Abstract

Anaerobic digestion (AD) has been considered as a promising technique for food waste (FW) recycling. However, the accumulation of volatile fatty acids (VFAs) restricts the stability of anaerobic reactors. The present study investigated the use of biochar produced at different conditions (750 °C-30 min, 750 °C-60 min, 750 °C-120 min, 550 °C-60 min, 650 °C-60 min, 850 °C-60 min, 950 °C-60 min) for enhancing the AD of FW. Batch experiments showed that all the biochar increased the methane production rates and biochar obtained at 750 °C-60 min resulted in the highest enhancement by 21.5%. It was further showed surface oxygen-containing functional groups and graphitization degree of biochar were the critical factors for improving methane production. Microbial analysis showed that biochar addition formed different microbial communities, and Methanosaeta, Romboutsia, and norank_f_Anaerolineaceae were enriched, which might be correlated with direct interspecies electron transfer (DIET). This research showed biochar could enhance the AD of FW and also revealed the main characteristics of biochar relating with the enhancement of AD.

Graphical Abstract

Highlights

-

Biochar produced at 750 °C-60 min had the highest capacity to enhance AD of FW.

-

Surface oxygen-containing functional groups and graphitization degree affected the capacity of biochar to promote AD.

-

Biochar resulted in different microbial community formation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

In recent years, the generation and utilization of food waste (FW) have grown rapidly, which have attracted much attention due to environmental pollution and carbon footprint. There is approximately 13.8 percent of produced food wasted worldwide every year in light of the United Nations Food and Agriculture Organization (FAO 2019). The main components of FW include meat, vegetables, rice, and pasta with high amounts of organics and water. FW is highly metamorphic and putrefactive, of which improper handling will lead to wastage of resources and social burdens.

Anaerobic digestion (AD) can not only stabilize the labile FW but also generate renewable biogas (i.e., methane) for energy production, which has been widely applied in FW treatment (Meng et al. 2022). However, high concentrations of volatile fatty acids (VFAs) produced by the rapid degradation of organic substances reduce the pH value of the system, resulting in an acid crash and inhibiting the activity of methane production, thereby compromising the performance of the AD systems (Appels et al. 2011; Ye et al. 2018).

The measure to add extrinsic materials is an efficacious method to improve the methane production and stabilize the AD systems (Kumar et al. 2021; Ren et al. 2020). It has been found that conductive materials and redox-active materials such as zero-valent iron and activated carbon could promote the degradation of organic acids by direct interspecies electron transfer (DIET), which was more efficient than interspecies hydrogen transfer (IHT) (Dai et al. 2022). Carbon-based materials have been proven effective for replacing C-type cytochromes and conductive pili, directly or indirectly promoting the electron transfer process, thereby accelerating the degradation of VFAs and the production of methane (Ren et al. 2020; Shi et al. 2021). Li et al. (2022) found that iron-loaded biochar shortened AD duration by 42% and increased methane production by 115.39%. Wang et al. (2021) improved methane production to 475.47 ± 4.68 mL g−1 VS by changing the distribution of VFAs with the addition of Fe/C. Biochar is a climate-positive and promising additive, as a carbon-rich material, which is formed by thermochemical carbonization of biomass raw materials in the absence of oxygen, with rich surface functional groups, large specific surface area, prominent pore structure, and pH buffer ability (Li et al. 2020; Qi et al. 2021). Previous researches have shown that biochar exhibited good performance in sludge hydrothermal liquids and pig manure AD processes (Shi et al. 2021; Xu et al. 2022). It was shown that biochar with Ni loading < 0.88 mg g−1 was favorable for AD, and the methane yield could reach 134.7 mL g−1 VS (Li et al. 2022). In addition, biochar contained multiple trace elements (i.e., Ka, Ca, and Mg) that could improve the elemental composition of AD residues, favoring the further utilization of solid digestates for fertilizer utilization in agricultural fields (Kumar et al. 2021). The enhanced contaminant adsorption by biochar was also considered to be beneficial to beneficial to alleviate the inhibition of toxic to anaerobic microorganisms, while surface functional groups might trigger DIET mechanism between anaerobic microorganisms (Chiappero et al. 2020). Compared with activated carbon, carbon cloth, and other materials, using biochar as an additive to promote AD has advantages of achieving long-term carbon sequestration at a low production cost, fostering biomass waste valorization, and facilitating simpler and more convenient use (He et al. 2022; Kumar et al. 2021).

Previous research has shown that biochar prepared from different raw materials (AD residue, coconut shell, corn stalk) differed in their ability to enrich Thermogota, and Firmicute during AD (Liu et al. 2022). Recent studies have reported biochars with different electrochemical properties for promoting methanogenesis and found that biochar affected differently in the relative abundance of Coriobacteria, Synergistia, and Cloacimonadia (Sun et al. 2022). Research has also shown that surface areas, porosity, degradation, and functional group distribution affected bacterial and archaeal diversities (Liu et al. 2022; Qi et al. 2021; Shi et al. 2021). However, the pyrolysis conditions (e.g., temperature, duration, and purging gas) also have critical impact on the biochar properties such as pH, surface area, electrical conductivity, porosity, carbonization degree, and functional group distribution (He et al. 2021). Identifying the main characteristics affecting AD performance will provide a direction for preparation and modification of biochar in the future. In addition, biochar produced under different conditions might have distinct effects on the AD process and the microbial communities in AD systems, which has not been well elucidated.

We surmise that the AD of FW could be affected significantly by biochar. To test this hypothesis, this work was conducted to evaluate the effects of different biochar properties on the AD performance of FW such as methane production rate, pH and VFA concentration and the resulting composition of microbial communities. Biochars with different target pyrolytic temperatures and durations were prepared using wood waste as raw materials. The characteristics of different biochars and the microbial communities in the AD process were analyzed. In summary, this paper served for the guidance of biochar production and selection, an exogenously added material for improving methane production and stabilizing AD systems in the near future.

