Abstract

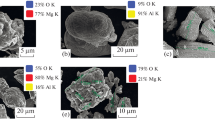

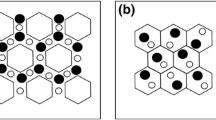

The paper deals with a procedure of preparing a specimen surface for the EBSD analysis of a metal matrix composite (MMC) with a high volume fraction of reinforcing particles. Unlike standard procedures of preparing a specimen surface for the EBSD analysis, the proposed procedure is iterative with consecutive application of mechanical and electrochemical polishing. This procedure significantly improves the results of an indexed MMC matrix in comparison with the standard procedure of specimen preparation. The procedure was verified on a MMC with pure aluminum (99.8% Al) as the matrix, SiC particles being used as reinforcing elements. The average size of the SiC particles is 14 μm, and their volume fraction amounts to 50% of the total volume of the composite. It has been experimentally found that, for making the EBSD analysis of a material matrix near reinforcing particles, the difference in height between the particles and the matrix should not exceed 2 µm.

Similar content being viewed by others

References

A. J. Schwartz, M. Kumar, B. L. Adams, and D. P. Field (eds) Electron Backscatter Diffraction in Materials Science, Second Edition, Springer, 2009, p 1–403

W. Zhou and Z. Wang (eds) Scanning Microscopy for Nanotechnology. Techniques and Applications, Springer, 2007, p 1–552

D.J. Dingley and V. Randle, Microtexture Determination by Electron Back-Scatter Diffraction, J. Mater. Sci., 1992, 27(17), p 4545–4566

X. Wang, Y. Xing, H. Huang, Y. Li, Z. Jia, and Q. Liu, Growth Directions of Precipitates in the Al-Si-Mg-Hf Alloy Using Combined EBSD and FIB 3D-Reconstruction Techniques, Microsc. Microanal., 2015, 21(3), p 588–593

S. Dziaszyk, E.J. Payton, F. Friedel, V. Marx, and G. Eggeler, On the Characterization of Recrystallized Fraction Using Electron Backscatter Diffraction: A Direct Comparison to Local Hardness in an IF Steel Using Nanoindentation, Mater. Sci. Eng. A, 2010, 527(29–30), p 7854–7864

A.S. Smirnov, A.V. Konovalov, and OYu Muizemnek, Modelling and Simulation of Strain Resistance of Alloys Taking into Account Barrier Effects, Diagn. Resour. Mech. Mater. Struct., 2015, 1, p 61–72

R. Basu, L. Jain, B. Maji, and M. Krishnan, Dynamic Recrystallization in a Ni-Ti-Fe Shape Memory Alloy: Effects on Austenite–Martensite Phase Transformation, J. Alloy. Compd., 2015, 639, p 94–101

T. Zienert and O. Fabrichnaya, Phase Relations in the A356 Alloy: Experimental Study and Thermodynamic Calculations, Adv. Eng. Mater., 2013, 15(12), p 1244–1250

H. Jafarian, J. Habibi-Livar, and S.H. Razavi, Microstructure Evolution and Mechanical Properties in Ultrafine Grained Al/TiC Composite Fabricated by Accumulative Roll Bonding, Compos. B Eng., 2015, 77, p 84–92

X. Jiang, M. Galano, and F. Audebert, Extrusion Textures in Al, 6061 Alloy and 6061/SiCp Nanocomposites, Mater. Charact., 2014, 88, p 111–118

S. Sankaranarayanan, R.K. Sabat, S. Jayalakshmi, S. Suwas, and M. Gupta, Effect of Hybridizing Micron-Sized Ti with Nano-sized SiC on the Microstructural Evolution and Mechanical Response of Mg-5.6Ti Composite, J. Alloy. Compd., 2013, 575, p 207–217

M.M. Wang, W.J. Lu, D. Zhang, J.N. Qin, T. Fan, B. Ji, F. Zhu, and S. Ji, An EBSD and TEM Study on the Microstructural Evolution of In Situ Synthesized (TiB + TiC)/Ti Matrix Composites During Superplastic Deformation, Mater. Trans., 2005, 46(8), p 1833–1838

