Abstract

Background

The use of local foods has been widely recognized as a sustainable strategy to address micronutrient deficiencies among resource-constrained households in rural areas in developing countries. Acholi sub-region of Uganda has recently recorded a high prevalence of micronutrient deficiencies due to inadequate iron, zinc, and calcium contents in complementary foods. Thus the sub-region was used as a case study to examine the potential of amaranth grain-silverfish-iron rich beans micronutrient dense composite flour in improving nutritional quality of complementary foods.

Design

Microsoft Excel was used to derive ingredient combinations based on the micronutrient requirements. Laboratory analyses were used to determine (1) nutritional quality; (2) functional properties and; (3) storage stability of the micronutrient-dense composite flour. Data was analysed using a one-sample t-test and analysis of variance by Statistical Package for Social Sciences (SPSS) version 25.

Results

The micronutrient-dense composite flour contained 19 mg/100 g, 13 mg/100 g, and 354 mg/100 g of iron, zinc, and calcium, respectively. The cost (0.037–0.058 USD) of the micronutrient-dense composite flour required to meet the RDA for iron and zinc among children 6–24 months old was found lower than the cost (4.81 USD) of a sachet of standard micronutrient powder equivalent to RDA. The product exhibited low bulk density (0.68 g/l), high water solubility index (25.56–29.16%), and short reconstitution time (40.00–45.00 s), and remained safe during the entire 70 days of storage. Theoretically, daily enrichment of complementary foods for children 6–11 and 12–24 months old with 58 and 37 g of the composite, respectively would contribute 100% of the recommended dietary allowance for iron and zinc and 50% for calcium.

Conclusion

The developed micronutrient-dense composite flour has the potential to improve the micronutrient quality of complementary foods. A concerted effort is required to promote its use as a strategy to address micronutrient deficiencies among children 6–24 months in resource-constrained settings.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Globally, malnutrition accounts for 45% of child mortality annually and the trend is projected to increase [1]. Children who survive death due to malnutrition often have impaired development including cognitive function, which in turn undermines learning outcomes and attainment of full potential in adulthood [2]. Globally, 162 million children under five years have low height-for-age (stunting) [3] whereas up to 45.4 million have low weight-for-height (wasting) with Sub-Saharan Africa being one of the most affected regions [4]. Uganda is one of the countries in Sub-Saharan Africa which experiences high prevalence of malnutrition. Indeed, the prevalence of stunting, wasting, and underweight among children under five years stands at 29%, 4%, and 11%, respectively whereas death due to poor nutrition has been estimated at 88 per 1000 live births which translates to a mortality rate of about 8.8% [5]. Specifically, the Acholi sub-region of Uganda has had 30.6, 15.4, and 3.9% of children under five years being stunted, underweight, and wasted, respectively [6]. As such, the Acholi sub-region is among the sub-regions in Uganda with high malnutrition prevalence based on the aforementioned stunting, wasting, and underweight prevalence statistics [7]. Associated with this high level of malnutrition indicators are deficiencies of essential micronutrients such as iron, zinc, and calcium [8].

Micronutrient deficiencies are a threat to the well-being of young children ages 6–24 months due to their high demand for growth and development of the body [9]. Micronutrient deficiencies have largely been attributed to household food insecurity that often results in the routine consumption of predominantly carbohydrate-based foods, which are known to contain limited quantities of minerals and vitamins [10]. The occurrence of micronutrient deficiencies among children in a given population causes both direct and indirect impairments in psychoemotional, social, behavioural, and cognitive development [11]. For instance, minerals such as iron, zinc, and calcium promote a healthy immune system, act as cofactors in metabolic pathways, and maintain homeostasis in the body [12]. Despite these benefits, iron deficiency among children under five years has been estimated at 43% globally [13] and at 71% in the Acholi sub-region of Uganda [5]. On the other hand, calcium deficiency has been associated with a peak incidence of rickets among infants and young children 6–23 months old [14]. Accordingly, 9.5% of children diagnosed with severe pneumonia at Uganda’s national hospital also presented with nutritional rickets [15]. This observation could be a snapshot for other regions of the country since not all patients visit the national referral hospital. Furthermore, low zinc status is estimated at 17–29.6% globally and children are the most affected, especially in developing nations which account for 4% of childhood deaths due to low zinc status [16]. Micronutrient deficiencies among children 6–24 months old in Sub-Saharan African countries has been associated with low contents of the respective micronutrients in complementary foods thus leading to inadequate intake [17, 18]. Similar observations have been made in the Acholi sub-region where iron, zinc, and calcium intake are inadequate in commonly used complementary foods (maize/millet flour porridges) [8]. This situation if left unattended can potentially lead to compromised human capital development in the sub-region and country at large, taking into account the positive impact of good nutrition in childhood on healthy growth, education, and human potential in adulthood [19]. Furthermore, annual gross domestic product loss due to malnutrition has been estimated at 11% for Asia and Africa [20]. In monetary terms, preventing malnutrition has been estimated to deliver 16 United States Dollars (USD) as a return on investment for every dollar spent [20]. In the context of developing countries such as Uganda, it is therefore apparent that preventing malnutrition by food enrichment using nutrient-dense locally formulated food composites does not only contribute to better health outcomes but also economic development.

Amaranth grains, iron-rich beans, and silverfish are rich in iron, zinc, and calcium. The aforementioned ingredients are readily available in the study community, and provide an opportunity for formulating nutrient-dense flour for the enrichment of complementary food. Amaranth grains for instance contain 17.4, 3.7, and 175 mg/100 g of iron, zinc, and calcium, respectively [21] whereas 100 g of iron-rich beans contain 10, 33, and 113 mg of iron, zinc, and calcium, respectively [22]. On the other hand, one hundred grams of silverfish contain 8.18–10.91, 4.07–10.25, and 1556.4–1866.5 mg of iron, zinc, and calcium, respectively depending on the form of silverfish, that is, fresh, boiled or dried [23]. As such, these foods have the potential of complementing one another when formulated and used for routine enrichment of complementary food(s). Furthermore, these three ingredients are fairly affordable and hence suitable for resource-constrained households, which are unable to access commercial micronutrient powders for complementary feeding such as those in the Acholi sub-region of Uganda [5]. However, despite the nutritional value of amaranth grains, iron-rich-beans, and silverfish and their availability in the study community, they remain underutilized as a composite for complementary food enrichment, and limited information is available on nutritional quality, functional properties, and storage stability of Micronutrient Dense Composite Flour (MDCF) formulated from these ingredients. Therefore, this study sought to develop MDCF from amaranth grains, iron-rich beans, and silverfish for routine enrichment of commonly used complementary foods in the Acholi sub-region of Uganda.

2 Materials and methods

2.1 Study area and population

This study was carried out in Lamwo district in Acholi sub-region located in the Northern part of Uganda (supplementary material I) in which iron, zinc, and calcium deficiencies attributable to limited micronutrient quality of complementary foods in the community have been reported [8]. For instance, the highest anaemia prevalence (71%) among children ages 6–24 months nationally has been reported in the sub-region [5]. Children ages 6–24 months were the target population in this study mainly because they rely largely on complementary feeding for nutrient intake and are at risk of micronutrient deficiencies if fed foods of low nutrient quality. Complementary food used in rural areas of Uganda is usually porridge, and largely constituted by carbohydrates [24]. This could explain the high prevalence of micronutrient deficiencies as documented in the latest national demographic and health survey report [5]. Therefore, it was found extremely vital to improve the micronutrient quality of complementary foods through the development of MDCF for routine enrichment.

