Abstract

Photocatalysis is a promising technique to reduce hazardous organic pollutants using semiconductors under visible light. However, previous studies have been concerned with the behavior of silver phosphate (Ag3PO4) as n-type semiconductors, and the problem of their instability is still under investigation. Herein, 4,4′-(((oxalylbis(azanediyl)) bis(carbonothioyl)) bis(azanediyl)) dibenzoic acid is synthesized by green method and used to enhance the photocatalytic behavior for Ag3PO4. The incorporated Ag3PO4 core–shell is prepared and characterized via XRD, FT-IR, Raman, TEM and BET. Besides, the thermal stability of the prepared core shell was investigated via TGA and DSC measurements. The optical properties and the energy band gap are determined using photoluminescence and DRS measurements. The photodegradation of methylene blue in the presence of the synthesized Ag3PO4 core–shell under visible light is examined using UV/Vis measurements. The effect of initial dye concentration and contact time are studied. In addition, the kinetic behavior of the selected dye during the photodegradation process shows a pseudo-first order reaction with rate constant of 0.015 min−1 for ZAg. The reusability of the Ag3PO4 core shell is evaluated, and the efficiency changed from 96.76 to 94.02% after three cycles, indicating efficient photocatalytic behavior with excellent stability.

Similar content being viewed by others

Introduction

The leading cause of environmental pollution, which harms both people and aquatic life in the water ecosystem, is the release of highly toxic inorganic and organic pollutants from various industries to the water surface1,2,3. Energy and the environment are two of the biggest problems associated with the growth of humanity, the advancement of industrialization, and the vast usage of fossil fuels4,5. The majority of conventional pollution control methods have issues like high costs and lengthy implementation times. They are challenging to fulfill environmental management demands2,6.

Photocatalysis prevents secondary pollutants, saves energy, and operates efficiently7,8. There are numerous uses for photo-catalysis in the cleanup of the environment9,10,11. Traditional photo-catalysts like ZnO and TiO2 have a lower quantum efficiency and can only absorb UV light12,13. They need to meet the requirements of extensive practical applications. Therefore, it is essential to discover a visible light photo-catalyst that is more effective and reliable.

With plenty of solar light available, semiconductor photocatalysis has been viewed as a potentially promising method for addressing current energy and environmental issues14,15,16. However, the photocatalytic efficiency of the available semiconductor materials are typically weak in the visible light range or has insufficient charge separation ability17,18. In order to solve this problem, much work has been done in recent years to discover and create novel semiconductor catalysts with enhanced photocatalytic capabilities19,20. Ag3PO4 is a brand-new n-type semiconductor that has an indirect bandgap width of 2.45 eV and can absorb both ultraviolet and visible light. Ag3PO4 has lower edge potentials than ZnO, with the conduction band edge potential being 0.4 eV and the valence band edge potential being 2.9 eV, respectively21. The photo-generated holes provide strong oxidizing power due to the exceptionally low valence band potential. Ag3PO4 has remarkable photo-oxidation capabilities because of its band gap and band potential, including the oxidation of organic dyes under visible light and the creation of oxygen22,23.

Hybrid photocatalyst is recommended and concerned by different research24,25. In 2023, Ansari26 Compared the photocatalytic performance of red phosphorus/ZnO nanohybrids by the non-hybrid catalyst. The results showed superior visible-light-driven photocatalytic activity toward the destruction of methyl orange dye, further demonstrating the potential of the ideal reaction parameter to increase visible light photocatalytic activity effectively.

Ag3PO4 has numerous benefits, including excellent efficiency of both photocatalytic behavior and quantum especially when at irradiation wavelength of > 420 nm23,27, its insolubility in water, and a better conduction band.

The primary purpose of Ag3PO4 and other semiconductors is to guide the transmission of the built-in electric field-driving carrier, which allows the separation of electron/hole (e/h)28. This lessens Ag3PO4 corrosion and enhances photocatalytic activity29,30,31. Ag3PO4's e- on the conduction band are either transported to other semiconductors or are abundant in free radical linking reactions (for example, the reduction of oxygen) that decrease the silver ion liberation from the Ag3PO4 lattice. Because Silver ions are vulnerable to photo-corrosion to create Ag, Ag3PO4 improvement is recommended for use as a photocatalyst. In order to increase Ag3PO4's photocatalytic activity, researchers have conducted in-depth studies on the modification of this compound using various techniques. The use of the organic compounds as an outer coating for the Ag3PO4 supports the electronic activity and delays their combination. In addition, heterorganic compound possesses additional properties such as corrosion resistance by donating their electron32,33,34.

