Abstract

The current study has been designed to investigate the possible biodegradtion of native keratin by fungi isolated from chicken feathers collected from chicken farms in Egypt. Out of 56 fungal isolates 23 species and 2 species varieties showed different degrees of keratinolytic activity, with Chrysosporium tropicum showing the highest keratinase productivity (23.15 U/ml) as well as the highest value of specific activity for keratinase (197.90 U/mg protein) indicating a great degree of purity for the enzyme. Our present study indicates that the highest production of keratinase by C. tropicum was recorded at pH 8 and a temperature of 35 °C during a period of 20 days. In addition the optimal value of ionic strength for keratinase production was 100 mM NaCl. Monitoring the influence of constituents deprivation from basal salt medium on production of keratinase enzyme showed that K+, Fe2+, Mg2+, Ca2+ and Zn2+ were necessary for keratinase production. Sulfur deprivation has no significant influence on keratinase production. Keratinase activity of C. tropicum showed that, the optimal values of temperature and ionic strength were 35–40 °C and 80 mM NaCl, individually. The optimum pH range was (7.8–9). These promising findings demonstrate a high potentiality of C. tropicum keratinase in keratin proteolysis, suggesting that keratinase producing isolates of C. tropicum may be suitable as a biodegradation agent.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Keratinases (E.C. 3.4.99.11) are proteolytic inducible enzymes produced by different microorganisms when they growing on substrates containing keratin. Microbial keratinases attracted much attention, because their multiple industrial applications in different areas including feed, detergent, fertilizer, leather and pharmaceutical industries [1,2,3]. Mature chicken possess around 5–7% feathers from their total weights. The large quantities of the discarded chicken feathers during industrial poultry-processing represent environmental hazard responsible for environmental pollution. Keratins as substrates are insoluble and resistant against digestion by animal, plant and different known microbial proteases, hindered the utilization of feathers as a source of valuable products [4]. In an attempt to overcome this problem, enzymatic fungal degradation of feathers may introduce a possible resolution and provide an available alternative for improving feather utilization. Some of saprophytic and parasitic fungal species possess the capability of keratin degradation [5,6,7,8,9,10]. Using natural materials such as chicken feather during new biofertilizers development has attracted more attention of research interest [11]. The application of nitrogen-rich organic amendments in organic farming improves plant growth rate of and stimulates the soil microflora activity. Feather meals are rich in nitrogen (15% N), cheap and easily obtainable can be used as a potential biofertilizer [2]. Application of microorganisms to hydrolyze feathers has several advantages over than steaming process as fertilizer including, high nutrition content, simple production and economically efficient, therefore these microorganisms may considered to be a possible alternative for providing nitrogen sources in fertilizer application [11]. Microbiological decomposition of poultry biowastes during storage causes liberation of some toxic gases such as ammonia and hydrogen sulfide [12]. In addition it has been observed that the increase in pH is a good indicator of keratinolysis, as it simultaneously reflects the utilization of keratin proteins, deamination, and ammonia production during chicken feather decomposition by fungi [13]. One of the microorganisms those involved in this degradation process is the fungal genus Chrysosporium. It has been demonstrated that some Chrysosporium species isolated from soil are characterized by high mineralization potential towards native keratin [14,15,16]. Although many keratinolytic enzymes have been isolated over the years, the exact and precise mechanism of keratin biodegradation is not fully understood [17, 18]. However, keratin biodegradation is thought to be composed of enzyme’s adsorption to the macromolecule’s surface followed by the proper catalytic action that can be further divided into reduction in disulfide bonds, (sulfitolysis) and disruption of the peptide chain (proteolysis) [19]. This study aims to isolate and characterize highly keratinase-producing fungi from chicken feathers, optimize the production of keratinase from the most powerful fungal isolate, and convert feather wastes into soluble amino acids used as animal feed additives or biofertilizers.