2.2 Development of micronutrient-dense composite flour

Study materials (silverfish [R. argentea], iron-rich beans [Naro 4C], and amaranth grains [A. hypochondriacus]) were purchased from local markets in Lamwo district (03031’N 32°47’E). This involved the purchase of four samples of two kilograms each per ingredient from at least 5 different stalls (n = 20), and thorough mixing to ensure uniformity as well as sample representativeness. The ingredients were purchased from different sellers to account for variations in the nutritional composition of ingredients due to differences in soil fertility, length of time the crops take on the farm before harvesting, health status of the crops on the farm, and the postharvest process involved [25]. To develop the composite flour, pebbles were removed from iron-rich beans by handpicking followed by winnowing. Thereafter, the beans were washed and soaked in distilled water for 6 h. The soaking water was then drained, and the beans dried under sunshine for forty-eight hours and stored at ambient temperature (approximately 28 °C ± 2). Silverfish were handpicked to remove unwanted solid matter such as stones and washed with distilled water. They were then dried in the sun and stored as in the case of beans. Amaranth grains were sorted, winnowed, and washed in distilled water to remove stones, leaves, and dust. Distilled water was then used for steeping the grains for 7 h followed by germination at ambient temperature (approximately 28 °C ± 2) in perforated black polythene bags for forty-eight hours. Germinated grains were then sun-dried for forty-eight hours, and the rootlets were removed after. All ingredients were then roasted separately in open saucepans mounted on charcoal stoves and allowed to cool at room temperature in readiness for subsequent processes. Roasted ingredients were mixed to yield a composite formula that fits the recommended dietary allowance (RDA) of 11 and 3 mg/day for iron and zinc, respectively, and RDA of 270 mg/day for calcium for children 6–11 months while covering slightly more than half of calcium demand for children 12–24 months [26]. Considering the sub-age categories, the formulation prioritized iron, zinc, and calcium in decreasing order following the recent report which showed that deficiencies of these micronutrients in the study community are associated with limited micronutrient quality of complementary food, especially iron and zinc [8]. Formulation was based on deficits in iron intake relative to the RDA requirements for children 6–11 months which stood at 5 mg/day as compared to that for children 12–24 months which stood at 1 mg/day [8]. Besides, a formulation that meets the RDA of 11 mg of iron/day for the 6–11 months age group would automatically meet that of 7 mg/day RDA for the 12–24 months age sub-group. Therefore, the formulation was done using Harvest Plus Food Composition Table [27] and Microsoft Excel [28]. Specifically, a linear equation with a fixed value for iron at 11 mg/day and varying concentrations of ingredients was developed. The proportion of ingredients providing the aforementioned quantity of iron was determined intuitively and later adjusted based on recommended acceptable levels [29] as shown in Table 1 in the results section. The composite was then milled into flour using a hammer mill (0.1 mm sieve). The composite was prepared in duplicate and subjected to laboratory analyses within 12–24 h and subsequently after 14-day intervals for 70 days for storage stability analysis upon storage at ambient temperatures (28 °C ± 2) in high-density polythene (HDPE). For all laboratory analyses, the samples were analyzed in triplicates. A schematic diagram showing the production process of MCDF is provided in Supplementary Material II.

2.3 Determination of nutritional quality and cost-effectiveness of the micronutrient-dense composite flour

For all laboratory analyses, the samples were analyzed in triplicates. The micronutrient-dense composite flour was analyzed for moisture, crude fibre, crude protein, crude ash, crude fat, total carbohydrate, iron, zinc, and calcium content, and anti-nutritional factors (phytates and tannins) at Gulu University laboratories. Moisture content was analyzed by oven drying method using a hot air oven (Huanghua Faithful Instrument, Huanghua, China) according to the Association of Official Analytical Communities (AOAC) 1995 method number 925.10-32.1.03. Ash analysis followed the dry ashing method using a muffle furnace (VELP Scientifica, New York, United States of America) according to AOAC (1995) method number 923.03-32.1.05. Crude protein was analyzed according to the Micro Kjeldahl method following digestion and automatic distillation [30]. Briefly, the samples were digested at 420 °C using concentrated sulphuric acid in a digestion block (VELP Scientifica, New York, United States of America) to liberate organic nitrogen as ammonium ions. The digests were then distilled using water, sodium hydroxide, and boric acid to form ammonium salt using an automated Kjeldahl machine (VELP Scientifica, New York, United States of America). The distillates were then titrated using 0.1N Sodium hydroxide while continuously being stirred using a magnetic stirrer to determine the nitrogen content. The nitrogen content was then multiplied by a constant factor of 6.25 to obtain the protein content. Crude fat was determined using the AOAC Soxhlet method (2005: method number 920.39C) using a soxhlet fat extractor (Shamboo Scientific Glass Works, Ambala, India). Accordingly, organic solvent (hexane) was used to extract fat from food samples and the solution was evaporated, causing the solvent to vaporize while leaving fat. The weight of the fat was then determined and expressed as a per cent of the initial sample weight. Crude fibre analysis followed the Weende method according to AOAC (method number: 978.10) using a raw fibre extractor (VELP Scientifica, New York, United States of America). Upon determination of sample moisture content, the samples were hydrolyzed using sulphuric acid and potassium hydroxide solutions. The residue was then dried in a hot air oven overnight and subsequently ashed as previously explained for ash content. Crude fibre was therefore determined by the weight difference of the residue before and after ignition. The percentage of total carbohydrate was determined by difference method [31]. This method is based on the assumption that carbohydrate is originally any compound in food that is not protein, fat, moisture, fibre, or ash. The findings of these analyses were compared to standard cut-off values as well as findings of similar studies to determine the suitability of the product for its application. For instance, the proximate parameters of MDCF were compared to the standard cut-off of < 10.00%, < 5.43%, > 15.20%, 8.15–8.50%, < 2.17%, and 48.90% for moisture content, crude ash, crude protein, crude fat, crude fibre, and carbohydrates, respectively [32]. Crude ash in particular is an indication of the total quantity of minerals available in the product [33] and this reflects the research concept of dense mineral content of the product. On the other hand, phytate and tannin contents were compared to maximum limits of < 25 and < 10 mg/100 g for phytates and tannins, respectively which is an indication of the bioavailability of micronutrients [34].

