Abstract

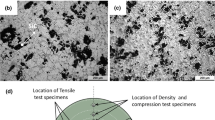

This work is aimed at solving the challenging problem of developing an approach to determining the representative volume of an Al/SiC metal matrix composite material (MMC) with 55 vol % silicon carbide synthesized by a unique squeeze casting technology. This volume is referred to as representative volume element (RVE). Initially, the minimum unit cell size was found by a metallographic method. The RVE of the MMC, where the average filler content is equal to the average filler content in the composite material, begins with a 40 × 40-μm region. The RVE is determined by the finite element method. To perform numerical RVE calculations, we solved the two-dimensional problem of tension an element in the cross section of the MMC consisting of hard SiC particles and a pure aluminum matrix. A stress–strain curve recorded during uniaxial tension is used as the response of MMC to an external action. The problems with regions of 40 × 40, 50 × 50, 70 × 70, 100 × 100, 200 × 200 and 400 × 400 μm are solved. The results of the numerical calculations demonstrate that the minimum RVE of the Al/SiC MMC with 55 vol % silicon carbide is 200 × 200 μm. In addition, depth-sensing indentation is recommended as an experimental method for estimating RVE. When a pyramidal indenter is pressed into the surface of an MMC sample, the indentation diagram reflects the influence of both the composite matrix and silicon carbide particles. The indentation force (correspondingly, surface area) used in experiments is such that the influence of the site of indentation on the indentation diagram is minimal. Instrumented indentation used to determine RVE demonstrates that it is 200 × 200 × 200 μm.

Similar content being viewed by others

REFERENCES

N. Chawla and K. Chawla, Metal Matrix Composites (Springer, New York, 2013).

Yu. A. Kurganova and A. G. Kolmakov, Structural Metal-Matrix Composite Materials: Tutorial (Izd. MGTU, Moscow, 2015).

N. Natarajan, V. Krishnaraj, and J. P. Davim, Metal Matrix Composites: Synthesis, Wear Characteristics, Machinability Study of MMC Brake Drum (Springer, New York, 2015).

N. Gangil, A. N. Siddiquee, and S. Maheshwari, “Aluminium based in-situ composite fabrication through friction stir processing: a review,” J. Alloys Compd. 715 (25), 91–104 (2017).

M. Rajamuthamilselvan and S. Ramanathan, “Development of processing map for 7075 Al/20% SiCp composite,” J. Mater. Eng. Perform., No. 21, 191–196 (2012).

T. A. Chernysheva, L. I. Kobeleva, L. K. Bolotova, and I. V. Katin, “Tribological properties of cast aluminum matrix composites,” Deform. Razrushenie Mater., No. 1, 16–21 (2014).

A. Pramanik, M. N. Islam, I. J. Davies, B. Boswell, Y. Dong, A. K. Basak, M. S. Uddin, A. R. Dixit, and S. Chattopadhyaya, “Contribution of machining to the fatigue behaviour of metal matrix composites (MMCs) of varying reinforcement size,” Int. J. Fatigue 102, 9–17 (2017).

M. Ozerov, M. Klimova, A. Kolesnikov, N. Stepanov, and S. Zherebtsov, “Deformation behavior and microstructure evolution of a Ti/TiB metal-matrix composite during high-temperature compression tests,” Mater. Design. 112, 17–26 (2016).

W. Zhang, H. Chen, and R. Prentki, “Numerical analysis of the mechanical behavior of ZTAp/Fe composites,” Comput. Mater. Sci. 137, 153–161 (2017).

D. Dumont, F. Lebon, and A. O. Khaoua, “A numerical tool for periodic heterogeneous media: application to interface in Al/SiC composites,” J. Appl. Mech. 67 (1), 214–217 (1999).

C. A. Lurie, A. A. Kasimovsky, Yu. O. Solyaev, and D. D. Ivanova, “Modeling of a high-temperature structural material based on SiC ceramics reinforced with carbon nanotubes,” Vestn. Perm. Nats. Issled. Politekh. Univ., Mekhanika, No. 4, 142–159 (2011).

Fugong Qi, Haimin Ding, Xianlong Wang, Qing Liu, Biqiang Du, and Xinchun Zhang, “The stress and strain field distribution around the reinforced particles in Al/TiC composites a finite element modeling study,” Comput. Mater. Sci. 137, 297– 305 (2017).

J. Zhang, Q. Ouyang, Q. Guo, Z. Li, G. Fan,Y. Su, L. Jiang, E. Lavernia, J. Schoenung, and D. Zhang, “3D microstructure-based finite element modeling of deformation and fracture of SiCp/Al composites,” Comp. Sci. Technol. 123, 1–9 (2016).

