introduction

Serious safety issues like toxic gas leakage, explosion, and fire events frequently burst out due to storage or piping defects in industrial sites dealing with various oxidizing, reducing, and high-pressure hazardous chemical gases [1,2,3,4,5,6,7,8,9]. Various sensors such as electric capacity-, surface acoustic wave-, catalytic combustion-, optical-, electrochemical-, and semiconductor-type with different operating mechanisms have been developed to prevent these risks in advance [10,11,12,13,14,15]. Although semiconductor-type sensors have lower selectivity and reliability than electrochemical sensors [16, 17], their simple operation, economically feasible manufacturing process, possible miniaturization, and device compatibility have drawn much attention [18, 19]. The semiconductor-type sensors utilize metal oxides (SnO2, ZnO, In2O3, WO3, Ga2O3, TiO2, CuO, TeO2, NiO, etc.) as sensing materials [20,21,22]. Among many metal oxides, TiO2 is one of the promising candidates for sensing materials since it has various crystal phases (anatase, rutile, and brookite) [23, 24] and generates carriers [25, 26]. Moreover, multiple forms of TiO2 with controlled defect structures can be easily prepared via the sulfuric acid method, chlorine method, chemical vapour deposition (CVD) method, sol–gel method, and anodization method [27, 28]. The easily manipulated defect structures of TiO2 are ideal for sensing gas molecules of interest. Different surface atomic sites [29, 30], defects [31], and cross-sectional areas of nanosheets [32] can selectively sense gas molecules with different electron affinities.

Recently, sensitive and selective sensing of ammonia (NH3) gas, which is highly corrosive, toxic, yet colourless, has become indispensable along with the increasing use of NH3 gas as a non-polluting fuel like hydrogen [33, 34]. Benefitting from easily engineered dimensions and defect structures of TiO2, 0- and 1-dimensional TiO2-based nanostructures and additional nano-heterostructures were found to be effective in sensing NH3 gas with high selectivity, sensitivity, and stability at room temperature [35,36,37,38,39,40]. Herein, we fabricated the 2-dimensional TiO2-based nano-heterostructures to improve NH3 gas-sensing performance at room temperature. TiO2 nanosheets (NSs) were first synthesized through flux growth and subsequent chemical exfoliation. This is because the flux growth method is advantageous for simultaneously obtaining large single crystals and large monolayer structures [41, 42]. Au nanoparticles (NPs) were then decorated onto the surface of the TiO2 NSs by hydrothermal method. The high response of ~ 2.8, twice as high as that of the pristine TiO2 NSs, was obtained at an NH3 gas concentration of 20 ppm due to the oxygen defects generated in the TiO2 NSs as well as the spillover effect activated in the presence of Au NPs [43, 44].

Experimental procedure

As illustrated in Fig. 1a, K0.8Ti1.73Li0.27O4 (KTLO) was first synthesized via a flux method to fabricate TiO2 NSs. Powders of TiO2 (99.9%, Grand C&M), K2CO3 (99.5%, Samchun Chemicals), and Li2CO3 (99.0%, Junsei) were used as starting materials, and MoO2 (99.5%, Samchun Chemicals) was added as a flux. Each powder was weighed in stoichiometry and mixed in a mortar. The mixed powder was put into a platinum (Pt) crucible and calcinated at 1200 °C for 10 h in air. After the calcination, it was slowly cooled to 900 °C for 50 h, followed by natural cooling. KTLO powder was obtained once the mixed powder was washed with distilled water at 80 °C to remove K2MoO4. The KTLO powder was converted to H1.07Ti1.73O4∙H2O (HTO) via an acid treatment process performed for 5 days using 0.5 M hydrochloric acid (HCl, Daejung). The HTO powder (1.2 g) was stirred in a mixed solution of tetrabutylammonium hydroxide (TBAOH, 10.26 cc) and distilled (DI) water (300 cc) with a magnetic bar for 14 days to exfoliate TiO2 NS. Finally, the TiO2 NSs were obtained after centrifuging (6000 rpm, 10 min) and subsequent filtering (membrane in DI water, 3 days) of the TiO2 NS-containing mixed solutions.

Au NPs were simply decorated onto the surface of TiO2 NSs via the hydrothermal method, as shown in Fig. 1b. The precursor of Au was prepared by stirring HAuCl6·H2O (0.23 g) and 2-propanol (10 g) for 12 h. The mixture of the Au precursor (HAuCl6·H2O, 1 ml), colloid of TiO2 NSs (4 ml), and distilled water (40 ml) was reacted in an autoclave at 70 °C for 4 h. The Au NP-decorated TiO2 NSs were obtained once the product of the hydrothermal reaction was washed in a mixed solution of DI water and ethanol using a centrifuge.

