Abstract

Production of value-added compounds from waste materials is of utmost importance for the development of a sustainable society especially regarding their use as catalysts in industrially relevant synthetic reactions. Herein, we show the production of laccases from four white-rot fungi, which were grown on agricultural residues, specifically Trametes versicolor 11269, Pleurotus ostreatus 1020, Panus tigrinus 707 and Lentinula edodes SC-495. The produced laccases were tested on a laccase-mediator system (LMS) for the biocatalytic oxidation of the model substrate benzyl alcohol into benzaldehyde. The LMS was carried out in the presence both of tetrahydrofuran as co-solvent and of the mediator 2,2,6,6-tetramethyl-1-piperidinyloxyl (TEMPO) due to its high redox potential and its ability to perform the oxidation. Tolerance studies showed that the dialyzed solutions were able to tolerate 1% (99:1 v/v) of co-solvent, whereas a concentration of 10% v/v had a detrimental activity. Performances in the biocatalytic oxidation of laccase solutions from different purification steps were compared. Similar conversion was observed for laccase in dialysis (raw) and gel filtration (GF) product versus commercial T. versicolor laccase. The latter oxidized almost 99% of substrate while the other laccase solutions were able to reach a conversion from 91% for the laccase solution from P. tigrinus 707 after dialysis, to 50% for the laccase solution from P. ostreatus 1020 after gel filtration. This work highlights the potential of unpurified laccase solutions to be used as catalysts in synthetic reactions.

Similar content being viewed by others

Introduction

The Green Transition is pushing towards the use of renewable resources to produce heat and energy, for a better employment of natural resources, such as solar, wind and hydropower energy. To produce chemicals, biomasses are used as sustainable alternatives to fossil resources by biorefining, which is one of the main drivers of bio-based economy1 . The use of agro-industrial waste has been reported in solid-state fermentation (SSF) due to the accessibility of biomass2. SSF has many advantages, such as higher product yield, lower wastewater output, simpler fermentation media and reduced energy requirements3.

Industrially relevant enzymes can be produced by solid-state fermentation for their deployment in organic synthesis. In this context, the laccases have been received enormous attention. Laccases (EC 1.10.3.2, benzenediol:oxygen oxidoreductases) are a well explored group of enzymes belonging to the multi-copper oxidase (MCO) family. Although laccases are widespread in nature, as they have been described from bacteria, fungi, higher plants and insects, fungal laccases represent the most significant group of the “blue” MCO family regarding the number and characterizations. Typical fungal laccases are 60–70 kDa monomeric glycoproteins with a well characterized catalytic mechanism for the formation of radical species4. They contain four copper ions which are organized in two sites. The type 1 copper receives one electron from the substrate and transfers it via a His-Cys-His motive to the trinuclear center. The trinuclear center contains one type 2 and two type 3 copper ions and this is the site where the oxygen reduces to water. In this reaction, four electrons from substrate molecules are transferred to one molecule of O2, reducing it to two molecules of water5. Plant laccases play an important role in the synthesis of lignin, while fungal laccases catalyze its degradation for wood-decay, pathogenesis, fungal morphology and detoxification6.

These natural activities are exploited in several applications by different industrial processes7,8 . Unlike other enzymes, laccases can oxidize various substrates, such as phenols9, aromatic and aliphatic amines and some inorganic ions, while reducing oxygen to water10 . In the food and textile industry, laccases are used to reduce the oxygen content, specifically in beer production to increase the product shelf-life and for their bleaching activities on denim fabrics, respectively11 . Moreover, different studies showed the ability of laccases to produce polymeric structures12,13,14 .

The catalytic cycle of laccases (redox potential 0.5–0.8 mV vs. normal hydrogen electrode) can only start if the substrate of interest has the appropriate redox potential15 . Through “Laccase-mediator system” (LMS), radicalic species may play a role as mediators in non-phenolic compounds oxidation. Indeed, due to steric hindrance and/or redox potential incompatibility of substrates, mediators can act as redox intermediates, following a nature mimicking strategy.

