Abstract

Differential scanning calorimetry belongs to a group of rather unique study methods, which makes it possible to investigate in situ the regularities of structural and phase transitions in metallic alloys within a broad range of temperatures (from –100 to 1600°C) at a sufficiently high precision of registering the heat effects of phase transitions. Our paper reviews the results of DSC studies for the alloys based on metals with polymorphism, the thermoelastic martensitic transitions, the decomposition and formation of solid solutions, and the crystallization of amorphous metallic metal-metal alloys. This review puts particular emphasis on considering phase transitions in hydrogen-containing alloys, both crystalline and amorphous.

Similar content being viewed by others

REFERENCES

K. Yu. Shakhnazarov, “Chernov’s iron–carbon diagram, the structure and properties of steel,” Met. Sci. Heat Treat. 51, 3–6 (2009).

M. L. Bernshtein, G. V. Kurdyumov, V. S. Mes’kin, A. A. Popov, V. D. Sadovskii, Yu. A. Skakov, V. M. Schastlivtsev, Yu. N. Taran, L. M. Utevskii, R. I. Entin, “Iron–Carbon / Metallurgy and Heat Treatment of Steel and Cast Iron, Ed. by A. G. Rakhshtadt, L. M. Kaputkina, S. D. Prkoshkin, and A.V. Supov (Intermet Inzhiniring, Moscow, 2005), Vol. 2, p. 526 [in Russian].

V. M. Schastlivtsev, D. A. Mirzaev, and I. L. Yakovleva, Perlite in Carbon Steels (UrO RAN, Yekaterinburg, 2006) [in Russian].

A. S. Pandit and H. K. D. H. Bhadeshia, “Divorced pearlite in steels,” Proc. R. Society A 468, No. 2145, 2767–2778 (2012).

V. G. Vaks and K. Yu. Khromov, “On the theory of austenite-cementite phase equilibria in steels,” J. Exp. Theor. Phys. 106, No. 2, 265–279 (2008).

V. I. Zel’dovich, “Three mechanisms of formation of austenite and inheritance of structure in iron alloys,” Met. Sci. Heat Treat. 50, No. 9–10, 442–448 (2008).

X. Zhang, T. Hickel, J. Rogal, S. Fahler, R. Drautz, and J. Neugebauer, “Structural transformations among austenite, ferrite and cementite in Fe–C alloys: A unified theory based on ab initio simulations,” Acta Mater. 99, 281–289 (2015).

I. K. Razumov, Yu. N. Gornostyrev, and M. I. Katsnel’son, “Towards the ab initio based theory of phase transformations in iron and steel,” Phys. Met. Metallogr. 118, No. 4, 362–388 (2017).

V. S. Biron and I. V. Blokhin, “ Some features of phase transformations in the iron-carbon system,” J. Siberian Federal Univ. Eng. Technol. 3, No. 2, 238–249 (2009).

S. A. Oglezneva, M. N. Kachenyuk, N. Portalov, and L. V. Spivak, “Effect of the dispersion of iron and nickel powders on the phase transformation temperatures and the sintering kinetics,” Russ. Metall., No. 3, 250−255 (2015).

L. V. Spivak and N. E. Shchepina, “Calorimetry of the phase transformations in carbon steels in the intercritical temperature range,” Russ. Metall. 2020, 583–588 (2020).

P. J. Van Ekeren, Handbook of Thermal Analysis and Calorimetry Vol. 1: Principles and Practice, Ed. by M. E. Brown (Elsevier, Amsterdam, 1998), pp. 75–114.

V. A. Aleshkevich, Molecular Physics (Fizmatlit, Moscow, 2016) [in Russian].

S. M. Sarge, G. W. H. Höhne, and W. F. Hemminger, Calorimetry. Fundamentals Instrumentation and Applications (Wiley, Weinheim, 2014), p. 304.

H. E. Kisinger, “Reaction kinetics in differential thermal analysis,” Anal. Chem. 29, 1702–1706 (1957).

Physical Metal Science, Ed. by R. U. Red Kan and P. T. Khaazen (Metallurgiya, Moscow, 1987), Vol. 2, p. 624 [in Russian].

Ya. S. Umanskii and Yu. A. Skakov, Metal Physics (Atomizdat, Moscow, 1978).

S. S. D’yachenko, Formation of Austenite in Iron–Carbon alloys (Metallurgiya, Moscow, 1982) [in Russian].

D. O. Panov and A. I. Smirnov, “Features of austenite formation in low-carbon steel upon heating in the intercritical temperature range,” Phys. Met. Metallogr. 118, No. 11, 1081–1090 (2017).