To characterize the morphology, crystallinity, composition, chemical bonding, and surface defect of the pristine and Au NP-decorated TiO2 NSs, several analyses using field emission scanning electron microscopy (FE-SEM, JEOL-7001F, Jeol Ltd.), field emission transmission electron microscopy (FE-TEM, Talos F2000X, Thermo Fisher Scientific) with high-angle annular dark field (HAADF), atomic force microscopy (AFM, Park systems), powder X-ray diffraction (PXRD, Smartlab, Rigaku), energy-dispersive X-ray spectroscopy (EDX), X-ray photoelectron spectroscopy (XPS, K-Alpha, Thermo Fisher Scientific), Raman spectroscopy (LabRam Aramis, Horriba Jovin-Yvon), and photoluminescence (PL, LabRam Aramis, Horriba Jovin-Yvon) were carried out.

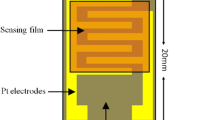

Sensing properties of the pristine and Au NP-decorated TiO2 NSs for various gases (NH3, H2S, CH3COCH3, C6H6, C2H5OH, NO2) were measured using the specially designed gas-sensing measurement system (Supporting Information (SI), Fig. S1), in which sensing materials were deposited on an alumina substrate masked with Au electrode by the drop-off technique. Gas sensing was performed for temperatures ranging from 30 to 110 °C with different gas concentrations (1, 2, 6, 10, and 20 ppm). The response was measured as a change in resistance before (Ra) and after (Rg) target gas injection. Oxidizing gas and reducing gas were expressed as R = Rg/Ra and R = Ra/Rg, respectively. Response time and recovery time were calculated as the time to reach 90% of the final resistance in the presence and absence of the target gas, respectively.

Results and discussion

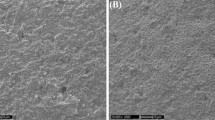

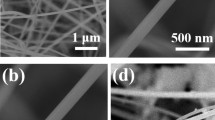

Figure 2a, b, and SI, Fig. S2a show the SEM and TEM images of the pristine TiO2 NSs with uneven and serpentine-like morphology. The TiO2 NS thickness of ~ 1.4 nm estimated from the AFM image (SI, Fig. S2b) indicates a successful insertion of TBA+ ion between monolayer TiO2 sheets just before the exfoliation (Fig. 1a), because the thickness of monolayer TiO2 NS (~ 0.5 nm) and the size of adsorbed TBA+ ion are approximately 0.5 and 0.9 nm, respectively [45]. Monodispersed Au NPs with an average diameter of 10–30 nm were decorated onto the surface of TiO2 NSs via the simple and scalable hydrothermal process (Fig. 1b), as shown in Fig. 2c, d. The decorated Au NPs were not detached from TiO2 NSs even after ultrasonication for 24 h.

