Abstract

Two-dimensional (2D) material has many advantages including high carrier mobilities and conductivity, high optical transparency, excellent mechanical flexibility, and chemical stability, which made 2D material an ideal material for various optoelectronic devices. Here, we developed a facile method of preparing MoS2 nanosheets followed by a facile liquid exfoliation method via ethyl cellulose-assisted doping and utilizing a plasma-induced p-doping approach to generate t effectively the partially oxided MoS2 (p-MoS2) nanosheets from the pristine n-type nanosheets. Moreover, an n-p junction type MoS2 photodetector device with the built-in potentials to separate the photogenerated charges is able to significantly improved visible light response. We have fabricated photodetector devices consisting of a vertically stacked indium tin oxide (ITO)/pristine n-type MoS2 nanosheets/p-MoS2/Ag structure, which exhibit reasonably good performance illumination, as well as high current values in the range of visible wavelength from 350 to 600 nm. We believe that this work provides important scientific insights for photoelectric response properties of emerging atomically layered 2D materials for photovoltaic and other optoelectronic applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Over the last decade, two-dimensional (2D) nanomaterials have drawn great attention because of their unique structures, large natural abundance, and distinctive properties compared to their bulk forms, and a broad range of applications in catalysis, electronics, energy-storage devices, optoelectronics, and so on [1–11]. In particular, the semiconducting layered transition metal dichalcogenides (LTMDs, e.g., WSe2, WS2, and MoS2) have gained significant interest on optoelectronics due to their direct bandgaps, possessing intriguing optical properties suitable for optoelectronic applications in light-emitting diodes and photovoltaics [12–14]. Usually, LTMDs have a unique 2D X–M–X structure in which the transition metal atom layer is sandwiched between two close-packed chalcogen atom layers [1, 2, 15–17].

As a prototypical compound of LTMDs, MoS2 has been extensively studied. Bulk MoS2 is a typical semiconductor with an indirect bandgap. Expectedly, monolayer MoS2 transistors have been demonstrated with on/off ratios of 108 and ultralow standby power dissipation [17–19]. However, to realize the highly efficient optoelectronic devices based on MoS2, it is also important to develop a strategy to prepare ultrathin MoS2 nanosheets and tune the bandgaps with facile process. Several methods, such as mechanical exfoliation (the so-called Scotch tape method), liquid exfoliation, colloidal synthesis, chemical vapor deposition, chemical exfoliation, and electrochemical exfoliation have been developed to prepare ultrathin MoS2 nanosheets [2, 20–30]. Among these methods, liquid exfoliation not only produces novel materials with the same composition yet dramatically changed electrical properties but also provides a facile way to prepare thin-layer nanosheets, which offers novel opportunities in the optoelectronics applications [17, 31–34].

In this work, we report that a novel liquid exfoliation method via ethyl cellulose-assisted doping can prepare an excellent thin MoS2 nanosheets and very effective method to generate the partially oxidized MoS2 (p-MoS2) nanosheets from the pristine n-type nanosheets. Moreover, an n-p junction type MoS2 photodetector device with the built-in potentials to separate the photogenerated charges can result in significantly improved visible light response. We have fabricated photodetector devices consisting of a vertically stacked indium tin oxide (ITO)/pristine n-type MoS2 nanosheets/p-MoS2/Ag structure, which exhibit reasonably good performance illumination, as well as high current values in the range of visible wavelength from 350 to 600 nm. This work provides important scientific insights for leveraging unique optoelectronic properties of 2D materials for photodetector applications.