D. O. Panov, Yu. N. Simonov, L. V. Spivak, and A. I. Smirnov, “Stages of austenitization of cold-worked low-carbon steel in intercritical temperature range,” Phys. Met. Metallogr. 116, No. 8, 802–809 (2015).

M. A. Dyshlyuk, “Influence of nitrogen on calorimetric effects in 38Kh2MYuA steel,” Abstracts of the Report. XV Ural School of Thermal Metals Science Specialists (Izd-vo Ural’skogo un-ta, Yekaterinburg, 2020), pp. 108–110.

L. M. Kleiner, L. V. Spivak, A. A. Shatsov, and K. A. Kobelev, “ Regularities of austenitization of low-carbon martensitic steels in the intercritical temperature range,” Vestnik Perm. Un–Ta. Ser.: Fizika, No. 1, 93–97 (2011).

S. Raju, J. B. Ganesh, A. K. Rai, R. Mythili, S. Saroja, and B. Raj, “A study on martensitic phase transformation in 9Cr–1W–0.23V–0.063Ta–0.56Mn–0.09C–0.02N (wt %) reduced activation steel using differential scanning calorimetry,” J. Nucl. Mater. 405, No. 1, 59–69 (2010).

M. D. Perkas and V. M. Kardonskii, High Strength Martensitic Steels (Metallurgiya, Moscow, 1970) [in Russian].

G. V. Kurdjumov, L. M. Utevskii, and R. I. Entin, Transformations in Iron and Steel (Nauka, Moscow, 1977) [in Russian].

L. M. Kleiner, L. V. Spivak, A. A. Shatsov, and M. G. Zakirova, “Multiplet behavior of the processes of austenitization and decomposition of austenite in low-carbon martensitic steels,” Vestnik Perm. Un–Ta. Ser.: Fizika, No. 1, 111–114 (2010).

L. V. Spivak, “Phase transformations during heating of steels of the martensitic class,” Vestnik Perm. Un-ta. Ser.: Fizika, No. 1, 62–64 (2013).

N. D. Zemtsova, M. A. Eremina, and V. A. Zavalishin, “Calorimetric effects during the α → γ transformation in Fe–Ni–Ti metastable alloys,” Phys. Met. Metallogr. 113, No. 5, 466–479 (2012).

N. D. Zemtsova, “Anomalies in the physical properties of metastable Fe–Ni alloys heated to the temperature interval of the α → γ transformation,” Tech. Phys. 59, 1050–1157 (2014).

L. V. Spivak and N. E. Shchepina, “Thermal decomposition of titanium hydride,” Al’ternativnaya Energetika i Ekologiya, No. 21, 84–89 (2015).

S. Primig and H. Leitner, “Separation of overlapping retained austenite decomposition and cementite precipitation reactions during tempering of martensitic steel by means of thermal analysis,” Thermochim. Acta. 526, 111–117 (2011).

J. B. Ganesh, S. Raju, A. K. Rai, E. Mohandas, M. Vijayalakshmi, K. B. S. Rao, and B. Raj, “Differential scanning calorimetry study of diffusional and martensitic phase transformations in some 9 wt % Cr low carbon ferritic steels,” Mater. Sci. Technol. 27, No. 2, 500–512 (2011).

V. M. Farber, V. A. Khotinov, O. V. Selivanova, O. N. Polukhina, A. S. Yurovskikh, D. O. Panov, “Kinetics of formation of austenite and effect of heating in the intercritical temperature range on the structure of steel 08G2B,” Met. Sci. Heat Treat. 58, 650–655 (2017).

A. Bojack, L. Zhao, P. F. Morris, and J. Sietsma, “In-situ determination of austenite and martensite formation in 13Cr6Ni2Mo supermartensitic stainless steel,” Mater. Charact. 71, 77–86 (2012).

V. M. Chernov, M. V. Leont’eva-Smirnova, M. M. Potapenko, N. A. Polekhina, I. Yu. Litovchenko, A. N. Tyumentsev, E. G. Astafurova, and L. P. Khromova, “Structure–phase transformations and physical properties of ferritic–martensitic 12% chromium steels EK-181 and CHS-139,” Tech. Phys. 16, No. 1, 97–102 (2016).

K. N. Vdovin, K. G. Pivovarova, and M. A. Lisovskaya, “Application of thermal analysis to study the structure and properties of roll steels,” MiTOM, No. 5, 22–25 (2014).