Crystal structure, chemical bonding, and defect structure of the pristine and Au NP-decorated TiO2 NSs were examined using XRD, Raman, PL, and XPS since the gas-sensing properties of semiconducting metal oxides are strongly correlated with these structural characteristics. Observed peaks in XRD analysis (Fig. 3a) are well matched to the planes of (0l0), which confirms the 2-dimensional sheet-like structure of TiO2 NSs [46]. This 2-dimensional feature is maintained even after the hydrothermal process for Au NPs decoration. Peaks for Au are not detected, suggesting that the Au NPs with uniform nm-scale size are decorated as confirmed in the TEM image (Fig. 2d). The presence of such Au NPs can be clearly confirmed through high-resolution transmission electron microscopy (HRTEM) (SI, Fig. S3). However, the HRTEM image showed that the monolayer of TiO2 was too thin (~ 0.5 nm); therefore, the interplanar spacing could not be clearly observed. Changes in bonding characteristics and defect structures of TiO2 NSs after the decoration of Au NPs are also investigated. In Raman spectra (Fig. 3b), peaks corresponding to the TiO2 NS (196, 283, 447, 706, and 784 cm−1) are observed both in the pristine and Au NP-decorated TiO2 NSs [47], suggesting no significant changes in Ti–O bonding states due to the Au NP decoration. This is also confirmed by XPS analysis, as represented in Fig. 3c, 3d. Peaks for Ti 2 s, Ti 2p, Ti 3 s, Ti 3p, and O 1 s [48] observed in the pristine TiO2 NSs are also detected in the Au NP-decorated TiO2 NSs at almost the same binding energies (peaks for Ti 2p3/2 and Ti 2p1/2 at 458.9 and 464.7 eV, respectively in Fig. 3d). The negligible change in the Ti–O bonding after the Au NP decoration can be attributed to the low reaction temperature (70 °C) of the hydrothermal process. On the other hand, the peak of Au 4f is clearly observed in XPS spectra of the Au NP-decorated TiO2 NSs (Fig. 3c). Different binding energies for Au (83.8 and 87.5 eV) and Au3+ (85.2 and 88.9 eV) are confirmed by the peak analysis (Fig. 3e), indicating the presence of metal Au NPs and the bonding between the Au NPs and TiO2. However, defect structures are changed by the Au NP decoration. According to the PL spectra (SI, Fig. S4), the peak intensities of the Au NP-decorated TiO2 NSs corresponding to defect structures of oxygen vacancies and Ti interstitials (425 nm and 525 nm) [49, 50] are considerably lower than those measured in the pristine TiO2 NSs. The surface oxygen defects, which play a critical role in gas sensing, are generated after the Au NP decoration. As shown in Fig. 3f, O 1s spectra are deconvoluted into three binding states: Ti–O lattice oxygen (Oa at ~ 530.3 eV), vacant oxygen (Ob at ~ 531.8 eV), and chemisorbed oxygen (Oc at ~ 532.8 eV). It is noted that the density of Ob was increased from 7.9 to 9.1% after decorating Au NPs. Unlike the Ti–O lattice oxygen binding state, the other two binding states played an important role in accelerating the properties of n-type semiconductors. When the vacancies of oxygen (Ob in Fig. 3f) increased, the ratio of fixed charge Ti ions increased. Therefore, the electrons acting as the main carriers of mobile charges also increased. Moreover, with regard to TiO2, the electrons acting as the main carriers of mobile charges also increased because the increase in chemisorbed oxygen (Au2O3 in Fig. 3e and Oc in Fig. 3f) provided the same effect as that provided by disappearing O. In general, a heterointerface occurring in a pristine metal oxide nanostructure is commonly accompanied by a carrier transfer [51]. However, in our study, when Au was decorated onto TiO2 NSs, the overall Ti frame was maintained according to the Raman (Fig. 3b) and XPS (Fig. 3d) spectra. Meanwhile, O was considered to be locally chemisorbed with Au (Au2O3 in Fig. 3e and Oc in Fig. 3f) or to have acted as a vacancy defect (Ob in Fig. 3f).

To investigate the reactivity of the pristine and Au NP-decorated TiO2 NSs with NH3 gas correlated to the overall characteristics of morphology, chemical bonding, and surface defects characterized as above, their responses under NH3 gas concentrations of 1–20 ppm at room temperature were measured (Fig. 4a, b). Owing to the n-type semiconducting nature of TiO2, its resistance decreased when TiO2 chemically reacted with the reducing NH3 gas. In the initial state, the reducing NH3 gas supplied electrons to the TiO2 semiconductor. The response of the Au NP-decorated TiO2 NSs is significantly improved in reference to that of the pristine TiO2 NSs, even at a low concentration of 1 ppm. Moreover, considering the high sensing process temperatures (200–300 °C) of most semiconducting metal oxides [52, 53], sensitive sensing demonstrated at room temperature suggests that this low-dimensional nano-heterostructured material is a promising candidate for NH3 gas-sensing materials. Dynamic responses for varying NH3 gas concentrations are shown in Table S1. In both samples, the response gradually decreased when the concentration of NH3 gas increased. The high response of ~ 2.8 is achieved with Au NP-decorated TiO2 NSs at 20 ppm NH3 gas concentration, which is approximately 6 times higher than that obtained with the pristine TiO2 NSs (Fig. 4c). The ionization of oxygen and the adsorption of NH3 gas molecules activated by the spillover effect from the decorated Au NPs are the physics behind the improved response [54]. Conventionally, the response of a semiconductor increases with temperature as more carriers are generated at high temperatures. In contrast, the opposite trend is observed in the response of the Au NP-decorated TiO2 NSs shown in Fig. 4d. This phenomenon can be attributed to the thin 2D structure of the sample used herein. When the temperature increased, the sample exhibited the properties of a metal rather than those of a semiconductor. Therefore, the number of carriers involved in sensing decreased with temperature. Room-temperature sensing can be understood with the following ionization processes, which occurs below 100 °C [55].