Micronutrient composition (iron, zinc, and calcium) was determined by the AOAC method (1995: method number 970.12) [35]. This involved acid digestion to remove the sample matrix thus leaving the minerals followed by atomic absorption spectrometry (AAS), which assumes absorption of atoms of a particular mineral is proportional to the concentration of the mineral present in the sample. An atomic absorption spectrophotometer (Perkin Elmer, Waltham, USA) was used. Phytate and tannin determination followed ultra-violet visible spectroscopy. This method measures the absorbance of a sample which is equivalent to the concentration of phytate or tannin in that sample. Accordingly, the anti-nutritional factor (phytate or tannin) was first extracted from the sample using hydrochloric acid followed by isolation from lower esters, and finally quantified by measuring absorbance. Phytate analysis in particular followed the AOAC method (986.11) [36] and the absorbance was read at 640 nm using an ultraviolet–visible spectrophotometer (Beckman instruments, California, USA). On the other hand, tannin levels were determined according to the vanillin-HCl procedure [37] and the absorbance was read at 500 nm using an ultraviolet–visible spectrophotometer (Beckman Instruments, California, USA). Results of micronutrient composition and anti-nutritional factors analyses were used to estimate the bioavailability of iron, zinc, and calcium using the molar ratios approach based on atomic weights of 660 g/mol, 56 g/mol, 65 g/mol, and 40 g/mol for phytate, iron, zinc, and calcium, respectively [38]. This method is widely recognized as a proxy indicator of invitro bioavailability [38]. Briefly, the mole of phytate and micronutrients (iron, zinc, and calcium) was determined by dividing the weight of phytate and micronutrients by their atomic weight. The molar ratio between phytate and each micronutrient was then determined by dividing the mole of phytate by the mole of each micronutrient [38]. The results were then compared against standard cut-off values of phytate-micronutrient molar ratios that quantify the bioavailability of each micronutrient [39]. The contribution of MDCF to the micronutrient needs of the age group under study was established by determining the quantity (grams) of the product that corresponds to the RDA of each micronutrient. To achieve this, the RDA value for each micronutrient was multiplied by 100 g and then divided by the quantity of the micronutrient in 100 g of MDCF. The cost of MDCF was based on the principle of comparison between the cost of MDCF required to achieve the RDA for the micronutrients versus the cost of one sachet of commercial micronutrient powder, which meets the RDA for micronutrients hence the basis for their comparison. First, the cost of MDCF was determined by dividing the total cost incurred in producing the MDCF by the quantity produced and then multiplied by the quantity required to meet the RDAs for the micronutrients. The resulting cost was then compared to the average price of a sachet of commercial micronutrient powder, which is equivalent to RDAs [40] in United States dollars.

2.4 Determination of functional properties of the micronutrient-dense composite flour

Pasting property (peak viscosity, final viscosity, pasting time, and pasting temperature) was determined using a Rapid Visco Analyzer linked to a computer system (Perten Instruments, New South Wales, Australia) [41]. This method examines the formation of viscous gel of the sample based on its rheology under variable and controlled conditions. First, the moisture content of the sample was determined followed by the addition of water into the sample to form a suspension that was then spun and heated under controlled time–temperature conditions. Bulk density measurement adopted standard procedure [37]. Briefly, a graduated cylinder of 100 ml was weighed and 15 g of sample was then transferred into the cylinder and shaken steadily to release air that was present, and the new volume was recorded. The mass of the cylinder plus the flour sample were recorded. Bulk density was then calculated as the mass of the sample divided by its volume. Water absorption capacity was determined by centrifugation method [42]. Accordingly, the principle underlying this method is the determination of the amount of water retained by the flour sample in the centrifuge tube after adding water to it. On the other hand, the water solubility index was determined by centrifugation followed by drying [42]. This method measures the ability of a sample to dissolve in water and expresses the weight as a percentage of the dry supernatant. Reconstitution time was assessed using the dispersion method [43]. Briefly, 2 g of flour sample was spread on the surface of 50 ml distilled water at room temperature in a 150 ml cylinder. The time taken for the flour to completely disperse was recorded as the reconstitution time.

2.5 Determination of storage stability of the micronutrient-dense composite flour

The storage stability of the MDCF was determined through microbial and chemical analyses. The former helps to identify and enumerate spoilage microorganisms [44] whereas the latter is an indication of biochemical and chemical reactions that have implications for the safety of a food product [45]. Accordingly, the results of microbial and chemical analyses of the MDCF were compared with standard critical values for food safety to establish its safety status as a function of storage time. To determine microbial quality, the MDCF flour was stored at ambient conditions (25 °C ± 2) followed by microbial tests (total microbial, yeasts and moulds, and coliform counts) every fortnight [46]. Briefly, sterile plate count agar, potato dextrose agar, and violet red bile agar (Himedia, Mumbai, India) were used to determine total microbial count, yeasts and moulds, and coliform counts, respectively for 70 days. The results were compared to acceptable limits of 5 log10 cfu/g, 2 log10 cfu/g, and 3 log10 cfu/g for the total microbial count, coliform count, and yeast and moulds, respectively [44]. On the other hand, chemical deterioration was determined using titration methods. This involved the use of organic solvents in which fats dissolve. Specifically, the AOAC method Ca 5a-40 (1990: 2000) was used to determine free fatty acid levels in the micronutrient-dense composite flour across the 70-days storage period. Specifically, 5 g of flour sample were added into a solution of diethyl ether and ethanol containing 1% phenolphthalein and drops of 0.1 M sodium hydroxide and titrated against aqueous 0.1 M solution of sodium hydroxide. Free fatty acid was then determined by multiplying the constant factor of oleic acid (28.2) by the volume of sodium hydroxide used for titration and the normality of sodium hydroxide and the results divided by the weight of the sample. On the other hand, the AOCS official method Cd 8–53 (1997) was used to assess the peroxide value in the flour. The principle underlying this method is that the quantity of iodine produced during the oxidation of fats reflects the quantity of peroxides present. As such, a solution containing acetic acid-chloroform, flour sample, and saturated potassium iodide was titrated against 0.1 N sodium thiosulfate solution and the peroxide level (mEq/kg) was determined using standard formula. Findings of chemical analysis were compared to maximum limits of 1.75% and 10 mEq/kg for free fatty acid and peroxide values, respectively.

2.6 Data analysis

Statistical Package for the Social Sciences (SPSS) version 25 was used for data analysis. One sample t-test was used to analyze data on proximate composition, anti-nutritional factors content, micronutrient content (iron, calcium, and zinc), and functional properties of the MDCF. This model was found appropriate to compare the nutritional and functional properties of the MDCF with the recommended standards and findings of earlier studies. As such, the proximate composition, antinutritional factors, and micronutrient content of MDCF were compared to standard recommendations for complementary foods [32] as well as findings of previous studies in which similar products containing 40% common dry bean, 30% amaranth, and 30% rice [31], and that of a study that used 90% amaranth grains and 10% sorghum [47]. Data on storage stability was analyzed using one-way analysis of variance (ANOVA) to compare microbial (total microbial count, yeast and moulds, and coliforms) and chemical (free fatty acid and peroxide value) parameters at different nodes during storage followed by mean separation using Tukey’s Honestly Significance Difference Test (HSD). Pearson’s correlation analysis was used to determine the association between the storage stability parameters examined. For all analyses, the level of statistical significance was fixed at 5%.

3 Results

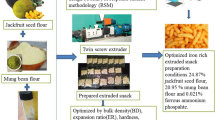

3.1 Formulation of the micronutrient dense composite flour (MDCF)

The ingredient composition of the micronutrient-dense composite flour is shown in Table 1.

3.2 Nutritional quality and cost-effectiveness of the micronutrient-dense composite flour

3.2.1 Proximate composition

The micronutrient-dense composite flour (MDCF) conformed to the Tanzania Bureau of Standards (TBS) recommendations for complementary foods. These recommended standards are < 10.00%, < 5.43%, > 15.20%, 8.15–8.50%, < 2.17%, and 48.90% for moisture content, ash, crude protein, crude fat, crude fibre, and carbohydrates, respectively. On the other hand, the MDCF was also compared to a similar product (nutrient-dense complementary flour [NDCF]) developed in a previous study [47] and the findings showed that MDCF conformed to the recommended standards more often than NDCF as shown in Table 2.

3.2.2 Micronutrient composition

The iron, zinc, and calcium contents of the micronutrient-dense composite flour were significantly lower (p < 0.05) than that of standard micronutrient powder but significantly higher (p < 0.05) than that of a similar nutrient-dense product (common bean-amaranth-rice composite flour) developed in a previous study [31] as depicted in Fig. 1.