Methods

Material Synthesis

Molybdenum disulfide (MoS2) nanosheets were synthesized by liquid ultrasound exfoliation as reported in the literature [35, 36]. Typically, MoS2 power (0.25 g, Aladdin) was dispersed in ethyl cellulose (EC) isopropanol solution (1 % w/v dispersion, 100 ml) in a SEBC bottle. The dispersion was sonicated for 24 h at 60 W in water bath. The resulting dispersion was centrifuged (Desktop High-speed Refrigerated Centrifuge Model TGL-16) at 5000 rpm for 15 min, and then the supernatant liquid was directly collected. Deionized water was mixed with the supernatant liquid (3:4 weight ratio) and subsequently centrifuged at 7500 rpm for 10 min. Whereafter, the lower precipitation was collected and dried. The resulting precipitation was redispersed in ethanol (10 mg/ml). NaCl aqueous solution (0.04 g/ml) was mixed with the redispersion (9:16 weight ratio) and centrifuged at 5000 rpm for 8 min, discarding the supernatant. To debride any residual salt, the resulting MoS2 precipitation was washed with deionized water and collected by vacuum filtration (0.45 μm filter paper). Finally, the MoS2 nanosheet product was dried as a fine black powder. The final MoS2 nanosheets were defined as n-MoS2. For the preparation of p-MoS2 nanosheets, the n-MoS2 powder was taken a UV-ozone plasma treatment for 40 min to completely change to p-MoS2 nanosheets.

Characterizations

TEM images were taken by a FEI TECNAI G2 F20-TWIN TEM. Raman spectra were recorded on inVia Raman microscope. XPS and UPS measurements were conducted using an ESCALAB 250Xi (Thermo) system. X-ray diffraction (XRD) patterns of the MoS2 was carried out on a Bruker D8 Focus X-ray diffractometer operating at 30 kV and 20 mA with a copper target (λ= 1.54 Å) and at a scanning rate of 1°/min.

Photodetector Device Fabrication

All devices were fabricated on pre-treatment ITO glass substrates [37] (sheet resistance <10 Ωsq−1, ShenZhen NanBo Display Technology Co., Ltd.); cleaned sequentially using sonication in acetone, detergent, deionized water, and isopropanol; and then dried under a nitrogen stream, followed by ultraviolet light irradiation. Then, the n-MoS2 nanosheets (10 mg/ml, in isopropanol) spin coated with 2000 rpm and thermally annealed at 150 °C for 15 min receive a thickness of 80 nm. Thereafter, the p-MoS2 nanosheets (15 mg/ml, in isopropanol) was spin coated on n-MoS2 nanosheets layer, followed by thermal annealing at 150 °C for 10 min in atmospheric environment. Eventually, Argentum Ag (150 nm) was deposited over the p-MoS2 nanosheets layer by thermal evaporation under a vacuum of 6 × 10−6 Torr to accomplish the device fabrication. The effective area of one cell was ~1 cm2. The photocurrent-voltage curves and I-T curves were measured with a Keithley 2400 source meter and a 150-W Xe lamp light source. The dark current-voltage curves were measured by Keithley 2400 source meter under dark. All the measurements were performed under ambient atmosphere at room temperature. The incident photo-to-electron conversion efficiency spectrum (IPCE) were detected under monochromatic illumination (Oriel Cornerstone 260 1/4 m monochromator equipped with Oriel 70613NS QTH lamp), and the calibration of the incident light was performed with a monocrystalline silicon diode.

Results and Discussion

The equal concentration of pristine MoS2 and MoS2 nanosheets after the liquid ultrasound exfoliation solution (10 mg/ml) was treated with ultrasound in ethanol for 30 min, respectively. The detailed process is demonstrated in experimental section. The photographs of pristine MoS2 and MoS2 nanosheets isopropanol dispersion solutions after ultrasound treatment are shown in Fig. 1. After storing for 48 h, humorous aggregation can be observed in pristine MoS2 solution (Fig. 1a) and evident MoS2 particles adhere to the sidewall. In contrast, the MoS2 nanosheets after the liquid ultrasound exfoliation solution show a highly uniform and homogeneous suspension solution (Fig. 1b), indicating the successful preparation of MoS2 nanosheets with the good dispensability.

In order to verify the degree of dispersion of exfoliated MoS2 nanosheets by ethyl cellulose ethanol solution via liquid ultrasound exfoliation, transmission electron microscopy (TEM) and scanning electron microscopy (SEM) were performed (Fig. 2). For comparison, the morphologies of the pristine MoS2 nanosheets prepared by 150 °C thermal annealing for 10 min were also determined. All of samples were spin-coated on ITO and tested in the same testing conditions. Figure 2a shows a rough morphology of the pristine MoS2, and clearly stacked MoS2 can be seen. However, Fig. 2b displays an individual MoS2 sheet with six spot pattern in the selected-area electron diffraction (SAED) of MoS2, suggesting that MoS2 is scattered as individual MoS2 nanosheet [38, 39]. Also, the severe aggregation of the pristine MoS2 can be observed in SEM images (Fig. 2c), intriguingly, after being treated by ethyl cellulose ethanol solution via liquid ultrasound exfoliation, MoS2 nanosheets can fully cover and tightly attach on the ITO substrate with a quite smooth surface morphology (Fig. 2d).