1 Materials and methods

1.1 Inoculum and biomass substrate

The inoculum used in the present study was taken from a UASB reactor treating cassava stillage. A grinder machine (QX-650, Qinxin, China) was employed 5 min beforehand for the homogenization of inoculum. FW collected from a FW treatment plant in Shanghai, China was selected as substrate. The characteristics of the inoculum were: pH 7.2 ± 0.1, total solids (TS) 37.2 ± 2.8 g L−1 and volatile solids (VS) 30.1 ± 1.9 g L−1. The characteristics of FW were: TS 24.93 ± 0.17 g L−1 and VS 20.76 ± 0.03 g L−1.

1.2 Wood waste biochar production

This research used local wood waste mixture (20 × 20 mm) as biochar feedstock, which was collected from Hong Kong Ecopark without further treatment. The wood waste was pyrolyzed in a tubular furnace at target pyrolytic temperatures (550, 650, 750, 850, and 950 °C) and lasted for a certain duration time (30, 60,120 min) with continuous N2 purging. The heating rate was set to 10 °C min−1. The flow rate of N2 was set to 200 mL min−1. The biochar sample was stored in an airtight container prior to use. The prepared wood waste biochar was denoted in the form of "B—pyrolytic temperature—duration time”. The characteristics of biochar are shown in Additional file 1: Table S1–S2.

1.3 Characterization of biochar

CHONS elemental ratio was estimated by ultimate elemental analysis (EA, Vario EL cube, Germany) on a moisture-free basis. To determine the textural characteristics, a surface analysis instrument (Quantachrome Autosorb, USA) was employed for surface area and porosity analyses. The defect level and graphitization degree of biochar were investigated using Raman spectrometer (Renishaw, UK) at 532 nm edge excitation. An X-ray photoelectron spectroscopy (XPS, Thermo Fisher Scientific, USA) was employed to explore the chemical state of the elements and the composition of functional group on the sample surface. The XPS data, binding energies (BEs) of characteristic peaks, were calibrated at 284.8 eV with carbon C1s core level. The devolution analysis of XPS data was performed in XPSPEAK41. BEs of the component peaks were 285.49 eV (O–C=O), 287.03 eV (C=O), and 289.19 eV (C–OH) according to the methods mentioned in previous research (Ren et al. 2020).

1.4 Batch experiments

118-mL serum bottles were selected for the batch experiments. All serum bottles contained 2 mL inoculum, 20 mL FW substrate, 14 mL NaHCO3 buffer, and 4 mL of deionized water. The use of 2 mL inoculum was based on our previous research, to ensure that biochar had a significant promotion effect on AD. Each bottle was added with different kinds of biochar at a concentration of 10 g L−1, which was the optimum dosage in our previous research (Ren et al. 2020). The initial pH of all the serum bottles was modified to 8.00. These bottles were sealed up with butyl rubber stoppers after flushing with pure N2 for 3 min in order to maintain an anaerobic environment. All of these experiment bottles were implemented in triplicate and incubated at 37 °C in a thermostat. Quantitative analysis of methane production was performed with a modified Gompertz model (Additional file 1: Equation S1). Batch experiments were performed on biochar with pyrolysis temperature 750 °C and pyrolysis duration of 30, 60, and 120 min (B-750-30, B-750-60, B-750-120) to investigate their effect on methane production from FW. The gas samples were gathered every two days for methane production analysis and liquid samples were gathered from the bottles every six days for analysis of PH and VFAs. All tests were performed in triplicate. In addition, bottles without FW but with inoculum were set up as controls to verify the methane production from the inoculum.

1.5 Microbial community analysis

The mixed culture was collected at the end of the batch experiments for microbial analysis. The 16S rRNA gene-based high-throughput sequencing was employed to analyze the taxonomic classification of all sequences. Powersoil™ DNA isolation kit (Mobio Laboratories Inc. Carlsbad) was used to extract total DNA under the manufacturer’s instruction. 515F (GTGCCAGCMGCCGCGGTAA) and 806R (GGACTACHVGGGTWTCTAAT) were used as primers for polymerase chain reaction (PCR) amplification on ABI GeneAmp® Model 9700 PCR machine. Purification, quantification and sequencing of PCR products were based on the Illumina miseq platform according to standard methods. More detailed information about bioinformatics analysis is narrated in the Supporting Information. Raw sequence data can be obtained from NCBI with the accession number PRJNA859282.

1.6 Analysis methods

The methane content was determined by a gas chromatograph with Helium as carrier gas (GC-960, Haixin, China). The temperatures of the injector, oven, and detector were 120 °C, 120 °C and 110 °C, respectively. The concentrations of VFAs were analyzed by HPLC (Agilent 1200, Agilent Technology, USA). The concentrations of VS and TS and pH values were determined according to standard methods (Association and Washington 1995). All deconvolution and area calculations were performed using OriginPro software. Data analysis used SPSS Statistics v20 and Excel, and the corresponding graphs were plotted by OriginPro 2019b.

2 Results and discussion

2.1 Effects of biochar on FW AD process

2.1.1 Effects of biochar on methane production

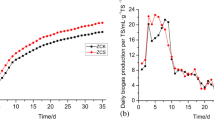

The methane production in batch experiments is shown in Fig. 1a. Additional file 1: Table S3 summarizes the kinetic parameters of methane production. All three biochars effectively promoted the AD process of FW. The methane production rates (Rm) of B-750-30, B-750-60, and B-750-120 were increased by 8.6%, 21.5%, and 13.3% compared to control experiments without biochar, respectively. The above phenomena suggested that the biochar could notably increase the rates of methane production. In comparison, B-750-60 showed a better methane production promotion effect and exhibited a higher Rm and shorter lag time (λ). Moreover, the accumulation of VFAs in the reactors with biochar was significantly lower than that in control. In particular, B-750-60 had less VFA accumulation and faster depletion.

