Abstract

The utilization of biochar derived from biomass residue to enhance anaerobic digestion (AD) for bioenergy recovery offers a sustainable approach to advance sustainable energy and mitigate climate change. However, conducting comprehensive research on the optimal conditions for AD experiments with biochar addition poses a challenge due to diverse experimental objectives. Machine learning (ML) has demonstrated its effectiveness in addressing this issue. Therefore, it is essential to provide an overview of current ML-optimized energy recovery processes for biochar-enhanced AD in order to facilitate a more systematic utilization of ML tools. This review comprehensively examines the material and energy flow of biochar preparation and its impact on AD is comprehension reviewed to optimize biochar-enhanced bioenergy recovery from a production process perspective. Specifically, it summarizes the application of the ML techniques, based on artificial intelligence, for predicting biochar yield and properties of biomass residues, as well as their utilization in AD. Overall, this review offers a comprehensive analysis to address the current challenges in biochar utilization and sustainable energy recovery. In future research, it is crucial to tackle the challenges that hinder the implementation of biochar in pilot-scale reactors. It is recommended to further investigate the correlation between the physicochemical properties of biochar and the bioenergy recovery process. Additionally, enhancing the role of ML throughout the entire biochar-enhanced bioenergy recovery process holds promise for achieving economically and environmentally optimized bioenergy recovery efficiency.

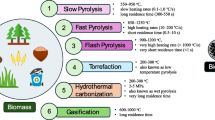

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

The process of Anaerobic digestion (AD) involves the biodegradation of organic wastes, while producing methane, hydrogen biofuel and organic acid alcohols and other valuable biological chemicals[48, 73]. In recent years, there has been significant interest in research focused on strategies to enhance AD performance and performance and increase energy generation. [112, 130]. Biochar has emerged as a highly beneficial carbon-based additive for AD due to its numerous advantages [11].

Biochar is a porous solid material with a high carbon content. It is produced through the thermal conversion of biomass, making it a viable method for directly sequestering carbon. [27, 39]. Biochar has been applied in AD process to facilitate the colonization of symbiotic microbial communities[122], accelerate electron transfer [61], enhance the bioavailability of the elements for microorganisms [131], and produce more biogas [11] and valuable chemicals [34]. Biochar has various physicochemical properties based on its precursors [45]. In general, biochar derived from biomass residue exhibits superior pH stability, cation exchange capacity, porosity, and adsorption properties compared to biochar obtained from other materials. [39, 43]. Biomass residue-based biochar can be produced from a variety of raw materials, such as algae [35], food waste [21], digestate residues [56] and lignocellulosic materials [99]. These organic wastes are generally difficult to biodegrade by AD and more favorable for biochar preparation due to the large amount of recalcitrant organic matter contained. Algae-based biochar is rich in various inorganic elements, such as potassium, calcium, and magnesium. Additionally, it contains a diverse range of functional groups containing nitrogen and oxygen [50]. This type of biochar has been shown to enhance the bioavailability of nitrogen and phosphorus within the system [50]. On the other hand, biochar derived from lignocellulosic materials has a high potential for energy recovery, with an energy yield ranging from 80 to 90%, as well as a mass yield of 70% to 80% [75]. The biochar derived from digestate residues is abundance in trace elements (iron, cobalt, nickel, molybdenum, zinc, selenium, copper and manganese) [6]. Additionally, this type of biochar contains a higher concentration of alkaline groups, which can effectively mitigate acidification by neutralizing fatty acids [19]. Furthermore, biochar obtained from food waste, such as grape, citrus, and corn, demonstrates significant potential for the colonization of specific microorganisms, namely K. marxianus and P. kudriavzevii. These microorganisms play a crucial role in facilitating optimal bioethanol production [49, 63]. As previously mentioned, the performance of biochar can be assessed based on several factors, including carbon conversion, energy loss during preparation, the presence of trace or common elements, and variations in functional groups and electron transport efficiency. The effectiveness of managing carbon sequestration using biochar derived from biomass residue can be observed in the following aspects: (1) the energy and material flow during the preparation of residue-based biochar, (2) the enhancement of AD microorganisms through the bioavailability of biochar elements derived from residue, and (3) the enrichment of residue-based biochar for interspecies electron transfer (IET) and direct interspecies electron transfer (DIET).

The adoption of AI-based machine learning (ML) technology has gained prominence as a viable strategy for facilitating decision-making processes in recent years. This is attributable to its ability to elucidate the promoting mechanism of biochar in the AD process by examining the relationship between biochar characteristics and output variables [42]. The adaptive network-based fuzzy inference system (ANFIS) has been demonstrated to accurately emulate nonlinear systems (such as biological wastewater treatment) with high precision across multiple parameters [80]. The use of support vector machine (SVM) has been proposed as a viable approach for the identification of graphitized carbon, CO structure and defect edges on N-doped food waste biochar [80]. Reinforcement learning combined with deep neural networks (DNN) controls maximizes the yield of microbial co-culture in bioreactors [101]. The impact of various models, namely, Lift (XGBoost), Random Forest (RF) and artificial neural network (ANN) has been devised to enhance the cumulative methane production. The following factors are among the most influential in determining methadone production: the intrinsic biological interactions in complex systems, the electron donor capacity of and the physicochemical properties of biochar [39]. ML can potentially predict the effects of biochar properties on microorganisms in AD. This approach enables a systematic exploration of the interaction among the three factors. For instance, to verify the influence of highly correlated between biochar dimensions and microbial colonization preferences on the methanogenesis rates [35]. Although the employment of the ML method has also been used to predict biochar yield and function from biomass residues, i.e., lignin [70], microalgae [134], food residues [65] and sludge [91], there remain specific research gaps concerning its integration with AD performance. It is provided a concise overview of the preparation methodologies predicated on ML predictions of biochar output, carbon content, aromaticity and capacitance [59]. Also, the predictive capabilities and research significance of ML techniques in the context of AD bioenergy production and the synthesis of valuable chemicals under the addition of biochar were summarized by using the intelligent biological process prediction of the interaction between biochar and microorganisms.

The main objective of this study is to comprehensively review the role of ML in the biochar-enhanced AD process, focusing on biochar preparation and the interaction between biochar and AD. Firstly, the current functional prediction methods of biochar based on ML are summarized. Insightful suggestions are provided regarding the formulation methodologies for biochar derived from residual materials. Additionally, the colonization and enhancement of microbial community functions and the regulation of element availability are specifically reviewed. Finally, the merits and demerits of ML techniques are scrutinized, and research gaps in biochar property prediction algorithms that affect microbial behavior are identified. Future research initiatives in this field prioritize the improvement of data quality and model transparency as significant benchmarks.

2 Characteristics and advantages of lignocellulose, microalgae and food waste based-biochar

2.1 Carbon recovery and loss rate during preparation

The ongoing advancements in the biochar preparation procedure have significantly increased the extraction of valuable resources from bio-waste. However, implementing this technology is confronted with impediments to its debatable energy efficiency and techno-economic features. These challenges encompass a range of considerations, including the bio-residue drying, the thermal energy consumption, and the need to consider the bio-residue recovery rate. Therefore, it is essential to investigate the effect of different pyrolysis process parameters on carbon recovery and loss rates during the preparation phase.

The production of bio-oil is commonly associated with the biochar preparation process. The parameters such as temperature, heating rate, reactor configuration, pressure, residence time, carrier gas flow rate, catalysts, feedstock composition and blending ratios could affect biochar production. The influence of feedstock composition on the material flow during biochar preparation has been demonstrated [24, 31].