To be considered a proper mediator, the compound must not inhibit the enzyme and its conversion must be cyclic. One of the most common mediators in LMSs is the compound 2,2,6,6-tetramethyl-1-piperidinyloxyl (TEMPO), which has sufficiently high redox potential and it is more efficient than other mediators. The TEMPO is present in the solution in the form of a relatively stable N-oxyl radicalic which is also able to oxidize (Fig. 1) non-phenolic structures16,17 .

Shortly, laccases oxidize TEMPO to produce the oxo-ammonium ion, which reacts with the substrate18 . Proton removal generates the oxidized product and the reduced (N–OH) form of TEMPO. The reduced TEMPO is converted by laccases to the oxidized form and then to the oxo-ammonium ion19,20. The LMS-TEMPO, is one of the most studied systems for converting primary (Fig. 1) and secondary alcohols into oxidized compounds, such as aldehydes, acids and ketones. The selective oxidation of alcohols to the corresponding carbonyl compounds is of utmost importance in both academia and industry. Primary alcohols are directly oxidized to carboxylic acids by H2CrO4 or KMnO4. A selective oxidation to aldehyde, instead, can be achieved using pyridinium chlorochromate (PCC) in stoichiometric amounts in aprotic solvents such as dichloromethane. Catalytic oxidation, instead, requires metal catalysts which are expensive and toxic21. An eco-sustainable alternative is the use of Laccase/TEMPO-mediator systems, that has been used for the biocatalytic selective conversion of alcohols to aldehydes22. The application of enzymes in synthetic chemistry requires the use of non-conventional reaction systems to dissolve hydrophobic substrates in the presence of water, including the use of organic solvents 4,23. Both water-miscible solvents24 and biphasic water-immiscible solvents25,26 have been applied to improve substrate solubility.

In the present work, we compare enzymatic activity of crude and purified laccase-containing mixtures produced from four edible mushrooms which were grown through SSF using wheat straw as substrate; the model reaction is the oxidation of benzyl alcohol to benzaldehyde through the laccase/TEMPO LMS system.

Materials and methods

Chemicals and reagents

All chemicals and reagents used in this work were of analytical grade. Potato Dextrose broth (PDB), ammonium sulfate, Tris–HCl, benzyl alcohol, 2,2,6,6-tetramethyl-1-piperidinyloxyl (TEMPO), 2,6-dimethoxyphenol (2,6-DMP) were purchased from Sigma-Aldrich (USA). Commercial laccase from Trametes versicolor (TV σ) was purchased from Sigma-Aldrich (USA). Organic solvents were purchased at the higher commercial quality and used without further purification.

Strain and culture media

Four white-rot fungi were used in this work: Lentinula edodes SC-495 and Panus trigrinus 707, belonging to the culture collection of ALSIA; Pleurotus ostreatus 1020 and Trametes versicolor 11269, were purchased from the strain collection of the DSMZ (Deutsche Sammlung von Mikroorganismen und Zellkulturen). These fungal cultures were cultivated in slant tubes using PDB as medium containing 25 g L−1 agar at 28 °C for 7 days. For each strain, a liquid pre-inoculum was prepared by adding 30 mL sterile water into the slant tube to resuspend the mycelium. To disrupt the mycelium, the suspension was then homogenized at 24,000 rpm for 30 min by a T25 Ultra-Turrax (IKA, Germany). An aliquot of 25 mL was then transferred into a sterile Erlenmeyer flask with 100 mL fresh PDB medium. The strains were grown at 28 °C for 7 days at 180 rpm. After further homogenization, 25 mL were transferred into a 250 mL fresh PDB medium and grown at 28 °C for 5 days at 180 rpm.

Agricultural biomass

Dry Saragolla (Triticum turgidum subsp. durum) straw was collected from Metapontum Agrobios Research Center (Italy) fields. The Saragolla grain is an early durum wheat variety with an exceptionally high and stable production potential in terms of biomass and grain yield27,28. Wheat bran was used as co-substrate for the mycelia growth and for laccase production with a composition as previously reported29 . All the experimental work on plant material described in this study complies with the relevant institutional, national, and international guidelines and legislation.