2 Materials and methods

2.1 Isolation and maintainace of fungi

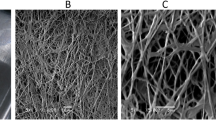

From chicken farms in Egypt, keratinolytic fungi were isolated from chicken feathers. Fungal species isolated during this current study have been cultivated in pure culture and identified macro- and micromorphologically via systematic studies [20, 21].The fungi were maintained in Sabouraud Dextrose Agar medium (SDA) at 4 °C for the next work.

2.2 Keratinase activity assay

The enzyme activity of Keratinase was detected according to Yu et al. [22] with some changes. Reaction mixture containing 50 mM Tris–HCl buffer (pH 7.8), 20 mg powder of keratin and 1 ml of fungal filtrate containing crude extracellular keratinase in a total volume of 4 ml. This reaction mixture was left for 4 h at temperature 37 °C under shaking and thereafter the liberated amino acids during proteolysis of keratin were detected by the ninhydrin method as described by Muting and Kaiser [23]. Unit of enzyme activity was identified as equal to the amount of enzyme that catalyzes the liberate of 1 μg amino acids per hour. The specific activity of keratinase was defined as the number of keratinase units per mg extracellular protein. Total amount of extracellular protein produced by the keratinolytic fungi was measured in extracellular crude enzyme according to Bradford [24].

2.3 Keratinase production optimization

After screening of fungal species for keratinase production and specific activity of enzyme, Chrysosporium tropicum has been chosen for consequent investigations (temperature, incubation period and initial pH) for production of keratinase and keratinase activity.

2.4 Metal ions dependency and ionic strength

The dependency of keratinase production on ionic strength has been monitored by using several concentrations of salt varying from 0.0 to 2 M NaCl in basal salt medium (BSM). The fungus C. tropicum was grown in BSM medium as a control and the same medium deprived of K+, Ca2+, Mg2+, Zn2+ or Fe2+ at both the optimum temperature and initial pH. After 2 weeks of incubation period the yield of keratinase produced was measured.

3 Results and discussion

3.1 Screening of fungal keratinase production in liquid medium

Screening of fungal species for keratinase production in this current study has been designed of the of fungi in submerged culture and obtained results have been summarized in Table 1. Twenty three and 2 species varieties among 105 fungal isolates showed different levels of keratinolytic activities when cultured on chicken feather medium and 80 fungal isolates exhibited no keratinolytic activity (data not shown). Five fungal isolates among 25 keratinolytic isolates were considered to be highly keratinase producers. Within the first group, the highest activity was recorded by C. tropicum followed by Chrysosporium keratinophilum, Scopulariopsis brevicaulis, Aspergillus fumigatus and A. terreus. While the second group includes producers with moderate activity for keratinases production such as Absida corymbifera, Acremonium strictum, Aspergillus flavus, A. flavus var. columinaris, Botryotrichum piluliferum, Fusarium oxysporum, F. solani, Penicillium funiculosum, Scopulariopsis brumptii and Trichoderma harzianum. The rest of fungal isolates show low keratinase production, as presented in Table 1. The fungus C. tropicum showed the highest productivity value for keratinase (23.15 U/ml) and also the highest keratinase specific activity (197.90 U/mg protein). This indicates a greater purity of the C. tropicum extracellular keratinase, so it has been selected for further optimization of keratinase production and activity experiments. Among common fungi the keratinolytic activity is widespread and many fungal species release enzymes into the surrounding environment and can be used as producers of keratinolytic enzymes. The non-dermatophytes kerationlytic fungi attract much of research interest due to safety approach in fungal handling and manipulation. In this current investigation, five efficient keratinase producing non-dermatophytic fungal species have been isolated. Among the non-dermatophytic fungi, keratinases possessing attractive biochemical characteristics were reported to be produced by Aspergillus [10, 25, 26], Trichoderma [27], Doratomyces [28], Myrothecium [29], Paecilomyces [30], Scopulariopsis [31], also Acremonium, Alternaria, Beauveria, Curvularia, and Penicillium [32]. Chrysosporium tropicum strain, showed outstanding activity in comparison with other fungi which showed the highest keratinase productivity (23.15 U/ml) and also the highest specific activity for keratinase was (197.90 U/mg protein), this indicates a higher purity of the C. tropicum extracellular keratinase. El-Naghy et al. [33] reported that the degradation of chicken feathers by 28 different fungal species indicated that fungi belonging to the genus Chrysosporium were the most active in degrading feathers, and C. georgiae was the most active one. More recently the keratinolytic activity of C. tropicum has been assessed [34]