Biochar resulted in less pH decrease because of the rapid consumption of VFAs during the AD process. In summary, the results of Rm, VFAs, and pH in these reactors proved that 60 min was the optimal pyrolysis time for preparing biochar used to improve methane production. Based on the above results, 60 min was selected as the pyrolysis duration of biochar for the subsequent batch experiments. The effects of biochar prepared under different pyrolysis temperature conditions on FW methane production were further investigated.

Methane production in the presence of biochar produced at different pyrolysis temperatures is shown in Fig. 2a. Additional file 1: Table S4 summarizes the kinetic parameters of methane production. With the pyrolysis temperature increasing, Rm of FW AD process first increased and then decreased, and the lag time showed a gradually shortened trend with the pyrolysis temperature increasing. The methane production rates of B-650-60, B-750-60, B-850-60, and B-950-60 were increased by 7.8%, 21.5%, 16.4%, and 9.4%, respectively (p < 0.05). The kinetic parameters indicated that the Rm between B-550-60 (20.4 ± 1.3 mL d−1) and control (20.0 ± 1.9 mL d−1) was not significantly different. Although B-550-60 had no significant effect on the methane production rates (Rm = 20.4 ± 1.3 mL d−1; control: Rm = 20.0 ± 1.9 mL d−1), a shorter lag time could speed up the recovery of acidification reactor. It is worth noting that the lag time of the B-850-60 and B-950-60 was shorter than that of the B-750-60, but the Rm of the B-750-60 was much higher than that of the B-850-60 and B-950-60. Therefore, B-750-60 was considered to be the most effective biochar for promoting the AD performance of FW in this study. To dissect the reasons for this, this study conducted further experiments to examine the roles of different biochar in the AD process of FW from the perspectives of pH, organic acid decomposition, biochar characteristics, and microbial community structure.

2.1.2 Effects of wood waste biochar on the change of VFAs and pH

The transformation of VFAs was examined to delve deep into the impacts of biochar on the AD of FW. Acetate, propionate, and butyrate were the main VFAs in each reactor at the beginning of the reaction. The ability to promote VFA degradation by B-750-60 was more prominent than all other groups, corresponding to its highest capacity for the enhancement of AD. Although the transformation extent of VFAs in other groups was not as good as that in B-750-60, it was still better than that of the control group. The concentration of VFAs in B-550-60 (6419.95 mg L−1) was much higher than that in other biochar-containing groups (3466.27–4426.53 mg L−1) on the 6th day of the experiment, while it was still significantly lower than that in control (8086.03 mg L−1). With enhanced microbial fitness, these intermediates could be rapidly consumed to 2713.73 mg L−1 by the 12th day of the experiment and microbial analysis was mentioned in 4.3. Acetic acid and butyric acid contents significantly decreased, and VFAs were rapidly consumed in each biochar-containing group as the reaction progressed until 18 days. The proportion and concentration of acetic acid showed an opposite change trend with the Rm value, which revealed that biochar promoted the methanation of acetate.

It was found that biochar was beneficial to maintain the pH stability with good buffer capacity in the anaerobic reactors. Due to the production of VFAs on the 6th day, the pH value of each group noticeably decreased. The pH value of the control group decreased significantly from 8.0 to 6.9, while the addition of biochar could maintain the lowest pH value in the reactor between 7.1 and 7.2 and allow for a fast recovery from solution acidity. On one hand, it might be because biochar promoted the conversion of organic acids via DIET. On the other hand, the alkalinity of biochar might alleviate the pH decrease, which was obviously shown in the AD reactors containing biochar B-850-60 and B-950-60 with PH values of 10.0 and 9.8, respectively (Fig. 2b). It is known that a lower pH (< 6.6) decreased the activity of methanogens (Demirel and Scherer 2008). A relatively stable pH environment is more conducive to the survival of microorganisms especially methanogens, which corresponds to the actual enhancement in methane production in this study. The longer lag period in the control group was because methanogens needed more adaption time in a wider pH range. In general, biochar could promote the degradation of VFAs and facilitate the methane production in the FW treatment.

2.2 Relationship between the main characteristics of biochar and the enhancement of AD

Previous researches have suggested that the surface functional groups, surface morphology, porosity, and pore volume could influence the mass transfer and microbial metabolisms in AD process (Chiappero et al. 2020). To better determine the critical factors for promoting the methane production, the elemental composition, surface functional groups, pore volume, and other characteristics of biochar were determined in this section.

It is believed that biochar could accelerate methanogenesis by promoting DIET, and most of previous studies considered electrical conductivity as the main reason for achieving DIET (Zhang et al. 2018). However, B-750-60 and B-850-60 with shorter lag time and high methane production rate had lower conductivity (770 and 870 μS cm−1). Oddly, no significant correlation was found between conductivity and methane production rates in this study (P < 0.05). The conductivity of biochar might have been over-considered in previous studies (Sun et al. 2017), and perhaps it was not a main limiting factor affecting DIET under most conditions (Table 1).