Solid-state fermentation for laccase production

Grinded straw/bran mix (100 g), with a straw:bran ratio of 4:1 w/w, containing 70% moisture content (233 mL 0.5 mM Cu2SO4 solution), were inserted in an autoclavable plastic bag and sterilized by autoclave at 121 °C 29,30. After cooling the mixture at room temperature, 30 mL liquid inoculum from a 250 mL culture, containing a concentration of 3 mg mL−1 (dry weight of the mycelium) from each strain, were added and properly mixed to accurately spread fungal cells. The bags were kept in the dark at 28 °C for 7 days.

Extraction and purification of laccase

To extract the extracellular liquor containing enzymes and organic compounds from the SSF batch, 100 g of biomass was pressed through a hydraulic press (Ravaglioli Spa, Italy) with a maximum pressure of 415 bar and a maximum capacity of 15,000 kg. To remove solid particles, a volume of 150 mL extracted liquor was centrifuged at 15,000 rpm for 25 min at 4 °C.

The prepared supernatant was then mixed with (NH4)2SO4 to reach 70% w/v saturation. The mixture was stored at 4 °C under magnetic stirring for 24 h. To collect precipitated proteins, the mixture was then centrifuged at 10,000 rpm for 30 min at 4 °C. The protein pellet was then solubilized in 0.05 M Tris–HCl pH 7.8 and centrifuged at 4,000 rpm for 10 min at 4 °C to remove impurities. To remove the excess of (NH4)2SO4 from the solution, dialysis was performed into a dialysis tube of 14 kDa cut-off and dialyzed against 2 L 0.05 M Tris–HCl pH 7.8 overnight at 4 °C under magnetic stirring.

To further purify the liquor of each strain, 30 mL protein solution were loaded onto an ion-exchange chromatography column packed with Sepharose Q as stationary phase connected to a Fast Protein Liquid Chromatography (FPLC) ÄKTA system (GE Healthcare, Sweden). The column was equilibrated with solution A, which contained 50 mM Tris–HCl, 15 mM NaCl pH 7. The elution was allowed using solution B, which contained 50 mM Tris–HCl, 1 M NaCl pH 7.8 with a flow of 1 mL min-1 and a gradient from 0 to 100% solution B within 50 min. The protein elution was detected with a UV detector at 280 nm.

For each strain, fractions rich in laccase activity were combined and concentrated for the next purification step of gel filtration chromatography. A 60-cm column was packed with Toyopearl resin 50H (TosoH Bioscience, Japan) and connected to an FPLC ÄKTA system. Proteins were eluted with 50 mM Tris–HCl pH 7.8. Fractions which contained laccase activities were collected and stored at −20 °C until further analysis.

Laccase activity assay

Enzyme solutions were spectrophotometrically assayed at 477 nm using 2,6-dimethoxyphenol (2,6-DMP) as substrate at 30 °C (ε477 = 14,600 M−1 cm−1) 31 . The assay mixture consisted of 2 mM 2,6-DMP in 0.1 M sodium acetate buffer pH 4.5. All experiments were performed in triplicate. One unit of enzyme activity (U) was defined as the amount of enzyme transforming 1 µmol of substrate 2,6-DMP into 3,3’,5,5’-tetramethoxy-p-diphenoquinone (cerulignone) per minute under the given experimental conditions. The laccase activity was expressed as international units (U).

Protein determination

Protein concentrations were determined by the method of Bradford32 with bovine serum albumin (Fluka) as standard.

Oxidative biocatalysis

The laccase oxidation of benzyl alcohol to benzaldehyde was carried out at room temperature under magnetic stirring at 800 rpm in a final volume of 3 mL with 20 mM (0.06 mmol) benzyl alcohol, 6 mM TEMPO solution in 30 µL THF, 0.6 U laccase solution in 0.1 M citrate buffer at pH 5 with addition of oxygen. The addition to the reaction medium was performed at 0, 3, 6, and 24 h.

