Abstract

Mixtures of multiple grains at varied ratios can provide multiple and higher micronutrients than a single grain. Thus, this research was aimed at examining the effect of blending ratios variation on micro-compositions and phytate/minerals molar ratios of pre-processed local dabi teff-field pea based novel composite complementary flours. Inductively Coupled Plasma-Optical Emission Spectrometry was used to determine dietary minerals. Nutrisurvey software was employed to define ranges of the mixture components and they were constrained at 20–35% for dabi teff, 0–30% field pea and 5–20% maize, while the remaining were set constant at 25% barley, 15% oats and 5% linseed. Design-Expert ® software version 11, D-optimal was used to generate eleven experimental blends and to examine the effects of blending ratio variation on the responses. Mean mineral contents were significantly different (P < 0.05) among the blends (as affected by component ratios variation) and ranged from 24.01–31.58 mg/100 g for iron, 73.46 -78.81 mg/100 g for calcium, and 2.33–2.61 mg/100 g for zinc contents. The phytate/minerals molar ratios were significantly different among the blends except phytate/calcium molar ratio (Ph:Ca), ranged from 0.232–0.344 for phytate/iron molar ratio (Ph:Fe), 0.067–0.085 for (Ph:Ca), 3.356–4.18 for phytate/zinc molar ratio (Ph:Zn) and 6.457–7.943 for phytate by calcium to zinc molar ratio (Ph*Ca:Zn). A linear model was significant (P < 0.05) and adequate to describe variations in iron, zinc, Ph:Fe, Ph:Zn and Ph*Ca:Zn. There was a remarkably linear increase in iron and calcium contents with an increased dabi teff ratio in the blends accompanied by a significant decrease (P < 0.05) in phytate/minerals molar ratios. The findings showed that increasing dabi teff ratio in the blends notably increased iron content with reduced Ph:Fe molar ratio, providing the bases for developing iron-dense novel composite complementary flour with improved iron bioavailability to combat iron deficiency anemia among children.

Graphical Abstract

Similar content being viewed by others

Introduction

In Africa, the consumption of animal foods which are good sources of high bioavailable dietary minerals is low because of affordability and religious reasons. This low consumption of animal-source foods combined with suboptimal complementary feeding practices (Bolton 2019; FAO 2020), resulted in higher micronutrient malnutrition among children. For example, the prevalence of anemia among under-five children is about 64.6% in Africa (McLean et al. 2009) and according to the Ethiopian Public Health Institute (EPHI) and International Classification of Functioning, Disability and Health (ICF) survey, 57% of children under-five years were anemic (EPHI and ICF 2019). In Ethiopia, the lower consumption of animal-source food is majorly associated with economic and religious reasons due to which plant foods are the major staple diets and major food choices among the people. Thus, micronutrients and their bioavailability from plant foods need to be improved especially when used for infants and young child feeding. This is generally because micronutrients from plant sources are not in an easily absorbable forms like the non-heme forms of iron and inorganic forms of zinc as well as the presence of high mineral absorption inhibitors referred to us the anti-nutrients (Gibson et al. 2006).

The contribution of micronutrients from breast milk declines with a child’s age and would be almost zero after 12 months for all micronutrients and nearly all iron requirements (> 97%) should come from complementary foods after 6 months (Abeshu et al. 2016). Exploring different locally available, underutilized, affordable and nutritious plant foods (the dietary diversity approach) and blending them together after the application of simple pre-processing is the best option (FAO/WHO 1991) to get multiple and higher micro-nutrients from their mixture and to provide dietary minerals rich foods or food with easily absorbable and bioavailable minerals as a main drive to prevent child micronutrient malnutrition (McLaren 1974).

Complementary feeding (from 6–24 months of age), is one of the most critical periods in children’s life during when ‘milk from the mother’s breast’ which is an ideal child food, can no longer meet the increasing nutrient needs of the growing child (Rasane et al. 2015) and infant’s transfer from nutritious, adequate and uncontaminated breast milk to complementary foods (often regular family food). It should be underscored that complementary foods do not replace (but complement) breastfeeding (Abebe et al. 2006, FAO/WHO 1991). The significantly higher prevalence of micronutrient malnutrition in under-five children occurs during or after the introduction of complementary foods because of the poor quality and inadequate required micronutrients nutrients for the optimal growth and development of the children (Muhimbula & Issa-Zacharia 2010).

Traditional complementary foods in developing countries including Ethiopia are characterized by low nutritive value, low micronutrient density and high anti-nutrients (Dewey & Adua Afarwuah 2008; Gibson et al. 2000) and children are more susceptible to micronutrient deficiencies due to poor minerals bioavailability, inadequate dietary intake and low intake of animal food sources (Soetan & Oyewole 2009).

Currently, the bioavailability of minerals and protein is the top buy than their higher amounts in the food system because of the nutritional implication that nutrients need to be absorbed and efficiently utilized for normal body function. The bioavailability of nutrients/minerals is affected by factors like chemical forms of the nutrients in foods (e.g. heme and non-heme forms of iron, organic and inorganic forms of zinc), interactions between nutrients and other organic components including anti-nutrients, dietary fiber, ascorbic acids and by the processing or preparation practices applied (Gibson et al. 2006).

Despite cereals, and legumes in particular being highly nutritious, the problem associated with the higher anti-nutritional contents present in these crops limits their nutritional quality. Anti-nutrients such as phytate, tannin, trypsin inhibitor, cyanogenic glycosides and oligosaccharides are naturally occurring constituents majorly in cereals and legumes which antagonize the absorption of one or more minerals through non-digestible insoluble complex formation, particularly with positively charged divalent minerals and reduce the bioavailability of the minerals as well as prevent their efficient utilization in human body (Bouchenak & Lamri-Senhadji 2013; Graham et al. 2000), thus, required to be eliminated or reduced below their critical limits by proper treatments. However, phytates and tannins have been identified to have some health benefits for instance; they can play a high antioxidant and anti-carcinogenic activity (Roy et al. 2007), lowering chronic inflammation and the chance of diabetes mellitus and lower obesity (Bouchenak & Lamri-Senhadji 2013) and cardiovascular disease (Thorisdottir et al. 2023). Hence, the anti-nutritional effects of phytate and tannin need to be evaluated against these health-benefit properties. That is, they can play a free radical scavenging activity against oxidation and thus alleviate the onset and progression of cancer and cardiovascular diseases.