With regards to food waste, biochar yield was increased with the escalation of pyrolysis temperature. The highest biochar recovery can reach 60.55% at 300 °C [79]. When the temperature exceeds 800 °C, the resulting products are apportioned among three phases, namely gas (15–25%), liquid (50–60%) and solid residue (25%) [24]. The higher oxygen content of the feedstock is responsible for the higher liquid recovery rate and the lower biochar recovery rate. Lower temperatures result in greater charcoal yields than higher temperatures, while an increase in pyrolysis temperature hastens the hydrogen evolution [21]. The microalgal biochar presentation reveals a noteworthy similarity between the biochar yield and pyrolysis temperature of food waste [50]. The preparation of microalgae biochar is deemed appropriate within a temperature range of 300–700 °C. Approximately 50% carbon could be recovery as biochar by pyrolysis [5]. Moreover, it should be noted that the heating rate can affect biochar production significantly. A gradual heating rate at (0.1–1℃/s) could obtain a high amount of biochar while producing less liquid and gaseous by-products. [45]. In contrast, a high heating rate at 1000 ℃/s will generate 10–20% of gaseous products, 15–25% of biochar, and 60–75% of bio-oil [3]. In addition, the lignocellulose (LC) is also often used to prepare biochar by pyrolysis. Abdullah et al. [1] investigated the effect of different process temperatures (230–300 °C) and residence times (30–90 min) on the yield of biochar product based on LC. The highest yield of biochar was obtained (91%) at 230 °C for 30 min, which is lower than that obtained from of food waste and microalgae. The calorific value ranged from 22 to 27 MJ/kg, an increase of 22–59% when compared to the relative virgin biomass [1]. Previous studies have reported that an increase in residence time and temperature is associated with a decline in biochar yield. This phenomenon is attributed to the accelerated decomposition rate of the highly reactive hemicellulose. The outcome of this process is the partial carbonization and volatilization of lignocellulosic compounds [63].

Overall, the form of carbon in pyrolysis/gasification products is primarily influenced by the reactor temperature, holding times, and heating rate. When preparing biochar, it is important to consider the characteristics of the substrate in order to enhance carbon recovery and minimize loss rates. Although the optimal temperatures and holding times typically fall below 800 ℃ and 30–90 min, respectively.

2.2 Reinforced biochar with non-metallic and metallic elements

2.2.1 Reinforced biochar with non-metallic

Biochar is a highly efficient carbon-rich product with enhanced properties obtained by pyrolysis of residual biomass. The versatile utilization of biochar allows its application in the energy recovery and the environmental remediation [41, 46, 74]. Tables 1 and 2 lists what reason contribute its superior physicochemical properties, including the N element and O-containing functional groups, etc. However, the further modification of virgin biochar by a variety of physical, mechanical, and chemical processes to produce engineered biochar for energy and environmental applications is a topical issue requiring an up-to-date review [4].

The modification of biochar with non-metallic elements is predominantly achieved through the modification of functional groups, organic polymer modification, and other techniques. The process of modification induces changes in the physicochemical attributes of biochar, including but not limited to polarity, ion exchange capacity, surface charge, and specific surface area. These modifications have a consequential impact on the interactions between biochar and the surrounding environment. These adjustments present advantages with respect to the adsorption of pollutants and the augmentation of biological mechanisms. The functional groups that are frequently utilized comprise of O-containing functional groups, N-containing functional groups, P-containing functional groups and S-containing functional groups [31]. The O-containing functional groups (e.g., hydroxyl groups, phenolic groups, lactonic groups) has an important effect on the physicochemical properties of biochar. These functional groups have a pronounced impact on the surface behavior, hydrophilicity, electrical and catalytic of biochar [116]. The incorporation of functional groups increases the adsorption capacity of biochar for various wastewater heavy metals [52]. Biochar from lignocellulosic materials has many O-containing functional groups, which boosts methane production in AD. This is due to microbial activity and electron transfer processes [89, 99, 122]. Jiang et al. [34] modified the blue algal based biochar with H2O2 to improve the content of phenolic and lactonic groups. The result demonstrated that the redox capacity of biochar, especially the electron-donating capacity, increased by 64.9%, which is beneficial for the electron transfer and methanogenesis.

The implementation of N-containing functional groups modification, specifically pyridinic-N and oxidized-N, on biochar has been identified as a highly efficacious approach. It can be introduced into the biochar surface via hydrothermal carbonization and high-temperature carbonization [51]. By this way, the electrical conductivity of biochar could be improved [86]. The biochar surface modified with pyrroline-N, pyridine-N and oxide-N showed basicity, which could promote the interaction of BC with acidic CO2, enhance the adsorption of CO2 and utilization by hydrogenophilic methanogenic [18]. However, it should be noted that the pH of the system should be maintained at a stable level when N-containing functional groups of biochar are input because the released nitrate or nitro groups in system decrease the pH of system (lower than 6), which causing a inhibit effect on the methanogenesis [34]. The incorporation of P into biochar has been identified as a potential strategy to enhance biochar performance. This addition can reduce a charge transfer resistance from microbes to the carbon surface, which is beneficial for the electron transfer [69]. Li et al. [51] investigated the effects of dual-heteroatom doping, specifically N-P and N-S, on AD systems. The findings indicated that the presence of P-OH facilitated the diffusion of H during AD system, which improved hydrogen consumption by hydrogenotrophic methanogenesis [32, 69]. N-containing functional groups has been observed to enhance the adsorption of CO2 and promote the charge transfer between acetogens and methanogens in the digestion system [51].

The main types of organic polymer modification include surface active agents, chitosan, amino acids, etc. Yu et al. [119] found that chitosan-modified biochar could increase the Cr (VI) adsorption and bio-reduction. The chitosan could induce Cr (VI) migration from an aqueous to a solid phase and accelerate the EET by Mtr respiratory pathway in Shewanella oneidensis MR-1. Also, previous research has demonstrated that arginine modification can alter the zeta potentials of biochar. The biochar capture ability of microorganisms can also be improved [127].

2.2.2 Reinforced biochar with metallic elements

The utilization of metal elements or metal oxides as modifiers for biochar represents a promising approach to augment the energy recovery efficiency through AD. Common metals include Fe, Cu, and Mg, among others. Fe or Fe oxides have been the most prevalent modification materials due to their low cost, abundant source availability, and high efficiency [31, 46, 62]. Applying iron-based biochar derived from biogas residue and ferric chloride could show higher specific surface area and more abundant functional groups, which increased 22.50% than the control group for methane production from food waste [56]. The relative abundance of functional genes involved in DIET can be promoted. Also, the biochar based on zero-valent iron (ZVI) derived by corn straw pyrolysis could showed an increased performance for methane production potential [128]. However, acetotrophic methanogens can be inhibited by ZVI-based biochar, which showed that this element could only enrich the hydrogenotrophic methanogens and improve the DIET between bacteria and methanogens [118, 128]. In addition, iron-based biochar could also achieve higher energy recovery efficiency from industrial organic wastewater, like sulfamethoxazole wastewater [78] and salty organic wastewater [9]. Using iron-based biochar exhibits diverse potential applications within environmental science. Su et al. [96] found that the use of magnesium (Mg) and calcium (Ca) as a means of modifying biochar improved its physicochemical properties, thus favoring the AD process. However, despite the numerous advantages of metal-modified biochar in enhancing methane production, it is crucial to exercise caution in the use of metallic-containing reagents during the modification process. It is imperative to explore low-carbon footprint synthesis methods to enhance the efficiency of modification [36].

2.3 Machine learning assists in predicting the yield and properties of biochar

2.3.1 Biochar yield prediction

The yield of biochar plays a crucial role in its preparation, as it requires a careful balance between energy-consuming processes and energy recovery. To assist in predicting the biochar yield, the use of ML models can be explored, taking into account factors such as feedstock characteristics and temperature. However, predicting the biochar yield can be challenging due to the diverse characteristics of feedstocks and the complex conditions involved in the preparation process. ML models designed for biochar yield prediction must consider various input parameters, including feedstock characteristics, pyrolysis conditions, and process parameters. Different algorithms perform differently with different data types, and the accuracy of model predictions can be impacted by several variables [2]. ML-assisted biochar yield prediction has been extensively studied. Zhu et al. [134] proposed that the RF algorithm could effectively predict biochar yield, achieving a high R2 value of 0.85, given appropriate input variables. They discovered that structural information, such as the relative proportions of lignin, cellulose, and hemicellulose, produced more accurate results than constituent compositions. Similarly, Hai et al. [26] demonstrated that RF outperformed other algorithms, including Multiple Linear Regression (MLR), Decision Tree (DT), SVM, and K-Nearest Neighbor (KNN), with an R2 value of 0.855 in biochar yield prediction. Pathy et al. [83] suggested that Extreme Gradient Boosting (XGBoost) could achieve comparable performance with an R2 value of 0.84 in biochar prediction.

In contrast, Li et al. [59] showcased the impressive accuracy of Multi-Layer Perceptron Neural Network (MLP-NN) in biochar yield prediction, achieving an R2 value of 0.964. However, selecting appropriate hyperparameters for the model is crucial to avoid underfitting or overfitting the data, which can lead to inaccurate predictions. In a comparative study that explored integrated methods (ML models integrated with Genetic Algorithm and Particle Swarm Optimization). Haq et al. [28] found that the Ensembled Learning Tree (ELT-PSO) model outperformed others, achieving an R2 value of 0.99. Even though various studies have identified various parameters for feature importance analysis, the pyrolysis temperature has emerged as the most significant variable in all of these investigations.