In preliminary experiments, the crude reaction mixture was analysed by H(1)-NMR, in which benzyl alcohol, benzaldeyde and benzoic acid were detected by three peculiar signals (the 8.16–8.13 multiplet for the benzoic acid; the 7.65 doublet for the benzaldehyde; the 4.64 broad singlet for the benzyl alcohol). Since no significant amount of benzoic acid was detected in these experiments, the benzaldehyde formation was measured with UV spectroscopy at 290 nm33 (Kawamura et al. 2016), a wavelength in which benzyl alcohol gave no absorption, in a 1-mL quartz cuvette against a calibration curve of the product between 0.2 and 10 mM. All experiments were performed in triplicate.

Statistical analysis

Analysis of variance (ANOVA) of data from Benzaldehyde production was performed using Minitab ver.17 (Statistical software). Results were reported as mean of the production ± standard deviation (SD). Statistical differences (P < 0.05) among different laccases were determined according to Tukey’s test.

Scale-up oxidation reaction of benzyl alcohol

10 mg of dialyzed liquor, in the lyophilized form, of P. tigrinus 707 (corresponding to 14.2 U) were dissolved in 1 ml of citrate buffer 0.1 M pH 5. The solution was kept at room temperature for 1 h. In a 100 mL reaction flask a solution of benzyl alcohol (150 mg, 1.38 mmol), TEMPO (65 mg, 0.416 mmol, 30 mol%) in 0.69 ml of THF was mixed with 68,3 ml of 0.1 M citrate buffer at pH 5. 1 ml of laccase solution was added to this mixture. At this stage, the flask was charged with oxygen for about 10 min and was stirred at rt for 36 h. The crude reaction mixture was extracted with diethyl ether when conversion of benzyl alcohol is complete (TLC analysis). The combined organic layers were dried over anhydrous Na2SO4 and concentrated under vacuum. The crude reaction mixture was purified on a silica-gel chromatography to give 128 mg of benzaldehyde (Isolated Yield 85%).

Ethical approval and consent to participate

This article does not contain any studies with human participants or animals performed by any of the authors.

Results and discussion

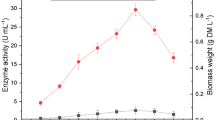

Production and purification of laccases

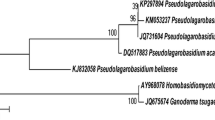

Four different white-rot fungi strains were grown on the agricultural residues composed of Saragolla straw:bran with a ratio 4:1 w/w. The collected laccase-containing liquor was further purified through different steps performing dialysis, ion exchange chromatography and gel filtration.

The maximum laccase production was obtained for all strains at the end of 7th day of fermentation with a specific activity of liquor of 6.4 U/mg protein for Trametes versicolor 11269, 14.5 U/mg for Pleurotus ostreatus 1020, 20.7 U/mg for Panus tigrinus 707 and 11.6 U/mg for Lentinula edodes SC-495. The crude laccase of the liquor was precipitated with 70% ammonium sulfate saturation, dialyzed, purified on ion-exchange chromatography and the pooled fractions further purified by gel filtration. A typical trend of increase of specific activity and purification fold was observed in all fungal laccases. Indeed, laccase from Trametes versicolor 11269, Pleurotus ostreatus 1020 and Panus tigrinus 707 exhibited a similar specific activity of 379.7 U/mg, 377.0 U/mg and 375.8 U/mg using 2,6-DMP at the standard assay conditions with an overall fold purification of 59.5, 26.0 and 18.1 and a yield of 17%, 30% and 16% respectively. Laccase from Lentinula edodes SC-495 was purified with the lowest specific activity of 118.2 U/mg with a 10.1 fold purification and a yield of 13% (Table 1).