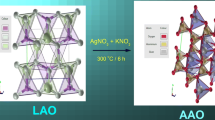

In this work, the composite structure, the core–shell structure, is used to improve the photocatalytic activity of Ag3PO4. The green synthesis method is used to prepare 4,4′-(((oxalylbis(azanediyl))bis(carbonothioyl))bis(azanediyl))dibenzoic acid abbreviated as Z. The prepared Z is characterized via FT-IR, then it used to prepare the incorporated Ag3PO4 core–shell as an enhanced photocatalytic material abbreviated as ZAg. The synthesized photocatalyst is characterized using FT-IR, XRD, Raman, BET and TEM techniques and its band gap is calculated from DRS measurements. The thermal stability is determined using TGA and DSC measurements. The efficiency of ZAg as photocatalytic material on Methylene blue (MB) was investigated under the irradiation of visible light using UV/Vis measurements. The stability and the reusability of the synthesized Zag were also examined.

Experimental sections

Chemicals and materials

Silver nitrate, Ammonium dihydrogen phosphate, Oxalyl chloride, and antharanilic acid, were obtained from the American company Sigma-Aldrich in Egypt, NaOH powder was obtained. Methylene blue dye obtain from Merck. Freshly deionized water was used to prepare the dye solutions for all products.

Synthesis of 4,4'-(((oxalylbis(azanediyl))bis(carbonothioyl))bis(azanediyl)) dibenzoic acid

Stirring oxlayal chloride (1.27 gm, 100 mmoles) with ammonium thisyanate (1.52 gm, 200 mmoles) in 50 ml dry acetone for 10 min, then filter the product to remove ammonium chloride after that we add antharnilic acid ((2.74 gm, 200 mol) with stirring for 20 min, furthermore, we evaporate the acetone to abstain the product, then we crystalize it from ethanol to obtain yellow crystal. Scheme 1 show the preparation of 4,4′-(((oxalylbis(azanediyl))bis(carbonothioyl))bis(azanediyl)) dibenzoic acid.

Synthesis of Ag3PO4 nanoparticles

Green synthesis methods are used for the preparation without the addition of any solvents35,36,37. The co-precipitation was applied to synthesize the Ag3PO4 nanoparticles, and the procedure was as follows: a suitable quantity of AgNO3 salt was completely dissolved in 50 ml of deionized water while continuously stirring. Also, an equivalent volume of crystalline NH4H2PO4 was dissolved in 50 ml of deionized water with constant magnetic stirring. The second solution, comprising NH4H2PO4, was then gradually added to the first solution, containing AgNO3, while being continuously stirred until forming a yellow precipitate. The precipitate was then crushed and calcined at 400 °C for one hour to produce the Ag3PO4 nanocrystalline sample, which was then ready for usage.

Synthesis of core–shell

A calculated amount of the Z as shell was combined with the silver phosphate core, followed by a 10-min period of rigorous grinding to produce a homogeneous coating of the Z over the Ag3PO4 core. To produce prepared core–shell nanoparticles, the resultant mixture was heated at a 3°/min for 1 h in a muffle furnace at 400 °C. Scheme 2 declares the structure of the synthesized compound.

Characterization techniques

Using the Philips X'Pert X-ray diffraction (XRD) system with Cu–Ka radiation (= 1.54056 Å), the crystallographic pattern of the produced nanocomposite was examined. A typical 2 scan had a scan speed of 4o/min and ranged from 10° to 80°. The functional groups were identified using Nicolet iS10 FT-IR spectroscopy, which uses Fourier-transform infrared spectroscopy. A JEOL-JEM 3200 electron microscope operating at 300 kV was used to capture TEM pictures. To examine the optical characteristics of the produced materials, a Shimadzu IRS-2200 diffuse reflection (DRS) system in combination with an ultraviolet–visible spectrometer (Jasco V-507) was utilized. A Perkin Elmer fluorometer (model LS-55) was used to analyze solid-state photoluminescence (PL) at ambient temperature.

Photocatalytic activity study

500 Watt halogen lamp used as a radiation source to evaluate the photocatalytic activity of ZAg for the degradation of the molecules of MB dye as a model of organic pollutants (as shown in Fig. 1S). In each test, 50 mL of the dye solution with varying initial concentrations of 10, 20, 35 and 50 ppm were taken in a glass beaker, and the effect of the prepared catalyst with 1.0 g/L were added. For 30 min, the mixture was agitated in the dark to achieve adsorption/desorption equilibrium between the catalyst and the MB dye molecule and then continued while being exposed to visible light while being constantly stirred. Then, 3 mL of suspensions were withdrawn regularly from the reactor at predetermined intervals (30, 60, 90, 120,150,180 and 210 min). ZAg was separated using a centrifuge, and the supernatant was measured using UV/Vis measurements at maximum absorption wavelength of 660 nm. Before the addition of ZAg, and after doing a blank experiment, it was discovered that dye degradation was constrained.