M. Herrmann, R. Neher, K. Brandt, and S. Hoehn, Micro-segregations in Liquid Phase Sintered Silicon Carbide Ceramics, J. Eur. Ceram. Soc., 2010, 30(6), p 1495–1501

S. Simões, F. Viana, M.A.L. Reis, and M.F. Vieira, Influence of Dispersion/Mixture Time on Mechanical Properties of Al–CNTs Nanocomposites, Compos. Struct., 2015, 126, p 114–122

V. Ocelík, J.A. Vreeling, and J.T.M. De Hosson, EBSP Study of Reaction Zone in SiC/Al Metal Matrix Composite Prepared by Laser Melt Injection, Journal of Materials Science, 2001, 36(20), p 4845–4849

M. Alizadeh, M.H. Paydar, D. Terada, and N. Tsuji, Effect of SiC Particles on the Microstructure Evolution and Mechanical Properties of Aluminum During ARB Process, Mater. Sci. Eng., A, 2012, 540, p 13–23

R. Bauri, V. Pancholi, I. Samajdar, and M.K. Surappa, Relating Microtexture and Dynamic Micro Hardness in an Extruded AA8090 alloy and AA8090-8 vol% SiCp Composite, Sci. Technol. Adv. Mater., 2005, 6(8), p 933–938

C.S. Ramesh, R. Keshavamurthy, P.G. Koppad, and K.T. Kashyap, Role of Particle Stimulated Nucleation in Recrystallization of Hot Extruded Al 6061/SiCp Composites, Trans. Nonferr. Metals Soc. China, 2013, 23(1), p 53–58

R. Kirchhofer, J.D. Hunn, P.A. Demkowicz, J.I. Cole, and B.P. Gorman, Microstructure of TRISO Coated Particles from the AGR-1 Experiment: SiC Grain Size and Grain Boundary Character, J. Nucl. Mater., 2013, 432(1–3), p 127–134

J. Guo, S. Amira, P. Gougeon, and X.G. Chen, Effect of the Surface Preparation Techniques on the EBSD Analysis of a Friction Stir Welded AA1100-B4C Metal Matrix Composite, Mater. Charact., 2011, 62(9), p 865–877

E. Mariani and E. Ghassemieh, Microstructure Evolution of 6061 O Al Alloy During Ultrasonic Consolidation: An Insight from Electron Backscatter Diffraction, Acta Mater., 2010, 58(7), p 2492–2503

T. Ma, H. Yamaura, D.A. Koss, and R.C. Voigt, Dry Sliding Wear Behavior of Cast SiC-Reinforced Al MMCs, Mater. Sci. Eng. A, 2003, 360(1–2), p 116–125

S.S. Kumar, V.S. Bai, and T. Rajasekharan, Aluminium Matrix Composites by Pressureless Infiltration: The Metallurgical and Physical Properties, J. Phys. D Appl. Phys., 2008, doi:10.1088/0022-3727/41/16/169801

S. Ren, X. He, X. Qu, and Y. Li, Effect of Controlled Interfacial Reaction on the Microstructure and Properties of the SiCp/Al Composites Prepared by Pressureless Infiltration, J. Alloy. Compd., 2008, 455(1–2), p 424–431

M. Zhao, G. Wu, and L. Jiang, Aging Behavior and Precipitation Kinetics of SiCp/6061Al Composites, Journal of Materials Science, 2004, 39(5), p 1759–1763

C. Kawai, Effect of Interfacial Reaction on the Thermal Conductivity of Al-SiC Composites with SiC Dispersions, J. Am. Ceram. Soc., 2001, 84(4), p 896–898

Acknowledgments

The work was partially financially supported by the Russian Science Foundation (Project No. 14-19-01358) in the part of developing the specimen preparation procedure for EBSD analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Smirnov, A.S., Belozerov, G.A., Smirnova, E.O. et al. Specimen Preparation for Metal Matrix Composites with a High Volume Fraction of Reinforcing Particles for EBSD Analysis. J. of Materi Eng and Perform 25, 2907–2913 (2016). https://doi.org/10.1007/s11665-016-2164-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2164-7