In this work, we compared the raw and purified laccases produced from mycelia, which were grown on agricultural residues, with commercially available enzyme in the oxidation of benzyl alcohol. We chose this reaction as a model of Laccase-catalyzed oxidation using TEMPO as a mediator. Since TEMPO has a poor solubility in water, a certain amount of organic co-solvent was needed. An excellent solvent for both protic and aprotic polar organic molecules is THF. THF is miscible in water, prevents the formation of undesired emulsions and has a limited volatility, if compared to acetone or ethyl acetate, a fact that is relevant when the reaction must last several days. Before testing our raw enzymes on the model reaction, it was necessary to evaluate their activity (tolerance) in the presence of different amounts of THF.

Tolerance of laccase systems versus tetrahydrofuran (THF)

Dialyzed laccase solutions and commercial Trametes versicolor laccase were tested under different concentrations of THF to identify their specific tolerance level. Recently, it was reported that commercial laccases were employed also in water-miscible organic solvents 34.

The commercial TV laccase (TV σ) and the dialysate (raw) protein mixtures of the four strains were assayed for their tolerance to THF at concentrations of 1% and 10% v/v, after 24 h incubation time and compared with the control without THF. The TV 11269 raw laccase solution showed the highest tolerance to the THF 1% v/v, which showed a 96% activity. The enzymatic activity is almost completely lost (3%) at a concentration of THF of 10% v/v. The commercial TV laccase showed a lower tolerance (59%) in THF at 1% v/v and a slightly higher tolerance at 10% THF (17%), compared to TV 11269 laccase. LE SC-495, PO 1020 and PT 707 laccase solutions were more affected by the presence of the THF co-solvent compared to the TV 11269 laccase solutions (Fig. 2). In fact, they showed lower residual activity with 47%, 57% and 65% residual activity respectively in 1% THF and not detectable activity at 10% THF (Fig. 2 and Table S1).

Tolerance to THF of the commercial laccase (TV σ) and the dialysate protein mixtures of TV 11269, PO 1020, PT 707, and LE SC-495. THF concentrations of 1% v/v and 10% v/v were tested and related to the laccase activity in aqueous solution. Data are mean values of three different measurements, different letters indicate differences according to Tukey Test at p < 0.05.

For this reason, the optimized 1% concentration of THF was used as the co-solvent for the biocatalytic model oxidation.

Biocatalytic oxidation of benzyl alcohol

The oxidation of benzyl alcohol to benzaldehyde was investigated as a model of a green chemistry process and of circular economy with possible future applications on an industrial scale. THF was used as the co-solvent with a minimal concentration of 1% (99:1 v/v) in the presence of 0.1 M sodium citrate buffer pH 5 at room temperature, with 0.06 mmol of benzyl alcohol. Oxygen was introduced throughout the entire incubation at different times. Aliquots of the dialysis and the gel filtration products were used on the reaction. The amount of benzaldehyde obtained by oxidation of benzyl alcohol through laccases was measured after 3 h, 6 h, 24 h and 30 h (Fig. 3, Table S2).

Time course of conversion of benzyl alcohol to benzaldehyde by dialyzed and gel filtrated laccase solutions produced from four different white-rot fungi compared to the commercial T. versicolor laccase (TV σ), after 3 h, 6 h, 24 h and 30 h from inoculation. Each point of time course represents mean of three different measurements with standard deviation.

The data indicate that the benzylic alcohol oxidation rates are not constant over time, and, in most cases, the enzyme appears to be more active as time progresses until 24 h, when the reaction reaches the plateau. Only in the case of dialyzed and GF (Gel filtrated) TV11269 laccases we observed a linearity in the benzaldehyde production and the curve seems to continue growing after 24 h.

The highest performance was observed for the commercial T. versicolor laccase (TV σ) with a 99% of conversion in product after 30 h. Nevertheless, no significant differences were shown about the activity of laccases from all the tested strains and for both steps of purification with exception of P. ostreatus 1020 (Fig. 4 and Tables S2 and S3).

Conversion of benzyl alcohol to benzaldehyde by laccase solutions produced from four different white-rot fungi compared to the commercial T. versicolor laccase (TV σ), after 30 h from inoculation. Data are mean values of three different measurements, different letters indicate differences according to Tukey test at p < 0.05.