Result and discussion

Characterization of the synthesized materials

The crystalinity of ZAg are confirmed with the sharp characteristic peaks illustrated in Fig. 1. Characteristic diffraction peaks are located at different 2θ (degrees) that are assigned to the indexed planes of silver phosphate that match with the previous research and the standard XRD data for Ag3PO4 JCPDS file NO. 00-006-0505 (see Fig. 2S). The peaks at 2θ and their related crystal plane is summarized as: 20.88° [1 1 0], 29.69° [2 0 0], 33.28° [2 1 0], 36.58° [2 1 1], 42.52° [2 2 0], 47.79° [3 1 0], 52.68° [2 2 2], 55.01° [3 2 0], 57.27° [3 2 1], 61.65° [4 0 0], 65.87° [4 1 1], 69.95° [4 2 0], 71.89° [4 2 1] and 73.96° [3 3 1]38,39. The average particle size of ZAg calculated using Debye–Scherrer equation40,41 and found to be 36.55 nm.

Figure 2 shows FT-IR spectra of Z and ZAg core–shell. Concerning the spectra of Z, the absorption band that present at 333.14 cm−1 corresponds to the stretching vibration of NH and OH groups42,43. Symmetric and asymmetric stretching vibration COO groups are located at 1400 cm−1 and 1620 cm−1, respectively44,45. The bands present at 1091.92 cm−1 and 1629.12 cm−1 are due to the stretching vibration of COH and C=O groups46,47. In addition, the absorption peak of S=O is located at 1184.09 cm−1, while that present at 1311.12 cm−1 is related to C–O and C–N groups. The peak found at 3030.64 cm−1 is due to the stretching vibration of the C–H group of the benzene ring48,49. The FT-IR spectra of ZAg show the characteristic peaks related to Z with low intensity confirming their interaction. Moreover, the peaks at 555.66 cm−1 and 1007 cm−1 are assigned to the bending vibration of O=P–O and asymmetric stretching vibration of O–P–O, respectively50,51. Besides, new peak present at 495 cm−1 in ZAg is attributed to the formation of Ag–N bond40. The previous data confirm not only the formation of Z (due to the presence of all the prepared functional groups) but also the formation of ZAg (see Fig. 3).

Raman spectroscopy is applied as a complement analysis to FT-IR is measured for the ZAg and displayed in Fig. 3. The symmetrical vibration of the AgO bending bond is located at 113 cm−152. The peak located at 500 cm−1 are attributed to the symmetrical str. vibration of P–O–P bonds53. In addition, the peak present at 919.13 cm−1 is due to the vibration of the terminal oxygen of the phosphate group51,54. The aromatic ring and C=S are strong peaks in the range 995–1050 cm−155,56.

The stability of the photocatalysts is an important parameter that determines their efficiencies over higher temperatures57. Figure 4a declares the thermal stability of ZAg using Thermal gravimetric analysis. The decomposition of any impurities and the adsorbed water molecules on the surface of the investigated photocatalytic substances (ZAg) is present in the 100 to 200 °C range. Then, the decomposition of organic material started until it reached complete decomposition around 550 °C. Excellent thermal (> 800 °C) stability of the Ag3PO4 was observed and matched with the literature58.

Besides, the DSC of ZAg is determined and displayed in Fig. 4b. A weight loss of ≈10% accompanies the sharp endo peak near 400 °C (see Fig. 4), confirming the starting decomposition of the organic molecules (Z).

The surface area of the investigated photocatalyst was determined via BET measurements and found to be 0.395 m2/g, indicating moderate surface area. Concerning Fig. 5, The synthesized ZAg shows Type IV isotherm with H3 hysteresis determined from Nitrogen adsorption–desorption isotherm. The previous results suggest that ZAg is a mesoporous material59.

The morphology of the synthesized ZAg was obtained from TEM images (see Fig. 6) Irregular spherical particles of ZAg are distributed indicating the coating of the Ag3PO4 with Synthesis of 4,4′-(((oxalylbis(azanediyl))bis(carbonothioyl))bis(azanediyl)) dibenzoic acid. Besides, the image shows aggregation of the core shell Ag3PO4 that occur due to the intermolecular interaction between the coated Z. the previous data is matched with FT-IR and confirming the formation of heterojunction photocatalyst.

Using UV/Vis—DRS optical spectroscopy in the 200–800 nm region, the diffuse reflection spectra of the Z and ZAg core–shell were examined (see Fig. 7a). It has been found that the ZAg core–shell absorbs visible light at a substantially faster rate than the Z.

The production of electron–hole pairs, light absorption, charge carrier transfer, and charge carrier utilization are a few of the mechanisms that control photocatalytic activity60. The photocatalytic material's energy band gap (Eg), which affects the efficiency of the product and the transfer of the e/h pairs, is crucial for maximizing the photocatalytic activity. The graph relationship of the Kubelka–Munk equation was used to determine the Eg value61,62:

where n: the proportionality constant (n = 1), v: the frequency of light, and α: the absorption coefficient.

