Abstract

This study is aimed at developing prediction model for structural behavior of Porous Asphalt Pavement (PAP) using ABAQUS software and also developing ANN (Artificial Neural Network) model to predict void percentages in Porous Asphalt mix gradations. Data from the past literatures were used to analyze various mixing parameters affecting the properties of Porous Asphalt gradation mixes. The study analyzed PAPs using KENPAVE software. The findings indicated that fewer allowable repetitions to fatigue and rutting failures were observed for thinner Porous Asphalt Concrete (PAC) layer thicknesses. This suggests that thicker PAC layers may offer better resistance to fatigue and rutting failures in pavement systems. The study found that the nature of subgrade material significantly influenced the rutting performance of PAP systems. Specifically, clayey soils exhibited a 77.74% reduction in the design life of the pavement compared to gravelly soil subgrades. This highlights the importance of considering subgrade characteristics in pavement design and construction to optimize pavement performance and longevity. Higher contact pressures resulted in higher tensile stresses at the bottom of PAC layer which in turn reduced the fatigue life of PAP. The findings from ABAQUS analysis indicated that an increase in the void percentage in Porous Asphalt Concrete (PAC) mixes led to a significant increase in horizontal tensile strain at the bottom of the PAC layer, with a 12.3% increase observed. Additionally, there was a noticeable increase in tensile strain for a PAC mix with 28% voids compared to a mix with 16% voids. This suggests that higher void percentages in the PAC mixes can potentially enhance the flexibility and deformation resistance of the pavement structure, which may contribute to improved performance under various loading conditions, hence leading to 92.8% reduction in allowable load repetitions to fatigue failure.

The study further revealed that an increased void percentage in Porous Asphalt Concrete (PAC) mixes resulted in a decrease in vertical stress and deflection in the PAP system. However, no significant effect on the allowable repetitions to rutting failure was observed. This suggests that higher void percentages may lead to better load distribution and reduced vertical stresses within the pavement structure, contributing to improved performance in terms of stress and deflection.

Moreover, Asphalt Pavement mixes were compiled to develop an Artificial Neural Network (ANN) prediction model. The results demonstrated good conformity between predicted and actual data, with a mean square error of 0.109 and a coefficient of correlation of 0.994. This indicates that the ANN model accurately predicts pavement performance based on the compiled asphalt pavement mixes, providing a valuable tool for pavement design and analysis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Porous Asphalt Pavement (PAP) serves as a deliberate departure from traditional impermeable asphalt pavements. Unlike conventional pavements, which direct rainfall and runoff into catch basins, PAP is specifically engineered to facilitate the infiltration of water through its surface. This unique characteristic makes PAP a highly sought-after solution, particularly in areas plagued by drainage issues.

The construction of PAP involves laying down an open-graded stone bed beneath the asphalt surface. This underlying structure acts as a conduit for water, allowing it to drain freely through the pavement. As rainfall and runoff permeate the PAP surface, they are directed into the stone bed reservoir. This reservoir is designed to temporarily hold the water before gradually releasing it into the natural ground below.

By allowing water to infiltrate through the pavement surface and into the underlying stone bed, PAP effectively manages stormwater runoff, mitigating the risk of flooding and reducing strain on existing drainage systems. This innovative approach to pavement design not only addresses drainage concerns but also contributes to environmental sustainability by promoting groundwater recharge and reducing the burden on municipal stormwater infrastructure. Consequently, PAP has emerged as a favored solution for enhancing both the functionality and resilience of paved surfaces in diverse geographical settings.

Porous Asphalt Pavement has proven to be a promising technique [1,2,3,4,5,6] and effective in enhancing the traffic safety in rainy weather, reducing splash and spray on the roads, having good skid resistance at elevated speeds [7]. Also, PAP is getting attention due to remarkable performance in drainage, noise reduction, stormwater management and treatment, mitigation of floods and urban heating island effect [8,9,10]

The performance of Porous Asphalt Concrete (PAC) is not only governed by material properties but also the distribution of constituents of PAC mix and formation of voids [11,12,13,14]. The voids in PAC mix play a vital role in determining the functional performance of PAC. Many researchers have evaluated the relation between air voids and hydrological performance of PAC. Jiang et al. (2015) reported that air void contents not only affected the functional performance of Porous Asphalt Concrete (PAC), but void features were also significantly influenced by nominal maximum aggregate size (NMAS) and aggregate gradation. High temperature performance shear and anti-clogging ability were detected for coarse gradation, while anti-stripping and noise reduction ability were observed for fine gradations. Król et al. (2018) linked permeability performance of PAC with pore structure, observing high permeability values for PAC mixes with maximum aggregate size. It was suggested that the fine content in PAC should be low enough to avoid the closure of void spaces, resulting in low permeability of Porous Asphalt Pavement (PAP). Mixtures containing a high amount of fine aggregates indicated more resistance to deformation but produced a low coefficient of permeability (Ahmad et al., 2018). Chen and Wong (2015) established a relation between aggregate gradation and permeability performance of PAC pavement, recommending less than 7% fines in PAC mix for suitability in wet environments.