Enzymatic (use of phytase and amylase enzymes) processing such as germination and/or fermentation ‘the amylase-rich food technology’ or non-enzymatic processing like roasting, soaking and dehulling are the globally accepted low-cost methods used to reduce the anti-nutrients and their adverse interference with minerals absorption such as iron, calcium and zinc (Gibson et al. 2010; Ndagire et al. 2015; Soetan & Oyewole 2009). Dietary factors such as ascorbic acid, meat, poultry and fish are also important enhancers of non-hem iron (plant-source) and zinc absorption (Etcheverry et al. 2006; Hallberg & Hulthan 2000). But in many developing countries, meat is too expensive and consumed on special occasions only, if not at all, where it is even unthinkable for people with poor settings or limited resources in developing countries to purchase meat regularly.

Processing and blending of cereals, legumes and oilseeds constitute a good source of micronutrients with many health benefits as well as a reduced phytate/minerals molar ratio or enhanced bioavailability (FAO/WHO 1991). Thus, it was hypothesized that mixing different locally available cereals and legumes such as dabi teff, field pea and others which are expected to be rich in micronutrients accompanied by proper processing techniques would be promising to provide multiple and higher micronutrients with improved bioavailability.

Dabi teff is the ‘afaan oromoo language’ name for an early maturing variety of dark red teff. The early maturing property makes the crop to be harvested twice within one rainy season (at early rainfall called “daabi gannoo” and late rainfall called “daabi birraa”). Farmers in Wollega and Illuababor, western Ethiopia, cultivate dabi teff either for its grain seeds or its straw. The contribution of the grains to household food and nutrition security is considerable when viewed through a food security lens while the straw is composed of fine stems used for plastering (finishing) mud hut walls during house construction and rated higher among others for animal fodder especially oxen feeding (Tura et al. 2023). There are many social beliefs regarding the nutritional and health benefits of dabi teff among the consumers that after eating its different food form such as ‘kita/maxinoo (unleavened bread), muk/mooqa (gruel), mooqa manyee and cafaqoo (the favorite cultural dishes)’, it “dhiiga dabalaa” to mean it increases blood volume, “humna dabalaa” meaning it boosts energy/strength, “dugda jabeessa” meaning it repairs/strengthening backbone and fractured bone which could be implicated for its high calcium content where dabi teff is prized as medicinal food among the rural elderly people in particular and the consumers in general (unpublished observations by the researchers). Hence, in this study, the effects of blending ratios variation on micronutrient compositions, anti-nutritional factors and phytate/minerals molar ratio of pre-processed dabi teff-field pea based novel composite complementary flours were examined. The findings from this study can be used for providing the bases for developing dabi teff-field pea based novel composite complementary food to be used as a sustainable food-based strategy in combating iron deficiency anemia among children.

Materials and methods

Food crops sample collection

The food crops viz., dabi teff (Eragrostis teff (Zucc.) farmer variety), maize (Zea mays L.), barley (Hordeum vulgare), white field pea (Pisum sativum), oats (Avena. sativa) and linseed (Linum usitatissimum) were purchased from the open market of Nedjo town, Oromia, Ethiopia which is located at 575 km away to the west from Addis Ababa where Nedjo district is the potential dabi teff growing area. 3 kg of each apparently uninfected sample (visual inspections like the absence of black spots and discoloring) were purchased from the center and corners of the market on two different market days to assure representativeness. The samples were then packed separately in polyethylene bags and transported to the Ethiopian Institute Agricultural Research, Food Science and Nutrition laboratory for further treatments. All laboratory analyses of micronutrients and anti-nutritional factors were conducted in the stated laboratory which was certified by the International Organization for Standardization (ISO), ISO-17025:2017 by International Laboratory Accreditation Cooperation (ILAC) where the phytate/minerals molar ratios were computed based on their molecular weights.

Sample processing

It is not only the wise selection of nutritionally promising crops, but also the processing techniques applied that determine the quality of the final product. Accordingly, the obtained crop samples underwent various controlled processing techniques. In brief, cleaning of dabi teff grains was performed manually by winnowing to remove chaffs, straw, dust and other extraneous and washed with tap water and sundried for two days at an average temperature of 27 ℃ while the other cereals (maize, barley and oats) and the legumes (field pea and linseed) were sorted out from sands, sticks, stones and defective seeds, later washed and sundried for two days at an average temperature of 27 ℃ and were ready for further individual processing. Due to the small size of dabi teff seeds, it was made into whole-seed milled flour which could be the reason for the higher nutrient contents of the crop. Barley and oats samples were soaked in clean tap water for 2 h. The water used for soaking was drained off and the crops were immediately decorticated (while the seeds were still wet) using a wooden decorticator and the hulls were removed by winnowing.

Germination of maize seeds was adapted from the method previously described by Rasane et al. (2015) with little modification. Briefly, soaking of the maize grains was performed in water (1:3 w/v) for 3 h to achieve hydration, drained, spread on a clean jute sack placed on a wooden platform and covered with another jute sack for germination at room temperature (25 ℃ ± 2 ℃) for 72 h and water was sprayed every 12 h to stay humid (60% relative humidity). This 72 h was used because Rasane et al. (2015) reported that the maximum amylase activity was obtained at 72 h of germination time. After 72 h, the germinated seeds were rinsed, drained for 10 min, transferred to aluminum trays and dried in an air oven at 40 °C for 5 h to terminate the germination process. The dried germinated sample was further roasted for 10 min at a temperature of 120 ± 5 °C and allowed to cool.

The crop samples viz., barley, oats, field pea and germinated maize were minimally roasted for 20 min at 120 °C oven temperature until light brown colored and then cooled to room temperature (25 ± 2 °C) as described by Rasane et al. (2015). The roasting process was carefully controlled to prevent over-roasting and the formation Maillard reaction that may lead to protein quality damage. The linseed sample was minimally cooked for 5 min at 90 ℃ (Castro-Alba et al. 2019) with little amount of water for the purpose of conditioning the seeds to release oil from the oil cells and later sundried without draining the water used for cooking.