3.2 Optimization of keratinase production

During keratinase production process C. tropicum showed an optimum pH ranging from 6 to 9 (Fig. 1A), this finding indicate that the fungus productivity is not influenced by the increase in pH value of the medium due to ammonium release. The incubation temperature influence on the production of keratinase by C. tropicum was presented in (Fig. 1B), maximum keratinase enzyme production was recorded at 35 °C.

After 2 days of incubation period, Keratinase production was measured. The maximum productivity has been detected after 20 days (Fig. 2A). Study of the dependency of keratinase production on the ionic strength was conducted; maximum keratinase production was observed at (100 mM NaCl) and declined as NaCl concentration was increased in the culture medium (Fig. 2B). By depriving the medium of each constituent individually, we studied the influence of the constituent BSM on keratinase production. Keratinase production was not significantly influenced by sulfur deprivation (Fig. 2C). Deprivation of K+ or Zn2+ strongly decrease enzyme production indicating that these elements are necessary for keratinase enzyme production. While deprivation of Ca2+, Mg2+ or Fe2+ moderately affected the keratinase production. In this current study, during the incubation period of 20 days, the highest production of keratinase enzyme(s) was observed from C. tropicum.. Within the incubation time range of 2–20 days, the production of keratinase increased proportionally. Thereafter, production of keratinase has declined. The optimum production of keratinase enzyme(s) was measured within an incubation temperature of (35 °C). The optimum pH value for keratinase production ranges from 6 to 9, pointing out that the fungus productivity is not affected by the increase in pH value of the medium due to ammonium release as suggested by Gupta and Ramnani [2]. El-Naghy et al. [33] found that, optimum degradation of feather keratin by Chrysosporium georgiae was obtained after 21 days at pH 6 or pH 8 and an optimal incubation temperature of 30 °C. The optimal concentration values of NaCl for keratinase production by C. tropicum is 100 mM NaCl, and then it decreased by increasing NaCl concentration in the culture medium. Sulfur deprivation did not show significant effect on the keratinase productivity by C. tropicum, this might be attributed to the release of amino acids containing sulfur and sulfahydral groups from keratin degradation which might provide the fungus with its sulfur requirements for growth and keratinase production, as reported by Gupta and Ramnani [2]. In spite of strong effect of Zn2+ or k+ on keratinase production, deprivation of Ca2+, Mg2+ or Fe2+ had moderate effected. It has been reported that Ca2+ and Mg2+ cause a threefold increase in the enzymatic activity [35]. These metal ions possibly engaged with the stability of the tertiary structure conformation of metalloproteases and protect these enzymes against autoproteolysis [36, 37].