Abdullah et al. [7] studied the influence of aggregate type and its gradation on the voids in mineral aggregate and air voids of asphalt concrete paving mixtures. They concluded that a coarser mix resulted in a higher rate of increase in water permeability for the same type of aggregate. In the current study, Finite Element Modeling (FEM) is employed to investigate the structural behavior of Porous Asphalt Pavement (PAP) using ABAQUS software. ABAQUS is a powerful finite element analysis tool commonly used for simulating the behavior of complex structures subjected to various loading and environmental conditions.

Numerous researchers have utilized ABAQUS software to evaluate the structural behavior of flexible pavements, including both conventional and porous asphalt pavements. Through finite element analysis, researchers can simulate the response of pavement structures to different types of loads, such as traffic loading, thermal effects, and environmental factors.

By conducting FEM analysis with ABAQUS, researchers can determine critical structural criteria for pavement performance, including stresses, strains, deformation, fatigue life, and rutting behavior. This allows for a comprehensive understanding of how different design parameters, material properties, and environmental conditions influence the structural integrity and longevity of PAP.

Overall, the use of ABAQUS software for Finite Element Modeling enables researchers to gain valuable insights into the structural behavior of Porous Asphalt Pavement, facilitating the development of optimized pavement designs and maintenance strategies. The study by Yassenn et al. [15] focused on Finite Element Modeling (FEM) of flexible pavements to assess their structural criteria. In particular, the researchers aimed to evaluate the effects of stress and strains induced by traffic loading on the fatigue and rutting damage life of the pavement structure.

Linear elastic modeling was employed in the study to simulate the behavior of normal pavements under typical loading conditions. Linear elastic modeling is a common approach in pavement analysis where materials are assumed to behave linearly elastic within the range of stresses encountered during service life. This approach is suitable for assessing the structural response of pavements to normal traffic loads.

By employing linear elastic modeling in their FEM analysis, Yassenn et al. were able to accurately capture the stress and strain distribution within the pavement structure under various loading conditions. This allowed them to evaluate the fatigue life and rutting resistance of the pavement based on the predicted structural response.

Overall, the study by Yassenn et al. demonstrates the utility of Finite Element Modeling, particularly using linear elastic modeling, for assessing the structural performance of flexible pavements and predicting their durability under traffic loading. Huang, J et al. [16] carried out FEM analysis to evaluate dynamic behavior of asphalt pavement structure. Analysis of the results reveal when surface layer thickness is increased, pore-water pressure in surface layers increase correspondingly and hence is disadvantageous for resistance of pavement for water-induced damages. Further increase of modulus of the surface layer leads to reduction of the pore-water pressure thus increasing shear stress. Hongchang, W. et al. [17] analyzed double layer porous asphalt pavement for noise reducing property. Results reveal that sound absorption coefficient for porous asphalt is related to acoustic frequency and reabsorption coefficient rises to peak in case of double layer porous asphalt pavement. In the study conducted by Gao et al. (2017), the cooling effect of porous asphalt pavement was investigated using ABAQUS software. The researchers aimed to understand how the air voids within the porous asphalt pavement influenced its ability to reduce surface temperature and mitigate the urban heat island effect.

Through Finite Element Modeling (FEM) with ABAQUS, Gao et al. simulated the thermal behavior of porous asphalt pavement under various environmental conditions. By varying the air void content within the pavement structure, they were able to analyze its impact on heat dissipation and surface temperature reduction.

The study revealed a positive linear correlation between the cooling effect of porous asphalt pavement and the percentage of air voids. This suggests that higher air void content within the pavement leads to more effective heat dissipation and consequently lower surface temperatures.

Overall, the findings of this study provide valuable insights into the thermal performance of porous asphalt pavement and highlight the importance of air voids in enhancing its cooling effect, which can contribute to mitigating the urban heat island effect in urban environments.

