Abstract

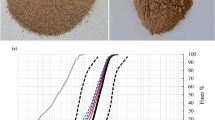

Erosion is so widespread and undesirable in various engineering applications such that it is so incumbent to find anti-erosion means to address it. In previous researches (Han et al. in J Bionic Eng 7(09):S50–S58, 2010; J Wuhan Univ Technol Mater Sci Ed 26(2):305–310, 2011; Langmuir 28(5):2914–2921, 2012; Adv Colloid Interface Sci 234:27–50, 2016; Surf Coat Technol 313:143–150, 2017; Zhang et al. in Adv Mater Sci Eng 2013(5):1–9, 2013), people found that the surface of desert scorpion Androctonus australis, which belonged to the parabuthus, had very complex microstructures that had the strong anti-erosion qualities in the blown sand environment. Here, through further research, a new microstructure, hexagonal pit structure, was firstly discovered on the back of desert scorpion. These microstructures were applied in the design of biomimetic samples, which were fabricated by 3D printer using EOS stainless steel GP1. These biomimetic samples were used to test the erosion rate under the impact of quartz sand of three different sizes. The experiment was carried out using a blasting jet machine with injection angle, velocity and time of 30°, 25 ms−1 and 90 s, respectively, and the results showed that the biomimetic samples with different microstructures had better anti-erosion performance. The hexagonal pit structure, whose depth was 200–300 μm and the length was 200–500 μm, had also good anti-erosion performance. The physical model was established to express the mechanism of anti-erosion by controlling the motion direction and impacting velocity of the particles. The anti-erosion performance of all these biomimetic samples can be quantified by the erosion rate and improvement rate. On the whole, these microstructures all have good anti-erosion effect; hence, this paper research is of great practical significance.

Similar content being viewed by others

References

Han, Z., Zhang, J., Ge, C., You, L., Jiang, J., Liu, Q., Ren, L.: Anti-erosion function in animals and its biomimetic application. J. Bionic Eng. 7(09), S50–S58 (2010)

Han, Z., Zhang, J., Ge, C., Jiang, J., Ren, L.: Gas-solid Erosion on Bionic Configuration Surface. J. Wuhan Univ. Technol. Mater. Sci. Ed. 26(2), 305–310 (2011)

Han, Z., Zhang, J., Ge, C., Li, W., Ren, L.: Erosion resistance of bionic functional surfaces inspired from desert scorpions. Langmuir 28(5), 2914–2921 (2012)

Han, Z., Mu, Z., Yin, W., Li, W., Niu, S., Zhang, J., Ren, L.: Biomimetic multifunctional surfaces inspired from animals. Adv. Colloid Interface Sci. 234, 27–50 (2016)

Han, Z., Zhu, B., Yang, M., Niu, S., Song, H., Zhang, J.: The effect of the micro-structures on the scorpion surface for improving the anti-erosion performance. Surf. Coat. Technol. 313, 143–150 (2017)

Zhang, J., Han, Z., Cao, H., Yin, W., Niu, S., Wang, H.: Numerical analysis of erosion caused by biomimetic axial fan blade. Adv. Mater. Sci. Eng. 2013(5), 1–9 (2013)

Thakre, A.A.: Prediction of erosion of polyetherimide and its composites using response surface methodology. J. Tribol. 137(1), 011603 (2015)

Hassani, S., Klemberg-Sapieha, J.E., Bielawski, M., Beres, W., Martinu, L., Balazinski, M.: Design of hard coating architecture for the optimization of erosion resistance. Wear 265(5), 879–887 (2008)

Srivastava, V.K., Pawar, A.G.: Solid particle erosion of glass fibre reinforced flyash filled epoxy resin composites. Compos. Sci. Technol. 66(15), 3021–3028 (2006)

Bijwe, J., Rattan, R., Fahim, M., Tiwari, S.: Erosive wear of carbon fabric reinforced polyetherimide composites: role of amount of fabric and processing technique. Polym. Compos. 29(3), 337–344 (2008)

Yang, J.-Z., Fang, M.-H., Huang, Z.-H., Hu, X.-Z., Liu, Y.-G., Sun, H.-R., Huang, J.-T., Li, X.-C.: Solid particle impact erosion of alumina-based refractories at elevated temperatures. J. Eur. Ceram. Soc. 32(2), 283–289 (2012)

Petrucci, R., Santulli, C., Puglia, D., Nisini, E., Sarasini, F., Tirillò, J., Torre, L., Minak, G., Kenny, J.M.: Impact and post-impact damage characterisation of hybrid composite laminates based on basalt fibres in combination with flax, hemp and glass fibres manufactured by vacuum infusion. Compos. B Eng. 69, 507–515 (2015)

Akbari, M.K., Baharvandi, H.R., Shirvanimoghaddam, K.: Tensile and fracture behavior of nano/micro TiB 2 particle reinforced casting A356 aluminum alloy composites. Mater. Des. 1980–2015(66), 150–161 (2015)

Mokhtari, M., Schipper, D.J., Vleugels, N., Noordermeer, J.W.M.: Existence of a tribo-modified surface layer on SBR elastomers: balance between formation and wear of the modified layer. Tribol. Lett. 58(2), 22 (2015)

O’Flynn, D.J., Bingley, M.S., Bradley, M.S.A., Burnett, A.J.: A model to predict the solid particle erosion rate of metals and its assessment using heat-treated steels. Wear 248(1), 162–177 (2001)

Desale, G.R., Paul, C.P., Gandhi, B.K., Jain, S.C.: Erosion wear behavior of laser clad surfaces of low carbon austenitic steel. Wear 266(9), 975–987 (2009)