D. V. Gadeev and A. G. Illarionov, “Determination of beta-transus temperature of two-phase titanium alloys using differential scanning calorimetry,” Solid State Phenom. 284, 259–264 (2018).

M. Behera, S. Raju, B. Jeyaganesh, R. Mythili, S. Saroja, “A Study on thermal properties and α (hcp) → β (bcc) phase transformation energetics in Ti–5 wt % Ta–1.8 wt % Nb alloy using inverse drop calorimetry,” Int. J. Thermophys. 31, No. 11, 2246–2263 (2010).

A. J. Prabha, S. Raju, B. Jeyaganesh, A. K. Rai, M. Behera, M. Vijayalakshmi, G. Paneerselvam, and I. Johnson, “Thermodynamics of α'' → β phase transformation and heat capacity measurements in Ti–15 at % Nb alloy,” Phys. B 406, No. 22, 4200–4209 (2011).

M. Behera, S. Raju, R. Mythili, and S. Saroja, “Study of kinetics of α → β phase transformation in Ti–4.4 wt % Ta–1.9 wt % Nb alloy using differential scanning calorimetry,” Int. J. Thermophys. 124, No. 3, 1217–1228 (2016).

V. V. Filippov, D. A. Yagodin, A. A. Kyltseva, S. K. Estimirovf, and K. J. Shunyaev, “The study of eutectoid decomposition kinetics of Cu50Zr50 alloy,” J. Therm. Anal. Calorim. 127, 773–778 (2017).

G. F. Brazolin, C. C. S. Silva, L. S. Silva, and R. A. G. Silva, “Phase transformations in an annealed Cu–9Al–10Mn–3Gd alloy,” J. Therm. Anal. Calorim. 134, 1405–1412 (2018). https://doi.org/10.1007/s10973-018-7586-z

J. S. Souza, D. A. Modesto, and R. A. G. Silva, “Thermal behavior of the as-cast Cu–11Al–10Mn alloy with Sn and Gd additions,” J. Therm. Anal. Calorim. 138, 3517–3524 (2019). https://doi.org/10.1007/s10973-019-08277-7

A. K. Rai, S. Raju, B. Jeyaganesh, E. Mohandas, R. Sudha, V. Ganesan, “Effect of heating and cooling rate on the kinetics of allotropic phase changes in uranium: A differential scanning calorimetry study,” J. Nucl. Mater. 383, 215–225 (2009).

L. V. Spivak and N. E. Shchepina, “Features of the polymorphic transformations in iron and zirconium,” Zh. Tech. Fiz. 90, No. 7, 1145–1150 (2020).

A. G. Illarionov, S. L. Demakov, S. I. Stepanov, and S. M. Illarionova, “Structural and phase transformations in a quenched two-phase titanium alloy upon cold deformation and subsequent annealing,” Phys. Met. Metallogr. 116, No. 3, 267–273 (2015). https://doi.org/10.7868/S0015323015030067

Yu. G. Krasnoperova, L. M. Voronova, M. V. Degtyarev, T. I. Chashchukhina, and N. N. Resnina, “Recrystallization of nickel upon heating below the temperature of thermoactivated nucleation,” Phys. Met. Metallogr. 116, No. 1, 79–86 (2015).

Yu. G. Krasnoperova, M. V. Degtyarev, L. M. Voronova, and T. I. Chashchukhina, “Effect of annealing temperature on the recrystallization of nickel with different ultradisperse structures,” Phys. Met. Metallogr. 117, No. 3, 267–274 (2016).

U. Sari and T. Kırındı, “Effect of deformation on microstructure and mechanical properties of a Cu–Al–Ni shape memory alloy,” Mater. Charact. 59, No. 7, 920–929 (2008). https://doi.org/10.1016/j.matchar.2007.07.017

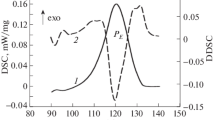

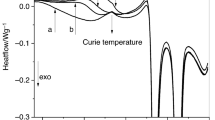

S. H. Chang and S. K. Wu, “Effect of cooling rate on transformation temperature measurements of Ti50Ni50 alloy by differential scanning calorimetry and dynamic mechanical analysis,” Mater. Charact. 59, 987–990 (2008).

H. J. Yu, X. T. Zu, H. Fu, X. Y. Zhang, and Z. G. Wang, “Effect of annealing and heating/ cooling rate on the transformation temperatures of NiFeGa alloy,” J. Alloy. Compd. 470, 237–240 (2009).