Comparison of micronutrient content of micronutrient-dense composite flour and similar products in milligrams per gram (mg/g). MNP refers to standard micronutrient powder; MDCF refers to micronutrient-dense composite flour developed in this study; BBCF refers to bean-based composite flour developed in a previous study; different letters on bars indicate that the difference in quantities of study micronutrients among the three products was statistically significant (p < 0.05); MDCF and BBCF are consumed in amounts > 1 g such as 58 g of MDCF for 6–11 months old children per day while MNP is consumed in 1 g portion daily dose

3.2.3 Antinutritional factors

Both phytate and tannin levels in the micronutrient-dense composite flour (MDCF) were lower than the critical limits of < 25 and < 10 mg/100 g for phytates and tannins, respectively as recommended in previous studies [49, 50]. These findings were also comparable to the amount of phytate and tannin observed in composites for complementary feeding similar to MDCF [47, 48] as shown in Table 3.

3.2.4 Estimated micronutrient bioavailability of the micronutrient-dense composite flour

The molar ratios of phytate to individual micronutrients studied were below the critical values of < 0.15, < 10, and < 0.24 for phytate to iron, phytate to zinc, and phytate to calcium, respectively (Table 4), indicating that the bioavailability of targeted micronutrients in the micronutrient dense composite flour developed might be good.

3.2.5 Micronutrient contribution of the micronutrient-dense composite flour to RDAs

Generally, about 58 and 37 g of the micronutrient-dense composite flour for children of ages 6–11 and 12–24 months, respectively would be required to meet the iron and zinc requirements adequately while catering for 76% and 26% of the RDA for calcium for the two age groups, respectively (Table 5). These quantities of MDCF are required to meet the RDA based on the micronutrient content in the product and do not provide excess micronutrients since the product is food-based but not pure mineral powders.

3.2.6 Cost of the micronutrient-dense composite flour

The market price for standard micronutrient powders in Uganda (including the Acholi sub-region) [51], is higher than the cost of MDCF produced in this study. On the other hand, the cost of the MDCF in this study is slightly higher than UNICEF's average price. For instance, MDCF has been established to cost 0.058 and 0.037 USD to meet the RDA of 6–11 and 12–24-months old children, respectively, whereas MNP costs 0.018 USD for achieving the RDA for both age groups based on UNICEF’s price projection. However, the market price of MNP in Uganda is higher than that projected by UNICEF and stands at 4.81 USD. Standard micronutrient powders are produced in high-income countries and imported by African countries. This could explain why the market price of the same standard micronutrient powder is high in Uganda compared to UNICEF’s prices factoring in importation costs and other expenses incurred. As such, producing MDCF as shown in this study is more cost-effective. Notably, standard micronutrient powders contain other micronutrients such as magnesium and vitamin A. MDCF on the other hand may contain additional micronutrients though not investigated in this study.

3.3 Functional properties of the micronutrient-dense composite flour

There are no specific cut-off standards for the functional properties of complementary foods. As such, the functional properties of the micronutrient-dense composite flour were compared to the results of previous studies in which similar products for complementary feeding were developed. These studies included optimization of the functional characteristics, pasting, and rheological properties of pearl millet-based composite flour [52], investigation of proximate composition and functional properties of composite flours of amaranth, rice, millet, and soybean [53], and investigation of the proximate, functional and pasting properties of FARO 44 rice, African yam bean, and brown cowpea seeds composite flour [54]. Therefore, the suitability of the MDCF for complementary feeding was determined by the aforementioned studies on similar products. As such, some of the functional properties of the MDCF were above, similar to, or lower than the findings reported in earlier studies as shown in Table 7. For instance, the water solubility index, water absorption capacity, and peak viscosity were higher than those obtained from earlier studies whereas bulk density, pasting time, and pasting temperature were similar to those of earlier studies. On the other hand, the final viscosity of MDCF was lower than that of pearl millet-based composite flour [52] but higher than that of FARO 44 rice, African yam bean, and brown cowpea seeds composite flour [54]. Lastly, the reconstitution time of MDCF was generally lower than similar products.

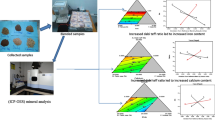

3.4 Storage stability of the micronutrient-dense composite flour

In terms of microbial quality, the three microbial groups investigated (total microbial, coliform, and yeast and mould count) increased gradually with an increase in storage time (Fig. 2). However, the nature and magnitude varied with specific microbial groups. Despite the increase in counts, all microbial groups remained within the acceptable limits of 5, 3, and 2 log10 cfu/g for total microbial count, yeast and moulds, and coliforms, respectively [44] for up to 70 days of storage. Notably, total microbial count followed a cluster pattern of 0–14, 28–42, and 56–70 days of storage. As such, the increase in total microbial count within a cluster was not significantly different (p > 0.05) however, the reverse was true for comparison between the clusters. Yeast and molds increased from 1.48 to 2.06 log10 cfu/g across storage time. There was a significant difference (p < 0.05) in yeast and mould counts among all nodes of storage except on days 0 and 14 which were not significantly different (p > 0.05) from each other although both were significantly lower than for the rest of storage nodes (p < 0.05). Coliform counts increased significantly (p < 0.05) among all nodes of storage except on days 28 and 42, which were not significantly different (p > 0.05) from each other. However, coliforms at day 28 and 42 were significantly higher (p < 0.05) than for all other storage nodes considered in the study.

The amount of free fatty acid in the micronutrient-dense composite flour increased with the storage time, ranging from 0.53% to 0.75% (Fig. 3). The increase in free fatty acid significantly (p < 0.05) occurred over a window period of 28 days. However, there was no significant difference (p > 0.05) in free fatty acid within 14-day window period. The free fatty acid values remained within the standard limit of 1.75% [56] at the end of the storage time.

Generally, there was a minimal increase in peroxide value during storage (Fig. 4).The difference in peroxide values at various days of storage portrayed different levels of statistical significance as shown in Fig. 4. However, all peroxide values remained within the maximum limit of 10 mEq/kg [57].

Parameters of storage stability showed positive and significant correlation with one another.

4 Discussion

Proximate composition has generally been used as an indicator of nutritional quality and shelf life of food products hence a reflection of their suitability for use [58]. For instance, the low moisture content observed in this study could be attributed to the processing methods used, and this quality suggests that the product potentially has good storage stability and could be devoid of unnecessary bulkiness that would otherwise occur due to excess moisture. On the other hand, the high ash content of MDCF could be due to silverfish and iron-rich beans, which are known for their richness in calcium and iron, respectively [23]. These findings suggest that the ingredients of MDCF have the potential to contribute to the reduction of hidden hunger when composited into flour for routine enrichment of complementary foods. The slightly high levels of crude protein in the MDCF could be attributed to the inclusion of iron-rich beans and silverfish, which are known to be rich in proteins [29, 59] while the fat content could be due to the inclusion of silverfish, which contains polyunsaturated fatty acids [60]. Accordingly, polyunsaturated fatty acids are essential for energy provision, brain development, growth, and immune function in children [61] though excessive intake (especially omega-6 fatty acid) is associated with allergies and inflammatory diseases as well as cell proliferation [62]. It is recommended that complementary foods be constituted of low fibre content to avoid bulkiness and reduced energy density [63]. However, the high fibre content of MDCF could be attributed to plant-based ingredients of the product, which are known to be rich sources of fibre [64] though it was below a 5% tolerable limit for complementary feeding products [65, 66]. Notably, fibre is undeniably an important component of foods and hence cannot be eliminated. For instance, soluble fibre nourishes the gut bacteria through fermentation in the colon hence maintaining the integrity of the digestive tract while insoluble fibre prevents constipation by facilitating bowel movement [67, 68]. Carbohydrate content of MDCF conformed to the Tanzania Bureau of Standards (TBS) recommended levels for complementary foods (Table 2). Accordingly, adequate carbohydrates are essential for energy provision though excessive amounts are associated with the risk of obesity in children [69].