Kumar, A., Sharma, A., Goel, S.K.: Effect of heat treatment on microstructure, mechanical properties and erosion resistance of cast 23-8-N nitronic steel. Mater. Sci. Eng. A 637, 56–62 (2015)

Paulitsch, J., Maringer, C., Mayrhofer, P.H.: Low friction CrNMPP/TiNDCMS multilayer coatings. Tribol. Lett. 46(1), 87–93 (2012)

Björling, M., Larsson, R., Marklund, P.: The effect of DLC coating thickness on elstohydrodynamic friction. Tribol. Lett. 55(2), 353–362 (2014)

Cernuschi, F., Lorenzoni, L., Capelli, S., Guardamagna, C., Karger, M., Vaßen, R., Von Niessen, K., Markocsan, N., Menuey, J., Giolli, C.: Solid particle erosion of thermal spray and physical vapour deposition thermal barrier coatings. Wear 271(11), 2909–2918 (2011)

Yang, Q., McKellar, R.: Nanolayered CrAlTiN and multilayered CrAlTiN–AlTiN coatings for solid particle erosion protection. Tribol. Int. 83, 12–20 (2015)

Amarendra, H.J., Prathap, M.S., Karthik, S., Abhishek, A.M., Anilkumar, T.: Combined slurry and cavitation erosion resistance of HVOF spray coated SS 410 steel. In: IOP Conference Series: Materials Science and Engineering. pp. 012053. IOP Publishing (2016)

Feng, T., Li, H., Fu, Q., Shi, X., Hu, M., Liu, L.: Erosion resistance of Mo–Si–Cr coating-modified C/C composites in a wind tunnel at 1873K. J. Alloys Compd. 622, 1049–1054 (2015)

Ali, O., Ahmed, R., Faisal, N.H., Alanazi, N.M., Berger, L.M., Kaiser, A., Toma, F.L., Polychroniadis, E.K., Sall, M., Elakwah, Y.O.: Influence of post-treatment on the microstructural and tribomechanical properties of suspension thermally sprayed WC–12 wt% Co nanocomposite coatings. Tribol. Lett. 65(2), 33 (2017)

Black, S.: Composite nacelles: flying toward new horizons. High Perform. Compos. 12(3), 49–51 (2004)

Steffens, K., Wilhelm, H.: Next engine generation: materials, surface technology, manufacturing processes. MTU Aero Engine Rep., 1–17 (2003)

Sutter, J.K., Miyoshi, K., Bowman, C., Naik, S.K., Ma, K., Sinatra, R., Cupp, R., Horan, R., Leissler, G.: Erosion coatings for polymer matrix composites in propulsion applications. High Perform. Polym. 15(4), 421–440 (2003)

Miyoshi, K., Sutter, J.K., Mondry, R.J., Bowman, C., Ma, K., Horan, R.A., Naik, S.K., Cupp, R.J.: Measurements of erosion wear volume loss on bare and coated polymer matrix composites. Berl. Munch. Tierarztl. Wochenschr. 94(22), 445–448 (2003)

Wilson, D.: Polyimides as resin matrices for advanced composites. In: Polyimides, pp. 187–226. Springer (1990)

Stevens, T.: New engineering with old resins. Mater. Eng. 107(11), 29–32 (1990)

Hoff, S.M.: Applying advanced materials to turboshaft engines. Aerosp. Eng. 15(2), 27–30 (1995)

Kuncheva, G.S.: Comparative study of microbial activity and chemical properties of soil by implementing anti-erosion measure vertical mulching with organic residues. Acta Universitatis Agriculturae et Silviculturae Mendelianae Brunensis 63(1), 59–63 (2015)

Huang, H., Zhang, Y., Ren, L.: Particle erosion resistance of bionic samples inspired from skin structure of desert lizard, Laudakin stoliczkana. J. Bionic Eng. 9(4), 465–469 (2012)

Han, Z., Yin, W., Zhang, J., Jiang, J., Niu, S., Ren, L.: Erosion-Resistant Surfaces Inspired by Tamarisk. J. Bionic Eng. 10(4), 479–487 (2013)

Han, Z., Yin, W., Zhang, J., Niu, S., Ren, L.: Active anti-erosion protection strategy in tamarisk (Tamarix aphylla). Sci. Rep. 3(7478), 3429 (2013)

Finnie, I.: The mechanism of erosion of ductile metals. In: Proceeding of the 3rd US National Congress of Applied Mechanics, pp.527–532. ASME, New York (1958)

Finnie, I.: Erosion of surfaces by solid particles. Wear 3(2), 87–103 (1960)

Song, X.Q., Lin, J.Z., Zhao, J.F., Shen, T.Y.: Research on reducing erosion by adding ribs on the wall in particulate two-phase flows. Wear 193(1), 1–7 (1996)

Acknowledgements

This study was funded by the Nature Science Foundation of China (Nos. 51675220; 51325501; 51205161), Natural Science Foundation of Jilin Province of China (20170101115JC), China Post doctoral Science Foundation funded project (No. 2014T70285), the 13th Five-Year scientific research project of Education Department of Jilin Province (2015474).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, and there is no professional or other personal interest of any nature.

Rights and permissions

About this article

Cite this article

Zhang, J., Chen, W., Yang, M. et al. The Ingenious Structure of Scorpion Armor Inspires Sand-Resistant Surfaces. Tribol Lett 65, 110 (2017). https://doi.org/10.1007/s11249-017-0895-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-017-0895-8