The transmission electron microscopy (TEM) images of a pristine MoS2 and b MoS2 nanosheets films on glass substrate, and the inset is selected area electron diffraction (SAED) pattern of the MoS2 nanosheets. The scanning electron microscopy (SEM) images of c pristine MoS2 and d MoS2 nanosheets films on glass substrate

To further verify morphology results, the XRD patterns of pristine and exfoliated MoS2 nanosheets (Fig. 3a) only the peaks of (103) and (002) plane remain after liquid exfoliation which confirms that the MoS2 nanosheets were successfully striped [40, 41]. Moreover, the disappearance of other peaks could prove that ultrathin MoS2 nanosheets are tightly deposited on the ITO glass with preferred ductility. The Raman spectrum can once again prove the exfoliation of MoS2 nanosheets. The two peaks (1 and 2 g) between 360 and 430 cm−1 are the main peak of MoS2 [42–44]. After liquid exfoliation, the obvious decrease of the intensity of the two peaks was observed.

It is well known that the MoS2 nanosheets are n-type semiconductor materials and several researches have been reported that MoS2 could be changed as a p-type semiconductor material with a relative high work function after UV-ozone plasma treatment. Thus, the properties of MoS2 nanosheets with or without the UV-ozone plasma treatment were also investigated. Figure 4a is the X-ray photoelectron spectroscopy (XPS) profile of n-MoS2 nanosheets (without plasma treatment) and p-MoS2 nanosheets (with plasma treatment). The Mo 3D spectra of pristine MoS2 nanosheets demonstrate outstanding Mo4+3d5/2 and Mo4+3d3/2 bands at 228.7 and 231.5 eV, in agreement with the other works for n-MoS2 nanosheets. However, the two strong peaks have a notable shift to 235.3 and 232.5 eV, respectively, which is similar with the spectra of MoO3 [45, 46]. Therefore, it proved that n-MoS2 nanosheets can be successfully oxidized to p-type materials after UV-ozone plasma treatment. Since the MoS2 layer is very thin via the spin-coating method, it is important to analyze the bilayer junction existing at the interface of n-MoS2/p-MoS2. To gain insight into the electronic structures of the n-MoS2/p-MoS2 bilayer junction, we have performed the UPS analysis. The work function was calculated through the difference between the cutoff of the highest binding energy and the photon energy of the exciting radiation. The valence band (VB) can be calculated from the cutoff from the lowest binding energy. As shown in Fig. 4b, after UV-ozone plasma treatment, the work function of the MoS2 nanosheets has increased from 4.3 to 5.2 eV. The energy difference between the Fermi level and valence band maximum is decreased from 1.4 to 0.4 eV, demonstrating the n-type MoS2 nanosheets change to p-type MoS2 nanosheets [47].

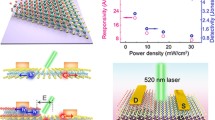

On the basis of the above results, we have constructed an energy diagram showing the band bending behavior at the n-MoS2/p-MoS2 bilayer junction interface, as shown in Fig. 5a. The n-MoS2/p-MoS2 bilayer junction with a built-in potential promises an excellent photodetector performance with a ITO/n-MoS2/p-MoS2/Ag device structure (Fig. 5b) which will be discussed later. The photocurrent-voltage curves and the photocurrent-voltage were measured with the Keithley 2400 source meter. As shown in Fig. 6a, b, the device shows the photovoltaic response under a 150-W Xe lamp light source illumination. The result shows the device have a p-n junction inside. In order to understand the photoelectric response properties in more detail and detect potential application in photoelectronic fields, we have performed further experiments of photodetector at a 1-V DC bias as shown in Fig. 7a, b. As seen from Fig. 7a, b, the photocurrent increases at an applied dc bias voltage of 0 and 1 V. Moreover, the photoresponse is steady, prompt, and reproducible during repeated on/off cycles of visible light illumination. More importantly, the n-MoS2/p-MoS2 bilayer junction-based device shows a very broad photoelectric response range from 350 to 600 nm, as shown in Fig. 7c, and therefore, the n-MoS2/p-MoS2 bilayer junction can harvest nearly the whole energy range of visible light.