In general, simple algorithms (e.g., MLR) might exhibit less acceptable outcomes compared with RF, XGBoost, SVM, and ANN. Combined methods have demonstrated exceptional performance, although one must consider the trade-off among computational complexity, cost-effectiveness and convergence speed when applying these models [123].

2.3.2 Predict carbon content, aromaticity and capacitance

Predicting the carbon content of biochar is a vital aspect of evaluating its potential. The carbon content of biochar is potentially linked to its carbon dioxide sequestration, stability, and adsorption capacity for various applications [81]. Accurate prediction of carbon content is essential for determining the effectiveness of biochar in mitigating carbon emissions and enhancing digestate quality. ML has been successfully applied to predict the carbon content of biochar with a high degree of accuracy. Interestingly, while the inclusion of structure information (such as lignin, cellulose, and hemicellulose contents) significantly improved the accuracy of predicting biochar yield, the elemental compositions (i.e. C-H–O-N) played a more critical role in predicting the carbon content [134].

Aromaticity in biochar plays a vital role in interactions with organic matter, adsorption capacity for contaminants, stability, and resistance to degradation [8]. Measuring aromaticity in biochar is often complicated, expensive, and time-consuming, making it less accessible in many research organizations. To address this challenge, researchers have explored more straightforward approaches using basic characteristic properties to predict biochar aromaticity [80]. Cao et al. [7] compared simple polynomial models with ML algorithms (Genetic Algorithms) and found that ML methods provided more accurate predictions, capturing the underlying mapping relationship between elemental compositions and biochar aromaticity. Similarly, Pan et al. [80] investigated the ANFIS and least square support vector machine (LSSVM) algorithms. The results indicated that the LSSVM method exhibited greater reliability (R2 = 0.986), with carbon percentage being the most influential input parameter. These results demonstrate the feasibility and dependability of using element composition-based input parameters for predicting biochar aromaticity with ML methods, offering a plausible solution to the dearth of support for aromaticity measurement in many academic institutions. Besides, the electron capacitance of biochar is a crucial characteristic for enriching microorganisms. Yang et al. [117] explored four regression algorithms (DT, ANN, XGBoost, and RF) to predict the specific capacitance of biochar. Among these algorithms, XGBoost demonstrated superior performance with an R2 of 0.983, with the activator ratio being the most influential factor. Additionally, accurate prediction of specific capacitance in heteroatoms-rich activated carbon was achieved using MLP-NN, where micropore surface area and volumes had the most significant impact on the prediction performance [88].

3 Biochar-assisted AD for bioenergy recovery: based on the biochar characteristic

3.1 Effects of biochar on elemental bio-utilization of microorganism on biofuel recovery

3.1.1 Biochar enhanced bioavailability of Fe for microorganism

The cellular and metabolic activity of anaerobic microorganisms is the key to the energy conversion of organic waste. Biochar plays a crucial role in facilitating the colonization and growth of microorganisms, enabling close interspecific material and energy exchange, and influencing pH, alkalinity, and oxidation–reduction (REDOX) potential. Additionally, the bioavailability of elements, despite being a neglected factor, is of utmost importance in terms of biological regulation. The bioavailability of elements determines the biological activity within anaerobic digesters, as trace elements serve as non-substitutable coenzymes and cofactors in the enzyme systems of anaerobic microorganism [120]. Notably, biochar contains significant amounts of trace elements, making it worthwhile to investigate the bioavailability of these elements when biochar or elementally modified biochar is introduced into AD systems. Previous studies have demonstrated that biochar can enhance the bioavailability of trace elements such as Fe, Co, and Ni [85].

Fe is the most crucial element involved in the synthesis of most enzymes, and is a necessary trace element for hydrogenase, methane monooxygenase and nitrogenase, which plays an essential role in the growth and metabolism of anaerobic bacteria [97]. However, most of the Fe in AD is generally found in carbonates, sulfides, hydroxides, and residual fractions, which are in a biologically unavailable state. In the previous research, lignocellulose-based biochar can increase Fe bioavailability by 5 times [85]. For instance, this phenomenon can contribute to the removal of sulfides and their derived anions, the enhancement of chemisorbed capacity by oxygen-rich functional groups and the release of bound Fe by other specific functional groups such as hydroxyl, carboxyl and carbonyl groups. Zhang et al. [131] found that the increase of iron bioavailability benefited the proportion of viable microorganisms and the increase of methane production. As a former preparation material for biochar, food waste comes from a variety of sources and carries more iron. Shin’s research demonstrates that food waste-based biochar leads to a 33-fold increase in micronutrient Fe in digestion. Iron elutes from food waste-based biochar lead to the growth and continuous increase in methanogenic microorganisms, and methane production increases by 4% [95]. The absolute concentration of iron is needed for bioavailability, but dosing concentration does not increase bioavailability [131]. Many factors affect the actual bioavailability of iron by microorganisms, such as its availability, interspecific competition and physical distance. Although the iron content of waste wood-based biochar is slightly lower than that of food waste-based biochar, the chemical adsorption capacity of cellulosic biochar for Fe is 15 mg/g (the highest relative to other trace elements). This contributes to the availability of Fe to electroactive microorganisms due to the increment of its electrical conductivity and accumulates a large number of electroactive microorganisms [6]. By increasing the proportion of exchangeable parts of iron, the bioavailability of Fe in the biochar treatment was nearly tripled to 0.33. The content of methane in biogas is stable in the range of 55–62% [6]. In addition to enhancing the methane production effect, under the same lignocellulosic biochar enhancement, Fe increased the H2 production by 63.27%. This strong promoting effect is related to the requirement of Fe by the H2-producing bacteria for hydrogenase protein redox [97].

3.1.2 Biochar enhanced bioavailability of non-Fe elements for microorganism

In addition to Fe, many other trace elements have good bioavailable functions and are indispensable growth factors for microorganisms [85]. The addition of biochar significantly increases the contents of total Co, Mo, and Ni in digestion, and since Ni is also required for hydrogenase, the metabolic pathways involved in methanogenesis have increased [85]. Biochar increases the bioavailability of Co, Ni, Mo, Se, Mn, Cu, and Zn, which are essential cofactors of key enzymes [124] involved in methane production and are generally used to improve methane production and substrate utilization [6]. The methane yield increased to 134.7 mL/(g VS) during the treatment of nickel-loaded shrimp shell biochar by promoted the number and activity of Methanosarcina and Methanosaeta [58]. Food waste-based biochar contains a wider range of trace elements (Ti, Cu, Cr and Zn). Notably, Ca is required for the growth and aggregation of certain methanogenic microorganisms [95]. The contents (wt) of total nitrogen, phosphate and potassium in microalgal biochar were 6.34%, 2.44% and 3.64wt %, respectively, which were 2.31%, 2.19% and 3.0% higher than the corresponding values in the control sample. These results suggest that biochar amendments increase the nutrient content of the digestives and enrich Genus Proteiniphilum and genus Defluviitoga, thereby increasing average methane production by 12–54% [125].

3.1.3 Inhibition and relieve inhibition of microorganism by biochar-induced element variation

Maintaining the stability of the microbial energy conversion process is dependent upon a reasonable level of element control. Excessive element concentration may be fatal to cell activity. Ca content in kitchen waste-based biochar is the highest, about 60% [6, 95], it was found that 47.4–237 mg/L of Ca can inhibit microbial growth [97]. However, it is important to note that the elemental composition of biochar may differ from the concentration of elements that are released from the biochar into the AD system. Therefore, it is necessary to conduct further evaluations to determine the extent to which these elements contribute to the performance of the AD system. In addition, excessive Fe input will cause excessive cell oxidation and reduce microbial activity [131]. The removal of heavy metals is also a crucial part of organic waste treatment, which not only inactivates methanogenic microorganisms but also damages the stability of anaerobic systems and eventually causes further harm when it flows into the environment. Biochar is a good metal passivator with a strong adsorption capacity for the exchangeable part of heavy metals. Adding lignocellulosic-based biochar promotes the transformation of Cr, Cu, Pb and Zn into bio-unavailable states, which is conducive to reducing the toxicity of Cr, Cu, Pb and Zn to cells [115]. It can improve the AD efficiency of pigment sludge containing heavy metals, reduce the bioavailability volatility of Cd and Pb, and increase the solid removal rate and cumulative methane production by 37.8% and 56.3% [90]. Previous studies have proposed to adsorb Hg (II) to biochar by complexation and precipitation to reduce the bioavailability of Hg (II). Another possibility is that biochar induces S and Fe to stabilize Hg (II) by solid-state precipitation of mercury sulfide minerals and FeS (s) minerals [110]. Paper mill sludge biochar has a high pH value, rich ash content and large pores, which can reduce the ecotoxicity of Cu, Zn and As in biogas. Additionally, it has been observed that As can be immobilized in a non-bioavailable state through the adsorption process of paper mill sludge biochar. Complex pollution of heavy metals can be reduced while higher methane production can be achieved [33]. Biochar prepared by mixing algae whit other biomass residues showed a maximum adsorption capacity of 50.71 mg/g for Cu2+, which was more than three times that of the original biochar [37].