There were more important factors affecting the AD process of FW in present research. Previous studies showed that the redox property could also affect DIET, and it was related to the surface oxygen-containing functional groups (Ren et al. 2020). To explore whether the enhanced methane production in the biochar-containing AD system was related to its redox-active components, XPS was employed to explore the surface functional groups of biochar. As the pyrolysis temperature increased, the richness of surface functional groups of the prepared biochar decreased as expected. However, no further changes in oxygen-containing functional groups was found at high pyrolysis temperatures (850–950 °C). B-750-60 and B-850-60 contained a higher surface O/C ratio, which was consistent with their better methane production effect than other biochar. Further analysis found that the oxygen-containing functional groups on biochar surface showed positive correlation with the rate of methane production (R2 = 0.916, P < 0.05). The existence of arene rings, phenol moieties, and quinone moieties on the biochar surface might facilitate the occurrence of DIET because of the ability to accept electrons and possess redox activity (Kluepfel et al. 2014). Other surface functionalities such as amino groups could accept electrons and adsorb H+, which could alleviate the sudden drop of pH value due to the accumulation of intermediates in the reactor (Chiappero et al. 2020) (Table 1).

Raman spectroscopy has a high molecular specificity and can be used for characterizing the structural evolution of biochar materials. The D-band integrated intensity ratio (1350 cm−1) ID of Raman spectroscopy analysis reflects the degree of defect and the G-band integrated intensity ratio (1570 cm−1) IG represents the disorder of carbon materials (Sun et al. 2020). The ID/IG ratio is used to measure the graphitization degree of materials (Yu et al. 2022). Regression analysis showed that ID/IG was correlated with the rate of methane production (R2 = 0.670, P< 0.05). The ID/IG was determined to be 0.65, 0.72, 0.77, 0.79, and 0.80 for B-550-60, B-650-60, B-750-60, B-850-60, B-950-60, respectively, which indicated that the graphitization degree of biochar was enhanced with pyrolysis temperature increasing, and this is in good agreement with other recent studies (Schuepfer et al. 2020). In particular, the G peak intensity illustrated a significant and positive correlation with Rm (R2 = 0.897, P < 0.05). This reinforces the significance of electrical conductivity of biochar in the FW AD process.

Mesopores and macropores were the main pore structure of biochar surface in this research. Nevertheless, the pore size of mesopores (2–50 nm) was still much smaller than the size of microorganisms (0.5–5 µm), and therefore direct contact with microorganisms or providing colonization sites for microorganisms by mesopores might be not possible (Ren et al. 2020). Correlation analysis also showed that there was no obvious correlation between methane production rates and BET surface area (R2 = − 0.362, P = 0.549) and average pore diameter (R2 = 0.343, P = 0.572).

In view of the effects of different metals and some essential elements on microbial growth, the contents of elements such as Cr, Pb, K, Ca, Na, and Mg in the biochar were determined. A significant and negative correlation between Mo contents and methane production rates was found by correlation analysis (R2 = − 0.931, P< 0.05). The effect of Mo on AD has not been studied, and the related mechanism needs to be further studied. It should be noted that there were no significant correlations found between K, Ca, Na, Mg and methane production rates.

2.3 Microbial community composition analysis

2.3.1 Effect of biochar on microbial community diversity

16S rRNA high-throughput sequencing based analysis showed that biochar addition significantly influenced the microbial community diversity. The species richness in biochar-addition samples was all higher than that in control, which was reflected by Chao 1 index (Fig. 3a). The Shannon index can provide both species richness andevenness of all species in the community. The FW AD reactors with biochar addition (except B-750-60) had lower Shannon indices than the control reactors (Fig. 3b), which indicated that the evenness of various microbial communities increased in these AD reactors after biochar addition. The above results suggested that biochar affected microbial community alpha diversity including both enhancing species richness and selectively enriching certain types of microorganisms. On one hand, biochar improved methanogenic performance by enriching many different microorganisms and increasing species richness. On the other hand, more efficient enrichment of certain microorganisms with high metabolic activity was achieved by biochar. The enrichment of more metabolically active microbes might also play an important role in AD (Shi et al. 2021).

PCA analysis based on Bray–Curtis distance showed that the samples with biochar addition were separated from the control samples. In addition, B-550-60 and B-650-60 experiments, B-750-60 and B-850-60 experiments, and B-950-60 experiment belonged to three different cluster modules (Fig. 3c). It was confirmed that biochar was the main factor affecting the microbial community. Differences among each reactor were further confirmed by generating dendrograms. Hierarchical clustering results showed that all the reactors, B-850-60 and B-750-60, B-550-60 and B-650-60 were clustered together, respectively, and all the samples with biochar addition were separated from the control (Fig. 3d). It showed that different biochar addition resulted in the formation of significantly different microbial community structures in the reactors compared to the control reactors.

2.3.2 Effects of biochar on phylum-level microbial community composition

Hydrochar and magnetite addition could promote methane production via DIET during the AD process (Baek et al. 2018). In this study, microbial community analysis confirmed that biochar might promote DIET in the process of AD. To comprehend the effect of biochar on FW AD process, the phylum level classification in each reactor was first analyzed. The phylum-level analysis suggested that Euryarchaeota, Halobacterota, Firmicutes, Bacteroidota, and Chloroflexi were dominated in all reactors (Fig. 4a). The addition of biochar, especially B-750-60 and B-850-60, resulted it the relative abundance of Bacteroidota decreased significantly. Moreover, Biochar increased the relative abundance of Chloroflexi significantly which is a microorganism widely present inside anaerobic reactors (Bovio et al. 2019). Studies found synergistic relationships between Chloroflexi and methanogens (Narihiro et al. 2015). Anaerobes belonging to the phylum Chloroflexi had the potential to degrade proteins, carbohydrates and cellulose , which were related to the bottleneck hydrolysis step of AD. The "spaghetti-like" structure and adhesive properties of Chloroflexi might facilitate the transfer of metabolites resulting in high methane production rates (Hug et al. 2013).