The diffuse reflectance spectra and the Z and ZAg band gab are illustrated (see Fig. 8a and b). As shown in Fig. 7b, the optical band gaps were computed using plots of (αhʋ)2 versus photon energy (hʋ). The band gap narrowed due to the conjugation of two bands, increasing the stability of the e/h couples (quantum confinement effect). The ZAg core shell has a band gap of 2.24 eV which is lower value than the value of band gap for pure Ag3PO4 (2.39 eV)63 indicating that the formed core shell silver phosphate (ZAg) move towards the redshift.

Mulliken electrochemical equation are used to determine the energy of valence band (EVB) and the energy of the conduction band (ECB)64:

where, \({E}_{e}\): the energy of free electron (4.5 eV), \({E}_{g}\): the energy of band gap, and \(x\): the electronegativity of Ag3PO4 = 5.96 eV63. The estimated \({E}_{CB}\) and \({E}_{VB}\) of Ag3PO4 are found to be − 0.265 eV and 2.655 eV, respectively.

The PL spectra of pure Z and ZAg at a 370 nm excitation wavelength are shown in Fig. 8. The PL spectra show the rate of charge separation and recombination within the photocatalysts. The rate of charge separation and recombination within the photocatalysts is shown by the PL spectra. As a result of the effective charge transfer at the heterostructure interface, the PL spectrum of pure Z has a prominent emission band at 498 nm. At the same time, the PL intensity of the ZAg core–shell has significantly reduced, indicating that the recombination between photo-electrons generated and holes has decreased. Additionally, pure Z and ZAg as a heterostructure have a synergistic effect of reducing PL intensity, which increases the lifetime of electron stability65,66.

Photocatalytic activity of ZAg Core–shell

Effect of the intial dye concentration

According to Fig. 9, which reveals that the best effectiveness was seen at an MB starting concentration of 50 ppm, the influence of MB initial concentration was examined depending on UV/Vis measurements in the range of 10–50 ppm.

It is clear that the removal efficiency increase significantly with the initial concentration of dye from 1–20 ppm. In the range from 20–40 ppm and 40–50 ppm the MB degradation increase slowly (around 2%) with increasing the initial dye concentration due to the trapping of photon to the solution.

Effect of contact time

Figure 8a depicts the photocatalytic degradation of MB dye under irradiation of visible light in the presence of Z and ZAg core shells with time irradiation of 0, 30, 60, 90, 120, 150, 180, and 210 min. It is evident that the ZAg is more photocatalytically active than Z for the MB degradation (see Fig. 11a). The photocatalyst's MB solution was left in the dark for 30 min before initiating the photocatalytic process to achieve the adsorption–desorption equilibrium (see Fig. 3S). The relation between the dye concentration in the absence and in the presence of ZAg is illustrated in Fig. 4S.

The following relation provided the efficiency of the deterioration of MB under visible light:

where C0 and C: the initial and the remaining concentration of the investigated dye. As shown in Fig. 10a, the efficiency of Z and ZAg as photocatalytic martials was found to be 87.82% and 96.76%, respectively after 210 min.

The next pseudo-first-order equation represents the kinetics of the photocatalytic degradation reaction of MB in accordance with the L–H kinetics model.

where ka: the rate constant (min−1), the concentration in mg L−1 and t: time in min. Concerning Fig. 10b, Ka is the slope of the linear relation between ln (C0/C) and t and found to be 1.240 × 10–4, 0.010, and 0.015 min−1 for MB, Z, and ZAg, respectively. The rate constants are increased in the following order: ZAg > Z > MB (see Fig. 5S), indicating excellent catalytic efficiency of the ZAg core–shell. From all the previous data, ZAg core–shell can work as an effective photocatalyst for organic compound degradation with good stability. The photocatalytic degradation of similar materials listed in Table 1.

The photocatalytic mechanism

Reactive oxidizing species were produced concurrently with the photocatalytic process to accomplish the photocatalytic destruction of organic contaminants. Two different processes produce reactive oxidizing species: first, the adsorbed water is oxidized with the help of the photocreated holes (h+), and second, the photostimulated electrons reduce the oxygen that has been adsorbed on the surface. The excited electrons (e−) in the conduction band will interact with the surface-adsorbed oxygen to produce reactive superoxide anion radicals (−O2·) when the adsorbed OH on the photocatalyst interacts with the reactive holes in the valence band, resulting in the formation of hydroxyl radicals (OH·). The two most well-known and influential oxidizing species are OH· and −O2·65.

In this instance, the two reactive species were involved in the photocatalytic degradation of MB. Organic molecules-derived carbon, sulfur and nitrogen decrease the Ag3PO4 band gap by generating energy levels above the Ag3PO4 valence band (VB) and oxygen vacancies. When visible light excites the electrons in the conduction band (CB) of Ag3PO4 band, these photostimulated electrons move from the (CB) to the lower CB. As a result, the transferred electrons' reduction potential will decrease. The potent reactive oxidizing species (OH· and −O2·) produced by these excited photocarriers will cause the photodegradation of MB and the conversion into H2O and CO2. The photodegradation mechanism is represented in Fig. 11.