3.2 Effects of biochar characteristic on microbial electron transfer during biofuel recovery

3.2.1 Effect of biochar characteristics on IET

Microbial electron transfer is fundamental to redox reactions and serves as the foundation for converting organic waste into energy. It is important to note that this electron transfer is not solely limited to the formation of polymers or the transfer of hydrogen and formic acid. Interspecific formic acid transfer and interspecific hydrogen transfer (IHT) are more common cooperative modes in AD, which methanogens use as electron donors for CO2 methanation and solve the thermodynamic adverse conditions caused by high hydrogen reaction for bacteria [129]. In a previous study, it was reported that biochar could serve as an ideal additive to promote IHT [12], sawdust biochar is believed to be a temporary electron acceptor that promotes butyrate oxidation, and methanogens accept these electrons from the reduced biochar to reduce carbon dioxide to methane. In this way, the inhibition of butyrate oxidation by high hydrogen partial pressure is alleviated [126]. At the same time, methanogens (such as Methanothermobacte and Methanosarcina) exhibit a synergistic effect of hydrogenotrophic and acetoclastic methanogenesis pathways [126].

3.2.2 Effect of biochar characteristics on DIET

The concept of DIET has garnered significant attention in recent years. Unlike IET, the transfer efficiency of DIET is not limited by the mass transfer rate and typically occurs between electroactive bacteria and methanogens. There was clear evidence that Geobacter, a type of electroactive bacteria, showed the highest abundance in the lignocellulose-based biochar treatment, increasing 34-fold. This phenomenon can potentially be attributed to an enhancement in the biochar's conductivity following the adsorption of trace elements, resulting in an approximate ten-fold increase in conductivity and improved DIET performance. Furthermore, biochar has the ability to enhance the growth of hydrogenophilic methanogenic archaea, a functional microorganism associated with DIET, and the presence of trace elements showed an enhanced performance on this effect. Trace element stimulated the abundance of Methanobacillus and Spirospira [6], and the effect of cyanobacteria biochar in Taihu Lake on methane production in the AD process of sludge. The study found that lower vaccination rates (4% and 1%, v/v) increased methane output. Algae-based biochar at lower vaccination rates enriched methane sarcoma better than higher vaccination rates. According to prior study, focused DIET may enable methane synthesis [35]. The algal biochar, owing to its porous structure and distinct functional groups, exhibits remarkable electron transport capabilities with superior storage capacity. This property expedites the reduction of Fe (III) to Fe (II) [104], and the cytochrome and ferredoxin involved in the synthesis of Fe (II) are key factors in electron transport [104]. It is worth mentioning that most microorganisms participating in DIET, such as Geobacter, Sphaerochaeta and Sporanaerobacter species, rely on exchangeable (bioavailable) iron and sulfur to complete the process of extracellular respiration [61]. Surface functional groups may trigger the DIET mechanism between anaerobic microorganisms. The addition of rice straw biochar has no significant effect on the function of bacterial flora, but biochar material with rich specific surface area and hydrophobicity can provide better electronic conductivity as an electronic conduit. Thus, enhancing electron transport capacity between microorganisms [108]. Besides, it is worth noting that the augmentation of distinct surface functional groups, namely phenolic and lactic acid groups, is the underlying cause of the alteration in redox characteristics of algal biochar. This phenomenon is also responsible for the rise in electron-donating potential. The coenzyme F420 activity of methanogenic was enhanced, and the methane yield was increased by 58.7%. Thus, algal biochar acts as an effective electron conduit for DIET during anaerobic methane generation [34]. In thermophilic digesters modified from waste wood pellet biochar, beneficial bacteria (e.g., Thermotogae and Defluviitoga) play a leading role in the fermentation of food waste. Due to the good electrical conductivity of biochar, the DIET process between methanogens and their syntrophic partners is promoted. The addition of sawdust biochar effectively shortened the lag period by 27.5–64.4%, and increased the maximum methanogenesis rate by 22.4%-40.3%, due to the enrichment of Anaerolineaceae and Methanosaeta, typical microorganisms for DIET [12]. Agricultural waste corn straw biochar also promoted the abundance of two electron-synergistic microorganisms, Clostridia and Methanosarcina [93]. Draff-based biochar has abundant active surface functional groups (such as -CO, pyridine-N, and graphite-N), and it has been shown that increased methane production is associated with DIET through the charge–discharge cycle containing C, N, and O functional groups on the surface [17]. Furthermore, previous reported that the presence of elements also exerts a significant influence on the development of biochar functional groups, which affect the DIET indirectly [133]. Accordingly, trace or common elements with bioavailability can enhance DIET through two paths: (1) Enhancing the DIET by abundant functional groups on biochar surface; (2) Enriching the electroactive microorganisms related to DIET and strengthening the cooperative relationship of DIET between electroactive microorganisms and methanogens.

3.3 Effects of biochar characteristic on biochemical recovery

3.3.1 Enhanced volatile fatty acids recovery efficiency by biochar

In addition to biofuels, biochar can also facilitate the recovery of value-added chemicals, such as volatile fatty acids (VFA). The surface functional groups on biochar surface, such as OH groups and C-O groups, can affine to the cell surface, which could facilitate biofilm development and accelerate the hydrolysis process of large molecular organic substance [20]. Also, the DIET efficiency could be accelerated by high biochar bulk crystallinity [71]. Nonetheless, considering the syntrophic growth of fermentative bacteria and homoacetogens in the biochar could lead to a change in the H2 partial pressure in the system, the main product of fermentation would vary with different types of biochar. For instance, Lu et al. [71] found that the enrichments of acetate over butyrate from glucose follow: boconut > longan shell > bamboo > borncob > pinecone. In addition, the algae-derived biochar has been proven to enhance the algae anaerobic fermentation for short-chain fatty acids production. And the acetate concentration varied with biochar content [20]. The algae-based biochar could destroy the algae cells and release more macromolecular organic substrates, which can be used for short-chain fatty acids production. Currently, the abundant hydrophilic functional groups permit the attachment and growth of microorganisms on its surface, while the conductive properties of biochar promote electron transport in the system. The economy analysis also showed that the algae-based biochar couple AD could have a 1.08 Yuan/kg profits more than that in solo-algae AD [20]. Although AD has widely used biochar in VFA production, VFA yield can be further improved by modifying the biochar. Du et al. [19] explored the effect of activated persulfate corn straw-based biochar on VFA production from animal wastewater. According to the research, persulfate modification could lengthen the acidification period and inactivate. The rate of released dissolved organic matter with low molecular weight (0–10 kDa) increased nearly 2.1 times that of the control group, which led to higher VFAs yield [19]. The research has given a novel strategy for enhancing the VFA recovery by synergistic chemical and microbial effects of biochar.

3.3.2 Enhanced alcohol recovery efficiency by biochar

Alcohol production from biomass is a meaningful modern adjunct to fossil fuels. However, during the production process, some pretreatment technology could introduce toxic substances, i.e., furfural and acetic acid [29]. Biochar has been proven to enhance alcohol production. The biochar could act as an effective adsorbent to remove this toxic inhibition. The research by Sun et al. [98] improves ethanol production by switchgrass, forage sorghum, redcedar and poultry litter-based biochar addition. In their research, the biochar could adsorb the lignocellulose-derived microbial inhibitory compounds. Also, Klasson et al. [44] used dew-retted flax shive-based biochar to adsorb the released by-product furfural and hydroxymethylfurfural during pretreatment of ethanol fermentation. The added 2.5% (w/v) biochar in fermentation broth could significantly reduce the fermentation lag phase [44]. However, Wang et al. [109] found that the increase in ethanol production from lignocellulosic biomass by biochar was mainly due to the biochar extracts in the fermentation broth and cell immobilization on biochar. Adsorption detoxification is not a factor in controlling ethanol production. Further studies are needed to elucidate the formation process of cell immobilization on biochar and the effect of biochar on alcohol production. Moreover, the biochar could couple with the bio-electrochemical system to enhance alcohol production [13]. The bio-electrochemical system coupled with biochar showed a high alcohol/acid ratio of 0.179 mol/mol, which increases nearly threefold of unmediated mixotrophy at an open circuit. The research indicated that the biochar could be coupled with other technology to enhance the biochemical recovery efficiency.