R. I. Babicheva, Doctoral Dissertation in Mathematics and Physics (Ufa, 2015).

K. Yildiz, M. Kök, and F. Dağdelen, “Cobalt addition effects on martensitic transformation and micristructural properties of high-temperature Cu-Fe shape-memory alloys,” J. Therm. Anal. Calorim. 120, No. 2, 1227–1232 (2015). https://doi.org/10.1007/s10973-015-4395-5

D. Velazquez and R. Romero, “Spinodal decomposition and martensitic transformation in Cu–Al–Mn shape memory alloy,” J. Therm. Anal. Calorim. 130, 2007–2013 (2017).

K. Kus and T. Breczko, “DSC-investigation of the effect of annealing temperature on the phase transformation behavior in Ni–Ti shape memory alloy,” Mater. Phys. Mech. 9, 75–83 (2010).

M. Stipcich and R. Romero, “β-phase thermal degradation in Zr-added Cu–Zn–Al shape memory alloy: a DSC study,” J. Therm. Anal. Calorim. 129, No. 1, 201–207 (2017).

Z. N. Zhou, L. Yang, R. C. Li, and J.-G. Li, “Martensitic transformations and kinetics in Ni–Mn–In–Mg shape memory alloys,” Intermetallics 92, 49–54 (2018).

A. G. Varzaneh, P. Kameli, V. R. Zahedi, F. Karimzadeh, and H. Salamati, “Effect of heat treatment on martensitic transformation of Ni47Mn40Sn13 ferromagnetic shape memory alloy prepared by mechanical alloying,” Met. Mater. Int. 21, 758–764 (2015).

H. X. Zheng, D. Z. Wu, S. C. Xue, J. Frenzel, G. Eggeler, and Q. J. Zhai, “Martensitic transformation in rapidly solidified Heusler Ni49Mn39Sn12 ribbons,” Acta. Mater. 59, 5692–5699 (2011).

Z. Q. Liao, “Martensitic transformation and magnetic properties of Ni-Mn-In Heusler alloys,” Master of Science Dissertation (Nanjing, 2013).

X. P. Fei, “The structure transformation and magnetic properties of Cu doped NiMnln alloys,” Master of Science Dissertation (Nanjing, 2015).

L. V. Spivak and A. V. Shelyakov, “Anomalous thermal effects during crystallization of amorphous alloys of the TiNi–TiCu system with hydrogen,” Pis’ma Zh. Tekh. Fiz. 35, No. 24, 28–34 (2009).

L. V. Spivak, “Decomposition of Pd–H alloys under heating,” Al’ternativnaya Energetika I Ekologiya (ISJAEE), No. 7, 103–110 (2010).

T. Schober and A. Carl, “A differential thermal analysis study of the vanadium-hydrogen systems,” Phys. Status Solidi A 43, 443–449 (1977).

Y. Fukai, The Metal – Hydrogen System. Basic Bulk Properties (Springer, Heidelberg, 1999), p. 955.

L. V. Spivak, “Calorimetric effects during thermal cycling of V–H alloys,” Al’ternativnaya Energetika i Ekologiya (ISJAEE)., No. 10, 18–21 (2012).

L. V. Spivak, “Abnormal heat effects when heating the alloy system V–H,” Al’ternativnaya Energetika i Ekologiya (ISJAEE), No. 10, 22–25 (2012).

M. Koiwa and O. Yoshinari, “Hydride precipitation peak in internal friction of V–H, Nb–H and Ta–H alloys,” Res. Mech. 11, No. 1, 27–45 (1984).

M. Koiwa and O. Yoshinari, “Twist effect of V–H, Nb–H and Ta–H alloys associated with the precipitation of hydrogen,” Acta Metall. 91, No. 12, 2079–2081 (1989).

S. Yang, W. Xu, and X. Fu, “Peak temperature correction in the TPD research,” Chin. J. Catal. 9, No. 1, 92–95 (1988).

K. G. Prashanth, “Influence of mechanical activation on decomposition of titanium hydride,” Mater. Manuf. Process. 25, No. 9, 974–977 (2010).

L. V. Spivak, “Thermokinetic effects during heating and cooling of system alloys Nb–H,” Al’ternativnaya Energetika i Ekologiya (ISJAEE), No. 8, 23–26 (2013).

