Abstract

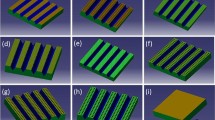

In order to improve the particle erosion resistance of engineering surfaces, this paper proposed a bionic sample which is inspired from the skin structure of desert lizard, Laudakin stoliczkana. The bionic sample consists of a hard shell (aluminum) and a soft core (silicone rubber) which form a two-layer composite structure. The sand blast tests indicated that the bionic sample has better particle erosion resistance. In steady erosion period, the weight loss per unit time of the bionic sample is about 10% smaller than the contrast sample. The anti-erosion mechanism of the bionic sample was studied by single particle impact test. The results show that, after the impact, the kinetic energy of the particle is reduced by 56.5% on the bionic sample which is higher than that on the contrast sample (31.2%). That means the bionic sample can partly convert the kinetic energy of the particle into the deformation energy of the silicone rubber layer, thus the erosion is reduced.

Similar content being viewed by others

References

Hassani S, Klemberg-Sapieha J E, Bielawski M, Beres W, Martinu L, Balazinski M. Design of hard coating architecture for the optimization of erosion resistance. Wear, 2008, 265, 879–887.

Patnaik A, Satapathy A, Chand N, Barkoula N M, Biswas S. Solid particle erosion wear characteristics of fiber and particulate filled polymer composites: A review. Wear, 2010, 268, 249–263.

Tilly G P. A two stage mechanisms of ductile erosion. Wear, 1973, 23, 87–96.

Ruff A W, Wiederhorn S M. Erosion by solid particle impact. In: Preece C M (ed). Treatise on Materials Science and Technology, Academic Press, New York, USA, 1979, 16, 69–125.

Humphrey J AC, Fundamentals of fluid motion in erosion by solid particle impact. International Journal of Heat and Fluid Flow, 1990, 11, 170–195.

Yang N, Nayeb-Hashemi H. The effect of solid particle erosion on the mechanical properties and fatigue life of fiber- reinforced composites. Journal of Composite Materials, 2007, 41, 559–574.

Harsha A P, Tewari U S, Venkatraman B. Solid particle erosion behavior of various polyaryletherketone composites. Wear, 2003, 254, 693–712.

Zhou R, Lu D H, Jinag Y H, Li Q N. Mechanical properties and erosion wear resistance of polyurethane matrix composites. Wear, 2005, 259, 676–683.

Desale G R, Paul C P, Gandhic B K, Jain S C. Erosion wear behavior of laser clad surfaces of low carbon austenitic steel. Wear, 2009, 266, 975–987.

Kulu P, Hussainova I, Veinthal R. Solid particle erosion of thermal sprayed coatings. Wear, 2005, 258, 488–496.

Lin J Z, Shen L P, Zhou Z X. The effect of coherent vortex structure in the particulate two-phase boundary layer on erosion. Wear, 2000, 241, 10–16.

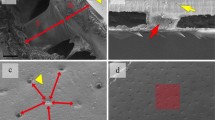

Han Z W, Zhang J Q, Ge C, Wen L, Ren L Q. Erosion resistance of bionic functional surfaces inspired from desert scorpions. Langmuir, 2012, 28, 2914–2921.

Bhushan B. Biomimetics: Lessons from nature — An overview. Philosophical Transactions of the Royal Society A, 2009, 367, 1445–1486.

Hu Y, Han Z W, Xu M X, Zhang Z H. Anti-wear properties on 20crmnti steel surfaces with biomimetic non-smooth units. Science in China E, 2010, 53, 2920–2924.

Tian X M, Han Z W, Li X J, Pu Z G, Ren L Q. Biological coupling anti-wear properties of three typical molluscan shells — Scapharca subcrenata, Rapana venosa and Acanthochiton rubrolineatus. Science in China E, 2010, 53, 2905–2913.

Rechenberg I, Khyari AR El. The Sandskink of the Sahara: Model for Friction and Wear Reduction, [2012-08-25], http://www.bionik.tu-berlin.de/institut/s2skink.html

Baumgartner W, Saxe F, Weth A, Hajas D, Sigumonrong D, Emmerlich J, Singheiser M, Bohme W, Schneider J M. The sandfish’s skin: Morphology, chemistry and reconstruction. Journal of Bionic Engineering, 2007, 4, 1–9.

Han Z W, Zhang J Q, Ge C, Lü Y, Jiang J L, Liu Q P, Ren L Q. Anti-erosion function in animals and its biomimetic application. Journal of Bionic Engineering, 2010, 7(Suppl), S50–S58.

Gao F. Research on the Coupling Characteristics of Anti-Erosiove Wear of Desert Lizard. Doctoral Thesis, Jilin University, Changchun, China, 2008. (in Chinese)

Hutchings I M, Winter R E, Field J E. Solid particle erosion of metals: The removal of surface material by spherical projectiles. Proceedings of Royal Society of London A, 1976, 348, 379–392.

Aquaro D. Erosion rate of stainless steel due to the impact of solid particles. International Conference on Tribology, Parma, Italy, 2006.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, H., Zhang, Y. & Ren, L. Particle Erosion Resistance of Bionic Samples Inspired from Skin Structure of Desert Lizard, Laudakin stoliczkana. J Bionic Eng 9, 465–469 (2012). https://doi.org/10.1016/S1672-6529(11)60141-8

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1672-6529(11)60141-8