3.3 Kinetics of extracellular keratinase activity of C. tropicum

Optimum pH value for keratinase activity was 7.8, however keratinase activity slightly decreased at higher pH values. In contrast, the keratinase activity decreased sharply at low pH values (Fig. 3A). The optimum temperature for C. tropicum keratinase was 35–40 °C (Fig. 3B). The optimal ionic strength for C. tropicum keratinase activity was 80 mM NaCl. The keratinase activity sharply decreased at ionic strength higher than 100 Mm NaCl (Fig. 3C). As the enzyme under investigation showed an optimum pH range of 7.8–9, it can be classified as alkaline keratinase. In agreement with our results, keratinase isolated from some other fungi such as Scopulariopsis brevicaulis, Microsporum canis, Doratomyces microsporus and Trichophyton marquandii were also reported as alkaline enzymes [28, 30, 38, 39]. It has been reported that keratinase activity from Trichophyton vanbruseghemii was optimum at pH 8 and remained high in the range of pH 7–11 [40]. The optimum temperature for C. tropicum keratinase was 35–40 °C. Keratinases from Scopulariopsis brevicaulis and Trichophyton sp. HA-2 showed similarity in optimum temperature 35–40 °C [38, 41]. The optimal ionic strength for keratinase activity was 80 mM NaCl. By increasing NaCl concentrations the keratinase activity sharply reduced, perhaps by inhibiting its interaction with keratin substrates. Moreover, NaCl concentration of more than 100 mM sharply reduced both growth and keratinase production by C. tropicum. The decrease in keratinase activity at high ionic strength might indicate an electrostatic interaction between the enzyme and its keratin substrate which would be adversely affected by high ionic strength. The activity of the major keratinolytic serine Proteinase of Streptomyces albidoflavus significantly decreased at NaCl concentration of more than 0.5 M which was attributed to the adverse effect of high ionic strength on the electrostatic interaction of the enzyme with its keratin substrate [42].

Our results were in agreement of an earlier report on keratin degradation [43, 44]. According to the current results, the feather hydrolyzate containing various amino acids could be utilized as feed additives or fertilizers. Also it has been found that amino acids play key roles in living organisms, there has been an increased demand for amino acids to be used in many areas such as pharmaceutical drug manufacturing, feedstuffs and feed additives. It is known that feather keratin can be converted to feedstuffs, fertilizers, and edible films or used for the production of the rare amino acids serine, cyteine and proline [4, 45, 46].

4 Conclusion

In conclusion, C. tropicum might be considered to be a potent keratinase producing fungus. The keratinase production optimization and characterization analyses revealed potential characteristics for its probable applicability in commercial keratin degradation process and conversion of keratin wastes to feedstock additives and effective soil fertilizer.

Data availability

Our manuscript has no associated data.

References

Friedrich J, Gradisar H, Mandin D, Chaumont JP (1999) Screening fungi for synthesis of keratinolytic enzymes. Lett Appl Microbiol 28:127–130

Gupta R, Ramnani P (2006) Microbial keratinases and their prospective applications: an overview. Appl Microbiol Biotechnol 70:21–33

Ghosh A, Chakrabarti K, Chattopadhyay D (2008) Degradation of raw feather by a novel high molecular weight extracellular protease from newly isolated Bacillus cereus DCUW. J Ind Microbiol Biotechnol 35:825–834

Onifade AA, Al-Sane NA, Al-Musallam AA, Al-Zarban S (1998) A review: potentials for biotechnological applications of keratin-degrading microorganisms and their enzymes for nutritional improvement of feathers and other keratins as livestock feed resources. Bioresour Technol 66:1–11

Safranek WW, Goos RD (1982) Degradation of wool by saprophytic fungi. Can J Microbiol 28:137–140

Bagy MMK (1982) Some ecological and physiological studies on keratinolytic fungi associated with birds in Egypt. Ph.D. Thesis, Bot Dept Fac Sci Assiut Univ, Egypt

Bahuguna S, Kushwaha RKS (1989) Hair perforation by keratinophylic fungi. Mycoses 32:340–343

Rajak RC, Parwekar S, Malviya H, Hasija SK (1991) Kertin degradation by fungi isolated from the grounds of a gelatin factory in Jabalupur (India). Mycopathologia 114:83–87

Hirchsman DJ, Zametkin JM, Rogers RE (1994) The utilization of wool by four saprophytic microorganisms in the presence of added nutrients. Am DyestuffRep 33:353–359

Santos RMDB, Firmino AAP, de Sa CM, Felix CR (1996) Keratinolytic activity of Aspergillus fumigatus Fresenius. Curt Microbiol 33:364–370