L. V. Spivak and N. E. Shchepina, “High-temperature calorimetric effects during heating of system alloys Nb–H,” Al’ternativnaya Energetika i Ekologiya (ISJAEE), No. 8, 31–34 (2013).

L. V. Spivak and N. E. Shchepina, “Calorimetric effects on heating metastable alloys of system Nb–H,” Al’ternativnaya Energetika i Ekologiya (ISJAEE), No. 8, 35–38 (2013).

L. V. Spivak, N. E. Shchepina, and M. A. Kulikova, “Low-temperature calorimetric effects during thermal cycling of system alloys Ta–H,” Al’ternativnaya Energetika i Ekologiya (ISJAEE), No. 16, 24–29 (2014).

L. V. Spivak, N. E. Shchepina, and M. A. Kulikova, “High-temperature calorimetric effects during heating of system alloys Ta–H,” Al’ternativnaya Energetika i Ekologiya (ISJAEE), No. 16, 30–34 (2014).

E. V. Kurikhina and V. N. Simonov, “Phase transformations. Exothermic reaction,” Nauka i Obrazovanie. Nauchnoe Izdanie MGTU Im. Baumana, No. 2, 1–6 (2012).

D. Velázquez and R. Romero, “Calorimetric study of spinodal decomposition in β-Cu–Al–Mn,” J. Therm. Anal. Calorim. (2020). https://doi.org/10.1007/s10973-019-09234-0

L. Ren, J. Zhu, L. Nan, and K. Yang, “Differential scanning calorimetry analysis on Cu precipitation in a high Cu austenitic stainless steel,” Mater. Des. 32, 3980–3985 (2011).

M. Long, T. Liu, H. Chen, D. Chen, H. Duan, H. Fan, K. Tan, and W. He, “Using differential scanning calorimetry to characterize the precipitation and dissolution of V(CN) and VC particles,” J. Mater. Res., No. 6, 1–12 (2018).

K. S. Ghosh and N. Gao, “Determination of kinetic parameters from calorimetric study of solid state reactions in 7150 Al–Zn–Mg alloy,” Trans. Nonferrous Met. Soc. China. 21, 1199–1209 (2011).

P. Lang, T. Wojcik, E. Povoden-Karadeniz, A. Falahati, and E. Kozeschnik, “Thermo-kinetic prediction of metastable and stable phase precipitation in Al–Zn–Mg series aluminum alloys during non-isothermal DSC analysis,” J. Alloys Compd. 609, 129–136 (2014).

A. Falahati, W. U. Jun, P. Lang, M. R. Ahmadi, E. Povoden-Karadeniz, and E. Kozeschnik, “Assessment of parameters for precipitation simulation of heat treatable aluminum alloys using differential scanning calorimetry,” Trans. Nonferrous Met. Soc. China. 24, 2157–2167 (2014).

M. Liu, Z. Wu, R. Yang, J. Wei, Y. Yu, P. C. Skaret, and H. J. Roven, “DSC analyses of static and dynamic precipitation of an Al–Mg–Si–Cu aluminum alloy,” Prog. Nat. Sci.: Mater. Int. 25, 153–159 (2015).

S. Colombo, P. Battaini, and G. Airoldi, “Precipitation kinetics in Ag–7.5 wt % Cu alloy studied by isothermal DSC and electricalresistance measurements,” J. Alloys Compd. 437, 107–112 (2007).

D. Hamana, M. Hachouf, L. Boumaza, and Z. E. A. Biskri, “Precipitation kinetics and mechanism in Cu–7 wt. % Ag alloy,” Mater. Sci. Appl. 2, No. 7, 899–910 (2011).

G. Wloch, K. Sokolowski, P. Ostachowski, A. Wicher, and J. Sobota, “Decomposition of supersaturated solid solution during non-isothermal aging and its effect on the physical properties and microstructure of the Ag–Cu7.5 alloy,” J. Mater. Eng. Perform., No. 12, 1–7 (2019).

S. K. Son, M. Takeda, M. Mitome, Y. Bando, and T. Endo, “Precipitation behavior of an Al–Cu alloy during isothermal aging at low temperatures,” Mater. Lett. 59, 629–632 (2005).

H. Fröck, M. Graser, B. Milkereit, M. Reich, M. Lechner, M. Merklein, and O. Kessler, “Precipitation behaviour and mechanical properties during short-term heat treatment for tailor heat treated profiles (THTP) of aluminium alloy 6060,” Mater. Sci. Forum, The 15th International Conference on Aluminium Precipitation (Behaviour and Mechanical Properties). 877, 400–406 (2017).