3.3.3 Enhanced other biochemical recovery efficiency by biochar

The recovery of other biochemical products can also be improved by biochar. Medium-chain carboxylates acids (MCCAs) such as hexanoate (C6) and caprylate (C8) are valuable commercial chemicals with relatively higher energy density and a wide range of applications. It can be the precursor of spices, renewable fuels, fungicides and food additives [87, 106]. The addition of biochar has been reported to enhance the MCCAs production and product selectivity [106]. The detailed mechanism can be divided into follows points: (1) reinforcement effect in chain elongation. The biochar addition could be inducing more extracellular polymers substance by its high conductivity, which is beneficial for creating a more demanding system with a more stable microorganism community structure on the biochar for chain elongation [68]. Moreover, it should be noted that the biochar smaller than 5 μm may be more efficient for enhancing chain elongation due to its higher K content in an aqueous solution, electrical conductivity and surface area[67]. (2) shorten the lag phase in the chain elongation reactions. The biochar could create some microlocations or ‘hotspots’ with higher local pH around the biochar, which would decrease the toxicity of undissociated carboxylates [68, 102]. (3) increasing the selectivity of MCCAs. Ghysels et al. [23] concluded that the biochar could enhance the ethanol conversion and selectivity to caproic acid by Clostridium kluyveri. The biochar could serve as a pH buffer and enrich the functional microorganism [68]. Recent research by Cheng et al. [13] found that butyrate and hexanoate production from glucose increased significantly by biochar. Beside the MCCAs, the production of acetone-butanol-ethanol (ABE) fermentation could also be enhanced by biochar. The biochar derived from switchgrass, forage sorghum, and red cedar could act as buffer and provide mineral nutrients to functional microorganism, i.e., Na、Ca、Mg、K、S、P、Fe、Zn and Mn, which are crucial for metabolic processes and the growth of microbes [103].

4 Machine learning for biochar-enhanced anaerobic systems

4.1 Machine learning for biochar-enhanced bioenergy recovery process

AD is a conventional technology employed for the efficient recovery of energy from organic waste. However, due to the diverse range of substrates and the variability of environmental factors, AD often encounters unexpected disturbances during the energy recovery process. Consequently, this leads to suboptimal energy recovery performance and increased operational costs. To address these challenges, the implementation of a suitable ML model can be beneficial in optimizing the AD process [107]. Additionally, in the context of biochar-enhanced AD systems, ML models can be utilized to predict the intricate properties of biochar (Fig. 1). By inputting easily measurable features of biochar and information on pyrolysis conditions, these models enable accurate predictions to be made. Furthermore, these results can be integrated with other feedstock properties and AD operational conditions to further predict AD products. It is important to note that these outputs are continuous data, and the nature of variables has been pre-identified. Therefore, the common algorithms used in this process are regression models (a category of supervised ML) [26]. On the other hand, discrete output data such as system faulty identification, process inhibition, biogas quality, etc., are commonly predicted using classification models [25].

Schematic diagram of predicting biochar application in AD. Abbreviations: SI (Structure information), includes the content of lignin, cellulose, and hemicellulose; EC (Element compositions), includes C, H, O, N and S; PT (Pyrolysis temperature); RT (Retention time); HR (Heating rate); PS (Particle size); Aro. (Aromaticity); Cap. (Capacitance); VS (Volatile solids); TS (Total solids); volatile fatty acids (VFA); COD (Chemical oxygen demand); HRT (Hydraulic retention time); OLR (Organic loading rate); T (Temperature); BD (Biochar dosage); PHA (polyhydroxyalkanoate); PI (Permutation importance); SHAP (SHapley Additive exPlanations); PDP (Partial Dependence Plot); PCA (Principal component analysis)

However, due to the “black box” nature of ML, many studies combine feature analysis methods with ML models to compensate for the limited interpretation capability of ML models. For instance, Permutation Importance is a technique used in ML to assess the significance of features in a predictive model. It determines the extent to which each feature contributes to the efficacy of the model. Additionally, when investigating microbial information, Principal Component Analysis (PCA) reduces high-dimensional datasets for better correlation analysis [59]. Combining these methods can enhance our understanding of microbial community interactions, biochar, and AD systems. It is envisioned that artificial intelligence (AI) can assist in the inverse design and development of an intelligent biological industry for AD with these techniques.

4.1.1 Machine learning prediction for biological energy recovery: methane and hydrogen

Recent importance analysis has highlighted a significant correlation between cumulative methane production (CMP) and the physicochemical properties of biochar [42]. This discovery implies that it may be possible to forecast CMP under unexamined conditions by accurately predicting these properties. This finding opens up new opportunities for comprehending and optimizing biochar-enhanced AD systems. And it is essential to consider the conditions and operational parameters of AD systems that can be optimized to favor either methane or hydrogen production, the latter of which is known as “dark fermentation” [111]. The prediction of energy production is an attractive application for industries, as it directly impacts profitability. Many methane prediction models have been applied in techno-economic analysis (TEA) to assess the economic feasibility of new biogas plants or evaluate optimization strategies for future scenarios [40, 60, 76]. Extensive work has been done in this field; however, the models vary in complexity and reliability.

Notably, many kinetic-based models are derived from the well-known Anaerobic Digestion Model No. 1 (ADM1), which requires multidisciplinary knowledge. In contrast, more straightforward techniques based on approximate stoichiometry equations have been more commonly used in TEA models without considering the kinetics of the reactions [76]. These prediction methods have complex expressions and may not be adaptable to novel feedstocks (e.g., lignocellulosic biomass), different reactor configurations, reaction temperatures, and reaction types (e.g., dry AD). Consequently, the prediction results can exhibit significant variations, leading to unreliable economic assessments. Moreover, conventional models often overlook factors affecting methane yields, such as inhibition factors, trace elements, and enhancement strategies [2, 64]. The conventional models are either too simple to adequately depict the overall performance or too complex to be applied at the commercial and full-scale industrial levels. Some studies have attempted to overcome these limitations by developing statistically based, multi-level regression optimal models [66]. However, these models often require a large amount of full-scale data and may struggle to accurately capture the complex nonlinear responses that occur in biogas or biohydrogen processes [47].

In contrast, ML methods offer a quick and effective way to predict methane production and identify the key parameters influencing the prediction. It requires no knowledge of the biological, physical, or chemical sciences [16, 114, 132]. Simple parameter inputs can lead to highly reliable predictions. For instance, Ghatak and Ghatak [22] utilized feedstock composition, HRT, and temperature to predict biogas production, achieving an R2 value of 0.99. Similarly, Cheon et al. [14] employed OLR, pH, alkalinity, VFA, and COD removal efficiency to predict methane yield, resulting in an impressive R2 value of 0.97. Similarly, Wang and Wan [105] demonstrated the usefulness of neural networks in optimizing multiple responses in fermentative hydrogen production processes. In a review by Kumar Sharma et al. [47], various ML algorithms were critically discussed, and it was concluded that ML methods hold promise in predicting biohydrogen yield. The authors encouraged using advanced ML techniques, such as deep learning, and integrating theoretical models to enhance interpretation and prediction capabilities. Pandey et al. [82] also discussed the applications of ML models for predicting and optimizing biohydrogen production. The study emphasized the need for robust ML techniques that can explore the target system and aid in decision-making processes.

Several cases have confirmed the outstanding performance of biochar-enhanced anaerobic systems. However, most ML models in this field primarily focus on conventional parameters and are limited to case-to-case studies. Only a few studies have investigated the correlation between biochar properties and energy production performance [42]. The feature importance of biochar concerning CMP remains unclear, and the impact of biochar on hydrogen production performance in this context is still unknown. These studies demonstrate the flexibility of ML in prediction, as it is not limited to specific input parameters. Such findings suggest the potential for developing highly efficient prediction models for industrial applications.