Owing to the limited accessibility of standard micronutrient powders among resource-limited households in developing countries, the formulation of composites using locally available food resources has been promoted as a feasible solution to address micronutrient deficiency [70]. Ideally, the micronutrient powders are used to fortify food at the point of use as sprinkles [71]. This is the concept upon which MDCF was developed. The iron and zinc content of the MDCF was significantly lower than for standard micronutrient powders (Fig. 1). This is possibly because standard micronutrient powders use elemental minerals [71] unlike MDCF which uses available food resources that contain other non-mineral portions like carbohydrates, fats, and proteins. The lower micronutrient content of MDCF relative to standard micronutrient powders suggests that the MDCF would contribute to the achievement of recommended dietary allowance when applied at higher quantities and frequency.

Phytates and tannins are anti-nutritional factors that occur naturally in foods of plant origin due to the presence of phosphate and phenolic compounds [72, 73]. These antinutritional factors have been associated with reduced bioavailability of minerals in foods [34]. Specifically, phytates and tannins, which are negatively charged, bind with the positively charged metal ions (such as iron, zinc, and calcium) forming chelates thereby preventing mineral absorption [34]. The low phytate and tannin content observed in MDCF (Table 3) could be attributed to the processing methods used which included steeping, soaking, germination, and roasting, which have been found to be effective in reducing the aforementioned antinutritional factors [74, 75]. Phytate-mineral molar ratios have been widely recognized as a method of estimating the bioavailability of micronutrients in plant-based foods [76, 77]. As such, the phytate-mineral molar ratios in this study were lower than the critical values [22] as shown in Table 4, indicating that the bioavailability of the study micronutrients might be good. Notably, there have been concerns about zinc inhibition of iron absorption but this only applies to high doses of zinc supplements over a long time and not the dietary sources [78]. On the other hand, calcium oxalate, which is a complex formed as a result of interaction between calcium and oxalic acid has been associated with reduced iron absorption [79]. This effect was countered by subjecting iron-rich beans and amaranth grains to processes such as soaking [16].

Iron and zinc are the major micronutrients of public health importance in developing countries whereas calcium intake is usually inadequate [71]. For this reason, the current study aimed at achieving 100% RDA for iron and zinc for children 6–11 and 12–24 months while contributing to RDA for calcium. Therefore, theoretical computation showed that daily enrichment of complementary foods (such as porridge) with 58 and 37 g of MDCF for children 6–11 and 12–24 months, respectively would meet 100% RDA for iron and zinc as well as calcium for 6–11 months old children and 50% of RDA for calcium for 12–24 months old children (Table 5). Accordingly, locally formulated foods have the potential to meet RDA for iron and zinc if applied in higher quantities and frequencies [80]. The market price for a sachet of standard micronutrient powder (1 g) in Uganda, which is adequate for achieving the RDA is higher than the cost of MDCF (58 and 37 g for children 6–11 and 12–24 months old, respectively) required to meet the RDA for iron and zinc among children 6–24 months old. However, the price of MDCF required to meet the RDA of iron and zinc for the two sub-age groups (6–11 and 12–24 months) is slightly higher than UNICEF's average price for standard micronutrient powders [40] (Table 6). Therefore, this study shows that it could be more cost-effective to use MDCF rather than micronutrient powder in developing countries.

Functional properties often determine the suitability of a given food product for its targeted end use [81] hence application-specific [82]. Accordingly, the bulk density of complementary foods should be low for easy feeding and to prevent choking [83, 84]. The bulk density of MDCF was relatively low. On the other hand, the high water solubility index observed for MDCF could be associated with a high amount of simple sugar following the germination of amaranth grains and due to high levels of protein from iron-rich beans and silverfish [85]. This property is an indication of improved digestibility of the product [85]. The MDCF also portrayed high water absorption capacity (Table 7) and this could be due to the high amount of protein (Table 2) as well as the change in protein quality due to germination, which increases hydrogen bonding and consequently water absorption [86]. As such, fair amounts of MDCF will be required for gelation [42], leading to adequate micronutrient intake. The low reconstitution time observed in this study could be attributed to high water absorption capacity [87], indicating that the MDCF can be incorporated into porridges easily [53]. The fairly low peak and final viscosities indicate that the MDCF forms a less viscous paste, which is suitable for complementary diets as it is not cumbersome to the digestive system [88], and this could be attributed to roasting of ingredients, which has been associated with reduced gelatinization tendency and increased swelling property of starch granules [89]. Notably, the rapid visco analyzer works in a range of 20–8000 cps at 160 rpm thus detecting the slightest changes in viscosity [41].

Generally, all three groups of microbial indicators of storage stability increased during storage. However, they were within the acceptable limits at the seventy days of storage (Fig. 2A–C). As such, the MDCF can be prepared in quantities that can be used for up to seventy days without posing any microbial risk. On the other hand, the free fatty acid content of MDCF increased significantly (p < 0.05) after every twenty-eight days (Fig. 3). However, the increase was minimal compared to the findings observed in a similar product [90]. The low free fatty acid content observed in MDCF could be attributed to the unfavourable temperatures of storage (approximately 28 °C ± 2) since the activity of lipolytic enzymes is accelerated at a temperature of 40 °C [91]. Similarly, the peroxide value of MDCF increased gradually during storage (Fig. 4). Similar observations were made in unpacked millet flour [92] and full-fat maize-groundnut composites [90] whose peroxide values increased gradually during storage. The minimal peroxides observed in MDCF could be attributed to the roasting of all the ingredients before milling, which could have inactivated lipolytic enzymes that would otherwise degrade triglycerides to free fatty acids and eventually to peroxides [92]. Both free fatty acid and peroxide values were highly positive and significantly correlated with storage time (Table 8). In addition, the peroxide value was highly positive and significantly correlated with free fatty acid content (Table 8). This observation could be explained by the fact that peroxides are derivatives of free fatty acid content [93]. Total microbial, coliform, yeast, and mould counts were significantly associated with storage time (Table 8). This is a known phenomenon based on the classical microbial growth curve [94]. Furthermore, microbial-induced rancidity could be the main factor accounting for the formation of free fatty acids and peroxides due to the strong correlation between microbial groups investigated with free fatty acid and peroxide values. Previous studies have documented the lipolytic effect of coliform yeast and moulds [95, 96]. On the other hand, both coliform count and yeast and moulds dominated the total microbial count and are likely to be found in MDCF at higher levels than any other microorganisms. Lastly, a co-existence was observed between yeast and moulds and coliform count, which could be an indication of their mutual growth in MDCF.

5 Study limitations and strengths

This study was limited to the ingredients used in the development of micronutrient-dense composite flour, namely, amaranth grains, silverfish, and iron-rich beans. Secondly, the micronutrients of interest in this study were limited to iron, zinc, and calcium though the product could be having other minerals and vitamins of nutritional significance. Furthermore, the bioavailability of the micronutrients were estimated using the phytate-mineral molar ratio method, as such future study should determine the actual bioavailability of the minerals in the micronutrient-dense composite flour. On the other hand, this study had several strengths. The study harnessed the potential of locally available foods with great potential in the alleviation of hidden hunger to develop MDCF. This study has availed a low-cost alternative (MDCF) to micronutrient powder on the market, hence more affordable to resource-constrained households.