Fröck H., B. Milkereit, P. Wiechmann, A. Springer, M. Sander, O. Kessler, and M. Reich, “Influence of solution-annealing parameters on the continuous cooling precipitation of aluminum alloy 6082,” Metals 8, No. 265, 1–16 (2018).

R. H. Kemsies, B. Milkereit, S. Wenner, R. Holmestad, and O. Kessler, “In situ DSC investigation into the kinetics and microstructure of dispersoid formation in Al–Mn–Fe–Si(–Mg) alloys,” Mater. Des. 146, No. 15, 96–107 (2018).

J. Osten, B. Milkereit, C. Schick, and O. Kessler, “Dissolution and precipitation behaviour during continuous heating of Al–Mg–Si alloys in a wide range of heating rates,” Materials 8, No. 5, 2830–2848 (2015).

Introduction to Thermal Analysis, Ed. by M. E. Brown (Kliwer, New York, 2001).

L. V. Spivak and N. E. Shchepina, “Calorimetric effects during phase transformations in duralumin,” Fundamental’Nye Problemy Sovremennogo Materialovedeniya 11, No. 3, 376–380 (2014).

L. V. Spivak and N. E. Shchepina, “Differential scanning calorimetry of the processes of dissolution and separation of the intermetallic phase in the α-solid solution of alloy D1,” Fundamental’Nye Problemy Sovremennogo Materialovedeniya 19, No. 2, 170–175 (2019).

V. V. Slezov and V. V. Sagalovich, “Diffusion decomposition of solid solutions,” Usp. Fiz. Nauk 151, 67–104 (1987).

Sudzuki, K., Fudzimora, H., Hasimoto, K., Amorphous Metals (Metallurgiya, Moscow, 1987).

G. E. Abrosimova, “Evolution of structure of amorphous alloys,” Usp. Fiz. Nauk 181, No. 12, 1265–1281 (2011).

L. Collins, N. Grant, and J. Sande, “Crystallizations of amorphous Ni60Nb40,” J. Mater. Sci. 18, 804–814 (1983).

W. Zhang and A. Inoue, “Effects of Ti on the thermal stability and glass-forming ability of Ni–Nb glassy alloy,” Mater. Trans. 43, No. 9, 2342–2345 (2002).

H. Choi-Yim, D. Xu, and W. L. Johnson, “Ni-based bulk metallic glass – alloy system,” J. Appl. Phys. Lett. 82, 1030–1032 (2003).

L. Shadowspeaker and R. Busch, “On the fragility of Nb–Ni based and Zr-based bulk metallic glasses,” J. Appl. Phys. Lett. 85, 2508–2510 (2004).

S. Matsumoto, T. Tokunaga, H. Ohtani, and M. Hasebe, “Thermodynamic analysis of the phase equilibria of the Nb–Ni–Ti system,” Mater. Trans. 46, No. 12, 2920–2930 (2005).

H. Choi-Yim, D. Xu, M. L. Lind, J. F. LoËfflec, and W. L. Johnson, “Structure and mechanical properties of bulk glass-forming Ni–Nb–Sn alloys,” Scr. Mater. 54, 187–190 (2006).

L. V. Spivak, “Calorimetric effects during crystallization of an amorphous alloy Nb60Ni40,” Vestnik Permskogo Universiteta. Seriya: Fizika, No. 3, 60–63 (2015).

S. P. Alisova and P. B. Budberg, Phase Diagrams of Metallic Systems, Ed. by N. V. Ageev, No. 18. (VINITI, 1975), p. 268 [in Russian].

M. G. Vasin and V. I. Lad’yanov, “Structural transitions and non-monotonic relaxation processes in liquid metals,” Phys. Rev. E 68, 051202-1–051202-6 (2003).

V. I. Lad’yanov, A. L. Bel’tyukov, V. V. Maslov, A. I. Shishmarin, M. G. Vasin, V. K. Nosenko, and V. A. Mashira, “Viscosity of glass forming alloys based on Fe–Si–B system,” J. Non-Cryst. Solids 353, 3264–3268 (2007).

M. Scott Shell, P. G. Debenedetti, and A. Z. Panagiotopoulos, “A conform al solution theory for the energy land scapean glass transition of mixtures,” Fluid Phase Equilib. 241, 147–154 (2006).

P. Schloßmacher, N. Boucharat, H. Rösner, G. Wilde, and A. V. Shelyakov, “Crystallization Studies of amorphous melt-spun Ti50Ni25Cu25,” EEICOMAT’02. (2002). Paper Index #O237.