NH3 gas concentration-dependent responses at room temperature of a the pristine TiO2 nanosheets and b Au nanoparticle-decorated TiO2 nanosheets. c Comparison of the NH3 gas concentration-dependent responses at room temperature between the pristine and Au nanoparticle-decorated TiO2 nanosheets. d Response of the Au nanoparticle-decorated TiO2 nanosheets according to the process temperature under 20 ppm NH3 gas concentration

Additionally, Au NP-decorated TiO2 NSs can selectively sense NH3 gas at room temperature. The responses to other gases such as H2S, CH3COCH3, C6H6, C2H5OH, and NO2 were 1.41, 1.59, 2.26, 2.06, and 1.43, respectively (SI, Fig. S5). Hence, the selectivity of Au-NP-decorated TiO2 NSs in sensing NH3 can be considered to be the best. Long-term stability of Au NP-decorated TiO2 NSs was confirmed by measurement of sensing dynamics after 1 month, which shows almost same behaviour as shown in SI, Fig. S6. However, humidity performance revealed a slight decrease in response (SI, Fig. S7). Herein, the samples with and without the effect of humidity showed similar responses in the three experiments repeated under the same conditions. Hence, a comparative analysis, as presented in Table 1, was conducted to demonstrate the improved performance of the proposed sensor. [5, 37, 56,57,58,59,60,61].

The NH3 gas-sensing mechanism for the Au NP-decorated TiO2 NSs is closely related to functions of the heterostructures between metal and metal oxide: (1) electronic sensitization with oxygen or adsorbed catalytic metal and (2) chemical sensitization between target gas and catalytic metal or semiconductor surface [62]. For example, the electron affinity of the oxygen adsorbed on the Au-Np-decorated TiO2 NS surface is 1.46 eV [63] and that of the TiO with an oxygen vacancy is 1.19 eV [64]. Hence, oxygen removes electrons from the TiO2 surface and ionizes the surface as shown in Eq. (2). An electron depletion layer (EDL) is consequently formed under the TiO2 surface. Given that Au efficiently decomposes the oxygen (from O2 to O2−) and ammonia (from NH3 to N2 or NO) adsorbed onto the TiO2 surface and helps to form highly reactive ionic species, electron transfer occurs actively. In addition, because Au and TiO2 have work functions of 4.86–4.92 eV [65] and 4.34 eV [66], respectively, a Schottky junction [67], in which electrons move only from the TiO2 side to the Au side, occurs locally. Therefore, this interface also increases the thickness of the EDL in the air state. However, when NH3 gas is injected in this state, the following reaction occurs [68, 69].

Additional electrons are supplied to the surface of TiO2 and the thickness of the EDL formed inside the surface is reduced, resulting in a further decrease in resistance. However, when the NH3 gas is desorbed, the original EDL thickness is restored owing to the influence of air on the TiO2 surface. In summary, the primary gas-sensing mechanism was understood in terms of the conductive channelling width of the semiconductor related to the thickness of the carrier depletion layer [37], where potential difference [70, 71] and energy band diagram [72, 73] models at heterogeneous interfaces (Au NPs and TiO2 NSs) could be used.

Conclusions

Au nanoparticle-decorated TiO2 nanosheets are prepared via combination of flux growth-exfoliation and hydrothermal method, and their NH3 gas-sensing properties were measured at process temperatures of 30–110 °C under different NH3 gas concentrations (1–20 ppm). NH3 gas was selectively detected by using the pristine monolayer TiO2 nanosheets even at room temperature. The Au nanoparticle decoration triggered the generation of oxygen defects, which activated the reaction with NH3 gas molecules, and also induced the spillover effect. Due to this synergetic effect, response of Au nanoparticle-decorated TiO2 nanosheets can be significantly improved and reaches ~ 2.8 at room temperature under 20 ppm NH3 gas concentration. Proposed design concept of low-dimensional nano-heterostructured sensing material and kinetics of gas sensing at room temperature are expected to be utilized to develop and optimize properties and performances of semiconducting metal oxide-based gas sensors.

Availability of data and material

All the data are available from the corresponding author on reasonable request.

References

Wang Z, Sackmann A, Gao S, Weimar U, Lu G, Liu S, Zhang T, Barsan N. Study on highly selective sensing behavior of ppb-level oxidizing gas sensors based on Zn2SnO4 nanoparticles immobilized on reduced graphene oxide under humidity conditions. Sens Actuators B-Chem. 2019;285:590–600.