Jeong J, Lee O, Jeon Y, Kim J, Lee N, Lee C, Son H (2010) Production of keratinolytic enzyme by a newly isolated feather-degrading Stenotrophomonas maltophilia that produces plant growth-promoting activity. Proc Biochem 45:1738–1745

Korniłłowicz-Kowalska T, Bohacz J (2011) Biodegradation of keratin waste: theory and practical aspects. Waste Manag 31:1689–170113

Godheja J, Shekhar SK (2014) Biodegradation of keratin from chicken feathers by fungal species as a means of sustainable development. J Biorem Biodegrad 5:5

Korniłłowicz-Kowalska T (1997) Studies on the decomposition of keratin wastes by saprotrophic microfungi. P. I. criteria for evaluating keratinolytic activity. Acta Mycol 32:51–79

Korniłłowicz-Kowalska T (1997) Studies on the decomposition of keratin wastes by saprotrophic microfungi. P. II sulphur and nitrogen balance. Acta Mycol 32:81–93

Bohacz J (2017) Biodegradation of feather waste keratin by keratinolytic soil fungus of the genus Chrysosporium and statistical optimization of feather mass loss. World J Microbiol Biotechnol 33(13):1–16

González V, Vargas-Straube MJ, Beys-da-Silva WO, Santi L, Valencia P, Beltrametti F, Cámara B (2020) Enzyme bioprospection of marine-derived actinobacteria from the chilean coast and new insight in the mechanism of keratin degradation in Streptomyces sp. G11C. Mar Drugs 18:537

Kang E, Jin HS, La JW, Sung JY, Park SY, Kim WC, Lee DW (2020) Identification of keratinases from Fervidobacterium islandicum AW-1 using dynamic gene expression profiling. Microb Biotechnol 13:442–457

Sypka M, Jodłowska I, Białkowska AM (2021) Keratinases as versatile enzymatic tools for sustainable development. Biomolecules 11:1900

Domsch KH, Gams W, Anderson TH (2007) Compendium of soil fungi, vol 1. Acad Press, London

van Orschot CAN (1980) A revision of Chrysosporium and allied genera. Stud. Mycol 20:1–89

Yu RJ, Harmon SR, Blank F (1968) Isolation and purification of an extracellular keratinase of Trichophyton mentagrophytes. J Bacteriol 96:1435–1436

Muting D, Kaiser E (1963) Spectrophotometric method of determining amino-N in biological materials by means of ninhydrin reaction. Seyler’s Zschr Physiol Chem 332:276

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of.protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Glickmann E, Dessaux Y (1995) A critical examination of the specificity of the Salkowski reagent for indole compounds produced by phytopathogenic bacteria. Appl Environ Microbiol 61:793–796

Farag AM, Hassan MA (2004) Purification, characterization and immobilization of a keratinase from Aspergillus oryzae. Enzyme Microb Technol 34:85–93

Cao L, Tan H, Liu Y, Xue X, Zhou S (2008) Characterization of a new keratinolytic Trichoderma atroviride strain F6 that completely degrades native chicken feather. Lett Appl Microbiol 46:389–394

Gradisar H, Kern S, Friedrich J (2000) Keratinase of Doratomyces microsporus. Appl Microbiol Biotechnol 53:196–200

Moreira-Gasparin FG, Marques de Souza CG, Costa AM, Alexandrino AM, Bracht CK, Boer CG, Peralta RM (2009) Purification and characterization of an efficient poultry feather degrading-protease from Myrothecium verrucaria. Biodegradation 20:727–736

Gradisar H, Friedrich J, Krizaj I, Jerala R (2005) Similarities and specificities of fungal keratinolytic proteases: comparison of keratinases of Paecilomyces marquandii and Doratomyces microsporus to some known proteases. Appl Environ Microbiol 71:3420–3426