The passage highlights the significant gap in research concerning Porous Asphalt Pavement (PAP) despite its importance. Several key aspects of PAP's structural behavior remain unexplored, including its response to diverse loading and environmental conditions, the influence of different mix proportions on stress and strain distribution within PAP layers, and the relationship between void percentage and structural response.

To address these gaps, the present study aims to develop a comprehensive understanding of PAP's structural behavior. It intends to leverage Finite Element Modeling (FEM) with ABAQUS and KENPAVE software to simulate PAP's response under various loading and environmental scenarios. By conducting detailed analyses, the study seeks to elucidate the role of different mix proportions in shaping the stress and strain experienced by PAP layers.

Furthermore, the study aims to establish a predictive model for PAP's structural behavior, utilizing both traditional engineering software and advanced techniques such as Artificial Neural Networks (ANN). This predictive model will enable researchers and practitioners to anticipate the performance of PAP under different conditions and optimize its design and construction accordingly.

One notable study by Li et al. [18] investigated the application of ANN models for air void prediction in porous asphalt mixes. The researchers developed ANN architectures trained on extensive datasets of mix parameters and corresponding air void content. Their findings demonstrated the ability of ANN models to effectively predict air void content, offering a promising alternative to traditional empirical methods.

Similarly, Zhang et al. [19] conducted a comprehensive review of ANN applications in various aspects of asphalt pavement engineering, including air void prediction for porous asphalt mixes. The review highlighted the versatility of ANN models in capturing complex nonlinear relationships inherent in mix design parameters and air void content. The authors emphasized the potential of ANN as a robust tool for enhancing the accuracy and efficiency of air void prediction models.

Furthermore, a study by Wang et al. [20] focused specifically on the development of ANN-based models for air void prediction in porous asphalt mixes considering a wide range of mix design variables. Their results indicated that ANN models outperformed conventional regression-based approaches, providing more accurate and reliable predictions of air void content.

Additionally, Gharaee et al. [21] investigated the integration of ANN models with genetic algorithms for optimizing porous asphalt mix designs based on desired air void content specifications. Their hybrid approach demonstrated superior performance in achieving target air void levels while minimizing the need for extensive trial-and-error experimentation.

Overall, by addressing these research gaps and developing predictive models, the study endeavors to advance the understanding and application of Porous Asphalt Pavement, ultimately contributing to the development of more resilient and sustainable transportation infrastructure.

2 Methodology

Stage 1: Data collection and analysis

-

Gather data on gradations of porous asphalt mixes from seven selected research studies [22,23,24,25,26,27,28].

-

Analyze the gradation information to understand the diverse mix parameters influencing the characteristics of porous asphalt concrete (PAC) mixtures.

Stage 2: Development of ANN prediction model

-

Utilize the NNTOOL Programme to construct an artificial neural network (ANN) prediction model.

-

Aim the model at estimating the void content of various porous asphalt mixes based on the analyzed gradation information.

-

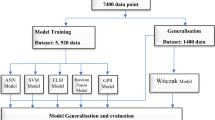

The input parameters and neural network architecture, including varying numbers of neurons in the hidden layer (10, 14, and 20), were analyzed to determine the optimal configuration for the neural network, as depicted in Table 1, Fig. 1, Fig. 2, and Fig. 3, respectively

Stage 3: Mechanistic analysis using KENPAVE software

-

Conduct mechanistic analysis using KENPAVE software to anticipate the structural performance of porous asphalt concrete (PAC) pavements.

-

Evaluate functional performance under varying thicknesses of PAC layers, different axle configurations, and diverse subgrade soils.

-

Design test sections for porous asphalt pavement (PAP) with four layers: PAC wearing course, choker course, stone bed recharge layer, and subgrade layer [29].

-

Examine several potential cross-sections for the PAC wearing course and choker course, resulting in eight cross-section configurations obtained through thickness variation as outlined in Table 2.

-

Incorporate various types of soils and their respective properties as detailed in Table 3.

-

Utilize data from Table 4 to assess the impact of different axle configurations and increased tire pressure on pavement responses and design life.

Stage 4: Structural response analysis using ABAQUS software

-

Model porous asphalt pavement (PAP) with real pores using ABAQUS software.

-

Assume square-shaped pores extending vertically from the top to the bottom of the PAC layer.

-

Assume a uniform distribution of a 40 KN wheel load over the contact surface with a tire pressure of 700 kPa.