R. Hill, “Elastic properties of reinforced solids: some theoretical principles,” J. Mech. Phys. Solids, 357–372 (1963).

I. M. Gitman, H. Askes, and L. J. Sluys, “Representative volume: existence and size determination,” Eng. Fract. Mech. 74, 2518–2534 (2007).

D. V. Griffiths, J. Paiboon, J. Huang, and G. A. Fenton, “Homogenization of geomaterials containing voids by random fields and finite elements,” Int. J. Solid Structur., 2006–2014 (2012).

L. Bouhala, Y. Koutsawa, A. Makradi, and S. Belouettar, “An advanced numerical method for predicting effective elastic properties of heterogeneous composite materials,” Comp. Structur. 117, 114–123 (2014).

A. Ramazani, K. Mukherjee, H. Quade, U. Prahl, and W. Bleck, “Correlation between 2D and 3D flow curve modeling of DP steels using a microstructure- based RVE approach,” Mater. Sci. Eng. A 560, 129–139 (2013).

S. V. Smirnov, A. V. Konovalov, M. V. Myasnikova, Yu. V. Khalevitskii, A. S. Smirnov, and A. S. Igumnov, “Numerical study of the localization of plastic deformation and fracture of an Al/SiC metal matrix composite,” Fiz. Mezomekh. 20 (2), 61–70 (2017).

A. S. Smirnov, G. A. Belozerov, E. O. Smirnova, A. V. Konovalov, V. P. Shveikin, and O. Y. Muizemnek, “Specimen preparation for metal matrix composites with a high volume fraction of reinforcing particles for EBSD analysis,” J. Mater. Eng. Perform. 25 (7), 2907–2913 (2016).

N. B. Pugacheva, N. S. Michurov, E. I. Senaeva, and T. M. Bykova, “Structure and thermophysical properties of aluminum matrix composites,” Fiz. Met. Metalloved. 117 (11), 1188–1195 (2016).

S. Smirnov, D. Vichuzhanin, A. Nesterenko, A. Smirnov, N. Pugacheva, and A. Konovalov, " A fracture locus for a 50 volume-percent Al/SiC metal matrix composite at high temperature," Int. J. Mater. Form. 10 (5), 831–843 (2017).

M. Dhanashekar and V. S. S. Kumar, “Squeeze casting of aluminium metal matrix composites—an overview,” Proced Eng. 97, 412–420 (2014).

Y. Wang, S. Zang, L. Sun, and J. Ma, “Constructing micro-mechanical representative volume element of medium Mn steel from EBSD data,” Mater. Design. 129, 34–43 (2017).

E. M. Morozov, V. A. Levin, and A. V. Vershinin, Strength Analysis: Fidesis in the Hands of an Engineer (LENAND, Moscow, 2015).

V. T. Kochetov, M. V. Kochetov, and A. D. Pavlenko, Resistance of Materials: Tutorial (Izd. BKhV-Peterburg, St. Petersburg, 2004).

P. I. Polukhin, G. Ya. Gun, and A. M. Galkin, Strain Resistance of Metals and Alloys: A Handbook (Metallurgiya, Moscow, 1983).

G. G. Gnesin, Silicon Carbide Materials (Metallurgiya, Moscow, 1977).

T. A. Zubkova, I. L. Yakovleva, L. E. Karkina, and I. A. Veretennikova, “Nanoindentation study of the hardness and the elastic modulus of cementite in the structure of granular pearlite,” Metalloved. Term. Obrab. Met., No. 6, 49–53 (2014).

D. A. Konovalov, “Development of a technique for reconstructing the stress–strain curve of metallic materials from the diagrams of indentation of conical indenters,” Extended Abstract of Cand. (Eng.) Sci. Dissertation, Yekaterinburg, 2007.

D. Konovalov and I. Veretennikova, “Studying the mechanical properties of a bimetallic composite, produced by explosion welding, under incremental plastic deformation,” Lett. Mater. 8 (2), 215–219 (2018).

ACKNOWLEDGMENTS

The experiments were carried on the equipment of the Plastometry Testing Center for Collective Use at the Institute of Engineering Science of the Ural Branch, Russian Academy of Sciences (Yekaterinburg).

Funding

This work was supported by the Institute of Engineering Science of the Ural Branch, Russian Academy of Sciences, project no. AAAA-A18-118020790145-0.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Konovalov, D.A., Veretennikova, I.A., Bykova, T.M. et al. Development of an Approach to Determining the Representative Volume Element of the Al/SiC Metal Matrix Composite Material Fabricated by Squeeze Casting. Russ. Metall. 2020, 738–745 (2020). https://doi.org/10.1134/S0036029520070101

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029520070101