Sun G-J, Lee JK, Choi S, Lee WI, Kim HW, Lee C. Selective oxidizing gas sensing and dominant sensing mechanism of n-CaO-decorated n-ZnO nanorod sensors. ACS Appl Mater Interfaces. 2017;9:9975–85.

Simonetti EAN, Oliveira TC, Machado ÁEC, Silva AAC, Santos AS, Cividanes LS. TiO2 as a gas sensor: the novel carbon structures and noble metals as new elements for enhancing sensitivity—a review. Ceram Int. 2021;47:17844–76.

Ramanavicius S, Tereshchenko A, Karpicz R, Ratautaite V, Bubniene U, Maneikis A, Jagminas A, Ramanavicius A. TiO2-x/TiO2-structure based ‘Self-Heated’ sensor for the determination of some reducing gases. Sensors. 2020;20:74.

Lee E, Lee D, Yoon J, Yin Y, Lee YN, Uprety S, Yoon YS, Kim D-J. Enhanced gas-sensing performance of GO/TiO2 composite by photocatalysis. Sensors. 2018;18:3334.

Ramanavicius S, Ramanavicius A. Insights in the application of stoichiometric and non-stoichiometric titanium oxides for the design of sensors for the determination of gases and VOCs (TiO2−x and TinO2n−1 vs. TiO2). Sensors. 2020;20:6833.

Sowmya B, John A, Panda PK. A review on metal-oxide based p-n and n-n heterostructured nano-materials for gas sensing applications. Sens Int. 2021;2:100085.

Srivastava S. Study of gas sensor detection for NOx gas: a review. Mater Today Proc. 2021;37:3709–12.

Gomes JBA, Rodrigues JJPC, Rabêlo RAL, Kumar N, Kozlov S. IoT-enabled gas sensors: technologies, applications, and opportunities. J Sens Actuator Netw. 2019;8:57.

Mohankumar P, Ajayan J, Yasodharan R, Devendran P, Sambasivam R. A review of micromachined sensors for automotive applications. Measurement. 2019;140:305–22.

Hallil H, Dejous C, Hage-Ali S, Elmazria O, Rossignol J, Stuerga D, Talbi A, Mazzamurro A, Joubert P-Y, Lefeuvre E. Passive resonant sensors: trends and future prospects. IEEE Sens J. 2021;21:12618–32.

Khan MAH, Rao MV, Li Q. Recent advances in electrochemical sensors for detecting toxic gases: NO2, SO2 and H2S. Sensors. 2019;19:905.

Balasubramani V, Chandraleka S, Rao TS, Sasikumar R, Kuppusamy MR, Sridhar TM. Review−recent advances in electrochemical impedance spectroscopy based toxic gas sensors using semiconducting metal oxides. J Electrochem Soc. 2020;167:037572.

Liu H, Zhang L, Li KHH, Tan OK. Microhotplates for metal oxide semiconductor gas sensor applications-towards the CMOS-MEMS monolithic approach. Micromachines. 2018;9:557.

Wang Y, Liu D, Yin J, Shang Y, Du J, Kang Z, Wang R, Chen Y, Sun D, Jiang J. An ultrafast responsive NO2 gas sensor based on a hydrogen-bonded organic framework material. Chem Commun. 2020;56:703–6.

Cui F, Zhou Z, Zhou HS. Molecularly imprinted polymers and surface imprinted polymers based electrochemical biosensor for infectious diseases. Sensors. 2020;20:996.

Jin H, Guo H, Gao X, Gui R. Selective and sensitive electrochemical sensing of gastrodin based on nickel foam modified with reduced graphene oxide/silver nanoparticles complex-encapsulated molecularly imprinted polymers. Sens Actuators B-Chem. 2018;277:14–21.

Korotcenkov G. Current trends in nanomaterials for metal oxide-based conductometric gas sensors: advantages and limitations. Part 1: 1D and 2D nanostructures. Nanomaterials. 2020;10:1392.

Nikolic MV, Milovanovic V, Vasiljevic ZZ, Stamenkovic Z. Semiconductor gas sensors: materials, technology, design, and application. Sensors. 2020;20:6694.

Dey A. Semiconductor metal oxide gas sensors: a review. Mater Sci Eng B. 2018;229:206–17.

Lin T, Lv X, Hu Z, Xu A, Feng C. Semiconductor metal oxides as chemoresistive sensors for detecting volatile organic compounds. Sensors. 2019;19:233.

Mahajan S, Jagtap S. Metal-oxide semiconductors for carbon monoxide (CO) gas sensing: a review. Appl Mater Today. 2020;18:100483.