4.1.2 Machine learning prediction for valuable chemicals production: PHA

Bioplastics have gained significant attention recently due to their environmental benefits and sustainable characteristics. Among the fully degradable bioplastics, PHA can be produced by a wide range of bacteria and archaea [54].

To optimize the selection process for PHA production, Xu et al. [113] integrated mechanistic and deep learning models to accurately predict the dynamic enrichment of PHA accumulating bacteria (PAB) in mixed microbial cultures. Luna et al. [72] developed a hybrid model to describe the continuous production of PHA at a laboratory culture scale. It is worth noting that the use of ML for PHA production prediction is an emerging field, and further research is needed to fully explore the capabilities and potential applications of ML models in this context. However, the eco-friendliness, biosynthesis capability, and modifiable properties of PHA-based polymers make them promising alternatives to petroleum-based plastics, fueling the interest in developing efficient production strategies [84].

4.1.3 Machine learning prediction for microorganisms interactions in anaerobic digestion

Biochar has been shown to enhance the performance of AD, a strategy known as the additive approach. Similar to carbon-rich materials such as activated carbon and graphene, biochar demonstrates immobilization and support for microbial growth, as well as mitigation of acid stress and ammonia inhibition [130]. Moreover, there is a growing interest in exploring the role of biochar in facilitating DIET among microbes [10].

ML methods provide a new approach to understanding these interactions with microorganisms, mitigating labor-intensive, costly, and time-consuming work. For instance, Treloar et al. [101] applied reinforcement learning combined with neural networks to control multiple interacting species in a bioreactor, showing promising results for co-culture control. Feature importance analysis conducted by Xu et al. [114] demonstrated that certain microbes play crucial roles despite having relatively low abundances. ML-assisted identification of these features can guide the proactive management of microbial communities. However, Li et al. [53] pointed out that most ML-assisted applications in the AD process have been limited to simple feature importance analysis, and there is a need for a more in-depth interpretation of microbial interactions.

4.2 Machine learning for visualizing correlations between biochar and anaerobic digestion

In recent years, AI-based ML has been applied not only to guide the preparation of biochar but also to guide the operation of AD. However, there is currently limited research on the application of machine learning to guide the preparation of biochar for enhancing energy recovery in AD. The reason behind this phenomenon stems from the fact that current experiments on the enhancement of AD by biochar primarily focus on the impact of biochar on anaerobic digestion-related indicators. However, there is a lack of research connecting experimental results with the structural characteristics of biochar, resulting in insufficient data. Zhang et al. [132] using tree-based ML models (the GBR, RF, and XGBoost) to investigate the effect of digestion time and particle size on methane yield. By employing this approach, it is possible to identify the optimal biochar characteristics that lead to maximum methane production. Also, it can save costs, time, and effort on the process. Consequently, feedback can be provided to the biochar preparation process to produce biochar with responsive properties, thereby optimizing the energy recovery process. However, it is important to note that different AI models need to be employed for predictions based on various experimental objectives in subsequent work. For instance, if the primary goal of the experiment is PHA recovery, the parameters of the model like input and output variables need to be modified accordingly.

4.3 Research gap and challenges for ML assisted biochar in AD system

As discussed above, ML has been extensively applied to individually predict the yield and properties of biochar and AD systems. However, there is a lack of studies that can explain the interactions when these two systems are coupled together [42]. Therefore, we propose investigating the interactional correlation between biochar properties and microbes to forecast further the performance of AD systems in producing fuels and chemicals. Furthermore, the current understanding of these interactions remains superficial, with most studies not considering the Phylum and Species level [53]. Comprehending the complex interactions between biochar and microorganisms is indispensable to achieving intelligent biological processes.

In addition to the specific challenges that AD systems may face, the application of ML also has intrinsic drawbacks.

-

Firstly, while the ‘black box’ nature of ML may appear as a robust and straightforward technique for industrial applications, there is still a need to uncover the underlying mechanisms and provide interpretability and rationale for scientific study. One possible solution is to combine kinetic models with multidisciplinary knowledge to address this challenge.

-

Secondly, it is important to consider the efficiency of ML models. While many models may demonstrate good performance, integrating complex models can increase computation time and reduce practical value in commercial applications.

-

Thirdly, the variation in feedstocks, scales, and evaluation metrics across different studies poses a challenge of inconsistency, limiting the ability to extrapolate findings from one condition to another.

-

Lastly, to achieve intelligent biological processes, a comprehensive comprehension of the complex interactions between biochar and microorganisms is indispensable.

By addressing these challenges and advancing our understanding of biochar-microorganism interactions and ML applications, we can pave the way for more effective and reliable intelligent biological processes in the context of biochar-enhanced AD systems.

5 Conclusion and future perspectives

Biochar, a by-product of pyrolysis, hydrothermal carbonization, and gasification, possesses distinct physicochemical properties that make it a valuable additive for enhancing the resource recovery efficiency of organic waste, including biofuels and high-value biochemicals. Furthermore, biochar holds great potential in contributing to global carbon reduction efforts. This review aims to explore the relationship between the physicochemical properties of biochar, its functionality, current applications in biofuel and biochemical recovery of organic waste, as well as the utilization of ML for carbon recovery. However, there are significant challenges that need to be addressed before biochar can be widely implemented on a large scale. To achieve efficient large-scale application of biochar derived from biomass residues for the conversion of organic carbon sources into valuable chemicals and biomass energy, further research is required in the following areas:

-

(1)

Enhancing the efficiency of biofuel and biochemical recovery relies on the unique physicochemical properties of biochar. These properties, which include functional groups, size, and porosity, are influenced by various factors such as the type of biomass (algae, food waste, or waste biomass), pyrolysis temperature, and preparation process (gasification, pyrolysis, or hydrothermal carbonization). When utilizing biochar to improve specific bioenergy recovery processes, it is crucial to select the appropriate biochar based on the principles of biochemical reactions and the characteristics of biochar. Therefore, it is necessary to investigate how these properties are preserved and how they transform under different carbonization conditions, whether through gasification or hydrothermal conversion, when biomass is converted into biochar. Furthermore, t is worth investigating the correlation between key characteristics of biochar and the process of bioenergy recovery. For example, the pH buffering capacity of biochar proves beneficial in pH-sensitive biological treatments involving acid-producing bacterial species and methanogenesis archaea. The presence of a high surface area, porosity, and functional groups can enhance the enrichment process of functional microorganisms. Additionally, the electrical conductivity of biochar facilitates electron transfer during anaerobic digestion. Furthermore, biochar can be modified to meet specific application requirements, such as functional group modification and metal/non-metal element doping, thereby further improving bioenergy recovery efficiency. Lastly, expanding the sources of biochar beyond the currently reported feedstocks can help identify more cost-effective options.

-

(2)

Focusing on the interactions between biochar and microorganisms is crucial in the context of bioenergy recovery. Since bioenergy production heavily relies on biological processes, understanding the relationship between biochar and microbial interactions becomes significant when incorporating biochar into the system. It is necessary to explore the corresponding relationships between biochar, microbial structure, and environmental conditions. This exploration can provide insights into establishing a targeted strategy for shaping the microbiome to enhance bioenergy production using biochar. Additionally, the metabolic pathways of microorganisms in the system are often complex, involving mixed-culture microbial systems with various functional microorganisms. Therefore, it is essential to address different technological limitations in biochar-enhanced bioenergy recovery processes to optimize the biological process. Furthermore, the micro-energetic strategies employed by functional microorganisms remain unclear. Investigating the impact of biochar on the micro-energetic strategies of functional microorganisms can help elucidate the interaction between biochar and microorganisms. Finally, employing statistical methods and a multi-group approach, such as macro-proteome and macro-transcriptome analysis, would be beneficial in this regard.

-

(3)

The economic and environmental assessment of biochar production and its application in bioenergy recovery systems is a crucial aspect. It has been demonstrated that biochar can enhance the efficiency of bioenergy recovery processes. However, it is important to note that the preparation of biochar involves energy-intensive procedures, such as high-temperature treatments. Therefore, a comprehensive evaluation of biochar sustainability is necessary, encompassing the gasification process, the resulting products (i.e., syngas and biochar), and the overall bioenergy recovery process. In order to establish a financially and environmentally sustainable system for the recovery of organic waste resources, a concept that effectively balances biochar production and application needs to be proposed.