6 Conclusion

This study has demonstrated that amaranth grain-silverfish-iron-rich beans micronutrient dense composite flour has the potential to adequately meet the recommended dietary allowance for iron and zinc and can improve calcium intake fairly among children 6–24 months old when used for routine enrichment of complementary foods. The micronutrient-dense composite flour largely had desirable functional properties indicating its suitability for application in complementary foods. The product was safe for use for up to seventy days when stored at ambient temperature and thus can be prepared in quantities that would last for such duration. The cost of the micronutrient-dense composite flour is lower than that of commercial micronutrient powders available in Uganda thus making it cost-effective for resource-constrained households typical of those in rural areas of Acholi sub-region of Uganda as well as other developing countries. Therefore, community nutritionists should provide nutrition education to caregivers on the application of MDCF to meet RDA for improved micronutrient intake among children under five years in micronutrient deficiency endemic localities.

Data availability

The data upon which the findings of this study were based is presented in this article.

Code availability

Not applicable.

References

Wilson K, Wakefield J. Child Mortality Estimation Incorporating Summary Birth History Data. 2018;1–50. Available from: http://arxiv.org/abs/1810.04140.

Moench-Pfanner R, Silo S, Laillou A, Wieringa F, Hong R, Hong R, et al. The economic burden of malnutrition in pregnant women and children under 5 years of age in Cambodia. Nutrients. 2016;8(5):1–14.

Kahssay M, Woldu E, Gebre A, Reddy S. Determinants of stunting among children aged 6 to 59 months in pastoral community, Afar region, North East Ethiopia: unmatched case control study. BMC Nutr. 2020;6(1):1–8.

Anchamo A. Predictors of wasting among children under five years in largely food insecure area of north Wollo, Ethiopia: a cross-sectional study. J Nutr Sci. 2022;12:1–8.

Uganda Bureau of Statistics. Uganda. 2018.

Uganda Bureau of Statistics. Uganda Demographic and Health Survey. 2018.

Amegbor PM, Yankey O, Sabel CE. Examining the effect of geographic region of residence on childhood malnutrition in Uganda. J Trop Pediatr. 2020;66(6):598–611.

Integrated Community Agriculture and Nutrition USA for I development; Market Nutrient and Consumer Demand Gap Analysis of Children (6–23 months) in Kotido, Lamwo, and Kisoro Districts, Uganda.

Knowles M, Khan S, Palakshappa D, Cahill R, Kruger E, Poserina BG, et al. Successes, challenges, and considerations for integrating referral into food insecurity screening in pediatric settings. J Health Care Poor Underserved. 2018;29(1):181–91.

Imamura F, Micha R, Khatibzadeh S, Fahimi S, Shi P, Powles J, et al. Dietary quality among men and women in 187 countries in 1990 and 2010: a systematic assessment. Lancet Glob Heal. 2015;3(3):e132–42.

Grineski SE, Morales DX, Collins TW, Rubio R. HHS public access. 2019;39(9):715–25.

Cormick G, Belizán JM. Calcium intake and health. Nutrients. 2019;11(7):1–16.

Engle-stone R, Aaron GJ, Huang J, Wirth JP, Namaste SML, Williams AM, et al. Predictors of anaemia in preschool children: Biomarkers Reflecting Inflammation and Nutritional Determinants of Anemia (BRINDA) project. 2017;106:402–15.

World Health Organization. (2019). Nutritional rickets.

Piloya T, Odongkara B, Were EM, Ameda F, Mworozi E, Laigong P. Nutritional rickets among children admitted with severe pneumonia at Mulago hospital, Uganda: a cross-sectional study. BMC Pediatr. 2018;18(1):1–7.

Gupta S, Brazier AKM, Lowe NM. Zinc deficiency in low- and middle-income countries: prevalence and approaches for mitigation. J Hum Nutr Diet. 2020;33(5):624–43.

Kuziga F, Adoke Y, Wanyenze RK. Prevalence and factors associated with anaemia among children aged 6 to 59 months in Namutumba district, Uganda : a cross-sectional study. BMC Pediatr. 2017. https://doi.org/10.1186/s12887-017-0782-3.

Philipo M, Ndakidemi PA, Mbega ER. Importance of common bean genetic zinc biofortification in alleviating human zinc deficiency in sub-Saharan Africa. Cogent Food Agric. 2021;7(1).

Poh BK, Lee ST, Yeo GS, Tang KC, Noor Afifah AR, Siti Hanisa A, et al. Low socioeconomic status and severe obesity are linked to poor cognitive performance in Malaysian children. BMC Public Health. 2019;19(Suppl 4):1–10.

Achadi E, Ahuja A, Bendech MA, Bhutta ZA, De-Regil LM, Fanzo J, et al. Ending Malnutrition by 2030. 2016;1–4. Available from: http://ebrary.ifpri.org/cdm/ref/collection/p15738coll2/id/130355.

Muyonga JH, Nabakabya D, Nakimbugwe DN, Masinde D. Efforts to promote amaranth production and consumption in Uganda to fight malnutrition. Using Food Technol to Improv Nutr Promot Natl Dev. 2008;(August 2015):1–10.

Fekadu GH. Antinutritional factors in plant foods: potential health benefits and adverse effects. Int J Nutr Food Sci. 2014;3(4):284.

Kabahenda MK, Amega R, Okalany E, Heck S. Protein and micronutrient composition of low-value fish products commonly marketed in the lake victoria region. 2011;7(5):521–6.

Kembabazi S. Formulation of a nutrient-rich complementary biscuit for children between eight months and fifty-nine months. Int J Food Sci Biotechnol. 2018;3(1):33.

Khodadad CLM, Hummerick ME, Spencer LSE, Dixit AR, Richards JT, Romeyn MW, et al. Microbiological and nutritional analysis of lettuce crops grown on the international space station. Front Plant Sci. 2020;11(March):1–15.

E.Brown J. Nutrition Through the Life Cycle. Modern Nutrition in Health and Disease: Eleventh Edition. 2012. 1480–1489 p.

Hotz C, Lubowa A, Sison C, Moursi M, Loechl C. A food composition table for central and Eastern Uganda. HarvestPlus Technical Monograph. 2012;9(B):31.

Nassanga P. Millet-Sesame-Soy Composite as a Complementary Food in Acholi Sub-Region of Uganda. 2016.

Elolu S, Ongeng D. Approach to address short-term hunger and undernutrition among primary school children in rural areas in a developing country setting: lessons from North and North-Eastern Uganda. BMC Nutr. 2020;6(73):1–10.

Sharma S, Prabhakar H, Thind SS, Chatli M, Kaur A. Evaluation of the effect of incorporation of functional ingredients on the shelf life of chicken patties using different packaging conditions during frozen storage. Int J Curr Microbiol Appl Sci. 2017;6(11):2797–809.

Ndagire CT, Muyonga JH, Manju R, Nakimbugwe D. Optimized formulation and processing protocol for a supplementary bean-based composite flour. Food Sci Nutr. 2015;3(6):527–38.

Mosha TCE, Laswai HS, Tetens I. Nutritional composition and micronutrient status of homemade and commercial weaning foods consumed in Tanzania. Plant Foods Hum Nutr. 2000;55(3):185–205.

Dada TA, Barber LI, Ngoma L, Mwanza M. Formulation, sensory evaluation, proximate composition and storage stability of cassava strips produced from the composite flour of cassava and cowpea. Food Sci Nutr. 2018;6(2):395–9.

Samtiya M, Aluko RE, Dhewa T. Plant food anti-nutritional factors and their reduction strategies: an overview. Food Prod Process Nutr. 2020;5:1–14. https://doi.org/10.1186/s43014-020-0020-5.