D. V. Louzguine and A. J. Inoue, “Structural basis for supercooled liquid fragility established by synchrotron-radiation method,” Mater. Sci. 35, 4159–4164 (2000).

M. Buchwitz, R. Adlwarth-Dieball, and P. L. Ryder, “Kinetics of the crystallization of amourphous Ti2Ni,” Acta Metall. 41, 1885–1892 (1993).

P. L. Potapov, A. V. Shelyakov, and D. Schryvers, “On the crystal structure of TiNi–Cu martensite,” Scr. Mater. 44, No. 1, 1–7 (2001).

H. Rösner, P. Schlossmacher, A. V. Shelyakov, and A. M. Glezer, “The influence of coherent TiCu plate-like precipitates on the thermoelastic martensitic transformation in melt-spun Ti50Ni25Cu25 shape memory alloys,” Acta Mater. 49, 1541–1548 (2001).

A. M. Glezer, “Amorphous-crystalline microstructures of heat-treated, melt-spun Ti50Ni25Cu25 ribbons,” Acta Mater. 49, 1541–1548 (2001).

V. G. Pushin, N. N. Kuranova, V. V. Makarov, A. V. Pushin, A. V. Korolev, and N. I. Kourov, “Structural and phase transformations in quasi-binary TiNi–TiCu alloys with thermomechanical shape-memory effects,” Phys. Met. Metallogr. 116, No. 12, 1221–1233 (2015).

V. G. Pushin, N. N. Kuranova, A. V. Pushin, A. V. Korolev, and N. I. Kourov, “Effect of copper on the structure–phase transformations and the properties of quasi-binary TiNi–TiCu alloys,” Tech. Phys. 61, 554–562 (2016).

V. G. Pushin, A. V. Pushin, N. N. Kuranova, T. E. Kuntsevich, A. N. Uksusnikov, V. P. Dyakina, and N. I. Kourov, “Thermoelastic martensitic transformations, mechanical properties, and shape-memory effects in rapidly quenched Ni45Ti32Hf18Cu5 alloy in the ultrafine-grained state,” Phys. Met. Metallogr. 117, No. 12, 1261–1269 (2016).

V. G. Pushin, A. V. Pushin, and N. N. Kuranova, “Specific features of the atomic structure of the Ti50Ni25Cu25 alloy amorphized during rapid quenching from a melt,” Phys. Met. Metallogr. 120, No. 2, 164–170 (2019).

V. G. Pushin, N. N. Kuranova, A. V. Pushin, A. N. Uksusnikov, and N. I. Kourov, “Structure and thermoelastic martensitic transformations in ternary Ni–Ti–Hf alloys with a high-temperature shape memory effect,” Tech. Phys. 61, 1009–1014 (2016).

L. V. Spivak and I. V. Lunegov, “On the problem of the existence of crystallization nuclei in amorphous metal alloys,” Vestnik Permskogo Universiteta. Fizika, No. 2, 33–35 (2013).

L. V. Spivak and A. V. Shelyakov, “Activation energy and thermal activation parameters of the crystallization process of rapidly quenched TiNi-based alloys,” Izv. RAN. Fiz. 73, No. 9, 1337–1339 (2008).

L. V. Spivak, D. I. Sidorov, and A. V. Shelyakov, “Differential calorimetry of crystallization processes during heating of rapidly quenched alloys Ti50Ni25Cu25 and Ti39.2Ni24.8Hf10Cu25,” Al’ternativnaya Energetika i Ekologiya (ISJAEE), No. 8, 26–29 (2010).

Ch. Chui, Introduction to Wavelets (Mir, Moscow, 2001).

A. A. Koronovskii and A. E. Khramov, Continuous Wavelet Analysis and its Applications (Fizmatlit, Moscow, 2003) [in Russian]

M. E. Glicksman, Principles of Solidification: An Introduction to Modern Casting and Crystal Growth Concepts (Springer, Berlin, 2011), p. 530.

W. Kurz and D. J. Fisher, Fundamentals of Solidification (Trans Tech Publications, Uetikon-Zuerich, 1998), 4th ed., p, 305.

L. V. Spivak, A. V. Shelyakov, and L. N. Malinina, “Features of the crystallization process of hydrogen-containing amorphous alloys based on the system TiNi–TiCu,” Vestnik Permskogo Un-Ta, No. 1, 102–105 (2010).