-

Analyze PAC layers with different void percentages ranging from 16.4% to 28%, maintaining a constant pore size of 3 mm x 3 mm.

-

Limit the size of the top PAC layer with pores to 210 × 200 mm for computation, ensuring coverage of a stress area of 198 × 144 mm.

-

Set dimensions of the choker course, stone bed reservoir, and subgrade to 1400 × 600 mm to represent half the width of the pavement.

-

Employ tetrahedral elements for proper meshing of pores within the PAC layer as in Fig. 4.

3 Result and discussions

3.1 Development of ANN prediction model

The collected data offered valuable insights into the factors influencing permeability and voids within PAC mixes. A correlation between total voids and the permeability coefficient of PAC was established, as depicted in Fig. 5. Artificial Neural Networks (ANN) were effectively deployed to construct a prediction model based on the gathered data regarding porous asphalt gradations. The ANN application primarily aimed at forecasting void percentages within specific PAC mixes. Employing a three-layered feed-forward error-backpropagation ANN architecture, a 15-10-1 model was identified as the optimal predictor, exhibiting a correlation coefficient of 0.994 and a mean square error of 0.106, as illustrated in regression plots in Fig. 6. Evaluation of this model using test data from 15 samples, depicted in Fig. 7, revealed a strong agreement between predicted and actual void percentages of PAC gradation. Furthermore, the model was utilized to investigate the impact of mix parameters on PAC, particularly focusing on the effect of Optimum Binder Content (OBC). Analysis indicated that an increase in OBC led to a reduction in void percentage for the respective mix.

3.2 Analysis of porous asphalt pavement in KENPAVE software

The KENPAVE analysis outputs provide insights into variations in maximum deflection, vertical stresses, tensile strain, and compressive strain along the depth of pavement for each analyzed cross-section. For rutting analysis, the focus is on the Maximum Horizontal Tensile Strain (εt) at the bottom of the PAC layer and the Maximum Vertical Compressive Strain (εz) at the top of the sub-grade layer. These values assist in estimating the maximum allowable number of load repetitions to prevent rutting and fatigue failures simultaneously for any given cross-section.

Graphical analysis reveals that cross-section E allows for the highest number of load repetitions concerning fatigue cracking (Nf) and rutting failure (Nr). Specifically, cross-section E accommodates 2.8E+06 cycles of single axle dual wheel load for fatigue cracking and 2.7E+08 cycles for rutting failure, making it the optimal arrangement in terms of pavement performance. The layer thicknesses for cross-section E are PAC top layer = 10 cm, Choker course = 5 cm, and Stone bed reservoir = 45 cm.

The KENPAVE results for cross-section E with various sub-grade materials offer insights into expected pavement damage during its service life, along with damage ratios and the expected design life of the pavement. For instance, the design life of pavement with gravelly soil sub-grade, the preferred soil for porous asphalt pavement construction due to its good permeability, is estimated at 15.32 years with a minimal damage ratio of 0.0653. Conversely, clay soil results in a maximum damage ratio of 0.3, leading to a 77.74% reduction in design life compared to gravelly soil sub-grade.

Additionally, KENLAYER analysis effectively evaluates the impact of different axle configurations and tire pressures on porous asphalt pavement performance. Notably, the maximum design life of 15.32 years is achieved with a single axle dual wheel assembly and a contact pressure of 550 kPa, while the least design life of 2.37 years occurs with a tandem axle dual wheel configuration and a contact pressure of 875 kPa. Various contact pressures for tandem axle dual wheel configurations yield different results, with the maximum design life of 9.6 years observed at 480 kPa.

Results indicate that the maximum damage ratio at the bottom of the top PAC layer is highest for the tridem axle configuration and tandem axle assembly with 875 kPa tire pressure. Conversely, damage ratios at the top of the sub-grade layer are minimal, indicating minimal tire pressure effects on pavement rutting damage.

3.3 Analysis of porous asphalt pavement in ABAQUS software

Before modeling Porous Asphalt Pavement (PAP) in ABAQUS, a comparative analysis was conducted between KENPAVE and ABAQUS to assess the latter's suitability for modeling pavement structures and evaluating critical responses. The results of this comparison indicate that ABAQUS software is well-suited for modeling PAP, yielding comparable outcomes to those obtained from KENPAVE.