Lazarte CE, Carlsson NG, Almgren A, Sandberg AS, Granfeldt Y. Phytate, zinc, iron and calcium content of common Bolivian food, and implications for mineral bioavailability. J Food Compos Anal. 2015;39:111–9.

Nwabugwu JCO and CC. Fermentation of Millet (Pennisetum americanum) and Pigeon pea (Canjanus cajan) Seeds for Flour Production: Effects on Composition and Selected Functional Properties.

Oludumila OR, Enujiugha VN. Physicochemical and rheological properties of complementary diet from blends of maize, African Yam Bean and Pigeon Pea. 2017;2(1).

Norhaizan ME, Nor Faizadatul Ain AW. Determination of phytate, iron, zinc, calcium contents, and their molar ratios in commonly consumed raw and prepared food in Malaysia. Malays J Nutr. 2009;15(2):213–22.

Gemede HF. Nutritional and antinutritional evaluation of complementary foods formulated from maize, pea, and anchote flours. 2020;(February):2156–64.

United Nations Children’s Fund 2020. Multiple Micronutrient Powder Price Data. Vol. 30. 2020. p. 1580201.

Adepeju AB, Gbadamosi SO, Omobuwajo TO, Abiodun OA. Functional and physico-chemical properties of complementary diets produced from breadfruit (Artocarpus altilis). 2014;5(4):105–13.

Adeola AA, Solola OM, Apata O, Ohizua ER. Assessment of some attributes of unripe cooking banana (Cardaba Musa ABB), pigeon pea (Cajanus cajan), and orange-fleshed sweet potato (Ipomoea batatas) flour blends for use as complementary feeding. Croat J Food Sci Technol. 2019;11(1):67–75.

Mastrocola D, Barbanti D, Dalla Rosa M, Pittia P. Physicochemical characteristics of dehydrated apple cubes reconstituted in sugar solutions. J Food Sci. 1998;63(3):495–8.

World Food Programme. Technical specification for manufacture of Super Cereal; Rice Soya Blend. Nutr Action Heal Lett. 2013; Available from: http://ezproxy.puc.cl/docview/1710270832?accountid=16788%0Ahttp://todosibuc.uc.cl/openurl/56PUC_INST/56PUC_INST_SP?url_ver=Z39.88-2004&rft_val_fmt=info:ofi/fmt:kev:mtx:journal&genre=unknown&sid=ProQ:ProQ%3Aagriculturejournals&atitle=SUPER+CEREAL&title=Nut.

Uchechukwu-Agua AD, Caleb OJ, Manley M, Opara UL. Effects of storage conditions and duration on physicochemical and microbial quality of the flour of two cassava cultivars (TME 419 and UMUCASS 36). CYTA J Food. 2015;13(4):635–45. https://doi.org/10.1080/19476337.2015.1029524.

Alsharjabi FA, Al-Qadasi AM, Al-Shorgani NK. Bacteriological evaluation of weaning dried foods consumed in Taiz City, Republic of Yemen. J Saudi Soc Agric Sci. 2019;18(3):302–8. https://doi.org/10.1016/j.jssas.2017.09.002.

Okoth JK, Ochola SA, Gikonyo NK, Makokha A. Development of a nutrient-dense complementary food using amaranth-sorghum grains. Food Sci Nutr. 2017;5(1):86–93.

Uche OC. Physicochemical characteristics and anti-nutritional factors of physicochemical characteristics and anti- nutritional factors of fermented complementary foods based on maize pigeon pea flour. 2017;(June).

Onomi S, Okazaki Y, Katayama T. Effect of dietary level of phytic acid on hepatic and serum lipid status in rats fed a high-sucrose diet. Biosci Biotechnol Biochem. 2004;68(6):1379–81.

Sharma K, Kumar V, Kaur J, Tanwar B, Goyal A, Sharma R, et al. Health effects, sources, utilization and safety of tannins: a critical review. Toxin Rev. 2019. https://doi.org/10.1080/15569543.2019.1662813.

Prabhakar EB& P. A Cost Analysis of Micronutrient Powder Distribution by Community Health Workers.

Awolu OO. Optimization of the functional characteristics, pasting and rheological properties of pearl millet-based composite flour. Heliyon. 2017;3(2):e00240. https://doi.org/10.1016/j.heliyon.2017.e00240.

Twinomuhwezi H, Awuchi CG, Rachael M. Comparative study of the proximate composition and functional properties of composite flours of amaranth, rice, millet, and soybean. Am J Food Sci Nutr. 2020;6(1):5–19.

Iwe MO, Onyeukwu U, Agiriga AN. Proximate, functional and pasting properties of FARO 44 rice, African yam bean and brown cowpea seeds composite flour. Cogent Food Agric. 2016;2(1):1–11. https://doi.org/10.1080/23311932.2016.1142409.

Compaoré WR, Nikièma PA, Bassole HIN, Savadogo A, Hounhouigan DJ, Mouecoucou J, et al. Nutritional properties of enriched local complementary flours. Adv J Food Sci Technol. 2011;3(1):31–9.

Afoakwa EO, Kongor JE, Takrama J, Budu AS. Changes in nib acidification and biochemical composition during fermentation of pulp pre-conditioned cocoa (Theobroma cacao) beans.

Alimentarius C. Codex Stan 210-1999: Standard for Named Vegetable Oils. Codex alimentarius international food standards. 2005.

Figura L, Teixeira AA. Food physics: physical properties-measurement and applications. Springer Science & Business Media; 2007.

Robinson GHJ, Balk J, Domoney C. Improving pulse crops as a source of protein, starch, and micronutrients. 2019;(Pgro 2018):202–15.

Masette M, Kwetegyeka J. The effect of artisanal preservation methods on nutritional security of “Mukene” Rastrineobola argentea caught from Lakes Victoria and Kyoga in Uganda. Uganda J Agric Sci. 2013;14(2):95–107.

Lutter CK, Grummer-Strawn L, Rogers L. Complementary feeding of infants and young children 6 to 23 months of age. Nutr Rev. 2021;79(8):825–46.

Mariamenatu AH, Abdu EM. Overconsumption of omega-6 polyunsaturated fatty acids (PUFAs) versus deficiency of omega-3 PUFAs in modern-day diets: the disturbing factor for their “balanced antagonistic metabolic functions” in the human body. J Lipids. 2021;17(2021):1–5.

Adetola OY, Onabanjo OO, Stark AH. The search for sustainable solutions: Producing a sweet potato-based complementary food rich in vitamin A, zinc, and iron for infants in developing countries. Sci African. 2020;8:e00363.

Oh H, Kim H, Lee DH, Lee A, Giovannucci EL, Kang SS, et al. Different dietary fibre sources and risks of colorectal cancer and adenoma: a dose-response meta-analysis of prospective studies. Br J Nutr. 2019;122(6):605–15.

Goday PS, Lewis JD, Sang CJ Jr, George DE, McGoogan KE, Safta AM, Seth A, Krekel C. Energy-and protein-enriched formula improves weight gain in infants with malnutrition due to cardiac and noncardiac etiologies. J Parenter Enter Nutr. 2022;46(6):1270–82.

Agbemafle I, Hadz D, Amagloh FK, Zotor FB, Reddy MB. Orange-fleshed sweet potato and edible insects. Foods. 2020;9:1–14.

Hijová E, Bertková I, Štofilov J. Dietary fibre as prebiotics in nutrition. Cent Eur J Public Health. 2019;27(3):251–5.