The relative abundances of Synergistota, Euryarchaeota, Crenarchaeota and Halobacterota, were also increased for the samples with biochar addition compared with the control group. The phylum Synergistota contained microorganisms capable of degrading proteins, amino acids, and peptides (Jumas-Bilak and Marchandin 2014), and their increased relative abundance was instrumental to the conversion of macromolecular organic matter of FW into substances with smaller molecular weights, thus facilitating the utilization for methane production. Euryarchaeota phylum contains some Hyperthermophilics such as Pyrococcus and Thermococcus (all known as methanogens) and extreme halophilic archae, which can start with acetate, methyl compounds, H2, and CO2, and form methyl coenzyme M through different metabolic pathways (Amils 2015). Finally, methane was formed under the catalysis of methyl coenzyme M reductase (Evans et al. 2015).

Crenarchaeota and Halobacterota were both novel methanogenic archaea found in recent studies, which were the most primitive archaeal groups at the root of a phylogenetic tree that could convert H2/CO2, methyl compounds (formate, methanol, methylamine, etc.) as well as substrates such as acetate into CH4, along with ATP production (Bates et al. 2011; Chadwick et al. 2022). The existence of Euryarchaeota, Crenarchaeota, and Halobacterota might be associated with the increase in FW methane production, which was also reflected in the high methane yields of the B-750-60 and B-850-60. The relative abundance of Halobacterota was higher with B-750-60 and B-850-60 addition compared to other biochar samples. Nonetheless, regarding the abundance changes of Euryarchaeota, Crenarchaeota and Halobacterota, it could be concluded that biochar facilitated the enrichment of methanogens, which might be contribute to the higher Rm.

2.3.3 Effects of biochar on genus-level microbial community composition

Genus-level identification of bacteria and archaea was also done to gain a deep-insight into microbial community variations induced by biochar addition (Fig. 4b and c). Anaerolineaceae belonging to Chloroflexi phylum was the most abundant genus in the samples with biochar addition (P < 0.05), the relative abundance of which was increased by 254.53%, 254.55%, 241.13%, 372.33%, 200.67% in B-550-60, B-650-60, B-750-60, B-850-60 and B-950-60, respectively, compared with the control group. Anaerolineaceae had the capacity of carbohydrate metabolism (Wang et al. 2018). It was previously reported that some species of Anaerolineaceae had a high transcript level of pilA gene, which might be related in the DIET (Xia et al. 2016). Therefore, the enrichment of Anaerolineaceae contributed to promoting acidification, but it might increase the rate of methane production through participating in DIET (Reguera et al. 2005).

The bacterium Geobacter, which was reported to perform DIET, was not the dominant species, but was enriched within the other biochar addition groups except in B-650-60. The relative abundance of Bacteroidetes_vadinHA17 belonging to Bacteroidota phylum and Romboutsia belonging to Firmicutes phylum was increased after biochar addition. Bacteroidetes_vadinHA17 was known to improve the activity of enzymes participating in the formation of lactic acid and propionic acid (Tan et al. 2010), which might facilitate the conversion of long-chain fatty acid to short-chain fatty acid in the AD system. The relative abundance of Macellibacteroides belonging to Bacteroidota phylum significantly decreased after biochar addition ( P < 0.05), especially in B-850-60. Macellibacteroides contained a number of carbohydrate-degrading enzymes and had the capacity for carbohydrate metabolism (Rout et al. 2017). Thus, its decreased relative abundance might present substrate competition with the previously mentioned Anaerolineaceae.

In all the reactors, archaea were mainly composed of Methanobacterium and Methanosaeta. Methanosaeta was the only known strict acetoclastic methanogen that could accept electrons for reducing CO2 to methane via DIET (Huser et al. 1982). The relative abundance of Methanosaeta in each group was higher after biochar addition, and its high proportion in the archaea could be attributed to the DIET facilitated by adding biochar. Redundancy analysis (RDA) further probed the correlation between microbial compositions and methane yields. It was found that Methanosaeta, Romboutsia, and norank_f_Anaerolineaceae were positively correlated with the improvement of methanogenic efficiency of B-750-60 and B-850-60. Romboutsia was able to utilize glucose, fructose, and maltose (Wang et al. 2015), and most members of Anaerolineaceae could participate in the degradation of sugars and proteins (Park et al. 2011).

It is noted that the abundance of Methanosarcina, which could carry out the H2/CO2 methanogenesis pathway and acetate methanogenesis, decreased in each reactor after the addition of biochar. The relative abundance of methylotrophic methanogens Methanofastidiosum and Methanomassiliicoccales increased in most reactors compared with the control. Methanobacterium, a hydrogenotrophic methanogen, accounted for 35.8–50.3% of archaea in each reactor, and the relative abundance increased in B-550-60, B-650-60, and B-850-60 reactors but decreased in B-750-60 and B-950-60 compared with the control reactor. The relative abundance of Methanolinea in biochar-containing samples all decreased except B-750-60. Although a lower abundance of Methanobacterium was in B-750-60 than in other biochar groups, in B-750-60 the abundance of Methanosaeta was higher, which might compensate for the ability of B-750-60 to methane production, thus keeping the methane production rate of B-750-60 at a high level. Anyway, the phenomena suggested that biochar altered the microbial community structures in AD reactors with FW as substrate, corresponding to the increased methane production.