The utility of ABAQUS was further examined by incorporating actual pores within the PAC layer, a capability not available in KENPAVE. Successfully, Porous Asphalt Pavement was modeled in ABAQUS with realistic pores represented in the top PAC layer. The analysis conducted in ABAQUS, as depicted in Fig. 8, demonstrates that as the void percentage in the PAC mix increases, the vertical stress dissipated beneath the PAC layer decreases. For instance, at a void percentage of 16.4%, the vertical stress under the PAC layer measures 267 kPa, whereas with 28% voids, the vertical stress decreases to 243 kPa. Consequently, the displacement beneath the PAC layer decreases with an increase in the percentage of voids in the PAC mix.

It is notable that an increase in the percentage of voids within the PAC mix corresponds to an escalation in horizontal tensile strain at the bottom of the PAC layer, consequently hastening the onset of fatigue failure in the pavement. For instance, at the lowest void percentage of 16.4%, the horizontal tensile strain at the bottom of the PAC layer measures 2.48e−04, while at the highest void percentage of 28%, this strain increases to 5.53e−04. Correspondingly, the number of repetitions allowable before fatigue failure occurs is 7.8e+05 for 16.4% voids and reduces to 5.6e+04 for 28% voids. The influence of horizontal stress predominantly affects the PAC layer, with horizontal tensile stresses beneath the wheel load escalating with an increase in the percentage of voids. In the void percentage range of 16 to 19%, the horizontal strain at the bottom of the PAC layer remains below 3E-04, resulting in minimal reduction in the allowable number of repetitions before fatigue failure. As depicted in Fig. 9, it is evident that the void content within the PAC layer has a more pronounced effect on horizontal tensile strain beneath the PAC layer compared to vertical compressive strains. Since horizontal tensile strain beneath the PAC layer is responsible for fatigue failure in the pavement, an increase in the total void percentage within the PAC layer may accelerate the deterioration of porous asphalt pavement due to a reduced number of allowable repetitions before fatigue failure occurs.

4 Conclusion

-

1.

Thickness of PAC layer significantly impacts pavement performance, affecting both fatigue and rutting failures. Increased thickness allows for more load repetitions to fatigue and rutting failure, while decreasing thickness reduces these allowances.

-

2.

Clayey subgrade soil results in a drastic reduction in the design life of PAP due to rutting failure. However, subgrade soil has minimal impact on fatigue failure and load repetitions to fatigue failure.

-

3.

Higher tire pressures increase stresses at the bottom of the PAC layer, leading to accelerated fatigue failure. Rutting failure, however, is less affected by tire pressure variations.

-

4.

Increasing void content in PAC layer decreases vertical compressive stress and displacement but increases tensile stress at the bottom layer, raising the risk of fatigue failure.

-

5.

An ANN prediction model effectively predicts void content in PAC mixes, showing high correlation with actual void percentages, indicating its potential for use in evaluating void content with low error rates.

Data availability

The authors declare that the data supporting the findings of this study are available. Upon request, the data can be provided by contacting the corresponding author (Mr. Yateen Lokesh).

References

Ahmad KA, Hassan NA, Abdullah ME, Bilema MA, Usman N, Hainin MRB. Image processing procedure to quantify the internal structure of porous asphalt concrete. Multidiscip Model Mater Struct. 2019. https://doi.org/10.1108/MMMS-08-2017-0073.

Chen MJ, Wong YD. Gradation design of porous asphalt mixture (PAM) for low-strength application in wet environment. Int J Pavement Eng. 2018;19(7):611–22.

Gao L, Wang Z, Xie J, Liu Y, Jia S. Simulation of the cooling effect of porous asphalt pavement with different air voids. Appl Sci. 2019;9(18):3659.

Imaninasab R, Bakhshi B, Shirini B. Rutting performance of rubberized porous asphalt using finite element method (FEM). Constr Build Mater. 2016;106:382–91.

Kumar, Harish. (2013). ANalysis Of flexible pavement using kenlayer (Master’s thesis, National Institute of Technology - Kurukshetra).

Liu M, Huang X, Xue G. Effects of double layer porous asphalt pavement of urban streets on noise reduction. Int J Sustain Built Environ. 2016;5(1):183–96.

Abdullah WS, Obaidat MT, Abu-Sa’da NM. Influence of aggregate type and gradation on voids of asphalt concrete pavements. J Mater Civil Eng. 1998;10(2):76–85.

Ahmad KA, Abdullah ME, Hassan NA, Daura HA, Ambak K. A review of using porous asphalt pavement as an alternative to conventional pavement in stormwater treatment. World J Eng. 2017;14(5):355.