a The output signal of photocurrent under alternating light on and light off, where the entire device was illuminated by a 150-W Xe lamp irradiation. Photoresponse of MoS2-based photodetector at a 0-V DC bias voltage. b Photoresponse of MoS2-based photodetector at 1-V DC bias voltage. c The spectral photoresponse vs. wavelength, showing a broad photoresponse range from 350 to 650 nm, which is, the absorption spectrum of the nanohybrid covers the whole energy range of visible light

Conclusions

We have demonstrated a high-quality n-MoS2/p-MoS2 bilayer junction-based device to achieve the high performance photoresponse which can harvest nearly the whole energy range of visible light. Excellent, thin exfoliated MoS2 nanosheets are realized by a facile liquid exfoliation, changing the n-type MoS2 nanosheets to p-type MoS2 nanosheets via a simple plasma treatment. This work shows that thin MoS2 nanosheets can be fully integrated into the photodetector manufacturing process, which holds promise for realizing 2D materials in a variety of optical electronic and optical devices.

References

Eda G, Fujita T, Yamaguchi H, Voiry D, Chen M, Chhowalla M (2012) Coherent atomic and electronic heterostructures of single-layer MoS2. ACS Nano 6:7311–7317

Eda G, Yamaguchi H, Voiry D, Fujita T, Chen M, Chhowalla M (2011) Photoluminescence from chemically exfoliated MoS2. Nano Lett 11:5111–5116

Gu X, Cui W, Li H, Wu Z, Zeng Z, Lee ST, Zhang H, Sun B (2013) A solution-processed hole extraction layer made from ultrathin MoS2 nanosheets for efficient organic solar cells. Adv Energy Mater 3:1262–1268

Wang QH, Kalantar-Zadeh K, Kis A, Coleman JN, Strano MS (2012) Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat Nanotechnol 7:699–712

Tan C, Liu Z, Huang W, Zhang H (2015) Non-volatile resistive memory devices based on solution-processed ultrathin two-dimensional nanomaterials. Chem Soc Rev 44:2615–2628

Tan C, Zhang H (2015) Two-dimensional transition metal dichalcogenide nanosheet-based composites. Chem Soc Rev 44:2713–2731

Huang X, Tan C, Yin Z, Zhang H (2014) 25th Anniversary article: hybrid nanostructures based on two-dimensional nanomaterials. Adv Mater 26:2185–2204

Huang X, Zeng Z, Zhang H (2013) Metal dichalcogenide nanosheets: preparation, properties and applications. Chem Soc Rev 42:1934–1946

Huang X, Yin Z, Wu S, Qi X, He Q, Zhang Q, Yan Q, Boey F, Zhang H (2011) Graphene-based materials: synthesis, characterization, properties, and applications. Small 7:1876–1902

Zhang H (2015) Ultrathin two-dimensional nanomaterials. ACS Nano 9:9451–9469

Huang X, Qi X, Boey F, Zhang H (2012) Graphene-based composites. Chem Soc Rev 41:666–686

Buscema M, Groenendijk DJ, Blanter SI, Steele GA, van der Zant HS, Castellanos-Gomez A (2014) Fast and broadband photoresponse of few-layer black phosphorus field-effect transistors. Nano Lett 14:3347–3352

Scalise E, Houssa M, Pourtois G, Afanas’ev V, Stesmans A (2012) Strain-induced semiconductor to metal transition in the two-dimensional honeycomb structure of MoS2. Nano Res 5:43–48

Remskar M, Mrzel A, Virsek M, Godec M, Krause M, Kolitsch A, Singh A, Seabaugh A (2010) The MoS2 nanotubes with defect-controlled electric properties. Nanoscale Res Lett 6:26