Flour preparation and handling

All the six processed samples were milled into flours using a standard miller (Cyclotec 1093 sample mill, Foss Analytical, Sweden) where smooth and consistent particle sizes flours were obtained and sieved through a 0.5 mm mesh sieve size. The flours were then packed in airtight high-density polyethylene bags (AACC, 2000), separately coded as X1-Dabi Teff flour, X2-Barley flour, X3-Oats flour, X4-Field Pea flour, X5-Lin Seed flour and X6-Germinated Maize flour and stored safely at room temperature till formulation.

Experimental design

Blending the flours

Stat-Ease Design-Expert® software version 11 (Randomized Mixture Design, D-optimal, Minneapolis, USA, 2018) was used to generate the blended design matrix (Table 1). Defining the range of each component in the blends was based on three considerations including targeting firstly to attain FAO/WHO (1991) macronutrients and micronutrients recommendation, where the recommendation specifies that the energy from protein (protein-calorie) should be between 6–15% of the total energy from a complementary product, fat-energy to be 20–30% of the total energy with the remaining energy 55–65% should be generated from a carbohydrate source and iron requirements should be 16 mg/100g, calcium 500 mg/100g and zinc 3.2 mg/100g of complementary food to be nutritionally adequate, secondly targeting the Ethiopian complementary feeding guideline (Federal Democratic Republic of Ethiopia 2012) which specifies enriched complementary food would be prepared using one third (1/3) of legumes/pulses and three-fourth (3/4) of cereals and thirdly based on the micronutrient contents of individual components. To obtain the high carbohydrate-energy requirement for children and to align with the Ethiopian complementary feeding guideline, the other components including barley, oats and linseed which are naturally good sources of energy and carbohydrate were set constant in the blends which was thoughtfully designed to maintain the higher carbohydrate-energy sources and requirements.

The micro-composition analysis results of individual flours (Table 2) were recorded (customized) ‘into’ Nutriurvey software (Version 2007) for analysis to estimate and define ranges of major components (Table 3). By estimating the amount of a meal to be consumed by 1-3 years old children to be 75 g (solid portion) per meal and adjusting for the required number of meals per day, several trials (iterations) were made to define ranges of the major components (dabi teff, field pea and germinated maize) by entering range related amounts into the software combined with the constant components and examine the output.

D-optimal mixture design was run to generate the blends using the range defined. The six components were constrained to generate a total of 16 experimental blends with 6 central points and 5 replicates to provide 11 experimental runs with an estimate of pure error and 5 lack of fit points. The amount in grams of individual components generated in each blend (experimental run) was carefully weighed on a digital balance gravimetrically and put together after which it was thoroughly mixed using an electrical blender for 3 min at 200 rpm to homogenize that was packed and sealed in high-density polyethylene bags and stored in a refrigerator at 4 °C till analysis.

Dietary minerals analysis of the complementary flour blends

Analysis of aqueous solutions by Inductively Coupled Plasma-Optical Emission Spectrometry (ICP-OES) with radial plasma observation method was used to determine the dietary mineral contents (Fe, Zn, Ca, Mg, K, P, Na) of the blended complementary flours used with radial plasma observation method (de Souza et al. 2008). All the measurements were performed using a sector arcos optical emission spectrometer optimized with small volume and 32 linear charge-coupled devices (CCD) detectors in the wavelength range between 130–770 nm and simultaneously analyzed. A nebulizer was used to introduce sample solution into the argon gas field plasma and the energy excitement was proceeded in the single spectra and the energy was expressed in intensity which is directly proportional to concentration, the concentration was calculated on the linear graph of the standard concentration and the corresponding intensities. All the measuring conditions, like plasma power, gas flows, torch positions and measuring time are configured. It was a concentration measurement. According to the standard, the calibration and standardization of the spectra method were performed and standardization was done daily and it is a quick procedure for correcting measuring intensities so that the correct concentration are obtained using the original calibration curve.

Determination of Anti-nutritional factors (Non-nutrient contents)

Determination of phytate content

Latta and Eskin (1980) method was used for the determination of phytate after extraction of sample with 10 mL of 0.2 N HCl for 1 h, centrifuged (Sigma 2-16KC, UK) and the clear supernatant sample extract (3 mL) was reacted with 2 mL of Wade reagent (0.03% FeCl3.6H2O and 0.3% sulfosalicylic acid in distilled water) and vortexed mixed for 5 s. The absorbance of the sample was measured at 500 nm using a UV–visible spectrophotometer (V-630, Jasco, USA). The phytate concentration was calculated from the difference between the absorbance of the blank (3 ml of 0.2N HCl + 2 mL of wade reagent) and that of the assayed sample. The phytate content was calculated using a phytic acid standard curve prepared in the same condition and the result was expressed as mg/100 g.

Condensed tannin content determination

Traditionally, tannins have been classified into condensed and hydrolyzable tannins, based on their hydrolytic properties in hot water or response to tannase enzyme. In the present study, condensed tannin (proanthocyanidins) was analyzed by Vanillin-HCl methods of Price et al. (1978). The sample was milled just to pass ≤ 750 µm sieve. About 200 mg of the sample was weighed into a screw-capped test tube and extracted with 10 mL methanol by vortex mixing for 20 min. Then it was centrifuged at 3000 rpm for 10 min. 1 mL of sample extract was mixed with the Vanillin reagent (5 mL) at 1 min intervals to one test sample set and for the blank only 1 mL was used. 5 mL of concentrated HCl was added in methanol 4% at 1-min intervals. The supernatant was used for the analysis after warming up along with the Vanillin-HCl reagent in a water bath at 30 °C. 1 mL of the sample extract was taken in a duplicate for each sample (one for mixing with Vanillin reagent and the other for blank) to be deducted from sample absorbance. Then it was immediately incubated in a water bath at 30° C for 20 min. After 20 min, the absorbance was immediately measured/read on a spectrophotometer at 500 nm in 1-min intervals as per the sequence used for mixing. The sample absorbance was deducted from the blank and the value was estimated from the catechin equivalent (CE) standard curve Price et al. (1978). A standard curve absorbance (y) against catechin concentration (x) was prepared from the catechin. Standard solution readings and the slope were computed and hence tannin concentration was determined from the equation of the curve.