PT 707 laccase showed 91% of conversion for the dialyzed laccase against 86% of conversion produced by the gel filtered enzyme, followed by LE SC 495 with an 83% of conversion for the dialyzed laccase against 78% of conversion of the gel filtration product and TV 11269 that achieved a 79% of conversion for the dialyzed laccase against 77% of conversion of the gel filtration product. The lowest conversion was recorded by the laccase solutions from PO 1020 which showed a 64% of conversion for the dialyzed laccase against 50% of conversion of the gel filtration product.

Those data show that purification steps are not justified by a substantial activity increase of enzyme solutions in the biocatalytic transformation of benzyl alcohol. Thus, raw liquor squeezed from fungal fermented wheat straw can be considered a useful biocatalyst reducing the production times and costs for possible future use of these in industrially relevant biocatalysed process.

Conclusions

We have demonstrated that solid-state fermentation (SSF) is a successful technique to cultivate white-rot fungi on agricultural residues to produce laccase-containing solutions which are tolerant to THF at a concentration of 1% (99:1 v/v). The activity of crude and purified laccase-containing mixtures produced from four edible mushrooms which were grown using wheat straw as raw material was compared on the model reaction of the green oxidation of benzyl alcohol to benzaldehyde through the laccase/TEMPO (LMS) in H2O-1%THF. Biomass and agro-industrial waste, indeed, can be a great alternative to produce chemicals and biocatalysts which can increase the sustainability of industrial processes. Further studies will be performed to characterize the composition of the dialysate and to extend the process to the sustainable and green production of industrially relevant organic building-blocks.

Data availability

All data generated during the current study are included into this published paper.

References

Dubois, O., & Gomez San Juan, M. How sustainability is addressed in official bioeconomy strategies at international, national, and regional levels—An overview. in Environment and Natural Resources Management. Working Paper (FAO). Vol. 63. https://www.fao.org/3/i5998e/i5998e.pdf (2016).

Wang, F. et al. Fungal laccase production from lignocellulosic agricultural wastes by solid-state fermentation: A review. Microorganisms 7(12), 665. https://doi.org/10.3390/microorganisms7120665 (2019).

Lizardi-Jiménez, M. A. & Hernández-Martínez, R. Solid state fermentation (SSF): Diversity of applications to valorize waste and biomass. 3 Biotech 7(1), 44. https://doi.org/10.1007/s13205-017-0692-y (2017).

Bassanini, I., Ferrandi, E. E., Riva, S. & Monti, D. Biocatalysis with laccases: An updated overview. Catalysts 11(1), 26. https://doi.org/10.3390/catal11010026 (2021).

Mot, A. C. & Silaghi-Dumitrescu, R. Laccases: Complex architectures for one-electron oxidations. Biochemistry 77(12), 1395–1407. https://doi.org/10.1134/S0006297912120085 (2012).

Zhao, Q. et al. Laccase is necessary and nonredundant with peroxidase for lignin polymerization during vascular development in Arabidopsis. Plant Cell 25(10), 3976–3987. https://doi.org/10.1105/tpc.113.117770 (2013).

Moreno, A. D., Ibarra, D., Eugenio, M. E. & Tomás-Pejó, E. Laccases as versatile enzymes: From industrial uses to novel applications. J. Chem. Technol. Biotechnol. 95(3), 481–494. https://doi.org/10.1002/jctb.6224 (2020).

Zerva, A., Simić, S., Topakas, E. & Nikodinovic-Runic, J. Applications of microbial laccases: Patent review of the past decade (2009–2019). Catalysts 9(12), 1023–1049. https://doi.org/10.3390/catal9121023 (2019).

Majcherczyk, A., Johannes, C. & Hüttermann, A. Oxidation of aromatic alcohols by laccase from Trametes versicolor mediated by the 2,2′-azino-bis-(3-ethylbenzothiazoline-6-sulphonic acid) cation radical and dication. Appl. Microbiol. Biotechnol. 51, 267–276. https://doi.org/10.1007/s002530051392 (1999).