The reusability and stability of ZAg after photocatalytic degradation reaction

The effectiveness of the photocatalytic degradation of MB using ZAg for three cycles under visible light illumination was 94.02% (See Fig. 12).

The FT-IR measurements (see Fig. 13) utilized to verify the stability of the synthesized materials after three cycles further show that ZAg has been applied as easily manufactured with low environmental impact and considered efficient and economical photocatalysis for organic pollutants under visible light.

Conclusion

Photodegradation enhancement of organic pollutants in aqueous media under visible light using photocatalysis consider serious challenge. Therefore, Ag3PO4 is prepared and enhanced by incorporating with 4,4′-(((oxalylbis(azanediyl))bis(carbonothioyl))bis(azanediyl)) dibenzoic acid forming ZAg. The performance of ZAg as photocatalytic material on MB under visible light was evaluated using UV–Vis measurements and found to be 96.76%. Excellent stability of the investigated photocatalytic materials up to 800 °C was confirmed via DCS and TGA measurements. The effect of initial concentration of the investigating dye and the contact time was determined. The photodegradation reaction of MD under visible light in the presence of ZAg is pseudo-first order. The data show that ZAg is highly efficient and stable after three cycles.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

El-Shamy, O. A. A., Nassar, I. M. & Ragab, A. A. Facile synthesis of graphene sand composite from asphalt as an effective adsorbent for chromium ions in aqueous media. Polym. Bull. https://doi.org/10.1007/s00289-022-04545-z (2022).

Balapure, K., Bhatt, N. & Madamwar, D. Mineralization of reactive azo dyes present in simulated textile waste water using down flow microaerophilic fixed film bioreactor. Bioresour. Technol. 175, 1–7 (2015).

El-Sharaky, E. A., Mishrif, M. R. & El-Shamy, O. A. A. Synthesis and evaluation of a new trianionic surfactant for the removal of Pb(II) by flotation method. Tenside Surfactants Deterg. 55, 148–152. https://doi.org/10.3139/113.110545 (2018).

Hayat, A. et al. Recent advances, properties, fabrication and opportunities in two-dimensional materials for their potential sustainable applications. Energy Storage Mater. 59, 102780. https://doi.org/10.1016/j.ensm.2023.102780 (2023).

Iqbal, O. et al. A review on the synthesis, properties, and characterizations of graphitic carbon nitride (g-C3N4) for energy conversion and storage applications. Mater. Today Phys. 34, 101080. https://doi.org/10.1016/j.mtphys.2023.101080 (2023).

Martinez-Huitle, C. A. & Ferro, S. Electrochemical oxidation of organic pollutants for the wastewater treatment: Direct and indirect processes. Chem. Soc. Rev. 35, 1324–1340 (2006).

El-Tabey, A. E., Mady, A. H., El-Shamy, O. A. A. & Ragab, A. A. Sustainable approach: Utilizing modified waste Styrofoam as an eco-friendly catalyst for dual treatment of wastewater. Polym. Bull. 78, 951–963 (2021).

Parlett, C. M. A., Wilson, K. & Lee, A. F. Hierarchical porous materials: Catalytic applications. Chem. Soc. Rev. 42, 3876–3893 (2013).

Hayat, A. et al. Recent advances in ground-breaking conjugated microporous polymers-based materials, their synthesis, modification and potential applications. Mater. Today 64, 180–208. https://doi.org/10.1016/j.mattod.2023.02.025 (2023).

Reddy, P. A. K. et al. Recent advances in photocatalytic treatment of pollutants in aqueous media. Environ. Int. 91, 94–103 (2016).

Li, Q., Li, X., Wageh, S., Al-Ghamdi, A. A. & Yu, J. CdS/graphene nanocomposite photocatalysts. Adv. Energy Mater. 5, 1500010 (2015).

Fujishima, A. & Honda, K. Electrochemical photolysis of water at a semiconductor electrode. Nature 238, 37–38 (1972).

Chen, D. et al. Influence of defects on the photocatalytic activity of ZnO. J. Phys. Chem. C. 118, 15300–15307 (2014).

Yao, W., Huang, C., Muradov, N. & Ali, T. A novel Pd–Cr2O3/CdS photocatalyst for solar hydrogen production using a regenerable sacrificial donor. Int. J. Hydrog. Energy 36, 4710–4715 (2011).

Wang, S. et al. A novel and highly efficient photocatalyst based on P25–graphdiyne nanocomposite. Small 8, 265–271 (2012).

Du, J. et al. Hierarchically ordered macro—mesoporous TiO2—graphene composite films: improved mass transfer, reduced charge recombination, and their enhanced photocatalytic activities. ACS Nano 5, 590–596 (2011).

Tian, G., Fu, H., Jing, L., Xin, B. & Pan, K. Preparation and characterization of stable biphase TiO2 photocatalyst with high crystallinity, large surface area, and enhanced photoactivity. J. Phys. Chem. C. 112, 3083–3089 (2008).