Where CE = catechin equivalent; CC = catechin concentration (mg/mL); VM = volume made up (mL); VE = volume of extracts and Wt = weight of sample.

Where: As = Sample Absorbance; Ab = Blank Absorbance; D = Density of solution (0.791 g/mL); W = Weight of sample in gram.

Phytate/Minerals molar ratios (In-vitro minerals bioavailability)

The phytate/minerals molar ratio of each blends were computed for iron, calcium and zinc using the method of Norhaizan et al. (2009). The amount of phytate and minerals in each blends were divided by their respective atomic weight, (phytate: 660 g/mol; Fe: 56 g/mol; Zn: 65 g/mol; Ca: 40 g/mol) and the phytate/minerals molar ratio were obtained by dividing the mole of phytate with the mole of the respective minerals. The molar ratios found were compared with the acceptable critical limits (FAO/WHO 1991) in which phytate/calcium molar ratio (Ph:Ca) (< 0.24), phytate/iron molar ratio (Ph:Fe) (< 1), phytate/zinc molar ratio (Ph:Zn) (< 15) and phytate by calcium to zinc molar ratio (Ph*Ca:Zn) (< 200) to be used as a proxy indicator of good mineral bioavailability or uncompromised absorption.

Statistical analysis and model evaluation

All the laboratory analysis results of the 11 experimental runs (Table 1) were subjected to ‘Sheffe’ polynomial mixture regression analysis using the Stat-Ease Design-Expert® software version 11 (D-optimal mixtures design). Mixture components were considered as model terms and mixture regression was designated as model fitting. Linear, quadratic, cubic and special cubic models and interactive effects of the independent variables were fitted for evaluation of the response variables viz., micro-compositions, phytate, tannin and phytate/minerals molar ratio of the blends (Table 4). Analysis of variance (ANOVA) of the Stat-Ease Design-Expert was performed to develop regression models (mathematical algorisms) to show the relationship between Xs’ (individual linear, quadratic, cubic and interactive effects of the components) and Ys’ (the response variables) and to determine the goodness of fit (significance) of the models developed. These effects (relationships) were further verified by running the ‘Model Graphs’ test through ‘2D’ (contour plot) and ‘trace plots’ graphs.

Linear and polynomial regression models were judged (verified) to be adequate and significant using F-statistic at a probability (P) of 0.05, 0.01, and 0.001 and the coefficient of determinations R2. R2% is the percentage variation of the response (dependent) variable that can be explained by its linear relationship with the independent variable and measures the degree of fitness of a regression model. The closer the R2 value is to unity (1) and the closer R2adj to R2pred (the difference less than 0.2) and the adequate precision value greater than 4 shows the better the model fits the actual data ensuring satisfactory fitted models and adequate to specify the correct relationship between response (Ys’) and independent variables (Xs’). The R2% value should be at least 80% to have a good fit of a regression model (Nahemiah et al. 2016). To determine whether a model meets the normality and constant variance assumptions for the analysis, the error terms residual plots were checked. On the other hand, datasets of minerals and phytate/minerals molar ratios were statistically analyzed using One-way ANOVA of SPSS (IBM version 24, Chicago, USA) to declare statistically significant differences between the blends and compared to the control and the Cerifam® faffa flour (the popular commercial complementary/weaning flour in Ethiopia). All the data collected were in triplicate. Levene’s test was used to check the equal variance assumptions (P > 0.05, should be non-significant). Tukey honestly significant difference (HSD) post hoc test was used for pairwise multiple comparisons (mean difference separation test) and the significant differences were declared at P < 0.05.

Results and discussion

Model fitting and testing model adequacy

The fitted models were found to be adequate and significant for almost all response variables based on the F-statistic (the ANOVA regressions outputs); the P-value, the coefficient of determinations R2 and the agreement between R2adj and R2pred (Table 4). Normality and constant variance assumptions were fulfilled; that normal plots of residuals were well aligned around the actual line for most response variables showing a well fitted model design.

Table 4 shown that the linear model was adequately fitted for iron, zinc, Ph:Fe, Ph:Zn and Ph*Ca:Zn contents at P-values of < 0.05 whereas for calcium the same linear model was suggested by the software but not significant or no predictive power (P > 0.05). This shows that x1, x4 and x6 were the significant model terms for these variables with their corresponding P-values at 0.0001, 0.0164 and 0.1959 for iron, zinc and calcium, respectively. Meaning changes in iron, zinc, Ph:Fe, Ph:Zn and Ph*Ca:Zn can adequately be described by the linear models (adequate predictive power) as a function of the component ratios variation in the blends.

The predictive regression models developed for the relationship between the independent (Xs’) and dependent (Ys’) in terms of mineral contents, anti-nutrients and phytate/minerals molar ratio of the blends was presented in Table 5 for iron, zinc, calcium, magnesium, phytate, Ph:Fe, Ph:Zn, Ph:Ca and Ph*Ca:Zn, respectively. The coefficients with single factor (linear model terms) (X1, X4, and X6) represent the independent effect of a particular determinant variable while coefficients with two of the factors (X1X4, X1X6, and X4X6) represent an interaction between the factors (interactive model terms). A negative sign in front of the regression model terms is an indication of an antagonistic relationship while a positive sign indicates a synergetic relationship or synergetic effect.

Prelimnary study and nutrisurvey analysis result

Prior to blending the component together, a preliminary study on selected micronutrient contents of our typical component, the ‘dabi teff’ was conducted and the result showed that it contained a considerable amount of iron at 122.66 mg/100 g, calcium at 190 mg/100 g and zinc at1.8 mg/100 g. In this study, the mean and standard deviations of the micronutrient contents of the individual components used were presented in Table 2 which were customized ‘into’ the Nutrisurvey software. The generated output from the Nutrisurvey analysis showed the percentage fulfillment by the meal of the mix (blend) of our comonents as compared to the recommended nutrient intake (RNI) to be 612–1045%, 133–225% and 229–400% for iron, zinc and magnesium, respectively (Table 3) which corresponds to 20–35% of dabi teff, 0–30% of field pea, 5–20% of germinated maize, 25% of barley, 15% of oats and 5% of linseed meal mixture, respectively which were used as constraints for generating the blending matrix.