Cahill T, Adams M, Marm C. 2003 Porous asphalt: the right choice for porous pavements. HMAT: Hot Mix Asphalt Technology, 8(5)

Mansour TN. (2011). Investigation of the effect of aggregate gradation on open graded friction course mixtures (Doctoral dissertation, Clemson University).

Lokesh Y, Parate HR, RajashekharSwamy HM. Study on effect of porous asphalt pavements on flood mitigation for Bangalore city. Int J Multidiscip Resea Growth Evaluation. 2022;3(2):38–46.

Sanjana YC, Nikhil TR, Lokesh Yateen. Performance evaluation of hot mix asphalt using modified binders for bituminous concrete grade-2. Int J Civil Eng. 2018;5(9):12–7.

Gopinath R, Ylokesh. Study on strength and physical properties of bituminous concrete grade-1 mix, with e-waste ceramics as replacement to aggregates. Sci Israel-Technol Adv. 2015;17(4):184.

Zhang H, Wang J, Liu Y. Review of artificial neural network applications in asphalt pavement engineering. J Infrastruct Syst. 2017;23(1):04016029.

Yassenn OM, Rohani I, Endut D, Ishak SZ, Hafez MA, Yaseen HM. 2015. Finite element modelling of flexible pavement. Parameters, 2(1).

Huang J, Pan X, Dai SB, Cai Y. (2015). FEM analysis of dynamic behavior of asphalt pavement structure weakened by grassroots with account of hydraulic and vehicle load coupling effects. In IOP Conference Series: Mater Sci Eng, 103(1), 012038.

Hongchang W, Huang X, Liao G, Guoqiang X. Finite element analysis for noise-reducing of double-layer porous asphalt pavement. In Road Pavement Mater Charact, Model, Maint. 2011. https://doi.org/10.1061/47624(403)22.

Li Y, Wu S, Wu K, Li S. Application of artificial neural networks in air void prediction for porous asphalt mixes. J Pavement Eng. 2014;20(6):521–36.

Zhang Y, Leng Z. Quantification of bituminous mortar ageing and its application in ravelling evaluation of porous asphalt wearing courses. Mater Des. 2017;119:1–11.

Wang L, Huang B, Zhang Z. Development of ANN-based models for air void prediction in porous asphalt mixes. Constr Build Mater. 2019;223:165–74.

Gharaee K, Shiravand Y, Alavipanah SK. Integration of artificial neural networks with genetic algorithms for optimization of porous asphalt mix designs. J Trans Eng, Part B: Pavements. 2020;146(4):04020026.

Chen JS, Chen SF, Liao MC. Laboratory and field evaluation of porous asphalt concrete. Asian Trans Stud. 2015;3(3):298–311.

Chen M. (2016). Design and performance of porous asphalt mixture for pedestrian/cyclist applications in Singapore (Doctoral dissertation).

Jiang W, Sha A, Xiao J. Experimental study on relationships among composition, microscopic void features, and performance of porous asphalt concrete. J Mater Civ Eng. 2015;27(11):04015028.

Król JB, Khan R, Collop AC. The study of the effect of internal structure on permeability of porous asphalt. Road Mater Pavement Des. 2018;19(4):935–51.

Setiawan A. Design and properties of hot mixture porous asphalt for semi-flexible pavement applications. Media TeknikSipil. 2009;5(2):41–6.

Suresha SN, George V, Shankar AR. Effect of aggregate gradations on properties of porous friction course mixes. Mater Struct. 2010;43(6):789–801.

Van Heystraeten G, Moraux C. (1990). Ten Years’ Experience Of Porous Asphalt In BelgiUM. *Transportation Research Record, *(1265).

Hall KD, Schwartz CW. Development of structural design guidelines for porous asphalt pavement. Transp Res Rec. 2018;2672(40):197–206.

Acknowledgements

Authors are thankful to Ramaiah University of Applied Sciences, Bangalore for extending their support with the necessary facilities in conducting the research.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript. Authors declare that no funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Yateen Lokesh, Dr. Harshad R Parate, Dr. H M Rajashekhar Swamy and Humaira Ali. The first draft of the manuscript was written by Yateen Lokesh and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lokesh, Y., Parate, H.R., Swamy, H.M.R. et al. Development of prediction model for structural behavior and gradation of porous asphalt pavement. Discov Civ Eng 1, 12 (2024). https://doi.org/10.1007/s44290-024-00012-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44290-024-00012-y