Yin Z, Li H, Li H, Jiang L, Shi Y, Sun Y, Lu G, Zhang Q, Chen X, Zhang H (2012) Single-layer MoS2 phototransistors. ACS Nano 6:74–80

Yuwen L, Xu F, Xue B, Luo Z, Zhang Q, Bao B, Su S, Weng L, Huang W, Wang L (2014) General synthesis of noble metal (Au, Ag, Pd, Pt) nanocrystal modified MoS2 nanosheets and the enhanced catalytic activity of Pd-MoS2 for methanol oxidation. Nanoscale 6:5762–5769

Xu M, Liang T, Shi M, Chen H (2013) Graphene-like two-dimensional materials. Chem Rev 113:3766–3798

Radisavljevic B, Radenovic A, Brivio J, Giacometti V, Kis A (2011) Single-layer MoS2 transistors. Nat Nanotechnol 6:147–150

Lopez-Sanchez O, Lembke D, Kayci M, Radenovic A, Kis A (2013) Ultrasensitive photodetectors based on monolayer MoS2. Nat Nanotechnol 8:497–501

Shi H, Yan R, Bertolazzi S, Brivio J, Gao B, Kis A, Jena D, Xing HG, Huang L (2013) Exciton dynamics in suspended monolayer and few-layer MoS2 2D crystals. ACS Nano 7:1072–1080

Wang H, Yu L, Lee Y-H, Shi Y, Hsu A, Chin ML, Li L-J, Dubey M, Kong J, Palacios T (2012) Integrated circuits based on bilayer MoS2 transistors. Nano Lett 12:4674–4680

Conley HJ, Wang B, Ziegler JI, Haglund RF Jr, Pantelides ST, Bolotin KI (2013) Bandgap engineering of strained monolayer and bilayer MoS2. Nano Lett 13:3626–3630

Bertolazzi S, Krasnozhon D, Kis A (2013) Nonvolatile memory cells based on MoS2/graphene heterostructures. ACS Nano 7:3246–3252

Mak KF, He K, Shan J, Heinz TF (2012) Control of valley polarization in monolayer MoS2 by optical helicity. Nat Nanotechnol 7:494–498

Lee Y-H, Yu L, Wang H, Fang W, Ling X, Shi Y, Lin C-T, Huang J-K, Chang M-T, Chang C-S (2013) Synthesis and transfer of single-layer transition metal disulfides on diverse surfaces. Nano Lett 13:1852–1857

Chen J-R, Odenthal PM, Swartz AG, Floyd GC, Wen H, Luo KY, Kawakami RK (2013) Control of Schottky barriers in single layer MoS2 transistors with ferromagnetic contacts. Nano Lett 13:3106–3110

Li H, Wu J, Yin Z, Zhang H (2014) Preparation and applications of mechanically exfoliated single-layer and multilayer MoS2 and WSe2 nanosheets. Accounts Chem Res 47:1067–1075

Li H, Yin Z, He Q, Li H, Huang X, Lu G, Fam DWH, Tok AIY, Zhang Q, Zhang H (2012) Fabrication of single- and multilayer MoS2 film-based field-effect transistors for sensing no at room temperature. Small 8:63–67

Li H, Lu G, Yin Z, He Q, Li H, Zhang Q, Zhang H (2012) Optical identification of single- and few-layer MoS2 sheets. Small 8:682–686

Li H, Wu J, Huang X, Lu G, Yang J, Lu X, Xiong Q, Zhang H (2013) Rapid and reliable thickness identification of two-dimensional nanosheets using optical microscopy. ACS Nano 7:10344–10353

Lee HS, Min S-W, Chang Y-G, Park MK, Nam T, Kim H, Kim JH, Ryu S, Im S (2012) MoS2 nanosheet phototransistors with thickness-modulated optical energy gap. Nano Lett 12:3695–3700

Yoon Y, Ganapathi K, Salahuddin S (2011) How good can monolayer MoS2 transistors be? Nano Lett 11:3768–3773

Zeng Z, Yin Z, Huang X, Li H, He Q, Lu G, Boey F, Zhang H (2011) Single-layer semiconducting nanosheets: high-yield preparation and device fabrication. Angew Chem Int Edit 50:11093–11097

