Abstract

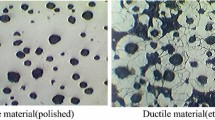

The weldability of a ferritic ductile cast iron was investigated as a function of diferent consumables and welding conditions. A 23 full factorial experimental design was used to analyze the effect of factors and their interactions on ultimate tensile strength of weldments. The shielded metal arc welding (SMAW) process was used with two types of consumables (E7018 and ENi-CI) under eight diferent conditions using asGcast samples. The microstructural evolution and fracture mechanisms were investigated by optical microscopy and scanning electron microscopy (SEM), respectively. The hardness, tensile and impact tests were also performed to determine the weld quality Based on experiment design, preheat, consumable, cooling condition, preheat-cooling and preheat-consumable interactions were significant factors. Preheat is the most efective factor and in the case of E7018, preheat and cooling conditions were the most sensible factors. It was found that butering was the most appropriate welding method for ferritic ductile cast iron.

Similar content being viewed by others

References

N. Fatahala, S. Bahi, Mater. Sci. 31 (1996) 5765–5772.

E. M. El-Banna, M. S. Nageda, M. M. Abo El-Saadat, Mater. Lett. 42 (2000) 311–320.

E. M. El-Banna, Mater. Let. 41 (1999) 20–26.

M. Pascual, J. Cembrero, F. Salas, M. P. Martínez, Mater Lett. 62 (2008) 1359–1362.

A. R. I. Kheder, G. S. Marahleh, Pure App. Sci. 3 (2007) 49–67.

M. J. Anderson, P. J. Whitcomb, DOE Simplified: Practical Tools for Efective Experimentation, Productivity Inc., New York, 2000.

Software Helps Design-Expert Software, Version 7.1, User’s Guide, Technical Manual, Stat-Ease Inc., Minneapolis, MN, 2007.

J. Antony, Design of Experiment for Engineers and Scientists, Elsevier Science and Technology Books, 2003.

D. C. Montgomery, Design and Analysis of Experiments, fifth ed., John Wiley and Sons, New York, 2000.

A. Dean, D. Voss, Design and Analysis of Experiments, Springer Text in Statics, 1999.

NIST/SEMATECH e-Handbook of Statistical Methods, http://www.itl.nist.gov/div898/handbook/, March, 2008.

R. Gotipati, S. Mishra, Chem. Eng. J. 160 (2010) 99–107.

Y. Song, D. Kim, Y. Park, Korean J. Chem. Eng. 99 (2011) 156–163.

Metals Handbook Welding, Brazing and Soldering ASM, Vol. 6, 9th ed., Metals Park, Ohio, 1989.

T. Alizadeh, Chin. J. Poly. Sci. 29 (2011) 658–669.

S. Costa, M. Barroso, A. Castañera, M. Dias, Anal. Bioanal Chem. 396 (2010) 2533–2542.

Howard B Cary, Scot Helzer, Modern Welding Technology, Upper Saddle River, Pearson Education, New Jersey, 2005.

S. Kehoe, M. Ardhaoui, J. Stokes, J. Mater. Eng. Perform 20 (2011) 1423–1437.

ASTM A 327-91R97, Standard Test Methods for Impact Testing of Cast Irons, ASTM International, United States, 1997.

S. Kou, Welding Metalurgy, 2nd Ed., John Wiley and Sons, New York, 2003.

Metals Handbook, Heat Treating ASM, 9th ed., Vol. 4, Metals Park, Ohio, 1989, p. 1487.

K. M. Pedersen, N. S. Tiedje, Mater. Charact. 59 (2008) 1111–1121.

R. D. Forrest, Welding Ductile Iron Casting, Casting Engineering and Foundry World, 1983.

M. Pascual, J. Cembrero, F. Salas, M. P. Martínez, Mater. Lett. 62 (2008) 1359–1362.

R. C. Voight, C. R. Loper Jr., Weld. J. 62 (1983) 82s–88s.

G. R. Pease, Weld. J. 39 (1960) 1–9.

H. Cetinel, Int. J. Mater. Res. 198 (2007) 128–136.

H. Cetinel, B. Uyulgan, T. Aksoy, Mater. Sci. Eng. A 387 (2004) 357–360.

D. J. Kotecki, N. R. Braton, C. R. Loper, Weld. J. 48 (1969) 161s–166s.

Weman Klas, Welding Processes Handbook, CRC Press LLC, New York, 2003.

D. R. Askeland, N. Birer, Weld. J. 2 (1979) 337s.

V. Di Cocco, F. Iacovielo, M. Cavalini, Eng. Fract. Mech. 77 (2010) 2016–2023.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Askari-Paykani, M., Shayan, M. & Shamanian, M. Weldability of Ferritic Ductile Cast Iron Using Full Factorial Design of Experiment. J. Iron Steel Res. Int. 21, 252–263 (2014). https://doi.org/10.1016/S1006-706X(14)60039-X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(14)60039-X