Riva, S. Laccases: Blue enzymes for green chemistry. Trends Biotechnol. 24(5), 219–226. https://doi.org/10.1016/j.tibtech.2006.03.006 (2006).

Mate, D. M. & Alcalde, M. Laccase: A multi-purpose biocatalyst at the forefront of biotechnology. Microb. Biotechnol. 10(6), 1457–1467. https://doi.org/10.1111/1751-7915.12422 (2017).

Agustin, M. B. et al. Laccase as a tool in building advanced lignin-based materials. Chemsuschem 14, 4615–4635. https://doi.org/10.1002/cssc.202101169 (2021).

Braunschmid, V. et al. Comparison of a fungal and a bacterial laccase for lignosulfonate polymerization. Process Biochem. 109, 207–213. https://doi.org/10.1016/j.procbio.2021.07.001 (2021).

Pollard, J. & Bruns, N. Biocatalytic ATRP. ACS Sympos. Ser. 1284, 379–393. https://doi.org/10.1021/bk-2018-1284.ch019 (2018).

Witayakran, S. & Ragauskas, A. J. Synthetic applications of laccase in green chemistry. Adv. Synth. Catal. 351(9), 1187–1209. https://doi.org/10.1002/adsc.200800775 (2009).

Fabbrini, M., Galli, C., Gentili, P. & Macchitella, D. An oxidation of alcohols by oxygen with the enzyme laccase and mediation by TEMPO. Tetrahedron Lett. 42(43), 7551–7553. https://doi.org/10.1016/S0040-4039(01)01463-0 (2001).

Fabbrini, M., Galli, C. & Gentili, P. Comparing the catalytic efficiency of some mediators of laccase. J. Mol. Catal. B Enzym. 16(5–6), 231–240. https://doi.org/10.1016/S1381-1177(01)00067-4 (2002).

d’Acunzo, F., Baiocco, P., Fabbrini, M., Galli, C. & Gentili, P. A mechanistic survey of the oxidation of alcohols and ethers with the enzyme laccase and its mediation by TEMPO. Eur. J. Org. Chem. 24, 4195–4201. https://doi.org/10.1002/1099-0690(200212)2002 (2002).

Morozova, O. V., Shumakovich, G. P., Shleev, S. V. & Yaropolov, Y. Laccase-mediator systems and their applications: A review. Appl. Biochem. Microbiol 43(5), 523–535. https://doi.org/10.1134/S0003683807050055 (2007).

Tromp, S. A. et al. Mechanism of laccase-TEMPO-catalyzed oxidation of benzyl alcohol. ChemCatChem 2(7), 827–833. https://doi.org/10.1002/cctc.201000068 (2010).

Hunsen, M. Pyridinium chlorochromate catalyzed oxidation of alcohols to aldehydes and ketones with periodic acid. Tetrahedron Lett. 46(10), 1651–1653. https://doi.org/10.1002/chin.200526029 (2005).

Díaz-Rodríguez, A., Martínez-Montero, L., Lavandera, I., Gotor, V. & Gotor-Fernández, V. Laccase/2,2,6,6-tetramethylpiperidinoxyl radical (TEMPO): An efficient catalytic system for selective oxidations of primary hydroxy and amino groups in aqueous and biphasic media. Adv. Synth. Catal. 356(10), 2321–2329. https://doi.org/10.1002/adsc.201400260 (2014).

Maijala, P. et al. Action of fungal laccases on lignin model compounds in organic solvents. J. Mol. Catal. B Enzym. 76, 59–67. https://doi.org/10.1016/j.molcatb.2011.12.009 (2012).

Wan, Y. Y. et al. F Effects of organic solvents on the activity of free and immobilised laccase from Rhus vernicifera. Int. J. Biol. Macromol. 47(4), 488–495. https://doi.org/10.1016/j.ijbiomac.2010.07.003 (2010).