Liu J, Zeng Z, Cao X, Lu G, Wang L-H, Fan Q-L, Huang W, Zhang H (2012) Preparation of MoS2-polyvinylpyrrolidone nanocomposites for flexible nonvolatile rewritable memory devices with reduced graphene oxide electrodes. Small 8:3517–3522

Viculis LM, Mack JJ, Mayer OM, Hahn HT, Kaner RB (2005) Intercalation and exfoliation routes to graphite nanoplatelets. J Mater Chem 15:974–978

Coleman JN, Lotya M, O’Neill A, Bergin SD, King PJ, Khan U, Young K, Gaucher A, De S, Smith RJ (2011) Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science 331:568–571

Hsu C-L, Tsai T-Y (2011) Fabrication of fully transparent indium-doped ZnO nanowire field-effect transistors on ITO/glass substrates. J Electrochem Soc 158:K20–K23

Fu W, Du F-H, Su J, Li X-H, Wei X, Ye T-N, Wang K-X, Chen J-S (2014) In situ catalytic growth of large-area multilayered graphene/MoS2 heterostructures. Sci rep-UK 4:4673

Yu X, Prévot MS, Sivula K (2014) Multiflake thin film electronic devices of solution processed 2D MoS2 enabled by sonopolymer assisted exfoliation and surface modification. Chem Mater 26:5892–5899

Zheng X, Xu J, Yan K, Wang H, Wang Z, Yang S (2014) Space-confined growth of MoS2 nanosheets within graphite: the layered hybrid of MoS2 and graphene as an active catalyst for hydrogen evolution reaction. Chem Mater 26:2344–2353

Nguyen EP, Carey BJ, Daeneke T, Ou JZ, Latham K, Zhuiykov S, Kalantar-Zadeh K (2014) Investigation of two-solvent grinding-assisted liquid phase exfoliation of layered MoS2. Chem Mater 27:53–59

Terrones H, Del Corro E, Feng S, Poumirol J, Rhodes D, Smirnov D, Pradhan N, Lin Z, Nguyen M, Elias A (2014) New first order raman-active modes in few layered transition metal dichalcogenides. Sci Rep-UK 4:4215

Chen C, Qiao H, Lin S, Luk CM, Liu Y, Xu Z, Song J, Xue Y, Li D, Yuan J (2015) Highly responsive MoS2 photodetectors enhanced by graphene quantum dots. Sci Rep-UK 5:11830

Wang S, Rong Y, Fan Y, Pacios M, Bhaskaran H, He K, Warner JH (2014) Shape evolution of monolayer MoS2 crystals grown by chemical vapor deposition. Chem Mater 26:6371–6379

Varrla E, Backes C, Paton KR, Harvey A, Gholamvand Z, McCauley J, Coleman JN (2015) Large-scale production of size-controlled MoS2 nanosheets by shear exfoliation. Chem Mater 27:1129–1139

Alov NV (2015) XPS study of MoO3 and WO3 oxide surface modification by low-energy Ar + ion bombardment. Phys Status Solidi C 12:263–266

Chuang S, Battaglia C, Azcatl A, McDonnell S, Kang JS, Yin X, Tosun M, Kapadia R, Fang H, Wallace RM (2014) MoS2 p-type transistors and diodes enabled by high work function MoOx contacts. Nano Lett 14:1337–1342

Acknowledgements

This study was financially supported by the Natural Science Research Projects Funded of Anhui Colleges and Universities (KJ2015A224) and Scientific Research Fund of Anhui Province Education Department (KJ2010B104).

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing Interests

The authors declare that they have no competing interests.

Authors’ Contributions

JY carried out the experiments. JY, XlL, JjZ, and QL participated in the design of the study. JY and XlL conceived of the study, participated in its design and coordination, and helped draft the manuscript. All authors read and approved the final manuscript.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Ye, J., Li, X., Zhao, J. et al. A Facile Way to Fabricate High-Performance Solution-Processed n-MoS2/p-MoS2 Bilayer Photodetectors. Nanoscale Res Lett 10, 454 (2015). https://doi.org/10.1186/s11671-015-1161-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-015-1161-3