Yi Z, Zeng Y, Wu H, Chen X, Fan Y, Yang H, Tang Y, Yi Y, Wang J, Wu P. Synthesis, surface properties, crystal structure and dye-sensitized solar cell performance of TiO2 nanotube arrays anodized under different parameters. Results Phys. 2019;15:102609.

Kang M, Kim SW, Park HY. Optical properties of TiO2 thin films with crystal structure. J Phys Chem Solids. 2018;123:266–70.

Meng A, Zhang L, Cheng B, Yu J. Dual cocatalysts in TiO2 photocatalysis. Adv Mater. 2019;31:1807660.

Guo Q, Zhou C, Ma Z, Yang X. Fundamentals of TiO2 photocatalysis: concepts, mechanisms, and challenges. Adv Mater. 2019;31:1901997.

Gonçalves RA, Toledo RP, Joshi N, Berengue OM. Green synthesis and applications of ZnO and TiO2 nanostructures. Molecules. 2021;26:2236.

Noman MT, Ashraf MA, Ali A. Synthesis and applications of nano-TiO2: a review. Environ Sci Pollut Res. 2019;26:3262–91.

Han Z, Qi Y, Yang Z, Han H, Jiang Y, Du W, Zhang X, Zhang J, Dai Z, Fletcher C, Wang Z, Liu J, Wu L, Lud G, Wang F. Recent advances and perspectives on constructing metal oxide semiconductor gas sensing materials for efficient formaldehyde detection. J Mater Chem C. 2020;8:13169–88.

Yuvaraja S, Bhyranalyar VN, Bhat SA, Surya SG, Yelamaggad CV, Salama KN. A highly selective electron affinity facilitated H2S sensor: the marriage of tris(keto-hydrazone) and an organic field-effect transistor. Mater Horiz. 2021;8:525537.

Cao Y, Maitarad P, Gao M, Taketsugu T, Li H, Yan T, Shi L, Zhang D. Defect-induced efficient dry reforming of methane over two-dimensional Ni/h-boron nitride nanosheet catalysts. Appl Catal B: Environ. 2018;238:51–60.

Jo YK, Lee JM, Son S, Hwang S-J. 2D inorganic nanosheet-based hybrid photocatalysts: design, applications, and perspectives. J Photochem Photobiol C Photochem Rev. 2019;40:150–90.

Hu T-T, Liu F, Dou S, Zhong L-B, Cheng X, Shao Z-D, Zheng Y-M. Selective adsorption of trace gaseous ammonia from air by a sulfonic acid-modified silica xerogel: preparation, characterization and performance. Chem Eng J. 2022;443:136357.

Kwak D, Lei Y, Maric R. Ammonia gas sensors: a comprehensive review. Talanta. 2019;204:713–30.

Wu H, Huang H, Zhou J, Hong D, Ikram M, Rehman AU, Li L, Shi K. One-step synthesis of ordered Pd@TiO2 nanofibers array film as outstanding NH3 gas sensor at room temperature. Sci Rep. 2017;7:14688.

Liu H, Shen W, Chen X. A room temperature operated ammonia gas sensor based on Ag-decorated TiO2 quantum dot clusters. RSC Adv. 2019;9:24519.

Shooshtari M, Salehi A. Ammonia room-temperature gas sensor using different TiO2 nanostructures. J Mater Sci Mater Electron. 2021;32:17371–81.

Zhou Y, Wang Y, Wang Y, Yu H, Zhang R, Li J, Zang Z, Li X. MXene Ti3C2Tx-derived nitrogen-functionalized heterophase TiO2 homojunctions for room-temperature trace ammonia gas sensing. ACS Appl Mater Interfaces. 2021;13:56485–97.

Wang Y, Zhou Y, Wang Y, Zhang R, Li J, Li X, Zang Z. Conductometric room temperature ammonia sensors based on titanium dioxide nanoparticles decorated thin black phosphorus nanosheets. Sens Actuators B-Chem. 2021;349:130770.

Zhou Y, Li X, Wang Y, Tai H, Guo Y. UV illumination-enhanced molecular ammonia detection based on a ternary-reduced graphene oxide−titanium dioxide−Au composite film at room temperature. Anal Chem. 2019;91:3311–8.

Kawamura F, Umeda H, Morishita M, Kawahara M, Yoshimura M, Mori Y, Sasaki T, Kitaoka Y. Growth of a two-inch GaN single crystal substrate using the Na flux method. Jpn J Appl Phys. 2006;45:L1136–8.

Kim J, Choi J-W. Synthesis of large monolayer titania nanosheets through flux method. J Asian Ceram Soc. 2021;9:916–25.