Effects of blending ratios variation on dietary mineral contents of complementary flour blends

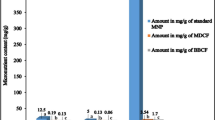

The mean and standard deviation of mineral contents of the eleven blends of complementary flours were summarized in Table 6. Results of mean difference separation showed that all the mineral contents were significantly different (P < 0.05) among the blends (as affected by components ratios variation) and ranged from 24.01–31.58 mg/100 g for iron, 73.46 -78.81 mg/100 g for calcium, 2.33–2.61 for zinc, 113.9–124.22 mg/100 g for magnesium, 364.77–497.48 mg/100 g for potassium, 281.03–308.54 mg/100 g for phosphorous and 3.46–6.25 mg/100 g for sodium, respectively. The control flour contained 7.25 mg/100 g, 49.45 mg/100 g, 2.64 mg/100 g, 96.45 mg/100 g, 398.67 mg/100 g, 282.65 mg/100 g and 4.07 mg/100 g for iron, calcium, zinc, magnesium, potassium, phosphorous and sodium, respectively (Table 6). The iron and calcium contents of the blended flours were significantly higher (P < 0.05) than that of the control flour whereas zinc content was slightly lower at 2.64 mg/100 g. This finding showed that the iron content of the blends exceeds (1.5–1.97 times higher than) the recommended value by FAO/WHO (1991) at 16 mg/100 g in formulated complemented food for infants and older children. On the other hand, calcium and zinc contents of the blends were below the recommendations at 500 mg/100 g for calcium and 3.2 mg/100 g for zinc which was in agreement with the report by Gibson et al. (2010) that an iron, calcium and zinc deficits were observed in indigenous complementary foods usually consumed by infants and young children in the southern part of Ethiopia.

In the contrary to the current findings, Mezgabo et al. (2018) reported a wider range of iron content at 9.38–34.86 mg/100 g but it fairly agrees and it was further reported a higher calcium content at 293.57 mg/100 g for complementary porridge formulation from red teff, malted soybean flour and papaya fruit powder where the report associated the high calcium content of the formulations with the higher calcium content of soybean. The zinc content of the current blends was lower than the report by Mezgebo et al. (2018) that it ranged from 4.05–5.58 mg/100 g for complementary porridge formulation from red teff, malted soybean flour and papaya fruit powder and the higher zinc content was associated with malted soya flour ratio in the formulation.

In this study, out of the seven minerals experimented (Table 6), the effects of component ratio variation in the blends on the major three minerals (iron, calcium and zinc) were more emphasized and narrated because of their relatively higher importance to be present in complementary food that determines child growth and development. Given then, there observed a remarkably linear increasing effect in iron content with an increased proportion of dabi teff (the single influencing mixture component) as shown by 2D contour and trace plots (Fig. 1a, b) which could be due to the significant higher iron content of dabi teff flour at 86.5 mg/100 g (Table 2). It can be seen from Table 6 that at the maximum ratio (35%) of dabi teff in the blends, the iron content was at the maximum value of 31.58 mg/100 g (B6) whereas at the lowest dabi teff ratio (20%), the iron content was at the lowest value of 24.01 mg/100 g (B4). These findings agreed with the report by Mezgebo et al. (2018) that the iron content had a direct positive association with the amount of red teff flour ratio in the porridge flour formulation from red teff flour, malted soya flour and papaya flour powder. But in contrary, the effect of dabi teff ratio variations in our blends was higher than the report by Alaunyte et al. (2012) who reported that by supplementing wheat bread with 30 percent teff flour, the iron content of the bread was more than doubled where in our blends, it was more than tripled (3.31–4.36 fold) than the control at dabi teff range of 20–35% in the blends. On the other hand, there observed a negative relationship between iron content and germinated maize as well as field pea flour ratios in the blends. The probable reason for this could be the very low iron contents of these two components (Table 2).

Similarly, there was a linear increasing effect in calcium content with an increased proportion of dabi teff flour ratio in our blends as shown by 2D contour and trace plots (Fig. 2a, b) which could be due to the significantly higher calcium content of dabi teff flour among the other components. On the other hand, there observed a negative relationship between calcium content and germinated maize as well as field pea flour ratios in the blends though the decrease in calcium content in relation to field pea was not as sharp as that of germinated maize. The probable reason for this could be the very lower calcium contents of germinated maize flour than the field pea flour (Table 2). On the contrary to the present finding, Mezgebo et al. (2018) reported that calcium content increased with an increase in soybean ratio (a pulse crop) in complementary food formulation from red teff flour, malted soya flour and papaya flour powder.

Concerning zinc content, there observed a moderatelyly increasing effect with an increased proportion of dabi teff and field pea flours while it showed a negative relationship with germinated maize flour in the blends as shown by 2D contour and trace plots (Fig. 3a, b). This finding agrees with the report by Mezgebo et al. (2018) that zinc content increased as the ratio of soybean flour increased in complementary flour formulation which is also a pulse crop as that of our field pea.

The ‘novelty’ of this study would be accounted for the incorporation of dabi teff flour into the blends containing high iron (86.5 mg/100 g) and linseed which is a leading source of α-Linolenic acid, omeg-3 polyunsaturated fatty acid that would make the blends super. The nutritional composition, particularly the iron content of dabi teff is quite different (much higher) from the others popular red teff varieties grown in Ethiopia. For example, (Mezgebo et al. 2018) reported lower level of iron content at 38 mg/100 g for the popular red teff grown in Ethiopia. Similarly, Daba (2017) reported a lower iron content of the red-teff (Dz-01–1681) variety at 20.6 mg/100 g, which makes dabi teff a unique and super iron bank.