L. V. Spivak and A. V. Shelyakov, " Crystallization processes in hydrogen-containing amorphous alloys based on TiNiCuHf systems,“ Vestnik Permskogo Un-ta, Fizika, No. 1, 107–110 (2010).

L. V. Spivak, A. V. Shelyakov, and N. E. Shchepina, “General laws of the effect of hydrogen on the crystallization of amorphous alloys based on the quasi-binary TiNi–TiCu system,” Tech. Phys. 84, No. 2, 52–56 (2014).

E. Stepura, V. Rosenband, and A. Gany, “Investigation of high temperature self-propagating combustion synthesis of titanium hydride,” Third European Combustion Meeting; ECM 2007 (Crete, 2007), pp. 1–6.

B. Metijasevic-Lux, J. Banhart, S. Fiechter, O. Goerke, and N. Wanderka, “Modification of titanium hydride for improved aluminum foam manufacture,” Acta Mater. 54, 1887–1900 (2006).

P. G. Berezhko, A. I. Tarasova, A. A. Kuznetsov, I. V. Anfilov, I. K. Kremzukov, and A. G. Leshchinskaya, “Hydrogenation of titanium and zirconium and thermal decomposition of their hydrides,” Al’ternativnaya Energetika I Ekologiya (ISJAEE), No. 11, 47–56 (2006).

L. V. Spivak, “Calorimetric effects during heating of Pd–H alloys,” Al’Ternativnaya Energetika I Ekologiya (ISJAEE), No. 7, 103–110 (2010).

A. V. Luk’yanov, V. G. Pushin, N. N. Kuranova, A. E. Svirid, A. N. Uksusnikov, Yu. M. Ustyugov, and D. V. Gunderov, “Effect of the thermomechanical treatment on structural and phase transformations in Cu–14Al–3Ni shape memory alloy subjected to high-pressure torsion,” Phys. Met. Metallogr. 119, No. 4, 374–382 (2018).

N. N. Kuranova, A. V. Pushin, V. G. Pushin, and N. I. Kourov, “Structure and thermoelastic martensitic transformations in ternary Ni–Ti–Zr alloys with high-temperature shape memory effects,” Phys. Met. Metallogr. 119, No. 6, 582–588 (2018).

A. E. Svirid, A. V. Luk’yanov, V. G. Pushin, E. S. Belosludtseva, N. N. Kuranova, and A. V. Pushin, “Effect of the temperature of isothermal upsetting on the structure and the properties of the shape memory Cu–14 wt % Al–4 wt % Ni alloy,” Phys. Met. Metallogr. 120, No. 12, 1159–1165 (2019).

V. G. Pushin, N. N. Kuranova, E. B. Marchenkova, and A. V. Pushin, “Deformation-induced atomic disordering and bcc → fcc transformation in Heusler alloy Ni54Mn21Ga25 subjected to megaplastic deformation by high pressure torsion,” Phys. Met. Metallogr. 121, No. 4, 300–336 (2020).

E. B. Marchenkova, V. G. Pushin, V. A. Kazantsev, A. V. Korolev, N. I. Kourov, and A. V. Pushin, “Thermoelastic martensite transformations and the properties of ultrafine-grained Ni54Mn20Fe1Ga25 alloys obtained by melt quenching,” Phys. Met. Metallogr. 119, No. 10, 936–945 (2018).

E. A. Golovkova, A. V. Surkov, and G. F. Syrykh, “Crystallization of amorphous Zr-Be alloys,” Phys. Solid State 57, No. 2, 266–269 (2015).

V. I. Tkach, E. A. Sviridova, S. V. Vasil’ev, and O. V. Kovalenko, “Relation between the structural parameters of metallic glasses at the onset crystallization temperatures and threshold values of the effective diffusion coefficients,” Phys. Met. Metallogr. 118, No. 8, 764–772 (2017).

O. V. Kovalenko, E. A. Sviridova, S. V. Vasil’ev, V. V. Burkhovetskii, and V. I. Tkach, “Effective diffusion coefficients and structure of metal glasses AL90Y10 and AL87NI8LA5 at temperatures of onset of crystallization,” Fiz. Tekh. Vys. Davlenii 27, No. 4, 79–92 (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Glushachenkova

Rights and permissions

About this article

Cite this article

Spivak, L.V., Shchepina, N.E. Calorimetric Effects in the Structural and Phase Transitions of Metals and Alloys. Phys. Metals Metallogr. 121, 968–995 (2020). https://doi.org/10.1134/S0031918X20100117

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X20100117