2.4 Implications

Regarding the environmental application of biochar, more attention has been paid to its application as an adsorbent in pollutant removal (Rangabhashiyam et al. 2022). The application of biochar as an additive in biological processes is an area with great potential (Kumar et al. 2021). In this study, biochar addition enriched Methanosaeta, which provided evidence for biochar promoting DIET in a mixed-culture system. This study focused on the effect of biochar characteristics on AD process rather than limited to specific preparation conditions (Qi et al. 2021), and found a more general conclusion: the surface functional groups and graphitization depth of biochar were key factors affecting Rm in AD of FW. Biochar with different target pyrolysis temperatures and durations was prepared from wood waste as raw materials. It was noted that the different purge gases (e.g., N2 and CO2) in pyrolysis also affected biochar characteristics, and it may affect the promotion effects on AD by biochar (Wang and Wang 2019), which deserves further investigation. In addition, this study only examined the effect of biochar prepared at different pyrolysis durations on AD under one temperature condition, and the effects of different pyrolysis durations under other pyrolysis temperature conditions should also be considered in future studies. Therefore, future research on the preparation of biochar with efficient anaerobic digestion capacity should also put it within the scope of consideration. Biochar can affect not only methane yield and methane production kinetics, but also digestate characteristics (Fagbohungbe et al. 2017). Biochar can effectively adsorb pollutants in biogas residues and is conducive to the retention of nutrients in digestate, and does not require recycling, thus increasing the economic value of the process for land application of the digest (Chen et al. 2021; Su et al. 2021). Despite this, the digestate might contain heavy metals, pathogenic bacteria, and organic contaminants (Jin et al. 2021), and current legislative frameworks for quality control and economic sustainability of digestate in China are still inadequate (Catenacci et al. 2022). Given the above, the economic aspects and the legislative background linked to biochar production and utilization could be briefly considered in future studies.

3 Conclusions

The present research showed that: (1) Biochar addition increased the Rm by 2.2-21.5%, and B-750-60 resulted in the highest Rm ; (2) Biochar promoted consumption of VFAs especially the methanation of acetate in AD processes ; (3) Correlation analysis revealed that the surface oxygen-containing functional groups of biochar and graphitization degree were important factors for enhancing the methane yield ; (4) Microbial analysis suggested that the biochar addition formed different microbial communities, and Methanosaeta, Romboutsia, and norank_f_Anaerolineaceae were obviously enriched with B-750-60 and B-850-60 for more efficient AD of FW.

Data availability

The datasets are included in the supporting information and the raw sequences data can be obtained from NCBI with the accession number PRJNA859282. Other reasonable data requests are available through the authors.

References

Amils R (2015) Euryarchaeota. In: Gargaud M, Irvine WM, Amils R, Cleaves HJ, Pinti DL, Quintanilla JC, Rouan D, Spohn T, Tirard S, Viso M (eds) Encyclopedia of astrobiology. Springer, Berlin, pp 764–765

Appels L, Lauwers J, Degreve J, Helsen L, Lievens B, Willems K, Van Impe J, Dewil R (2011) Anaerobic digestion in global bio-energy production: potential and research challenges. Renew Sustain Energy Rev 15(9):4295–4301. https://doi.org/10.1016/j.rser.2011.07.121

Association C, Washington D (1995) APHA, A. P. H. A. : Standard methods for the examination of water and wastewater. Am Phys Educ Rev 24:481–486

Baek G, Kim J, Kim J, Lee C (2018) Role and potential of direct interspecies electron transfer in anaerobic digestion. Energies. https://doi.org/10.3390/en11010107

Bates ST, Berg-Lyons D, Caporaso JG, Walters WA, Knight R, Fierer N (2011) Examining the global distribution of dominant archaeal populations in soil. ISME J 5(5):908–917. https://doi.org/10.1038/ismej.2010.171

Bovio P, Cabezas A, Etchebehere C (2019) Preliminary analysis of Chloroflexi populations in full-scale UASB methanogenic reactors. J Appl Microbiol 126(2):667–683. https://doi.org/10.1111/jam.14115

Catenacci A, Boniardi G, Mainardis M, Gievers F, Farru G, Asunis F, Malpei F, Goi D, Cappai G, Canziani R (2022) Processes, applications and legislative framework for carbonized anaerobic digestate: opportunities and bottlenecks. A critical review. Energy Convers Manage. https://doi.org/10.1016/j.enconman.2022.115691

Chadwick GL, Skennerton CT, Laso-Perez R, Leu AO, Speth DR, Yu H, Morgan-Lang C, Hatzenpichler R, Goudeau D, Malmstrom R, Brazelton WJ, Woyke T, Hallam SJ, Tyson GW, Wegener G, Boetius A, Orphan VJ (2022) Comparative genomics reveals electron transfer and syntrophic mechanisms differentiating methanotrophic and methanogenic archaea. PLoS Biol 20(1):e3001508–e3001508. https://doi.org/10.1371/journal.pbio.3001508

Chen T, Zhao Y, Qiu X, Zhu X, Liu X, Yin J, Shen D, Feng H (2021) Economics analysis of food waste treatment in China and its influencing factors. Front Environ Sci Eng. https://doi.org/10.1007/s11783-020-1325-y

Chiappero M, Norouzi O, Hu M, Demichelis F, Berruti F, Di Maria F, Masek O, Fiore S (2020) Review of biochar role as additive in anaerobic digestion processes. Renew Sustain Energy Rev. https://doi.org/10.1016/j.rser.2020.110037

Dai C, Yang L, Wan J, Li D, Zhang Y, Zhou X (2022) Enhancing anaerobic digestion of pharmaceutical industries wastewater with the composite addition of zero valent iron (ZVI) and granular activated carbon (GAC). Bioresour Technol. https://doi.org/10.1016/j.biortech.2021.126566

Demirel B, Scherer P (2008) The roles of acetotrophic and hydrogenotrophic methanogens during anaerobic conversion of biomass to methane: a review. Rev Environ Sci Bio/technol 7(2):173–190. https://doi.org/10.1007/s11157-008-9131-1

Evans PN, Parks DH, Chadwick GL, Robbins SJ, Orphan VJ, Golding SD, Tyson GW (2015) Methane metabolism in the archaeal phylum Bathyarchaeota revealed by genome-centric metagenomics. Sci 350(6259):434–438. https://doi.org/10.1126/science.aac7745