Effects of blending ratios variation on Anti-nutritional factors (Phyatae and Tannin) of the complementary flour blends

The mean and standard deviation of anti-nutrient contents of the blended complementary flours were summarized in (Table 7). The anti-nutrients among the blends ranged from 85.2–104.12 mg/100 g for phytate and from 8.35–23.1 mg/100 g for tannin content, respectively and they were significantly different (P < 0.05) among the blends. The first blending (B1) and the tenth blending (B10) had shown a significantly higher (P < 0.05) phayate content at 102.72 and 104.12 mg/100 g as compared to the rest of the blends while the control had shown incomparably higher phaytate content than all the blends at 126.54 mg/100 g.

There observed an increasing linear effect in phytate content as a function of field pea flour, where, as a field pea flour ratio increased in the blends, the phytate content linearly increased where this was inconsistent with the report by Mezgebo et al. (2018) that phytate content increased with an increase in the soybean ratio in the formulation of complementary food. But there observed a decrease in phytate content with an increasing ratio of dabi teff flour ratio in the blends as revealed by 2D contour and trace plots (Fig. 4a, b). The lowest phytate content was observed in the sixth blend (B6) at 86.27 mg/100 g and eighth blend (B8) at 85.2 mg/100 g where the ratio of dabi teff flour at these two blends was at the highest ratio. This suggested that dabi teff-enriched novel food products would be less likely to exhibit absorption inhibition due to the lower phytate content observed in dabi teff enriched product..

Regarding tannin content of the flour blends, the eighth blend (B8) shown significantly higher (P < 0.05) tannin content followed by the fourth blend (B4) and eleventh blend (B11) at 23.1, 18.06 and 18.06 mg/100 g, respectively while the lowest tannin content was observed in the ninth blend (B9) at 8.35 mg/100 g and the control had a similar tannin content (12.42 mg/100 g) as the rest of the blends (Table 7). Tannin content was inversely correlated to dabi teff flour typically revealed by the sixth blend (B6), lower tannin content (10.64 mg/100 g) at highest dabi teff ratio (35%) and ninth blend (B9), lowest tannin content (8.35 mg/100 g) at lowest dabi teff ratio (20%) also it was inversely correlated to field pea flour ratio as revealed by the eighth blend (B8), highest tannin (23.1 mg/100 g) at lower field pea ratio (6.48%) and tenth blend (B10), lowest tannin (8.56 mg/100 g) at higher field pea flour (22.74%). Thus it can be suggested that dabi teff-field pea based novel complementary food would pose a low association with the tannic acid absorption inhibition effect.

Effects of blending ratios on phytate/minerals molar ratio (In-vitro mineral bioavailability)

In nutrition science, the anti-nutrients/minerals molar ratio is more interesting than the level of the anti-nutrient content in foods because of its implication in the absorption and bioavailability of minerals. In this study, the mean values of Ph:Fe, Ph:Ca, Ph:Zn and Ph*Ca:Zn among the blends ranged from 0.232–0.344, 0.067–0.085, 3.356–4.18 and 6.457–7.943, respectively (Table 7). There was a significant difference (P < 0.05) in mean values of phytate/minerals molar ratios except Ph:Ca among the blended composite complementary flours. The mean Ph:Fe molar ratio among the blends at 0.29:1 was below the critical limit at 1:1, above which iron absorption can be impaired (Gibson et al. 2010). A value greater than 1:1 ratio has a negative effect on iron absorption; where the calculated values in the present study were all less than 0.4:1 which is a preferable Ph:Fe molar ratio (Castro-Alba et al. 2019; Hurrell & Egli 2010; Magallanes-LApez et al. 2017).

The Ph:Fe molar ratio showed a strong inverse relationship with the proportion of dabi teff flour in the blends where the lowest molar ratio was observed in the sixth blend (B6) and eighth blend (B8) at 0.232 (at highest proportion of dabi teff flour at 35% and 34.385%) and the highest Ph:Fe molar ratio was observed in seventh (B7) and tenth blends (B10) at 0.340 and 0.344, respectively where the proportion of dabi teff flour was at the minimum ratios. This inverse relationship was revealed in 2D contour and trace plots (Fig. 5a, b). The Ph:Fe molar ratio in this study was shown a direct (linear) relationship with the proportion of field pea flour in the blends (increasing field pea flour ratio resulted in increased Ph:Fe content and the vice-versa). There was also a linear relationship between Ph:Fe molar ratio and the proportion of germinated maize flour in the blends but moderate (Fig. 5a, b).

The mean Ph:Ca molar ratio among the blends at 0.076:1 was below the critical limit at 0.24:1, above which calcium absorption can be impaired (Gibson et al. 2010). The relationship between the proportions of dabi teff flour and Ph:Ca molar ratio was inverse in the blends with the lowest determined values of 0.067 at the maximum ratio of dabi teff flour at 35% and 34.385% (B6 and B8), respectively while the highest determined values of Ph:Ca at 0.083 and 0.085 were at minimum proportion ratio of dabi teff flour ratio at 22.73% and 27.5%, respectively and the relationship was revealed by 2D contour and trace plots (Fig. 6a, b). The germinated maize flour ratio was also negatively correlated to Ph:Ca molar ratio while field pea flour ratio in the blends was positively correlated to Ph:Ca molar ratio.

The mean Ph:Zn molar ratio among the blends at 3.83:1 was lower than the critical limit of 15:1 (Table 7). A value greater than the critical limit is associated with low estimated bioavailability, where 5–15 and below 5 Ph:Zn molar ratio are associated with moderate and high estimated bioavailability, respectively, with zinc absorption corresponding to 15%, 30%, and 50%, respectively (Castro-Alba et al. 2019; Magallanes-LApez et al. 2017). The calculated value in this study falls in the third category (Ph:Zn below 5) showing higher estimated bioavailability with an expected 50% absorption rate.

The relationship between the proportion of dabi teff flour and Ph:Zn molar ratio was strong inverse, where the lowest Ph:Zn values (3.468 and 3.356) were at the sixth blend (B6) and eighth blends (B8) (35% and 34.385% ratio of dabi teff) which was the maximum ratios and the realtioship was revealed by 2D contour and trace plots (Fig. 7a, b). A direct relationship was observed between Ph:Zn molar ratio and the proportion of field pea as well as germinated maize flour among the blends (i.e. an increase in the ratio of the two components in the blends resulted in an increased Ph:Zn molar ratio). In line with the present finding, Castro-Alba et al. (2019) have reported a significant negative correlation (P < 0.05) between Ph:Fe and cereals and a positive correlation between Ph:Zn and dry legumes. In contrary to the present finding, Castro-Alba et al. (Castro-Alba et al. 2019) has reported a negative correlation between Ph:Ca and dry legume which could be attributed to different factors.