Zhang X, Liu Y, Liu H, Liang T, Zhang P, Da Z. FeSe2/Hematite nn heterojunction with oxygen spillover for highly efficient NO2 gas sensing. Sens Actuators B-Chem. 2021;345:130357.

Liu B, Li K, Luo Y, Gao L, Duan G. Sulfur spillover driven by charge transfer between AuPd alloys and SnO2. Chem Eng J. 2021;420:12988.

Park HJ, Lee SE, Park JY. Optical property of atomically thin titanium-oxide nanosheet for ultraviolet filtration. Thin Solid Films. 2017;636:99–106.

Lee SE, Jung SY, Seo J, Joo JH, Lee J, Kim Y-M, Lee KH, Kim YI, Park HJ. Anomalous electronic and protonic conductivity of 2D titanium oxide and low-temperature power generation using its protonic conduction. Adv Mater Interfaces. 2021;8:2101156.

Wan J, Chen W, Jia C, Zheng L, Dong J, Zheng X, Wang Y, Yan W, Chen C, Peng Q, Wang D, Li Y. Defect effects on TiO2 nanosheets: stabilizing single atomic site Au and promoting catalytic properties. Adv Mater. 2018;30:1705369.

Wang H-Y, Soldemo M, Degerman D, Lömker P, Schlueter C, Nilsson A, Amann P. Direct evidence of subsurface oxygen formation in oxide-derived Cu by x-ray photoelectron spectroscopy. Angew Chem Int Ed. 2022;61:e202111021.

Samsudin EM, Hamid SBA, Juan JC, Basirun WJ, Kandjani AE. Surface modification of mixed-phase hydrogenated TiO2 and corresponding photocatalytic response. Appl Surf Sci. 2015;359:883–96.

Das TK, Ilaiyaraja P, Sudakar C. Template assisted nanoporous TiO2 nanoparticles: the effect of oxygen vacancy defects on photovoltaic performance of DSSC and QDSSC. Sol Energy. 2018;159:920–9.

Xia Y, Xu L, He S, Zhou L, Wang M, Wang J, Komarneni S. UV-activated WS2/SnO2 2D/0D heterostructures for fast and reversible NO2 gas sensing at room temperature. Sens Actuators B-Chem. 2022;364:131903.

Deng Z, Meng G, Fang X, Dong W, Shao J, Wang S, Tong B. A novel ammonia gas sensors based on p-type delafossite AgAlO2. J Alloys Compd. 2019;777:52–8.

Yao G, Yu J, Wu H, Li Z, Zou W, Zhu H, Huang Z, Huang H, Tang Z. P-type Sb doping hierarchical WO3 microspheres for superior close to room temperature ammonia sensor. Sens Actuators B-Chem. 2022;359:131365.

Choi MS, Kim MY, Mirzaei A, Kim H-S, Kim S-I, Baek S-H, Chun DW, Jin C, Lee KH. Selective, sensitive, and stable NO2 gas sensor based on porous ZnO nanosheets. Appl Surf Sci. 2021;568:150910.

Phawa C, Prayoonpokarach S, Sinthiptharakoon K, Chakthranont P, Sangkhun W, Faungnawakij K, Butburee T. Effects of matching facet pairs of TiO2 on photoelectrochemical water splitting behaviors. ChemCatChem. 2020;12:2116–24.

Galstyan V, Comini E, Faglia G, Sberveglieri G. TiO2 nanotubes: recent advances in synthesis and gas sensing properties. Sensors. 2013;13:14813–38.

Bairi VG, Bourdo SE, Sacre N, Nair D, Berry BC, Biris AS, Viswanathan T. Ammonia gas sensing behavior of tanninsulfonic acid doped polyaniline-TiO2 composite. Sensors. 2015;15:26415–29.

Pang Z, Yang Z, Chen Y, Zhang J, Wang Q, Huang F, Wei Q. A room temperature ammonia gas sensor based on cellulose/TiO2/PANI composite nanofibers. Colloids Surf A Physicochem Eng Asp. 2016;494:248–55.

Tai H, Jiang Y, Xie G, Yu J, Chen X, Ying Z. Influence of polymerization temperature on NH3 response of PANI/TiO2 thin film gas sensor. Sens Actuators B Chem. 2008;129:319–26.

Tai H, Jiang Y, Xie G, Yu J, Zhao M. Self-assembly of TiO2/polypyrrole nanocomposite ultrathin films and application for an NH3 gas sensor. Int J Environ Anal Chem. 2007;87:539–51.