Nicotra, S., Intra, A., Ottolina, G., Riva, S. & Danieli, B. Laccase-mediated oxidation of the steroid hormone 17β-estradiol in organic solvents. Tetrahedron Asymmetry 15(18), 2927–2931. https://doi.org/10.1016/j.tetasy.2004.06.034 (2004).

Ponzoni, C. et al. Laccase-catalyzed dimerization of hydroxystilbenes. Adv. Synth. Catal. 349(8–9), 1497–1506. https://doi.org/10.1002/adsc.200700043 (2007).

Acquistucci, R., Melini, V. & Galli, V. Durum wheat grain and pasta from locally-grown crops: A case-study on Saragolla (Triticum turgidum ssp. turanicum) and Senatore Cappelli (Triticum turgidum ssp. durum) wheats. Emir. J. Food Agric. 32, 47–54. https://doi.org/10.9755/ejfa.2020.v32.i1.2058 (2020).

Danzi, D. et al. Assessment of durum wheat (Triticum durum desf.) genotypes diversity for the integrated production of bioethanol and grains. Energies 14(22), 7735. https://doi.org/10.3390/en14227735 (2021).

Neifar, M., Jaouani, A., Ellouze-Ghorbel, R., Ellouze-Chaabouni, S. & Penninckx, M. J. Effect of culturing processes and copper addition on laccase production by the white-rot fungus Fomes fomentarius MUCL 35117. Lett. Appl. Microbiol. 49(1), 73–78. https://doi.org/10.1111/j.1472-765X.2009.02621.x (2009).

Neifar, M., Kamoun, A., Jaouani, A., Ellouze-Ghorbel, R. & Ellouze-Chaabouni, S. Application of asymetrical and hoke designs for optimization of laccase production by the white-rot fungus Fomes fomentarius in solid-state fermentation. Enzyme Res. https://doi.org/10.4061/2011/368525 (2011).

Slomczynski, D., Nakas, J. P. & Tanenbaum, S. W. Production and characterization of laccase from Botrytis cinerea 61-34. Appl. Environ. Microbiol. 61(3), 907–912. https://doi.org/10.1128/aem.61.3.907-912.1995 (1995).

Bradford, M. M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 72(1–2), 248–254. https://doi.org/10.1016/0003-2697(76)90527-3 (1976).

Kawamura, K. et al. Oxidation of aliphatic alcohols and benzyl alcohol by H2O2 under the hydrothermal conditions in the presence of solid-state catalysts using batch and flow reactors. Chem. Eng. J. 285, 49–56. https://doi.org/10.1016/j.cej.2015.09.088 (2016).

Wu, M.-H. et al. Enhancement of laccase activity by pre-incubation with organic solvents. Sci. Rep. 9, 9754. https://doi.org/10.1038/s41598-019-45118-x (2019).

Acknowledgements

Dedicated to Prof. Francesco Naso on the occasion of his 85th birthday. The authors acknowledge the METEA Interdepartmental Center on Environmental Methodologies and Technologies.

Funding

This work was financially supported by the University of Bari Aldo Moro (MAMC, Fondi Ateneo 17-18) and by ALSIA (IM, Annual Plan 2021), MIUR PON ARS01_00869 “PERCIVAL”, UNIBA: Horizon Europe Seeds-S27(CUP: H91I21001630006).

Author information

Authors and Affiliations

Contributions

I.M. and M.A.M.C. conceived and designed this study. I.M. and E.P. conducted experiments with support of F.C., C.C. and A.B. I.M., D.D., E.P., I.P. and A.B. analyzed data. All authors contributed to writing and editing the manuscript and approved the final version of the manuscript. All authors declare that agree with submit the manuscript to Scientific Report.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Marino, I., Pignataro, E., Danzi, D. et al. A comparative screening of laccase-mediator systems by white-rot fungi laccases for biocatalytic benzyl alcohol oxidation. Sci Rep 12, 21602 (2022). https://doi.org/10.1038/s41598-022-24839-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-24839-6

- Springer Nature Limited