The mean range of Ph*Ca:Zn molar ratio among the blends at 7.29:1was found to be far below the critical limits which is 200:1 above which zinc absorption would be impaired. In the same fashion, the relationship between dabi teff flour proportion and Ph*Ca:Zn molar ratio was strongly inverse where the value was at minimum at 6.457 and 6.778 with its corresponding maximum dabi teff flour ratio at 34.385% and 35% (B8 and B6), respectively and the relationship was revealed by 2D contour and trace plots (Fig. 8a, b). The relationship between Ph*Ca:Zn molar ratio and field pea flour as well as germinated maize flour proportion was direct, where the Ph*Ca:Zn molar ratio kept increasing as the proportion of these two flours increased in the blends.

From the present findings, it can be generalized that the inhibitory effect of phytate on iron, calcium and zinc absorption and bioavailability would be insignificant (unlikely to be markedly compromised) because the molar ratios computed for the minerals were far below the critical limit above which their absorption and utilization would be impaired. The probable reason for these low phytate/mineral molar ratios might be the effect of the pre-processing techniques applied; soaking, germination, roasting, and dehulling processes on the components used which is supported by the report by Gibson et al. (2006) that molar ratios of phytate/mineral were improved (reduced) by processing techniques such as roasting, germination, and fermentation.

Conclusion

Multiple grains at varied mixing ratios are more likely to contain multiple and higher micronutrients than grains from a single (mono) grain. The present study demonstrated that complementary fours that can compose the limiting minerals (iron, zinc and calcium) in an increased level could be prepared from dabi teff-field pea blends. The ratios variation of the major components have shown a significant effect on the dietary mineral contents as well as on the phytate/minerals molar ratios of the blends. There was a remarkably linear increase in iron and calcium contents of the blends with an increased dabi teff ratio accompanied by a significant decrease in phytate/minerals molar ratio which is a good proxy indicator of higher iron bioavailability. The findings revealed that, increased iron content accompanied by its enhanced bioavailability (the reduced phytate/iron molar ratio) can be prepared from dabi teff-field pea based local food crops, providing the bases for developing iron-dense novel composite complementary flours that can serve as a sustainable food-based strategy to alleviate iron deficiency anemia among children. Conducting a study on the functional properties of the flour and sensory acceptability of the porridge from the flours and conducting efficacy or feeding trials to see the effect of the flour on the iron status of under-five children was suggested as a future scope of this study.

Availability of data and materials

All supportive data were contained within the article in Tables and Figures.

References

AACC (2000) American Association of Cereal Chemists, 11th edition, Cereals and Grains Associations Technical Communities, Washington DC.

Abebe, Y., Stoecker, B. J., Hinds, M. J., & Gates, G. E. (2006). Nutritive value and sensory acceptability of corn-and kocho-based foods supplemented with legumes for infant feeding in Southern Ethiopia. African Journal of Food, Agriculture, Nutrition and Development, 6, 1–19.

Abeshu, M. A., Lelisa, A., & Geleta, B. (2016). Complementary feeding: review of recommendations, feeding practices, and adequacy of homemade complementary food preparations in developing countries - lessons from Ethiopia. Frontiers in Nutrition, 3, 1–9.

Alaunyte, I., Stojceska, V., Plunkett, A., Ainsworth, P., & Derbyshire, E. (2012). Improving the quality of nutrient-rich Teff (Eragrostis tef) breads by combination of enzymes in straight dough and sourdough breadmaking. Journal of Cereal Science, 55, 22–30.

Bolton, L. (2019). Animal sourced foods (ASF): evidence on stunting and programmes to increase consumption. Institute of Development Studies.

Bouchenak, M., & Lamri-Senhadji, M. (2013). Nutritional quality of legumes, and their role in cardiometabolic risk prevention: A review. Journal of Medicinal Food, 16, 185–198.

Castro-Alba, V., Lazarte, C. E., Bergenståhl, B., & Granfeldt, Y. (2019). Phytate, iron, zinc, and calcium content of common Bolivian foods and their estimated mineral bioavailability. Food Science & Nutrition, 7, 2854–2865.

Daba, T. (2017). Nutritional and soio-cultural values of teff (Eragrostis tef) in Ethiopia. International Journal of Food Science and Nutrition, 2, 50–57.

de Souza, R. M., Leocádio, L. G., & da Silveira, C. L. C. P. (2008). ICP OES simultaneous determination of Ca, Cu, Fe, Mg, Mn, Na, and P in biodiesel by axial and radial inductively coupled plasma-optical emission spectrometry. Analytical Letters, 41, 1615–1622.

Dewey, K. G., & Adua Afarwuah, S. (2008). Systematic review of the efficacy and effectiveness of complementary feeding interventions in developing countries. Maternal & Child Nutrition, 4, 24–85.

Etcheverry, P., Hawthorne, K. M., Liang, L. K., Abrams, S. A., & Griffin, I. J. (2006). Effect of beef and soy proteins on the absorption of non-heme iron and inorganic zinc in children. Journal of the American College of Nutrition, 25, 34–40.

EPHI & ICF. (2019). Ethiopia Mini Demographic and Health Survey 2019: key indictors. EPHI and ICF.

FAO. (2020). Livestock technical guidance to harness the potential of livestock for improved nutrition of vulnerable populations in programme planning. Nutrition FAO.

FAO/WHO. (1991). Guidelines on formulated complementary foods for older infants and young children, CAC/GL 8–1991, REV 2013.

Federal Democratic Republic of Ethiopia, M. O. H. (2012). Complementary feeding of children 6 up to 24 months old for IYCF trainers and promoters.

Gibson, R. S., Bailey, K. B., Gibbs, M., & Ferguson, E. L. (2010). A review of phytate, iron, zinc, and calcium concentrations in plant-based complementary foods used in low-income countries and implications for bioavailability. Food and Nutrition Bulletin, 31, 134S-146S.