Jung JY, Lee CS. Characteristics of the TiO2/SnO2 thick film semiconductor as sensor to determine fish freshness. J Ind Eng Chem. 2011;17:237–42.

Ding Y, Guo X, Du B, Hu X, Yang X, He Y, Zhou Y, Zang Z. Low-operating temperature ammonia sensor based on Cu2O nanoparticles decorated with p-type MoS2 nanosheets. J Mater Chem C. 2021;9:4838–46.

Kristiansson MK, Chartkunchand K, Eklund G, Hole OM, Anderson EK, Ruette N, Kamińska M, Punnakayathil N, Navarro-Navarrete JE, Sigurdsson S, Grumer J, Simonsson A, Björkhage M, Rosén S, Reinhed P, Blom M, Källberg A, Alexander JD, Cederquist H, Zettergren H, Schmidt HT, Hanstorp D. High-precision electron affinity of oxygen. Nat Commun. 2022;13:5906.

Qu Z, Kroes G. Theoretical study of the electronic structure and stability of titanium dioxide clusters (TiO2)n with n = 1–9. J Phys Chem B. 2006;110:8998–9007.

Sachtler WMH, Dorgelo GJH, Holscher AA. The work function of gold. Surf Sci. 1966;5:221–9.

Kashiwaya S, Morasch J, Streibel V, Toupance T, Jaegermann W, Klein A. The work function of TiO2. Surfaces. 2018;1:73–89.

Wei Y, Wang X, Yi G, Zhou L, Cao J, Sun G, Chen Z, Bala H, Zhang Z. Hydrothermal synthesis of Ag modified ZnO nanorods and their enhanced ethanol-sensing properties. Mater Sci Semicond Process. 2018;75:327–33.

Wu K, Debliquy M, Zhang C. Room temperature gas sensors based on Ce doped TiO2 nanocrystals for highly sensitive NH3 detection. Chem Eng J. 2022;444:136449.

Rahimi S, Abdi Y, Arzi E. Impact of TiO2/Graphene-Oxide coated on quartz crystal resonator on the sensing performance of NH3, N2 and ethanol at room temperature. Phys B. 2021;623:413348.

Tian X, Cui X, Lai T, Ren J, Yang Z, Xiao M, Wang B, Xiao X, Wang Y. Gas sensors based on TiO2 nanostructured materials for the detection of hazardous gases: a review. Nano Mater Sci. 2021;3:390–403.

Seekaew Y, Pon-On W, Wongchoosuk C. Ultrahigh selective room-temperature ammonia gas sensor based on Tin−Titanium dioxide/reduced graphene/carbon nanotube nanocomposites by the solvothermal method. ACS Omega. 2019;4:16916–24.

Zeng G, Cao H, Chen W, Lutz J. Difference in device temperature determination using p-n-junction forward voltage and gate threshold voltage. IEEE Trans Power Electron. 2019;34:2781–93.

Tanaka H, Mori N. Modeling of carrier scattering in MOS inversion layers with large density of interface states and simulation of electron Hall mobility in 4H-SiC MOSFETs. Jpn J Appl Phys. 2020;59:031006.

Acknowledgements

Not applicable.

Funding

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (2022R1A2C2005210), the Ministry of Education (2019R1A6A1A11055660), and the Ministry of Science and ICT (MSIT) (NRF-2021R1A5A8033165). This work was supported by the Industrial technology innovation project (20011034, Development of titania nano materials technology for high performance suncare for broadband UV protection) funded by the Ministry of Trade, Industry & Energy (MOTIE, Korea). This study was also supported by Samsung Electronics Co., Ltd. (IO201216–08204-01). Seung Yong Lee and Changhyun Jin were supported by the Korea Initiative for fostering University of Research and Innovation (KIURI) Program of the National Research Foundation (NRF) funded by the Korean government (MSIT) (NRF-2020M3H1A1077207).

Author information

Authors and Affiliations

Contributions

KHL, CJ, and MSC conceived the study, and designed the experiments. JYH, YL, and GHL synthesized the samples and measured the gas-sensing properties. SYL performed and analysed the XRD. HSK and HJP carried out the PL and XPS analysis. SIK, SJK, and BZL analysed the microstructures. JYH, CJ, and KHL co-wrote the manuscript. All the authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hwang, J.Y., Lee, Y., Lee, G.H. et al. Room-temperature ammonia gas sensing via Au nanoparticle-decorated TiO2 nanosheets. Discover Nano 18, 47 (2023). https://doi.org/10.1186/s11671-023-03798-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-023-03798-5