Fagbohungbe MO, Herbert BMJ, Hurst L, Ibeto CN, Li H, Usmani SQ, Semple KT (2017) The challenges of anaerobic digestion and the role of biochar in optimizing anaerobic digestion. Waste Manage 61:236–249. https://doi.org/10.1013/j.wasman.2015.11.028

FAO (2019) The State of food and agriculture 2019. Moving forward on food loss and waste reduction. Rome

He M, Xu Z, Sun Y, Chan PS, Lui I, Tsang DCW (2021) Critical impacts of pyrolysis conditions and activation methods on application-oriented production of wood waste-derived biochar. Bioresour Technol. https://doi.org/10.1016/j.biortech.2021.125811

He M, Xu Z, Hou D, Gao B, Cao X, Ok YS, Rinklebe J, Bolan NS, Tsang DCW (2022) Waste-derived biochar for water pollution control and sustainable development. Nat Rev Earth Environ 3(7):444–460. https://doi.org/10.1038/s43017-022-00306-8

Hug LA, Castelle CJ, Wrighton KC, Thomas BC, Sharon I, Frischkorn KR, Williams KH, Tringe SG, Banfield JF (2013) Community genomic analyses constrain the distribution of metabolic traits across the Chloroflexi phylum and indicate roles in sediment carbon cycling. Microbiome. https://doi.org/10.1186/2049-2618-1-22

Huser BA, Wuhrmann K, Zehnder AJB (1982) Methanothrix-soehngenii gen.-nov.-sp.-nov., a new acetotrophic non-hydrogen-oxidizing methane bacterium. Arch Microbiol 132(1):1–9. https://doi.org/10.1007/bf00690808

Jin C, Sun S, Yang D, Sheng W, Ma Y, He W, Li G (2021) Anaerobic digestion: an alternative resource treatment option for food waste in China. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2021.146397

Jumas-Bilak E, Marchandin H (2014) The phylum synergistetes. Prokaryotes 9783642389542:931–954

Kluepfel L, Keiluweit M, Kleber M, Sander M (2014) Redox properties of plant biomass-derived black carbon (Biochar). Environ Sci Technol 48(10):5601–5611. https://doi.org/10.1021/es500906d

Kumar M, Dutta S, You S, Luo G, Zhang S, Show PL, Sawarkar AD, Singh L, Tsang DCW (2021) A critical review on biochar for enhancing biogas production from anaerobic digestion of food waste and sludge. J Clean Prod. https://doi.org/10.1016/j.jclepro.2021.127143

Li G, Bai X, Huo S, Huang Z (2020) Fast pyrolysis of LERDADEs for renewable biofuels. IET Renew Power Gener 14(6):959–967. https://doi.org/10.1049/iet-rpg.2019.0852

Li X, Wu M, Xue Y (2022) Nickel-loaded shrimp shell biochar enhances batch anaerobic digestion of food waste. Bioresour Technol. https://doi.org/10.1016/j.biortech.2022.127092

Liu H, Wang X, Fang Y, Lai W, Xu S, Lichtfouse E (2022) Enhancing thermophilic anaerobic co-digestion of sewage sludge and food waste with biogas residue biochar. Renew Energy 188:465–475. https://doi.org/10.1016/j.renene.2022.02.044

Meng Q, Liu H, Zhang H, Xu S, Lichtfouse E, Yun Y (2022) Anaerobic digestion and recycling of kitchen waste: a review. Environ Chem Lett 20(3):1745–1762. https://doi.org/10.1007/s10311-022-01408-x

Narihiro T, Nobu MK, Kim N-K, Kamagata Y, Liu W-T (2015) The nexus of syntrophy-associated microbiota in anaerobic digestion revealed by long-term enrichment and community survey. Environ Microbiol 17(5):1707–1720. https://doi.org/10.1111/1462-2920.12616

Park S, Yu J, Byun I, Cho S, Park T, Lee T (2011) Microbial community structure and dynamics in a mixotrophic nitrogen removal process using recycled spent caustic under different loading conditions. Bioresour Technol 102(15):7265–7271. https://doi.org/10.1016/j.biortech.2011.04.091

Qi Q, Sun C, Cristhian C, Zhang T, Zhang J, Tian H, He Y, Tong YW (2021) Enhancement of methanogenic performance by gasification biochar on anaerobic digestion. Bioresour Technol. https://doi.org/10.1016/j.biortech.2021.124993

Rangabhashiyam S, dos Santos Lins PV, de Magalhaes Oliveira LMT, Sepulveda P, Ighalo JO, Rajapaksha AU, Meili L (2022) Sewage sludge-derived biochar for the adsorptive removal of wastewater pollutants: a critical review. Environ Pollut. https://doi.org/10.1016/j.envpol.2021.118581

Reguera G, McCarthy KD, Mehta T, Nicoll JS, Tuominen MT, Lovley DR (2005) Extracellular electron transfer via microbial nanowires. Nature 435(7045):1098–1101. https://doi.org/10.1038/nature03661

Ren S, Usman M, Tsang DCW, O-Thong S, Angelidaki I, Zhu X, Zhang S, Luo G (2020) Hydrochar-facilitated anaerobic digestion: evidence for direct interspecies electron transfer mediated through surface oxygen-containing functional groups. Environ Sci Technol 54(9):5755–5766. https://doi.org/10.1021/acs.est.0c00112

Rout SP, Salah ZB, Charles CJ, Humphreys PN (2017) Whole-genome sequence of the anaerobic isosaccharinic acid degrading isolate, Macellibacteroides fermentans strain HH-ZS. Genome Biol Evol 9(8):2140–2144. https://doi.org/10.1093/gbe/evx151