-

(4)

ML plays a crucial role in the preparation of biochar and the enhancement of energy recovery. As mentioned earlier, ML has been extensively utilized to predict the performance and properties of biochar and bioenergy recovery systems individually. However, there is a dearth of studies that explore the interactions between these two systems when they are combined. Employing ML to investigate the relationship between biochar properties and microbial activity can provide valuable insights for future experiments. Nevertheless, it is important to address the limitations of machine learning applications. For instance, the efficiency and reliability of machine learning models should be taken into consideration, given that the database is not yet comprehensive and evaluation metrics lack uniformity. To accurately evaluate the system, more precise models are required.

Availability of data and materials

Data sharing not applicable to this article as no datasets were generated during the current study.

Abbreviations

- AD:

-

Anaerobic digestion

- IET:

-

Interspecies electron transfer

- DIET:

-

Direct interspecies electron transfer

- ML:

-

Machine learning

- ANFIS:

-

Adaptive network-based fuzzy inference system

- SVM:

-

Support vector machine

- DNN:

-

Deep neural networks

- RF:

-

Random Forest

- ANN:

-

Artificial neural network

- LC:

-

Lignocellulose

- ZVI:

-

Zero-valent iron

- MLR:

-

Multiple Linear Regression

- DT:

-

Decision Tree

- KNN:

-

K-Nearest Neighbor

- XGBoost:

-

Extreme Gradient Boosting

- MLP-NN:

-

Multi-Layer Perceptron Neural Network

- ELT-PSO:

-

Ensembled Learning Tree

- CMP:

-

Cumulative methane production

- LSSVM:

-

Least square support vector machine

- REDOX:

-

Oxidation-reduction

- ATP:

-

Adenosine triphosphate

- IHT:

-

Interspecific hydrogen transfer

- VFA:

-

Volatile fatty acids

- MCCAs:

-

Medium-chain carboxylates acids

- ABE:

-

Acetone-butanol-ethanol

- PCA:

-

Principal Component Analysis

- AI:

-

Artificial intelligence

- SI:

-

Structure information

- EC:

-

Element compositions

- PT:

-

Pyrolysis temperature

- RT:

-

Retention time

- HR:

-

Heating rate

- PS:

-

Particle size

- Aro:

-

Aromaticity

- Cap:

-

Capacitance

- VS:

-

Volatile solids

- TS:

-

Total solids

- COD:

-

Chemical oxygen demand

- HRT:

-

Hydraulic retention time

- OLR:

-

Organic loading rate

- T:

-

Temperature

- BD:

-

Biochar dosage

- PHA:

-

Polyhydroxyalkanoate

- PI:

-

Permutation importance

- SHAP:

-

SHapley Additive exPlanations

- PDP:

-

Partial Dependence Plot

- PCA:

-

Principal component analysis

- TEA:

-

Techno-economic analysis

- ADM1:

-

Anaerobic Digestion Model No. 1

References

Abdullah I, Ahmad N, Hussain M, Ahmed A, Ahmed U, Park Y-K (2022) Conversion of biomass blends (walnut shell and pearl millet) for the production of solid biofuel via torrefaction under different conditions. Chemosphere 295:133894

Andrade Cruz I, Andrade LRS, Jesus AA, Vasconcelos BR, Bharagava RN, Bilal M, Figueiredo RT, Souza RL, Romanholo Ferreira LF (2022) Application of machine learning in anaerobic digestion: perspectives and challenges Biores Technol 345:126433

Andrade LA, Batista FRX, Lira TS, Barrozo MAS, Vieira LGM (2018) Characterization and product formation during the catalytic and non-catalytic pyrolysis of the green microalgae Chlamydomonas reinhardtii. Renewable Energy 119:731–740

Awasthi MK (2022) Engineered biochar: a multifunctional material for energy and environment. Environ Pollut 298:118831

Bird MI, Wurster CM, de Paula Silva PH, Bass AM, de Nys R (2011) Algal biochar – production and properties. Biores Technol 102:1886–1891

Cai Y, Meng X, Hu K, Zhao X, Usman M, Esposito G, Shen X, Chen S (2023) A novel strategy to reduce trace element supplementation in the semi-solid anaerobic digestion with gradient ammonia concentration: the role of biochar. Fuel 338:127332

Cao H, Milan YJ, Mood SH, Ayiania M, Zhang S, Gong X, Lora EES, Yuan Q, Garcia-Perez M (2021) A novel elemental composition based prediction model for biochar aromaticity derived from machine learning. Artif Intell Agric 5:133–141

Castan S, Sigmund G, Hüffer T, Tepe N, von der Kammer F, Chefetz B, Hofmann T (2020) The importance of aromaticity to describe the interactions of organic matter with carbonaceous materials depends on molecular weight and sorbent geometry. Environ Sci Process Impacts 22:1888–1897

Che L, Yang B, Tian Q, Xu H (2022) Iron-based biochar derived from waste-activated sludge enhances anaerobic digestion of synthetic salty organic wastewater for methane production. Biores Technol 345:126465

Chen L, Fang W, Chang J, Liang J, Zhang P, Zhang G (2022) Improvement of Direct interspecies electron transfer via adding conductive materials in anaerobic digestion: mechanisms, performances, and challenges. Front Microbiol 13:860749

Chen L, Fang W, Liang J, Nabi M, Cai Y, Wang Q, Zhang P, Zhang G (2023) Biochar application in anaerobic digestion: Performances, mechanisms, environmental assessment and circular economy. Resour Conserv Recycl 188:106720

Chen S, Rotaru A-E, Shrestha PM, Malvankar NS, Liu F, Fan W, Nevin KP, Lovley DR (2014) promoting interspecies electron transfer with biochar. Sci Rep 4:5019

Cheng C, Shao Y, Li W, Liu J, Liu X, Zhao Y, Li X, Yang S-T, Xue C (2022) Electricity-enhanced anaerobic, non-photosynthetic mixotrophy by Clostridium carboxidivorans with increased carbon efficiency and alcohol production. Energy Convers Manage 252:115118

Cheon A, Sung J, Jun H, Jang H, Kim M, Park J (2022) Application of various machine learning models for process stability of bio-electrochemical anaerobic digestion. Processes 10(1):158

Chiappero M, Fiore S, Berruti F (2022) Impact of biochar on anaerobic digestion: meta-analysis and economic evaluation. J Environ Chem Eng 10:108870

De Clercq D, Wen Z, Fei F, Caicedo L, Yuan K, Shang R (2020) Interpretable machine learning for predicting biomethane production in industrial-scale anaerobic co-digestion. Sci Total Environ 712:134574

Deng C, Lin R, Kang X, Wu B, Wall DM, Murphy JD (2021) What physicochemical properties of biochar facilitate interspecies electron transfer in anaerobic digestion: a case study of digestion of whiskey by-products. Fuel 306:121736

Dilokekunakul W, Teerachawanwong P, Klomkliang N, Supasitmongkol S, Chaemchuen S (2020) Effects of nitrogen and oxygen functional groups and pore width of activated carbon on carbon dioxide capture: temperature dependence. Chem Eng J 389:124413

Du X, Zhang Y, Ma Y-W, Feng S-X, Zhang Y-X, Kou H-J, Sun Y (2023) The synergistic effect of chemical oxidation and microbial activity on improving volatile fatty acids (VFAs) production during the animal wastewater anaerobic digestion process treated with persulfate/biochar. Sci Total Environ 857:159276

Duan X, Chen Y, Yan Y, Feng L, Chen Y, Zhou Q (2019) New method for algae comprehensive utilization: Algae-derived biochar enhances algae anaerobic fermentation for short-chain fatty acids production. Biores Technol 289:121637

Elkhalifa S, Al-Ansari T, Mackey HR, McKay G (2019) Food waste to biochars through pyrolysis: a review. Resour Conserv Recycl 144:310–320

Ghatak MD, Ghatak A (2018) Artificial neural network model to predict behavior of biogas production curve from mixed lignocellulosic co-substrates. Fuel 232:178–189

Ghysels S, Buffel S, Rabaey K, Ronsse F, Ganigué R (2021) Biochar and activated carbon enhance ethanol conversion and selectivity to caproic acid by Clostridium kluyveri. Biores Technol 319:124236

Grycová B, Koutník I, Pryszcz A, Kaloč M (2016) Application of pyrolysis process in processing of mixed food wastes. Pol J Chem Technol 18:19–23

Gupta R, Zhang L, Hou J, Zhang Z, Liu H, You S, Sik Ok Y, Li W (2023) Review of explainable machine learning for anaerobic digestion. Biores Technol 369:128468