Lai, Y., Meng, M., Yu, Y., Wang, X. & Ding, T. Photoluminescence and photocatalysis of the flower-like nano-ZnO photocatalysts prepared by a facile hydrothermal method with or without ultrasonic assistance. Appl. Catal. B Environ. 105, 335–345 (2011).

Ingram, D. B. & Linic, S. Water splitting on composite plasmonic-metal/semiconductor photoelectrodes: Evidence for selective plasmon-induced formation of charge carriers near the semiconductor surface. J. Am. Chem. Soc. 133, 5202–5205 (2011).

Wang, P. et al. Ag@ AgCl: A highly efficient and stable photocatalyst active under visible light. ChemInform https://doi.org/10.1002/chin.200901019 (2009).

Ty, J. T. D. & Yanagi, H. Electrochemical deposition of zinc oxide nanorods for hybrid solar cells. Jpn. J. Appl. Phys. 54, 04DK05 (2015).

Dong, C., Wu, K.-L., Li, M.-R., Liu, L. & Wei, X.-W. Synthesis of Ag3PO4–ZnO nanorod composites with high visible-light photocatalytic activity. Catal. Commun. 46, 32–35 (2014).

Yi, Z. et al. An orthophosphate semiconductor with photooxidation properties under visible-light irradiation. Nat. Mater. 9, 559–564 (2010).

Ansari, S. A. et al. Emerging NiO–rGO nanohybrids for antibiotic pollutant degradation under visible-light irradiation. Surf. Interfaces 40, 103078. https://doi.org/10.1016/j.surfin.2023.103078 (2023).

Hayat, A. et al. Different dimensionalities, morphological advancements and engineering of g-C3N4-based nanomaterials for energy conversion and storage. Chem. Rec. 23, e202200171 (2023).

Ansari, S. A. Elemental semiconductor red phosphorus/ZnO nanohybrids as high performance photocatalysts. Ceram. Int. 49, 17746–17752. https://doi.org/10.1016/j.ceramint.2023.02.140 (2023).

Bi, Y., Ouyang, S., Umezawa, N., Cao, J. & Ye, J. Facet effect of single-crystalline Ag3PO4 sub-microcrystals on photocatalytic properties. J. Am. Chem. Soc. 133, 6490–6492 (2011).

Mu, C., Zhang, Y., Cui, W., Liang, Y. & Zhu, Y. Removal of bisphenol A over a separation free 3D Ag3PO4-graphene hydrogel via an adsorption-photocatalysis synergy. Appl. Catal. B Environ. 212, 41–49 (2017).

Dhanabal, R., Velmathi, S. & Bose, A. C. Fabrication of RuO2-Ag3PO4 heterostructure nanocomposites: Investigations of band alignment on the enhanced visible light photocatalytic activity. J. Hazard. Mater. 344, 865–874 (2018).

Bu, Y. & Chen, Z. Role of polyaniline on the photocatalytic degradation and stability performance of the polyaniline/silver/silver phosphate composite under visible light. ACS Appl. Mater. Interfaces 6, 17589–17598 (2014).

Teng, W., Tan, X., Li, X. & Tang, Y. Novel Ag3PO4/MoO3 pn heterojunction with enhanced photocatalytic activity and stability under visible light irradiation. Appl. Surf. Sci. 409, 250–260 (2017).

El-Shamy, O. A. A. & Deyab, M. A. Novel anticorrosive coatings based on nanocomposites of epoxy, chitosan, and silver. Mater. Lett. 330, 133298. https://doi.org/10.1016/j.matlet.2022.133298 (2023).

Deyab, M. A., El-Shamy, O. A. A., Thabet, H. K. & Ashmawy, A. M. Electrochemical and theoretical investigations of favipiravir drug performance as ecologically benign corrosion inhibitor for aluminum alloy in acid solution. Sci. Rep. 13, 8680. https://doi.org/10.1038/s41598-023-35226-0 (2023).

Deyab, M. A. et al. Novel corrosion inhibitor for carbon steel in acidic solutions based on α-aminophosphonate (Chemical, Electrochemical, and Quantum Studies). Molecules 28, 4962 (2023).

Liu, Y., Yu, H., Chen, Y. & Zhao, Y. Synthesis of bridged and metallobridged bis(β-cyclodextrin)s containing fluorescent oxamidobisbenzoyl linkers and their selective binding towards bile salts. Chem. Eur. J. 12, 3858–3868 (2006).

Abdel-karim, A. M. et al. Green synthesis of novel bis structure of (Carbamothioyl) oxalamide derivatives as corrosion inhibitors for copper in 3.5% NaCl; experimental and theoretical investigation. J. Mol. Struct. 1295, 136597. https://doi.org/10.1016/j.molstruc.2023.136597 (2024).

Elazabawy, O. E., El-Shamy, O. A. A. & El-Sattar, N. E. A. Corrosion inhibitory characteristics, thermodynamics, and theoretical studies of N-((2-aminoethyl) carbamothioyl) acrylamide for carbon steel in 1 M HCl Egypt. J. Pet. 32, 7–14. https://doi.org/10.1016/j.ejpe.2023.07.001 (2023).