Gibson, R., Hotz, C., Temple, L., Yeudall, F., Mtitimuni, B., & Ferguson, E. (2000). Dietary strategies to combat deficiencies of iron, zinc, and vitamin A in developing countries: Development, implementation, monitoring, and evaluation. Food and Nutrition Bulletin, 21, 219–231.

Gibson, R. S., Perlas, L., & Hotz, C. (2006). Improving the bioavailability of nutrients in plant foods at the household level. The Proceedings of the Nutrition Society, 65, 160–168.

Graham, R. D., Humphries, J. M., & Kitchen, J. L. (2000). Nutritionally enhanced cereals: A sustainable foundation for a balanced diet. Asia Pacific Journal of Clinical Nutrition, 9, S91–S96.

Hallberg, L., & Hulthan, L. (2000). Prediction of dietary iron absorption: An algorithm for calculating absorption and bioavailability of dietary iron. The American Journal of Clinical Nutrition, 71, 1147–1160.

Hurrell, R., & Egli, I. (2010). Iron bioavailability and dietary reference values. American Journal of Clinical Nutrition, 91, 1461S-1467S.

Latta, M., & Eskin, M. (1980). A simple and rapid colorimetric method for phytate determination. Journal of Agricultural and Food Chemistry., 28, 1313–1315.

Magallanes-Lapez, A. M., Hernandez-Espinosa, N., Velu, G., Posadas-Romano, G., Ordoaez-Villegas, V. M. G., Crossa, J., Ammar, K., & Guzman, C. (2017). Variability in iron, zinc and phytic acid content in a worldwide collection of commercial durum wheat cultivars and the effect of reduced irrigation on these traits. Food Chemistry, 237, 499–505.

McLaren, D. (1974). The great protein fiasco. The Lancet, 304, 93–96.

McLean, E., Cogswell, M., Egli, I., Wojdyla, D., & de Benoist, B. (2009). Worldwide prevalence of anaemia, WHO Vitamin and Mineral Nutrition Information System, 1993–2005. Public Health Nutrition, 12, 444–454.

Mezgebo, K., Belachew, T., & Satheesh, N. (2018). Optimization of red teff flour, malted soybean flour, and papaya fruit powder blending ratios for better nutritional quality and sensory acceptability of porridge. Food Science & Nutrition, 6, 891–903.

Muhimbula, H. S., & Issa-Zacharia, A. (2010). Persistent child malnutrition in Tanzania: Risks associated with traditional complementary foods (A review). African Journal of Food Science, 4(11), 679–692.

Nahemiah, D. N., Badau, Iro, & Halidu, M. (2016). Application of Response Surface Methodology (RSM) for the production and optimization of extruded instant porridge from broken rice fractions blended with Cowpea. International Journal of Nutrition and Food Sciences, 5, 105–16.

Ndagire, C. T., Muyonga, J. H., Manju, R., & Nakimbugwe, D. (2015). Optimized formulation and processing protocol for a supplementary bean-based composite flour. Food Science & Nutrition, 3, 527–538.

Norhaizan, M. E., Jr., & Nor Faizadatul Ain, A. W. (2009). Determination of phytate, iron, zinc, calcium contents and their molar ratios in commonly consumed raw and prepared food in malaysia. Malaysian Journal of Nutrition, 15, 213–22.

Price, M. L., Van, S. S., & Butler, L. G. (1978). A critical evaluation of the vanillin reaction as an assay for tannin in sorghum grain. Journal of Agricultural and Food Chemistry, 26, 1214–1218.

Rasane, P., Jha, A., Kumar, A., & Sharma, N. (2015). Reduction in phytic acid content and enhancement of antioxidant properties of nutricereals by processing for developing a fermented baby food. Journal of Food Science and Technology, 52, 3219–3234.

Roy, M. K., Takenaka, M., Isobe, S., & Tsushida, T. (2007). Antioxidant potential, anti-proliferative activities, and phenolic content in water-soluble fractions of some commonly consumed vegetables: Effects of thermal treatment. Food Chemistry, 103, 106–114.

Soetan, K., & Oyewole, O. (2009). The need for adequate processing to reduce the anti-nutritional factors in plants used as human foods and animal feeds: A review. African Journal of Food Science, 3, 223–232.

Thorisdottir, B., Arnesen, E. K., Bärebring, L., Dierkes, J., Lamberg-Allardt, C., Ramel, A., Nwaru, B. I., Söderlund, F., & Kesson, A. (2023). Legume consumption in adults and risk of cardiovascular disease and type 2 diabetes: A systematic review and meta-analysis. Food & Nutrition Research, 67, 2023.

Tura, D. C., Belachew, T., Tamiru, D., & Abate, K. H. (2023). Optimization of dabi teff-field pea based energy and protein dense novel complementary food with improved sensory acceptability using D-optimal mixture design. Heliyon, 9, e19029.

Acknowledgements

The authors are thankful to the Ethiopian Agricultural Research Institute (Food Science and Nutrition Laboratory), Addis Ababa, Awash Melkasa Research Center and Horticoop Laboratory International, Debre Zeit for allowing us to use their laboratory facilities for the analysis of the micronutrients and anti-nutrient composition parameters. We thank Dr. Diriba Gelati, Dr. Kasayye Tolassa, Mrs. Zufan G/kidan and Mr.Demerew Abera for showing us their bright face and assisting in laboratory data generating activities.

Funding

No funding source is available.

Author information

Authors and Affiliations

Contributions

Diriba Chewaka Tura: Lead in conceptualization and designing; Formal analysis and interpretations; Methodology; Experimentation; Software; Writing original draft; Writing-review & editing; Approved the final version. Kalkidan Hassen Abate, Tefera Belachew and Dessalegn Tamiru: Conceptualization and designing; Methodology; Analysis and interpretations; Critical revision of the manuscript; Writing-review & editing, Approved the final version.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing of interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tura, D.C., Belachew, T., Tamiru, D. et al. Effects of blending ratios variation on micronutrient compositions and phytate/minerals molar ratios of dabi teff-field pea based novel composite complementary flours. Food Prod Process and Nutr 6, 16 (2024). https://doi.org/10.1186/s43014-023-00203-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s43014-023-00203-7