Hai A, Bharath G, Patah MFA, Daud WMAW, K, R., Show, P., Banat, F. (2023) Machine learning models for the prediction of total yield and specific surface area of biochar derived from agricultural biomass by pyrolysis. Environ Technol Innov 30:103071

Hamidzadeh Z, Ghorbannezhad P, Ketabchi MR, Yeganeh B (2023) Biomass-derived biochar and its application in agriculture. Fuel 341:127701

Haq ZU, Ullah H, Khan MNA, Raza Naqvi S, Ahad A, Amin NAS (2022) Comparative study of machine learning methods integrated with genetic algorithm and particle swarm optimization for bio-char yield prediction. Biores Technol 363:128008

He M-X, Wu B, Shui Z-X, Hu Q-C, Wang W-G, Tan F-R, Tang X-Y, Zhu Q-L, Pan K, Li Q, Su X-H (2012) Transcriptome profiling of Zymomonas mobilis under furfural stress. Appl Microbiol Biotechnol 95:189–199

He X, Zhang T, Ren H, Li G, Ding L, Pawlowski L (2017) Phosphorus recovery from biogas slurry by ultrasound/H2O2 digestion coupled with HFO/biochar adsorption process. Waste Manage 60:219–229

Huang W-H, Lee D-J, Huang C (2021) Modification on biochars for applications: a research update. Biores Technol 319:124100

Jia B, Yun S, Shi J, Han F, Wang Z, Chen J, Abbas Y, Xu H, Wang K, Xing T (2020) Enhanced anaerobic mono- and co-digestion under mesophilic condition: Focusing on the magnetic field and Ti-sphere core–shell structured additives. Biores Technol 310:123450

Jiang B, Tian J, Chen H, Zheng H, Xu Z, Lin Y (2022) Heavy metals migration and antibiotics removal in anaerobic digestion of swine manure with biochar addition. Environ Technol Innov 27:102735

Jiang Q, Wu P, Zhang X, Zhang Y, Cui M, Liu H, Liu H (2022) Deciphering the effects of engineered biochar on methane production and the mechanisms during anaerobic digestion: Surface functional groups and electron exchange capacity. Energy Convers Manage 258:115417

Jiang Q, Zhang C, Wu P, Ding P, Zhang Y, Cui M-H, Liu H (2021) Algae biochar enhanced methanogenesis by enriching specific methanogens at low inoculation ratio during sludge anaerobic digestion. Biores Technol 338:125493

Jin H-Y, Yang L, Ren Y-X, Tang C-C, Zhou A-J, Liu W, Li Z, Wang A, He Z-W (2023) Insights into the roles and mechanisms of a green-prepared magnetic biochar in anaerobic digestion of waste activated sludge. Sci Total Environ 896:165170

Jin H, Hanif MU, Capareda S, Chang Z, Huang H, Ai Y (2016) Copper(II) removal potential from aqueous solution by pyrolysis biochar derived from anaerobically digested algae-dairy-manure and effect of KOH activation. J Environ Chem Eng 4:365–372

Kanjanarong J, Giri BS, Jaisi DP, Oliveira FR, Boonsawang P, Chaiprapat S, Singh RS, Balakrishna A, Khanal SK (2017) Removal of hydrogen sulfide generated during anaerobic treatment of sulfate-laden wastewater using biochar: Evaluation of efficiency and mechanisms. Biores Technol 234:115–121

Kant Bhatia S, Palai AK, Kumar A, Kant Bhatia R, Kumar Patel A, Kumar Thakur V, Yang Y-H (2021) Trends in renewable energy production employing biomass-based biochar. Biores Technol 340:125644

Karellas S, Boukis I, Kontopoulos G (2010) Development of an investment decision tool for biogas production from agricultural waste. Renew Sustain Energy Rev 14:1273–1282

Kazemi Shariat Panahi H, Dehhaghi M, Ok YS, Nizami AS, Khoshnevisan B, Mussatto SI, Aghbashlo M, Tabatabaei M, Lam SS (2020) A comprehensive review of engineered biochar: production, characteristics, and environmental applications. J Clean Prod 270:122462

Khashaba NH, Ettouney RS, Abdelaal MM, Ashour FH, El-Rifai MA (2022) Artificial neural network modeling of biochar enhanced anaerobic sewage sludge digestion. J Environ Chem Eng 10:107988

Kizito S, Wu S, Kipkemoi Kirui W, Lei M, Lu Q, Bah H, Dong R (2015) Evaluation of slow pyrolyzed wood and rice husks biochar for adsorption of ammonium nitrogen from piggery manure anaerobic digestate slurry. Sci Total Environ 505:102–112

Klasson KT, Dien BS, Hector RE (2013) Simultaneous detoxification, saccharification, and ethanol fermentation of weak-acid hydrolyzates. Ind Crops Prod 49:292–298

Kumar A, Saini K, Bhaskar T (2020) Hydochar and biochar: Production, physicochemical properties and techno-economic analysis. Biores Technol 310:123442

Kumar M, Dutta S, You S, Luo G, Zhang S, Show PL, Sawarkar AD, Singh L, Tsang DCW (2021) A critical review on biochar for enhancing biogas production from anaerobic digestion of food waste and sludge. J Clean Prod 305:127143

Kumar Sharma A, Kumar Ghodke P, Goyal N, Nethaji S, Chen W-H (2022) Machine learning technology in biohydrogen production from agriculture waste: recent advances and future perspectives. Biores Technol 364:128076

Kusmayadi A, Huang C-Y, Kit Leong Y, Lu P-H, Yen H-W, Lee D-J, Chang J-S (2023) Integration of microalgae cultivation and anaerobic co-digestion with dairy wastewater to enhance bioenergy and biochemicals production. Biores Technol 376:128858

Kyriakou M, Chatziiona VK, Costa CN, Kallis M, Koutsokeras L, Constantinides G, Koutinas M (2019) Biowaste-based biochar: a new strategy for fermentative bioethanol overproduction via whole-cell immobilization. Appl Energy 242:480–491

Lee XJ, Ong HC, Gan YY, Chen W-H, Mahlia TMI (2020) State of art review on conventional and advanced pyrolysis of macroalgae and microalgae for biochar, bio-oil and bio-syngas production. Energy Convers Manage 210:112707

Li B, Yun S, Xing T, Wang K, Ke T, An J (2021) A strategy for understanding the enhanced anaerobic co-digestion via dual-heteroatom doped bio-based carbon and its functional groups. Chem Eng J 425:130473

Li F, Wang X, Yuan T, Sun R (2016) A lignosulfonate-modified graphene hydrogel with ultrahigh adsorption capacity for Pb(ii) removal. Journal of Materials Chemistry A 4:11888–11896

Li J, Zhang L, Li C, Tian H, Ning J, Zhang J, Tong YW, Wang X (2022) Data-driven based in-depth interpretation and inverse design of anaerobic digestion for CH4-rich biogas production. ACS ES&T Engineering 2:642–652

Li M, Wilkins MR (2020) Recent advances in polyhydroxyalkanoate production: feedstocks, strains and process developments. Int J Biol Macromol 156:691–703

Li Q, Xu M, Wang G, Chen R, Qiao W, Wang X (2018) Biochar assisted thermophilic co-digestion of food waste and waste activated sludge under high feedstock to seed sludge ratio in batch experiment. Biores Technol 249:1009–1016

Li X, Chu S, Wang P, Li K, Su Y, Wu D, Xie B (2022) Potential of biogas residue biochar modified by ferric chloride for the enhancement of anaerobic digestion of food waste. Biores Technol 360:127530

Li X, Shimizu N (2023) Biochar-promoted methane production and mitigation of acidification during thermophilic anaerobic co-digestion of food waste with crude glycerol: comparison with re-inoculation. Sustainable Environment Research 33:4

Li X, Wu M, Xue Y (2022) Nickel-loaded shrimp shell biochar enhances batch anaerobic digestion of food waste. Biores Technol 352:127092

Li Y, Gupta R, You S (2022) Machine learning assisted prediction of biochar yield and composition via pyrolysis of biomass. Biores Technol 359:127511

Li Y, Han Y, Zhang Y, Luo W, Li G (2020) Anaerobic digestion of different agricultural wastes: a techno-economic assessment. Biores Technol 315:123836

Li Y, Liu M, Che X, Li C, Liang D, Zhou H, Liu L, Zhao Z, Zhang Y (2020) Biochar stimulates growth of novel species capable of direct interspecies electron transfer in anaerobic digestion via ethanol-type fermentation. Environ Res 189:109983