Schuepfer DB, Badaczewski F, Guerra-Castro JM, Hofmann DM, Heiliger C, Smarsly B, Klar PJ (2020) Assessing the structural properties of graphitic and non-graphitic carbons by Raman spectroscopy. Carbon 161:359–372. https://doi.org/10.1016/j.carbon.2019.12.094

Shi Z, Usman M, He J, Chen H, Zhang S, Luo G (2021) Combined microbial transcript and metabolic analysis reveals the different roles of hydrochar and biochar in promoting anaerobic digestion of waste activated sludge. Water Res. https://doi.org/10.1016/j.watres.2021.117679

Su P, Gao X, Zhang J, Djellabi R, Yang B, Wu Q, Wen Z (2021) Enhancing the adsorption function of biochar by mechanochemical graphitization for organic pollutant removal. Front Environ Sci Eng. https://doi.org/10.1007/s11783-021-1418-2

Sun T, Levin BDA, Guzman JJL, Enders A, Muller DA, Angenent LT, Lehmann J (2017) Rapid electron transfer by the carbon matrix in natural pyrogenic carbon. Nat Commun. https://doi.org/10.1038/ncomms14873

Sun Y, Yu IKM, Tsang DCW, Fan J, Clark JH, Luo G, Zhang S, Khan E, Graham NJD (2020) Tailored design of graphitic biochar for high-efficiency and chemical-free microwave-assisted removal of refractory organic contaminants. Chem Eng J. https://doi.org/10.1016/j.cej.2020.125505

Sun Z, Feng L, Li Y, Han Y, Zhou H, Pan J (2022) The role of electrochemical properties of biochar to promote methane production in anaerobic digestion. J Clean Prod. https://doi.org/10.1016/j.jclepro.2022.132296

Tan R, Miyanaga K, Toyama K, Uy D, Tanji Y (2010) Changes in composition and microbial communities in excess sludge after heat-alkaline treatment and acclimation. Biochem Eng J 52(2–3):151–159. https://doi.org/10.1016/j.bej.2010.08.001

Wang J, Wang S (2019) Preparation, modification and environmental application of biochar: a review. J Clean Prod 227:1002–1022. https://doi.org/10.1016/j.jclepro.2019.04.282

Wang Y, Song J, Zhai Y, Zhang C, Gerritsen J, Wang H, Chen X, Li Y, Zhao B, Zhao B, Ruan Z (2015) Romboutsia sedimentorum sp. nov., isolated from an alkaline-saline lake sediment and emended description of the genus Romboutsia. Int J Syst Evol Microbiol 65:1193–1198. https://doi.org/10.1099/ijs.0.000079

Wang G, Li Q, Gao X, Wang XC (2018) Synergetic promotion of syntrophic methane production from anaerobic digestion of complex organic wastes by biochar: performance and associated mechanisms. Bioresour Technol 250:812–820. https://doi.org/10.1016/j.biortech.2017.12.004

Wang P, Ye M, Cui Y, Xiao X, Zou D, Guo R, Liu Y (2021) Enhancement of enzyme activities and VFA conversion by adding Fe/C in two-phase high-solid digestion of food waste: performance and microbial community structure. Bioresour Technol. https://doi.org/10.1016/j.biortech.2021.125004

Xia Y, Wang Y, Wang Y, Chin FYL, Zhang T (2016) Cellular adhesiveness and cellulolytic capacity in Anaerolineae revealed by omics-based genome interpretation. Biotechnol Biofuels. https://doi.org/10.1186/s13068-016-0524-z

Xu S, Duan Y, Zou S, Liu H, Luo L, Wong JWC (2022) Evaluations of biochar amendment on anaerobic co-digestion of pig manure and sewage sludge: waste-to-methane conversion, microbial community, and antibiotic resistance genes. Bioresour Technol. https://doi.org/10.1016/j.biortech.2021.126400

Ye M, Liu J, Ma C, Li Y-Y, Zou L, Qian G, Xu ZP (2018) Improving the stability and efficiency of anaerobic digestion of food waste using additives: a critical review. J Clean Prod 192:316–326. https://doi.org/10.1016/j.jclepro.2018.04.244

Yu W, Chu C, Chen B (2022) Enhanced microbial ferrihydrite reduction by pyrogenic carbon: impact of graphitic structures. Environ Sci Technol 56(1):239–250. https://doi.org/10.1021/acs.est.1c04440

Zhang J, Zhao W, Zhang H, Wang Z, Fan C, Zang L (2018) Recent achievements in enhancing anaerobic digestion with carbon-based functional materials. Bioresour Technol 266:555–567. https://doi.org/10.1016/j.biortech.2018.07.076

Acknowledgements

No applicable.

Funding

This research was financially supported by Science and Technology Commission of Shanghai Municipality (19DZ1204704, 22ZR1405900), National Natural Science Foundation of China (31970117), and Hong Kong Environment and Conservation Fund (Project 101/2020).

Author information

Authors and Affiliations

Contributions

CZ: Data curation, writing-original draft and editing. RY: Data curation. MS: Data curation. SZ: Funding. MH: Writing-review & editing. DCWT and GL: Writing—review and editing, funding. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

There are no competing interests to declare.

Supplementary Information

Additional file 1.

The Additional file contains a modified Gompertz model for quantitative analysis of methane production, the physicochemical properties of the prepared biochar, and kinetic parameters for methane production.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, C., Yang, R., Sun, M. et al. Wood waste biochar promoted anaerobic digestion of food waste: focusing on the characteristics of biochar and microbial community analysis. Biochar 4, 62 (2022). https://doi.org/10.1007/s42773-022-00187-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42773-022-00187-6