Huang, K. et al. One-step synthesis of Ag3PO4/Ag photocatalyst with visible-light photocatalytic activity. Mater. Res. 18, 939–945 (2015).

Septiarini, D. A., Kurniasih, M., Andreas, R., Hermawan, D. & Sulaeman, U. Synthesis of silver orthophosphate under dimethyl sulfoxide solvent and their photocatalytic properties. In IOP Conference Series: Materials Science and Engineering, 12151 (IOP Publishing, 2019).

Suresh, S., Karthikeyan, S., Saravanan, P., Jayamoorthy, K. & Dhanalekshmi, K. I. Comparison of antibacterial and antifungal activity of 5-amino-2-mercapto benzimidazole and functionalized Ag3O4 nanoparticles, Karbala. Int. J. Mod. Sci. 2, 129–137 (2016).

El-Dib, F. I., Mohamed, D. E., El-Shamy, O. A. A. & Mishrif, M. R. Study the adsorption properties of magnetite nanoparticles in the presence of different synthesized surfactants for heavy metal ions removal, Egypt. J. Pet. 29, 1–7 (2020).

El-Shamy, O. A. A. & Deyab, M. A. Eco-friendly biosynthesis of silver nanoparticles and their improvement of anti-corrosion performance in epoxy coatings. J. Mol. Liq. 376, 121488. https://doi.org/10.1016/j.molliq.2023.121488 (2023).

Abdelgawad, M. A. et al. Design, molecular docking, synthesis, anticancer and anti-hyperglycemic assessments of thiazolidine-2,4-diones Bearing Sulfonylthiourea Moieties as Potent VEGFR-2 Inhibitors and PPARγ Agonists. Pharmaceuticals 15, 226 (2022).

El-Shamy, O. A. A. & Al-Ayed, A. S. Investigation of the inhibitive effect of hexatriethanolamine derivatives on corrosion of carbon steel pipelines in 1M HCI. In Advanced Materials Research, 216–221 (Trans Tech Publ, 2013).

El-Mokadem, T. H., Hashem, A. I., Abd El-Sattar, N. E. A., Dawood, E. A. & Abdelshafi, N. S. Green synthesis, electrochemical, DFT studies and MD simulation of novel synthesized thiourea derivatives on carbon steel corrosion inhibition in 1.0 M HCl. J. Mol. Struct. 1274, 134567 (2023).

Ke, J. et al. Facile assembly of Bi2O3/Bi2S3/MoS2 np heterojunction with layered n-Bi2O3 and p-MoS2 for enhanced photocatalytic water oxidation and pollutant degradation. Appl. Catal. B Environ. 200, 47–55 (2017).

El-Shamy, O. A. A. Effectiveness of some nonionic surfactants as corrosion inhibitors for carbon steel in hydrochloric acid solution. In Advanced Materials Research, 211–215 (Trans Tech Publ, 2013).

Abdel-karim, A. M., Shahen, S., Elsisi, D. M., Hyba, A. M. & El-Shamy, O. A. A. Experimental and theoretical studies of corrosion resistance enhancement of carbon steel in 1 M HCl by quinoxalinosulfonamide hybrid-bearing theophylline moiety. J. Bio- Tribo-Corrosion. 8, 70. https://doi.org/10.1007/s40735-022-00666-0 (2022).

Hussien, H. et al. Experimental and theoretical evaluations: Green synthesis of new organic compound bis ethanethioyl oxalamide as corrosion inhibitor for copper in 3.5% NaCl, Egypt. J. Chem. 66, 189–196. https://doi.org/10.21608/ejchem.2023.182301.7364 (2023).

Zhang, F.-J. et al. A novel photofunctional g-C3N4/Ag3PO4 bulk heterojunction for decolorization of Rh.B. Chem. Eng. J. 228, 435–441 (2013).

Zhang, R. et al. Reduced graphene oxide-doped Ag3PO4 nanostructure as a high efficiency photocatalyst under visible light. J. Inorg. Organomet. Polym. Mater. 30, 543–553 (2020).

Liu, L. et al. A stable Ag3PO4@ g-C3N4 hybrid core@ shell composite with enhanced visible light photocatalytic degradation. Appl. Catal. B Environ. 183, 133–141 (2016).

Wan, J. et al. Z-scheme visible-light-driven Ag3PO4 nanoparticle@ MoS2 quantum dot/few-layered MoS2 nanosheet heterostructures with high efficiency and stability for photocatalytic selective oxidation. J. Catal. 345, 281–294 (2017).

Agbe, H., Raza, N., Dodoo-Arhin, D., Chauhan, A. & Kumar, R. V. H2O2 rejuvenation-mediated synthesis of stable mixed-morphology Ag3PO4 photocatalysts. Heliyon 4, e00599 (2018).