Cai Y, Folkerts G, Maurer M. Microbiota—dependent and—independent effects of dietary fibre on human health. 2020;(September 2019):1363–81.

D’auria E, Borsani B, Pendezza E, Bosetti A, Paradiso L, Zuccotti GV, et al. Complementary feeding: pitfalls for health outcomes. Int J Environ Res Public Health. 2020;17(21):1–19.

Teye E, Deha CI, Dadzie R, Macarthur RL. Review article delivering the nutritional needs by food to food fortification of staples using underutilized plant species in Africa. 2020;2020.

World Health Organization. WHO guideline: Use of multiple micronutrient powders for point-of-use fortification of foods consumed by infants and young children aged 6–23 months and children aged 2–12 years. World Health Organization. 2016. Licence: CC BY-NC-SA 3.0 IGO.

Gupta RK, Gangoliya SS, Singh NK. Reduction of phytic acid and enhancement of bioavailable micronutrients in food grains. J Food Sci Technol. 2013;52(2):676–84.

Timotheo CA, Lauer CM. Toxicity of vegetable tannin extract from Acacia mearnsii in Saccharomyces cerevisiae. Int J Environ Sci Technol. 2018;15(3):659–64.

Vadivel V, Biesalski HK. Effect of certain indigenous processing methods on the bioactive compounds of ten different wild type legume grains. 2012;49(December):673–84.

Nkhata SG, Ayua E, Kamau EH. Fermentation and germination improve the nutritional value of cereals and legumes through activation of endogenous enzymes. 2018;(July):2446–58.

Castro-Alba V, Lazarte CE, Bergenståhl B, Granfeldt Y. Phytate, iron, zinc, and calcium content of common Bolivian foods and their estimated mineral bioavailability. Food Sci Nutr. 2019;7(9):2854–65.

Sultana M, Hasan T, Shaheen N. Molar ratios of dietary phytate to minerals and iron status of female residential students in University of Dhaka, Bangladesh. Nutr Health. 2021;27:405.

Kondaiah P, Yaduvanshi PS, Sharp PA, Pullakhandam R. Iron and zinc homeostasis and interactions: does enteric zinc excretion cross-talk with intestinal iron absorption? Nutrients. 2019;11(8):1885.

Milman NT. A review of nutrients and compounds, which promote or inhibit intestinal iron absorption: making a platform for dietary measures that can reduce iron uptake in patients with genetic haemochromatosis. J Nutr Metab. 2020;2020.

Mbela DEN, Kinabo J, Mwanri AW, Ekesa B. Modification of local diets to improve vitamin A, iron and protein contents for children aged 6 to 23 months in Kagera, Tanzania. Afr J Food Agric Nutr Dev. 2018;18(1):13129–53.

Oluwole O, Akinwale T, Adesioye T, Odediran O, Anuoluwatelemi J, Ibidapo O, et al. Some functional properties of flours from commonly consumed selected Nigerian Food Crops. 2016;1(5):92–8. Available from: http://prudentjournals.org/wp-content/uploads/2016/07/PRJA39758700.pdf.

Godswill C, Somtochukwu V, Kate C. The functional properties of foods and flours. 2019;5(11).

Balasubramanian S, Sharma R, Kaur J, Bhardwaj N. Characterization of modified pearl millet (Pennisetum typhoides) starch. J Food Sci Technol. 2014;51(2):294–300.

Onweluzo JC, Nwabugwu CC. Development and evaluation of weaning foods from pigeon pea and millet. Pak J Nutr. 2009;8(6):725–30.

Alcázar-Alay SC, Meireles MAA. Physicochemical properties, modifications, and applications of starches from different botanical sources. Food Sci Technol. 2015;35(2):215–36.

Sreerama YN, Sashikala VB, Pratape VM, Singh V. Nutrients and antinutrients in cowpea and horse gram flours in comparison to chickpea flour: evaluation of their flour functionality. Food Chem. 2012;131(2):462–8. https://doi.org/10.1016/j.foodchem.2011.09.008.

Bello AA, Gernah DI, Ariahu CC, Ikya J. Physico-chemical and sensory properties of complementary foods from blends of malted and non-malted sorghum, soybean and moringa oleifera seed flours. Am J Food Sci Technol. 2019;8(1):1–13.

Omueti O, Otegbayo B, Jaiyeola O, Afolabi O. Functional properties of complementary diets developed from soybean (Glycine Max), groundnut (Arachis Hypogea) and crayfish (Macrobrachium Spp). Electron J Environ Agric Food Chem. 2009;8(8):563–73.

Mubaiwa J, Fogliano V, Chidewe C, Linnemann AR. Bambara groundnut (Vigna subterranea (L.) Verdc.) flour: a functional ingredient to favour the use of an unexploited sustainable protein source. PLoS ONE. 2018;13(10):1–19.

Temba MC, Njobeh PB, Kayitesi E. Storage stability of maize-groundnut composite flours and an assessment of aflatoxin B1 and ochratoxin A contamination in flours and porridges. Food Control. 2017;71:178–86.

Agrahar-Murugkar D, Jha K. Influence of storage and packaging conditions on the quality of soy flour from sprouted soybean. J Food Sci Technol. 2011;48(3):325–8.

Varsha R, Narayanan A. Storage stability of bio-fortified pearl millet flour. Int J Agric Innov Res. 2017;5(5):709–13. Available from: https://ijair.org/administrator/components/com_jresearch/files/publications/IJAIR_2282_FINAL.pdf.

Khanum R, Thevanayagam H. Lipid peroxidation: its effects on the formulation and use of pharmaceutical emulsions. Asian J Pharm Sci. 2017;12(5):401–11. https://doi.org/10.1016/j.ajps.2017.05.003.

López S, Prieto M, Dijkstra J, Dhanoa MS, France J. Statistical evaluation of mathematical models for microbial growth. Int J Food Microbiol. 2004;96(3):289–300.

Chipilev N, Daskalov H, Stoyanchev T. Study on the prevalence of lipolytic yeasts and moulds in raw cow milk and white brined cheese. Bulg J Vet Med. 2016;19(2):117–26.

Masiello SN, Martin NH, Trmčić A, Wiedmann M, Boor KJ. Identification and characterization of psychrotolerant coliform bacteria isolated from pasteurized fluid milk. J Dairy Sci. 2016;99(1):130–40.

Acknowledgements

The authors are grateful to MasterCard Foundation—Regional Universities Forum for Capacity Building in Agriculture (RUFORUM) for funding this study. In addition, the management and staff of Gulu University Multifunctional Research Laboratories are highly appreciated for the conducive environment and facilities provided during the study.

Funding

This study was funded by MasterCard Foundation—Regional Universities Forum for Capacity Building in Agriculture (RUFORUM) through the TAGDEV Project (RU/2019/ TAGDev-MCF 03).

Author information

Authors and Affiliations

Contributions

Concept development: AMU, LO, and DO. Methodology: AMU, LO, and DO. Data Collection and Analysis: AMU. Writing original draft: AMU. Writing review and editing AMU, LO, and DO. Overall supervision: LO and DO. All authors read and approved the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Permission to carry out the research was obtained from the Gulu University Research Ethics Committee (Reference number: GUREC-2020–13). In light of the COVID-19 pandemic, standard operating procedures set by the government of Uganda were observed throughout the research process.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Ugada, A.M., Okidi, L. & Ongeng, D. Development of micronutrient dense composite flour for routine enrichment of complementary foods for children 6–24 months old in Acholi sub-region of Uganda. Discov Food 3, 24 (2023). https://doi.org/10.1007/s44187-023-00064-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44187-023-00064-6