Anbu P, Gopinath SCB, Hilda A, Lakshni PT, Annadurai G (2005) Purification of keratinase from poultry farm isolate-Scopulariopsis brevicaulis and statistical optimization of enzyme activity. Enzyme Microbiol Technol 36:639–647

Marcondes NR, Taira CL, Vandresen DC, Svidzinski TIE, Kadowaki MK, Peralata RM (2008) New feather-degrading fungi. Microb Ecol 56:13–17

El-Naghy MA, El-Ktatny MS, Fadl-Allah EM, Nazeer WW (1998) Degradation of chicken feathers by Chrysosporium georgiae. Mycopathologia 143:77–84

Bohacza J, Korniłłowicz-Kowalskaa T, Kitowskib I, Ciesielska A (2020) Degradation of chicken feathers by Aphanoascus keratinophilus and Chrysosporium tropicum strains from pellets of predatory birds and its practical aspect. Int Biodeterior Biodegradation 151:104968

Venter H, Osthoff G, Litthauer D (1999) Purification and characterization of a metalloprotease from Chryseobacterium indologenes Ix9a and determination of the amino acid specificity with electrospray spectrometry. Protein Expr Purif 15:282–295

Kumar CG, Takagi H (1999) Microbial alkaline proteases: from a bioindustrial view point. Biotechnol Adv 17:561–594

Secades P, Guijarro JA (2001) Purification and characterization of a psychrophilic calcium induced growth-phase-dependent metalloprotease from the fish pathogen Flavobacterium psychrophilum. Appl Environ Microbiol 67:2436–2444

Malviya HK, Rajak RC, Hasija SK (1992) Purification and partial characterization of two extracellular keratinases of Scopulariopsis brevicaulis. Mycopathologia 119:161–165

Brouta F, Descamps F, Fett T, Losson B, Gerday C, Mignon B (2001) Purification and characterization of a 43.5 kDa keratinolytic metalloprotease from Microsporum canis. Med Mycol 39:269–275

Moallaei H, Zaini F, Larcher G, Beucher B (2006) Partial purification and characterization of a 37 kDa extracellular proteinase from Trichophyton vanbreuseghemii. Mycopathologia 161:369–375

Anbu P, Hilda A, Sur H, Hur B, Jayanthi S (2008) Extracellular keratinase from Trichophyton sp. HA-2 isolated from feather dumping soil. Int Biodeterior Biodegradation 62:287–292

Bressollier P, Letourneau F, Urdaci M, Verneuil B (1999) Purification and characterization of a keratinolytic serine proteinase from Streptomyces albidoflavus. Appl Environ Microbiol 65:2570–2576

Filipello Marchisio V, Fusconi A, Rigo S (1994) Keratinolysis and its morphological expression in hair digestion by airborne fungi. Mycopath 127:103–115

Vesela M, Friedrich J (2009) Amino acid and soluble protein cocktail from waste keratin hydrolysed by a fungal keratinase of Paecilomyces marquandii. Biotechnol Bioprocess Eng 14:84–90

Brandelli A (2008) Bacterial keratinases: useful enzymes for bioprocessing agroindustrail wastes and beyond. Food Bioprocess Technol 1:105–116

Brandelli A, Dariot DJ, Riffel A (2010) Biochemical feathers of microbial keratinases and their production and application. Appl Microbiol Biotechnol 85:1735–1750

Funding

The authors declare that no funding was received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

MMK: Conceptualization, experimental design, writing and reviewing. EAH: lab work, writing. FMM: Conceptualization, data analyses, writing and reviewing. MMKB: Conceptualization, experimental design, writing and reviewing.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or nonfinancial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Koutb, M.M., Hassan, E.A., Morsy, F.M. et al. Optimization of keratinase production by keratinolytic fungus Chrysosporium tropicum and its potentiality in bidegradation of chicken feathers. J.Umm Al-Qura Univ. Appll. Sci. 9, 50–56 (2023). https://doi.org/10.1007/s43994-022-00020-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43994-022-00020-7