Sakamoto, A. & Tasumi, M. Symmetry of the benzene ring and its normal vibrations: The “breathing” mode is not always a normal vibration of a benzene ring. J. Raman Spectrosc. 52, 2282–2291 (2021).

Van Wart, H. E. & Scheraga, H. A. Raman spectra of cystine-related disulfides. Effect of rotational isomerism about carbon-sulfur bonds on sulfur-sulfur stretching frequencies. J. Phys. Chem. 80, 1812–1823 (1976).

Jiang, E. et al. In-situ fabrication of Z-scheme Bi3O4Cl/Bi12O17Cl2 heterostructure by facile pH control strategy to boost removal of various pollutants in water. Chem. Eng. J. 388, 123483 (2020).

Zhang, R. et al. Photocatalytic Poly (vinylidene fluoride) membrane of Ag3PO4/GO/APTES for water treatment. Colloids Surfaces A Physicochem. Eng. Asp. 597, 124779 (2020).

Du, C. et al. Facile synthesis of Z-scheme ZnO/Ag/Ag3PO4 composite photocatalysts with enhanced performance for the degradation of ciprofloxacin. Mater. Chem. Phys. 260, 124136. https://doi.org/10.1016/j.matchemphys.2020.124136 (2021).

Diab, K. R. et al. Facile fabrication of NiTiO3/graphene nanocomposites for photocatalytic hydrogen generation. J. Photochem. Photobiol. A Chem. 365, 86–93 (2018).

Saravanan, R. et al. Mechanothermal synthesis of Ag/TiO2 for photocatalytic methyl orange degradation and hydrogen production. Process Saf. Environ. Prot. 120, 339–347 (2018).

Elshamy, O. A. & El-Fawal, E. M. Synthesis of NiFe2O4@ AC/UiO-66 (Zr) for enhancement of the photocatalytic performance of alizarin yellow R under visible-light. ChemistrySelect 6, 995–1007 (2021).

Xu, Y., Zhang, X., Zhang, Y., Zhu, J. & Zhu, R. Nano flake Ag3PO4 enhanced photocatalytic activity of bisphenol A under visible light irradiation. Colloid Interface Sci. Commun. 37, 100277 (2020).

Xu, Y. & Schoonen, M. A. A. The absolute energy positions of conduction and valence bands of selected semiconducting minerals. Am. Miner. 85, 543–556 (2000).

El-Fawal, E. M. & El-Shamy, O. A. A. Photodegradation enhancement of 2-chlorophenol using ZnO–CdS@CS nanocomposite under visible light. Int. J. Environ. Sci. Technol. https://doi.org/10.1007/s13762-019-02249-y (2019).

Raj, R. B., Umadevi, M., Parimaladevi, R. & Anuratha, M. ZnO/BaO nanocomposites: a promising photocatalyst in degrading anionic and cationic dyes under UV and visible light and an efficient antibacterial agent. J. Sol-Gel Sci. Technol. 102, 628–636 (2022).

Nyankson, E., Efavi, J. K., Agyei-Tuffour, B. & Manu, G. Synthesis of TiO2–Ag3PO4 photocatalyst material with high adsorption capacity and photocatalytic activity: Application in the removal of dyes and pesticides. RSC Adv. 11, 17032–17045 (2021).

Chen, G. et al. Ag3PO4/graphene-oxide composite with remarkably enhanced visible-light-driven photocatalytic activity toward dyes in water. J. Hazard. Mater. 244, 86–93 (2013).

He, P., Song, L., Zhang, S., Wu, X. & Wei, Q. Synthesis of g-C3N4/Ag3PO4 heterojunction with enhanced photocatalytic performance. Mater. Res. Bull. 51, 432–437 (2014).

Fritah, K. et al. New insight for enhanced photocatalytic activity of Bi4-xLaxTi3O12 (0≤ x≤ 1) solid solution: A case study on degradation of Rhodamine B under UV light irradiation. Opt. Mater. (Amst). 150, 115182 (2024).

Cao, J., Luo, B., Lin, H., Xu, B. & Chen, S. Visible light photocatalytic activity enhancement and mechanism of AgBr/Ag3PO4 hybrids for degradation of methyl orange. J. Hazard. Mater. 217, 107–115 (2012).

Zhuang, J. et al. Formation of Ag3PO4/AgBr composites with Z-scheme configuration by an in situ strategy and their superior photocatalytic activity with excellent anti-photocorrosion performance. J. Mater. Sci. Mater. Electron. 30, 11368–11377 (2019).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

All authors are contribute to the written and data declaration.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

El-Shamy, O.A.A., Selim, H., Elkholy, A.S. et al. Preparation of thiourea derivative incorporated Ag3PO4 core shell for enhancement of photocatalytic degradation performance of organic dye under visible radiation light. Sci Rep 14, 12671 (2024). https://doi.org/10.1038/s41598-024-62608-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-62608-9

- Springer Nature Limited